Tubular holder for holding tail end of mechanical arm of holding bone drill

A technology of mechanical arms and grippers, applied in the field of gripping mechanisms, can solve the problems of grippers that do not have positioning accuracy, assembly and disassembly, and gripping reliability, so as to reduce the probability of interference, simple operation, and fewer parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

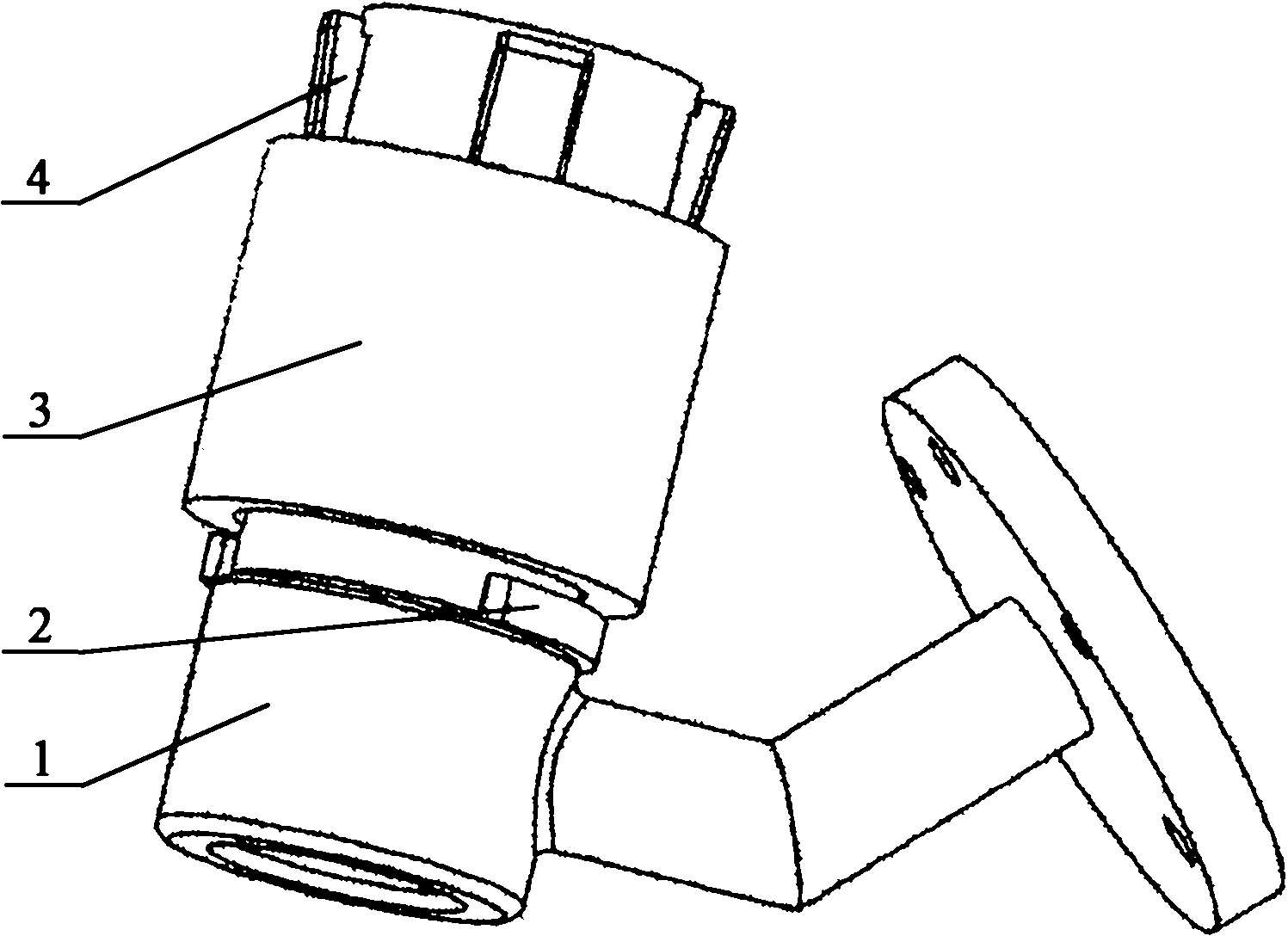

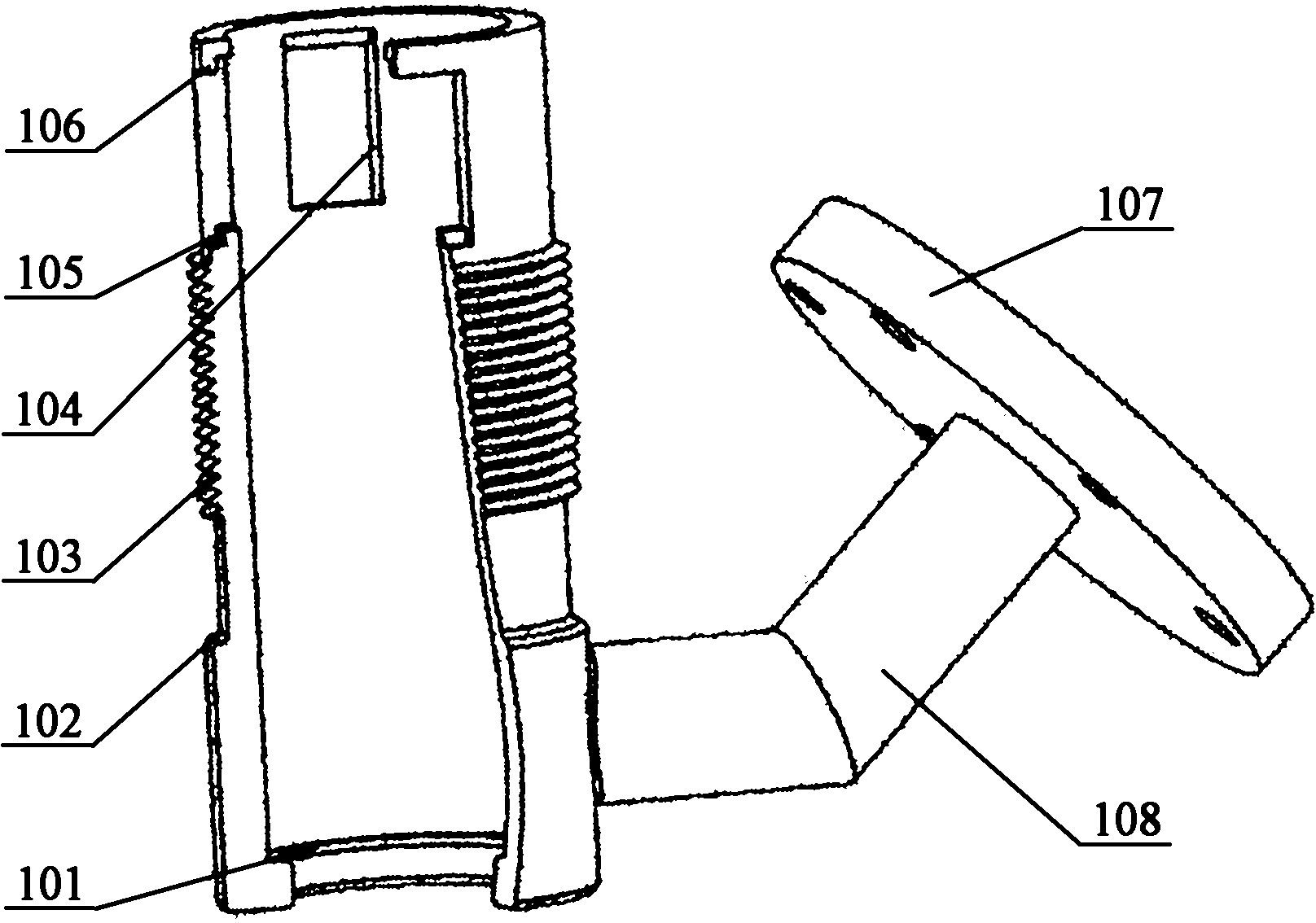

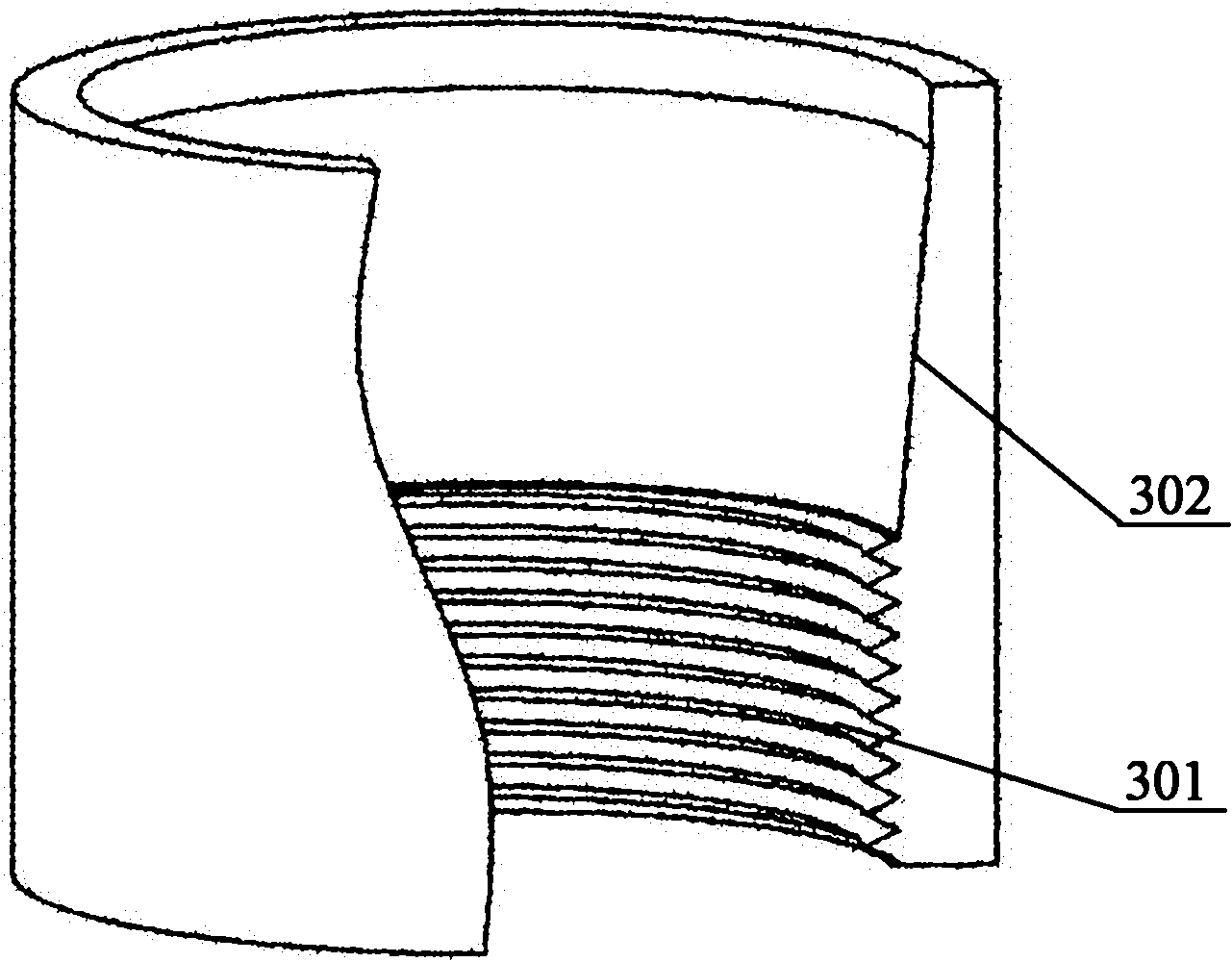

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0026] The tubular holder at the end of the mechanical arm holding the bone drill of the present invention should meet the following functional requirements: (1) As a medical device, the bone drill should be cleaned and disinfected frequently, so the holder must realize the installation and disassembly of the bone drill in a simple manner , to facilitate the operation of medical staff; (2) As a part of the robot system, the holder must have high positioning accuracy to ensure that the position and angle of the bone drill are always consistent after each disassembly; (3) The holder must have a small external dimension and a simple external shape to minimize the probability of its interference with other medical equipment and the patient's body, and at the same time be easy to clean; (4) In addition, the holder must be compatible with manual hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com