Friction induction-based single crystal quartz surface selective etching method

A single crystal quartz, friction-induced technology, applied in crafts for producing decorative surface effects, decorative arts, gaseous chemical plating, etc., can solve problems such as plastic deformation, scanning probe wear, large wear debris, etc. Precise and controllable etched shape, improved processing efficiency and less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

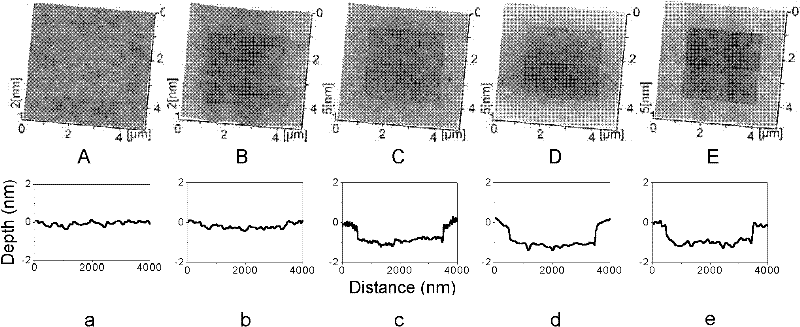

[0032] A specific embodiment of the present invention is a method for selectively etching the surface of single crystal quartz based on friction induction, and its specific operation method is:

[0033] A. Install the probe with spherical crown on the atomic force microscope, fix the cleaned single crystal quartz on the sample stage of the atomic force microscope, start the atomic force microscope, apply a constant load F to the probe, and make the probe along The set trajectory and number of cycles are scanned on the single crystal quartz surface, and the scanning rate is 12 μm / s during processing.

[0034] The value of the fixed load F in this example is 5μN, which is the theoretical critical load value F calculated according to the Hertz contact formula when the single crystal quartz surface is damaged during processing y = 0.047 times of 106 μN.

[0035] The processed single crystal quartz is specifically X-cut single crystal quartz, and the spherical crown probe used is ...

Embodiment 2

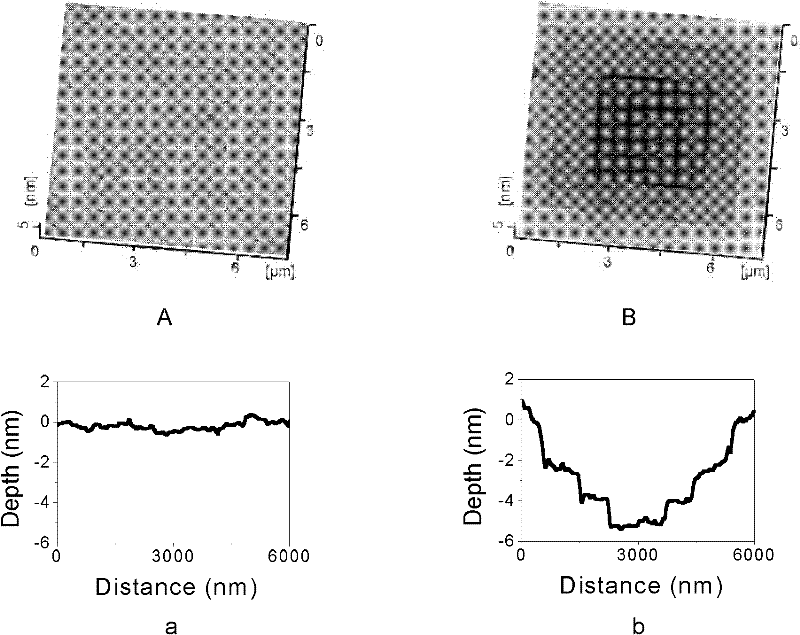

[0041] The specific operation method in this example is:

[0042] A. Install the probe with spherical crown on the atomic force microscope, fix the cleaned single crystal quartz on the sample stage of the atomic force microscope, start the atomic force microscope, apply a constant load F to the probe, and make the probe along The set trajectory and number of cycles are scanned on the single crystal quartz surface.

[0043] The value of the fixed load F in this example is 8μN, which is the theoretical critical load value F calculated according to the Hertz contact formula when the single crystal quartz surface is damaged during processing y = 0.075 times of 106 μN.

[0044] The material type of the single crystal quartz processed in this example and the spherical crown probe used are exactly the same as those in Example 1. Therefore, the critical load F corresponding to the yield of the single crystal quartz y Also 106 μN.

[0045] B. Place the scanned single-crystal quartz ...

Embodiment 3

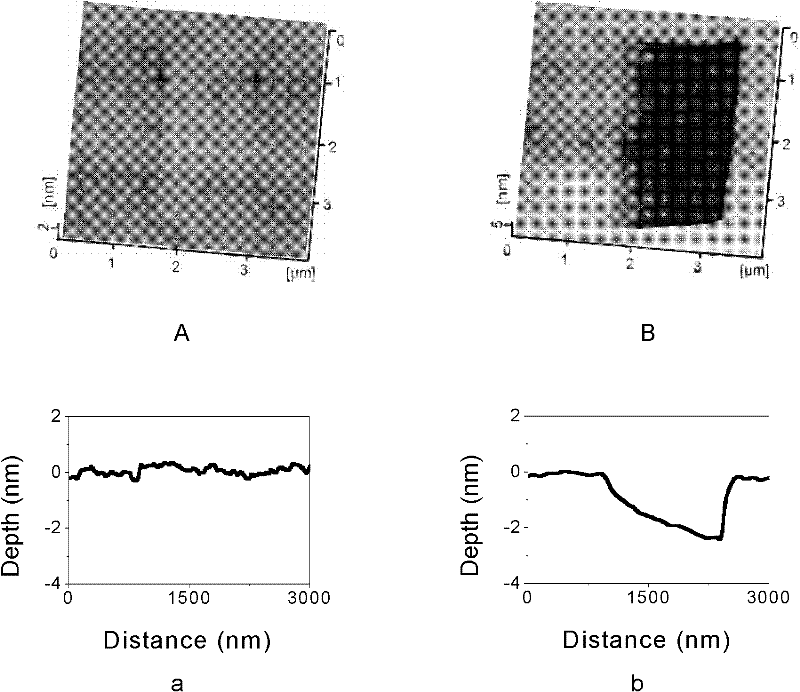

[0051] The specific operation method in this example is:

[0052] A. Install the probe with a spherical crown on the atomic force microscope, fix the cleaned single crystal quartz on the sample stage of the atomic force microscope, start the atomic force microscope, apply a variable load F' to the probe, and make the probe along the The single crystal quartz surface is scanned according to the set trajectory and number of cycles, and the scanning rate during processing is 12 μm / s.

[0053] The variation range of the variable load F' in this example is the theoretical critical load value F calculated according to the Hertz contact formula when the single crystal quartz surface is damaged during processing y (106μN) is 0.03-0.14 times, that is, the variation range of the variable load F' is 3.2μN-15μN.

[0054] The material type of the single crystal quartz processed in this example and the spherical crown probe used are exactly the same as those in Example 1. Therefore, the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com