Automatic detection and automatic unloading sorting wire mesh machine

An automatic cutting and automatic detection technology, applied in screen printing presses, printing presses, rotary printing presses, etc., can solve the problems of increasing labor costs, uncontrollable detection accuracy, etc. location-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

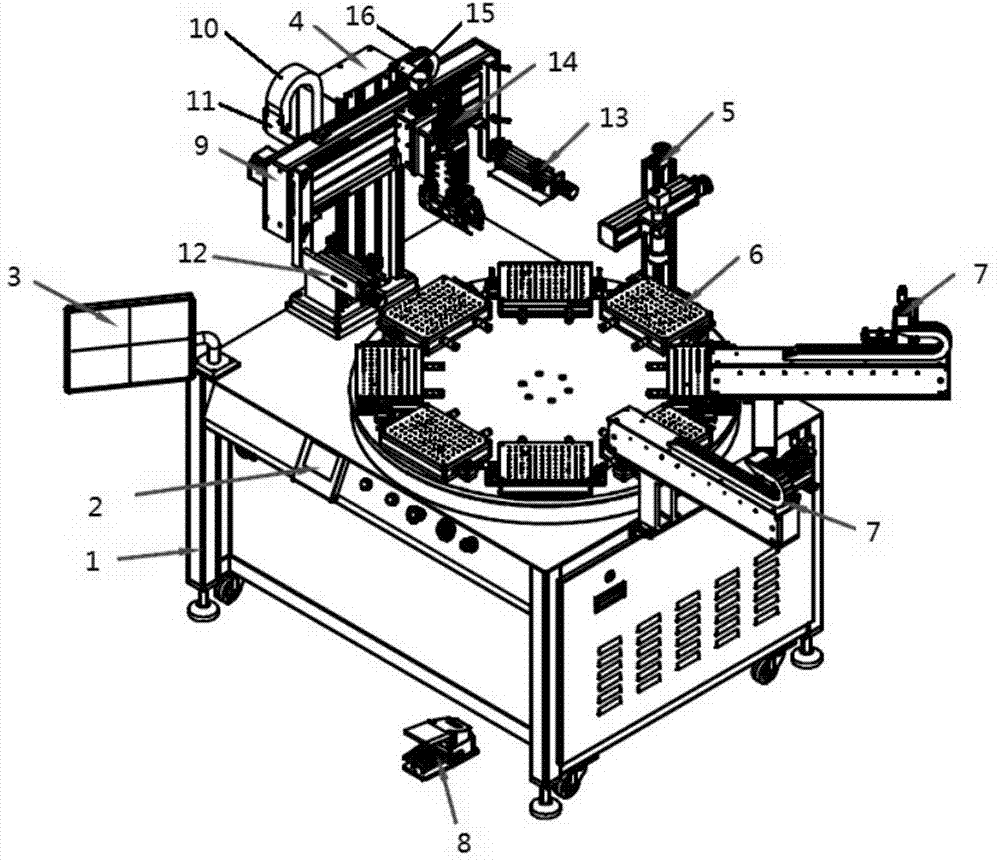

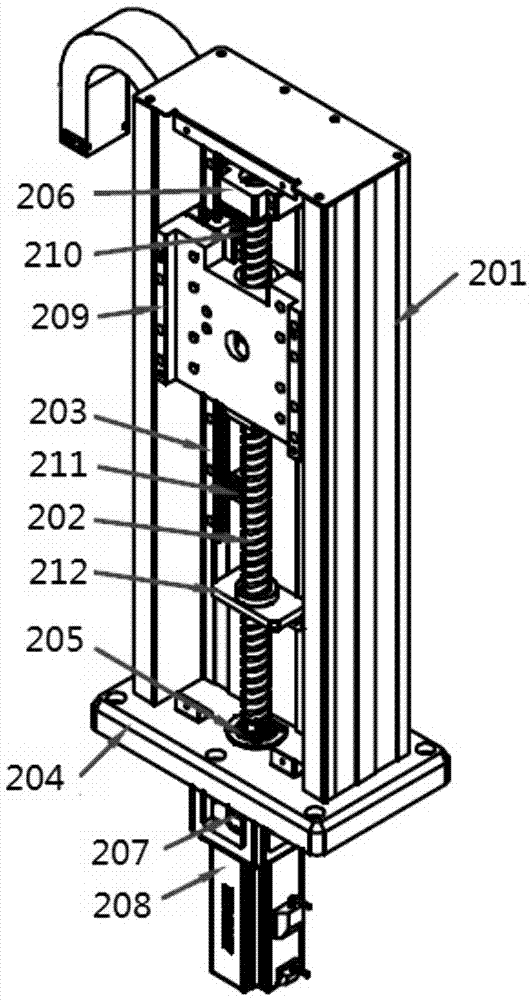

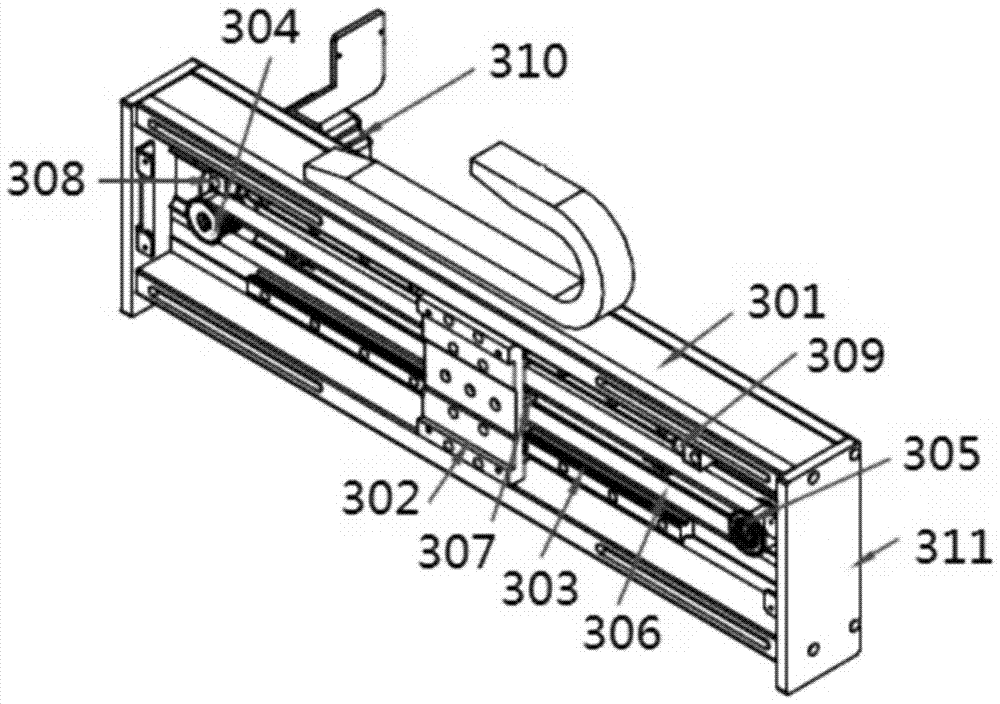

[0034] A kind of automatic detection and automatic unloading and sorting wire mesh machine of the present embodiment, such as Figure 1-Figure 8 As shown, it includes a frame 1, which is provided with a man-machine interface control system 2, an image detection system 3, a lifting column assembly 4, a CCD lens assembly 5, a turntable workbench 6, a feeding manipulator 7 and a foot switch 8, The lifting column assembly 4 is provided with a crossbeam 9 that can move up and down along the lifting column assembly 4, the lifting column assembly 4 is provided with a lifting towline 10, the beam 9 is provided with a lifting towline buckle 11, the lifting towline 10 and the lifting towline The buckle 11 is connected, and the left mesh arm 12 and the right mesh arm 13 that can be adjusted and fixed are arranged on the crossbeam 9, and the printing seat 14 that can slide left and right along the crossbeam 9 is arranged between the left mesh arm 12 and the right mesh arm 13. There is a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com