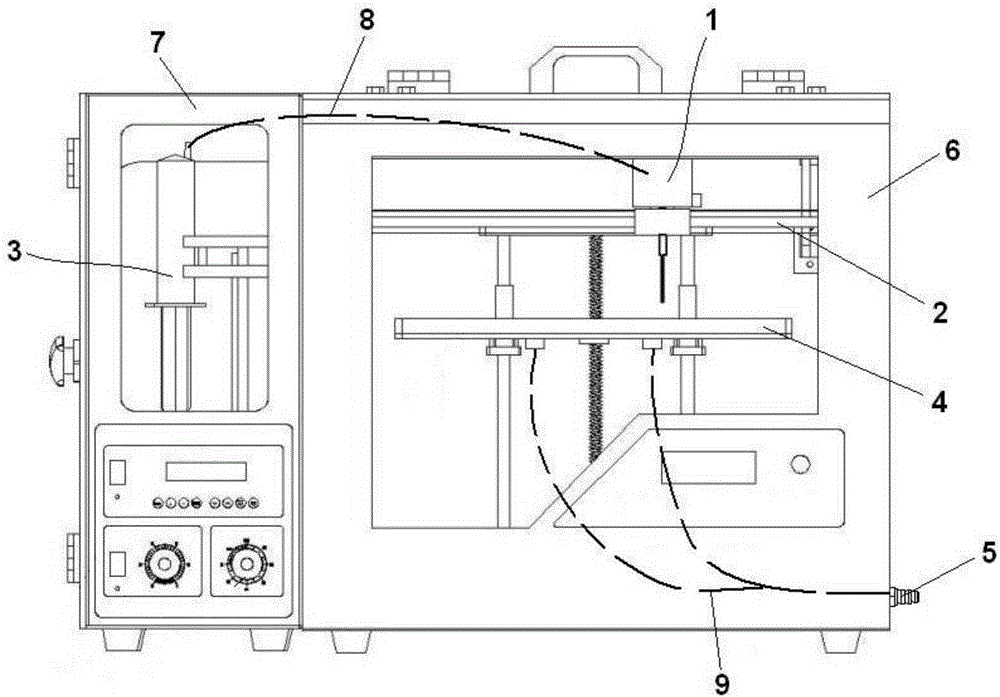

Programmed type electrostatic spraying device

An electrostatic spraying and program-controlled technology, which is applied in the direction of electrostatic spraying devices, spraying devices, liquid spraying equipment, etc., can solve problems such as technology and functions that cannot be realized, and achieve the effects of improving utilization, stabilizing slurry flow control, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The nanoscale platinum-carbon catalyst slurry is sprayed on the surface of the proton exchange membrane by using the invention, and is used for preparing the catalyst layer in the membrane electrode of the fuel cell. The specific usage steps are:

[0041] 1. Spread the proton exchange membrane on the center of the vacuum adsorption platform, set the temperature of the vacuum adsorption platform to 70~100°C, after the proton exchange membrane shrinks by heat, start the external vacuum pump to adsorb and fix the proton exchange membrane.

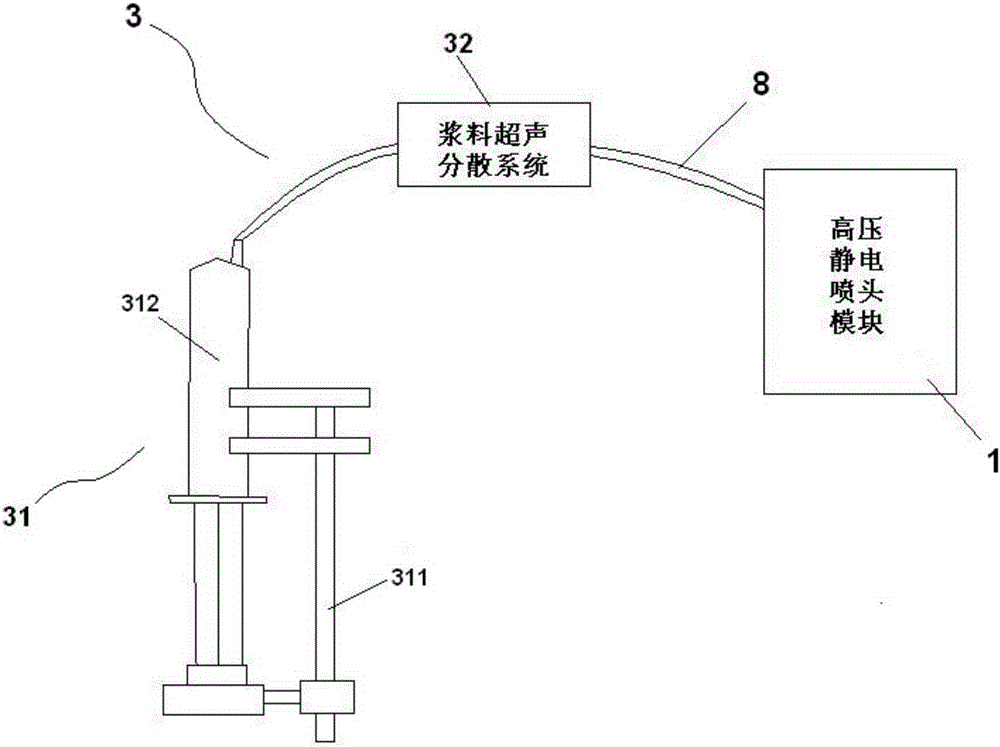

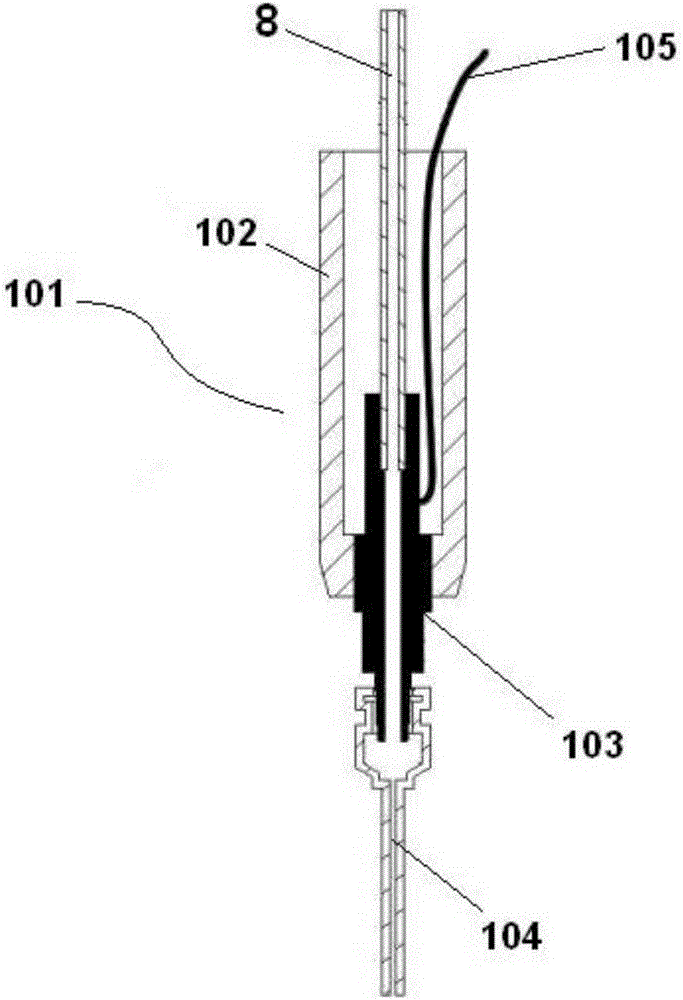

[0042]2. Use a disposable plastic syringe to draw a certain volume of catalyst slurry, clamp it into the syringe pump in the slurry delivery system, connect the polytetrafluoroethylene tube and start the syringe pump to push the catalyst slurry into the stainless steel needle at the front of the nozzle.

[0043] 3. Connect the program-controlled electrostatic spraying device to the computer with a USB cable and run the scanning spray...

Embodiment 2

[0048] The nanoscale platinum-carbon catalyst slurry is sprayed on the surface of the gas diffusion layer by using the invention, and is used for preparing the catalytic layer in the membrane electrode of the fuel cell. The specific usage steps are:

[0049] 1. Spread the proton exchange membrane on the center of the vacuum adsorption platform, set the temperature of the vacuum adsorption platform to 70-100°C, and then start the external vacuum pump to adsorb and fix the gas diffusion layer.

[0050] 2. Draw a certain volume of catalyst slurry with a disposable plastic syringe, clamp the syringe to the syringe pump in the slurry delivery system, connect the PTFE tube and start the syringe pump, and push the catalyst slurry to the stainless steel needle at the front of the nozzle middle.

[0051] 3. Connect the program-controlled electrostatic spraying device to the computer with a USB cable and run the scanning spraying program directly, or use an SD card with a running tr...

Embodiment 3

[0056] The nano-scale carbon black particle slurry is sprayed on the surface of the carbon fiber material by using the invention to prepare the gas diffusion layer of the fuel cell. The specific usage steps are:

[0057] 1. Spread the carbon fiber material in the middle of the vacuum adsorption platform, set the temperature of the vacuum adsorption platform to 70~100°C, and then start the external vacuum pump to adsorb and fix the carbon fiber.

[0058] 2. Use a disposable plastic syringe to draw a certain volume of carbon black slurry, clamp the syringe to the injection pump in the slurry delivery system, connect the PTFE tube and start the injection pump to push the carbon black slurry to the front end of the nozzle. In the stainless steel needle.

[0059] 3. Connect the program-controlled electrostatic spraying device to the computer with a USB cable and run the scanning spraying program directly, or use an SD card with a running track program and insert it into the SD ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com