Patents

Literature

32results about How to "Improve atomization ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

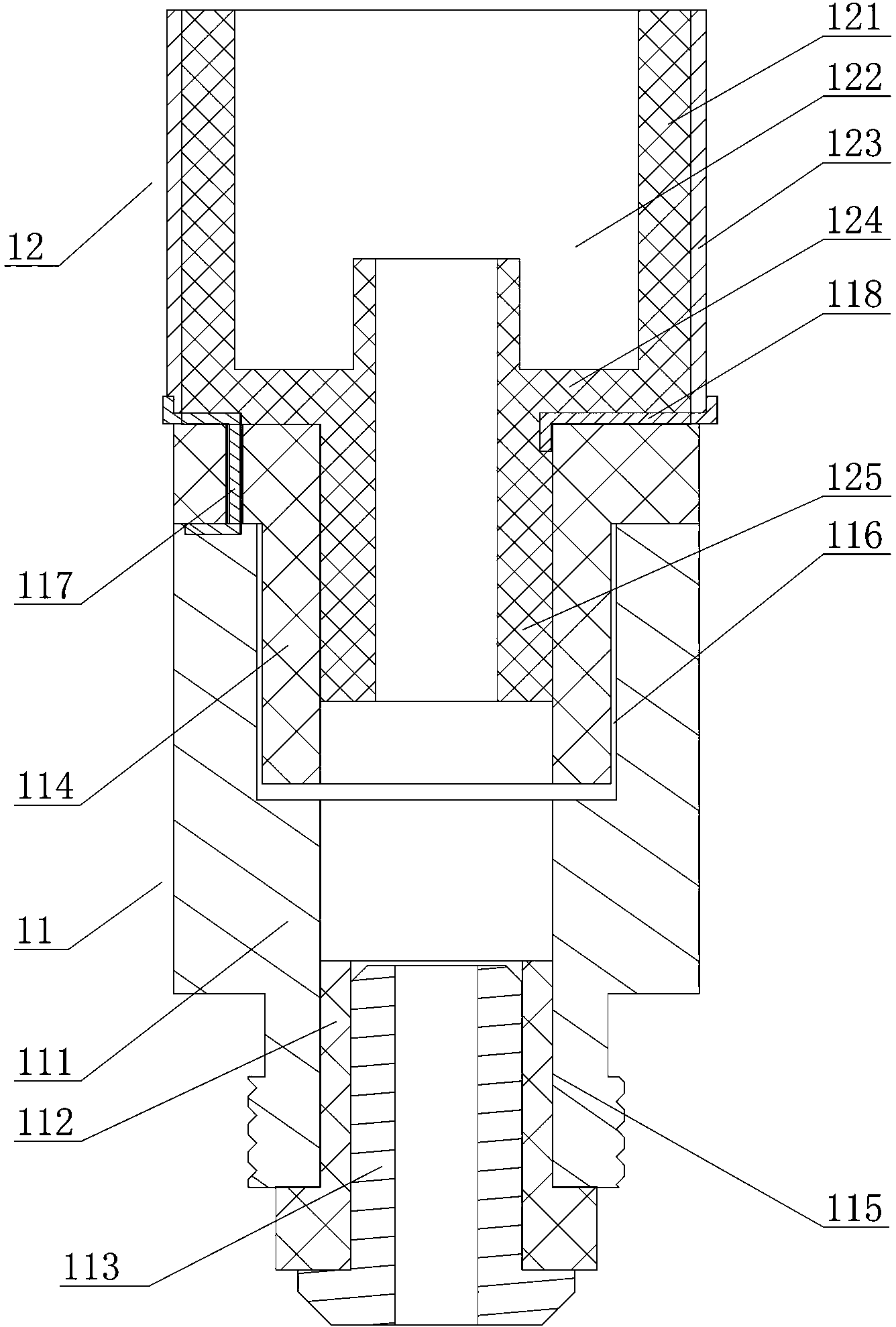

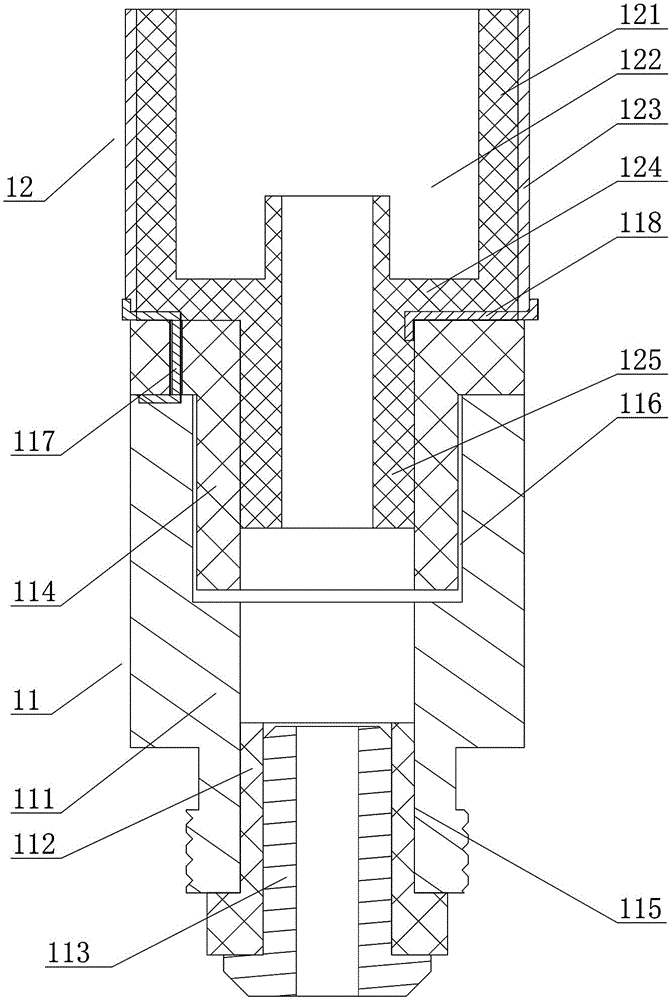

Surface heating type atomizer and electronic cigarette provided with same

The invention discloses a surface heating type atomizer and an electronic cigarette provided with same. The atomizer comprises a base and heating element, which are mutually connected; the heating element comprises a ceramic seat, an accommodating groove used for accommodating solid tobacco tar or paste is formed in the ceramic seat, a nano titanium metal heating material film is covered on the outer side of the ceramic seat; the electronic cigarette comprises an atomizer component and a cigarette rod component, which are mutually connected; the atomizer component comprises a cigarette holder, an atomizer tube, a first electrode connecting component and the atomizer, which are connected in sequence; the cigarette rod comprises a battery tube, as well as a second electrode connecting component, a battery and a control panel, which are arranged in the battery tube, the second electrode connecting component are connected with the battery through the control panel, a key switch connected with the control panel is arranged on the battery tube, and the first electrode connecting component and the second electrode connecting component are connected and conducted. The atomizer and the electronic cigarette provided with same have the advantages that the heating area is big, the atomization performance is good, the amount of the atomized oil smoke at a time is big, carbon deposition is avoided during the using process, the service life is long, and the atomizer and the electronic cigarette are energy-saving and environment-friendly.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

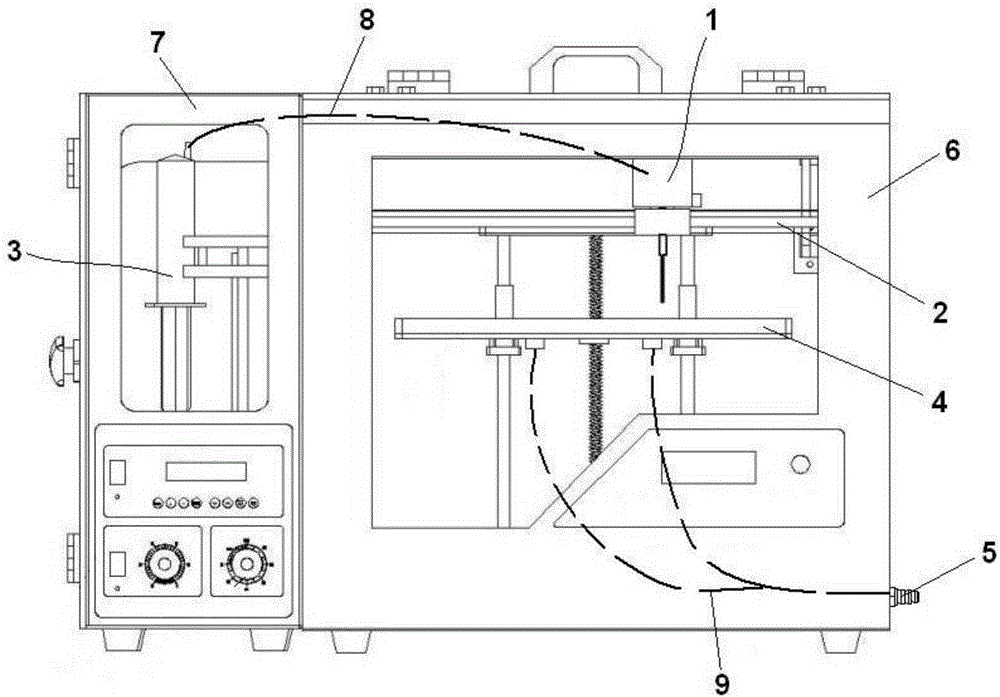

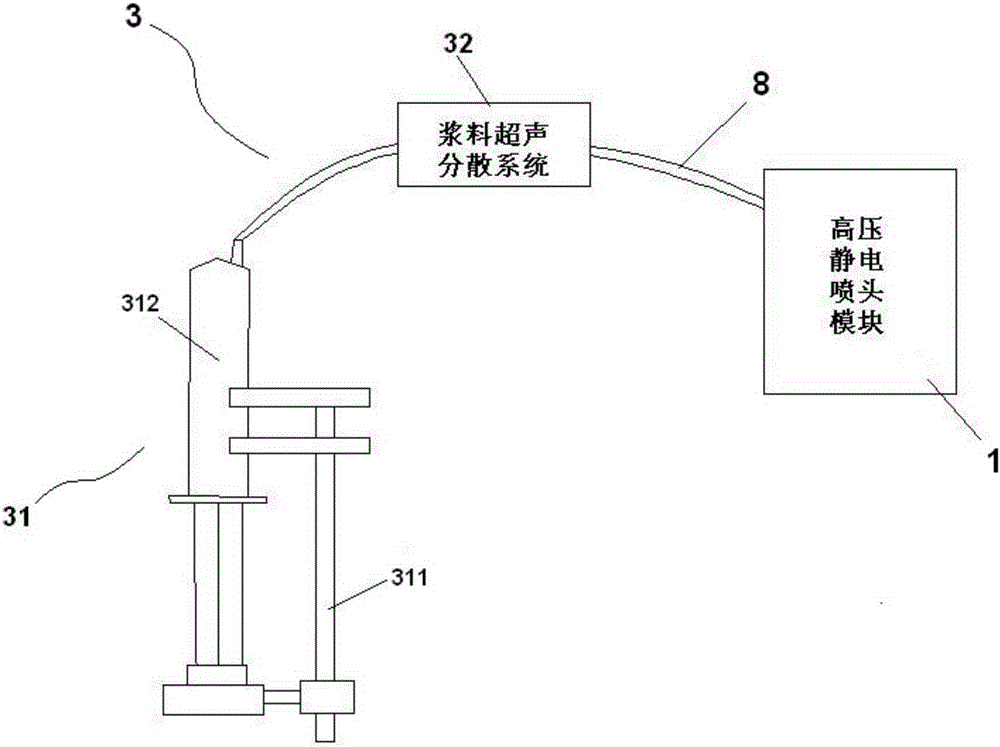

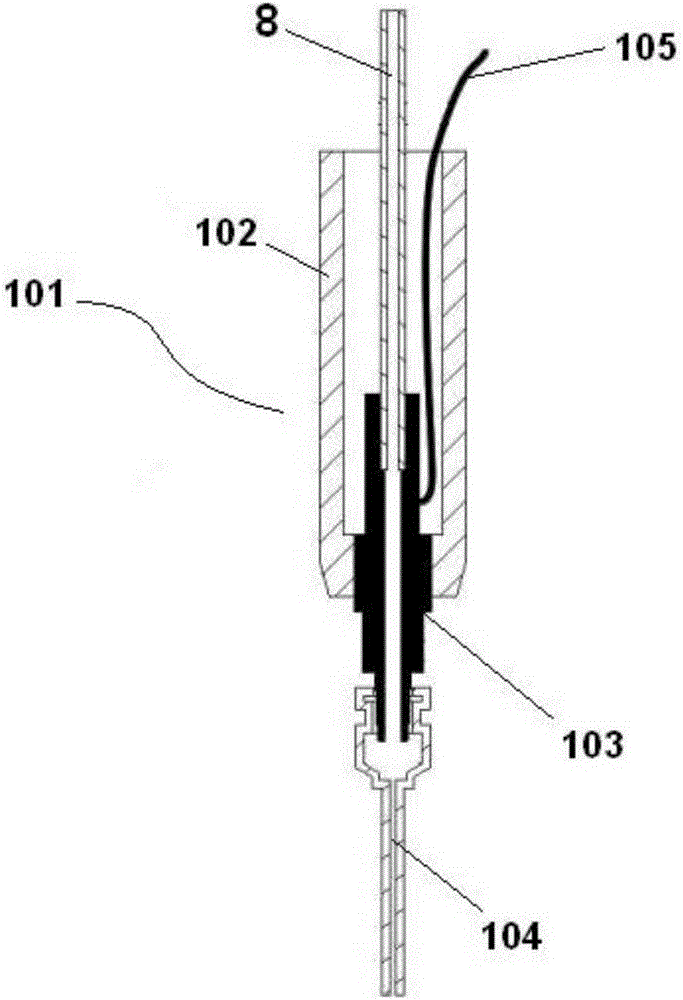

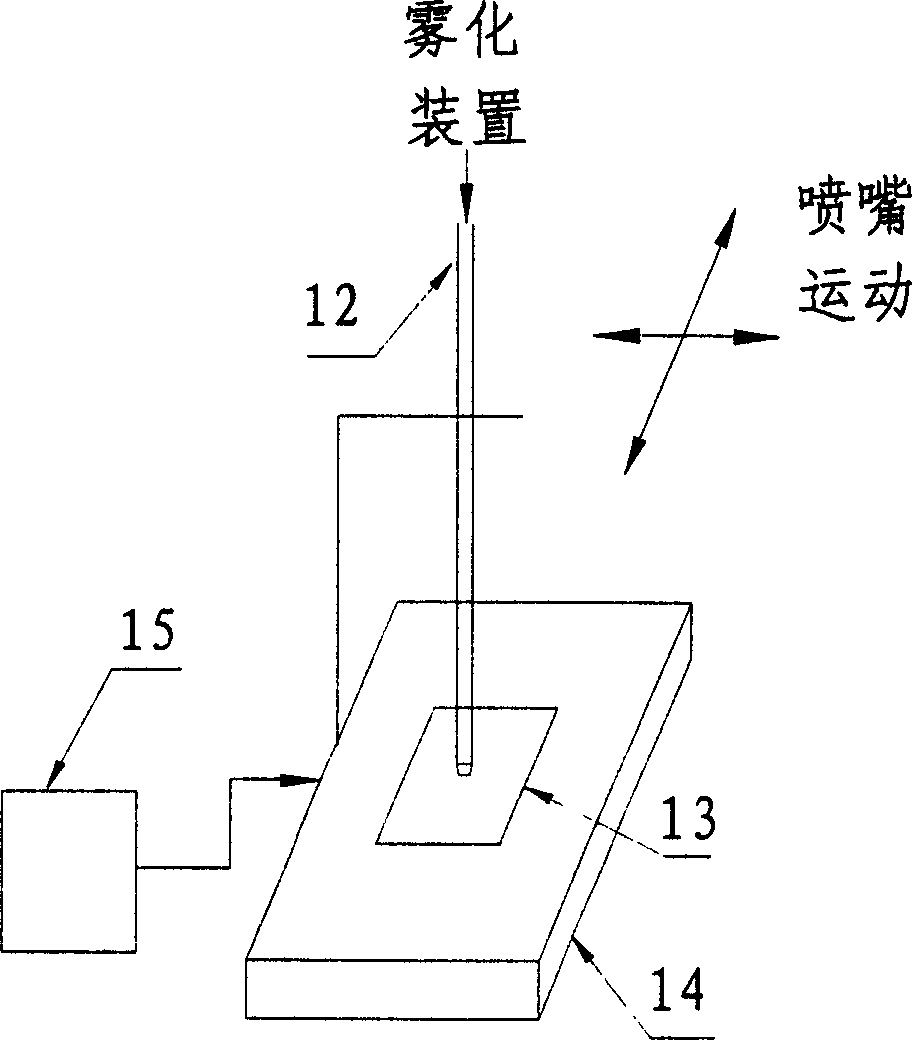

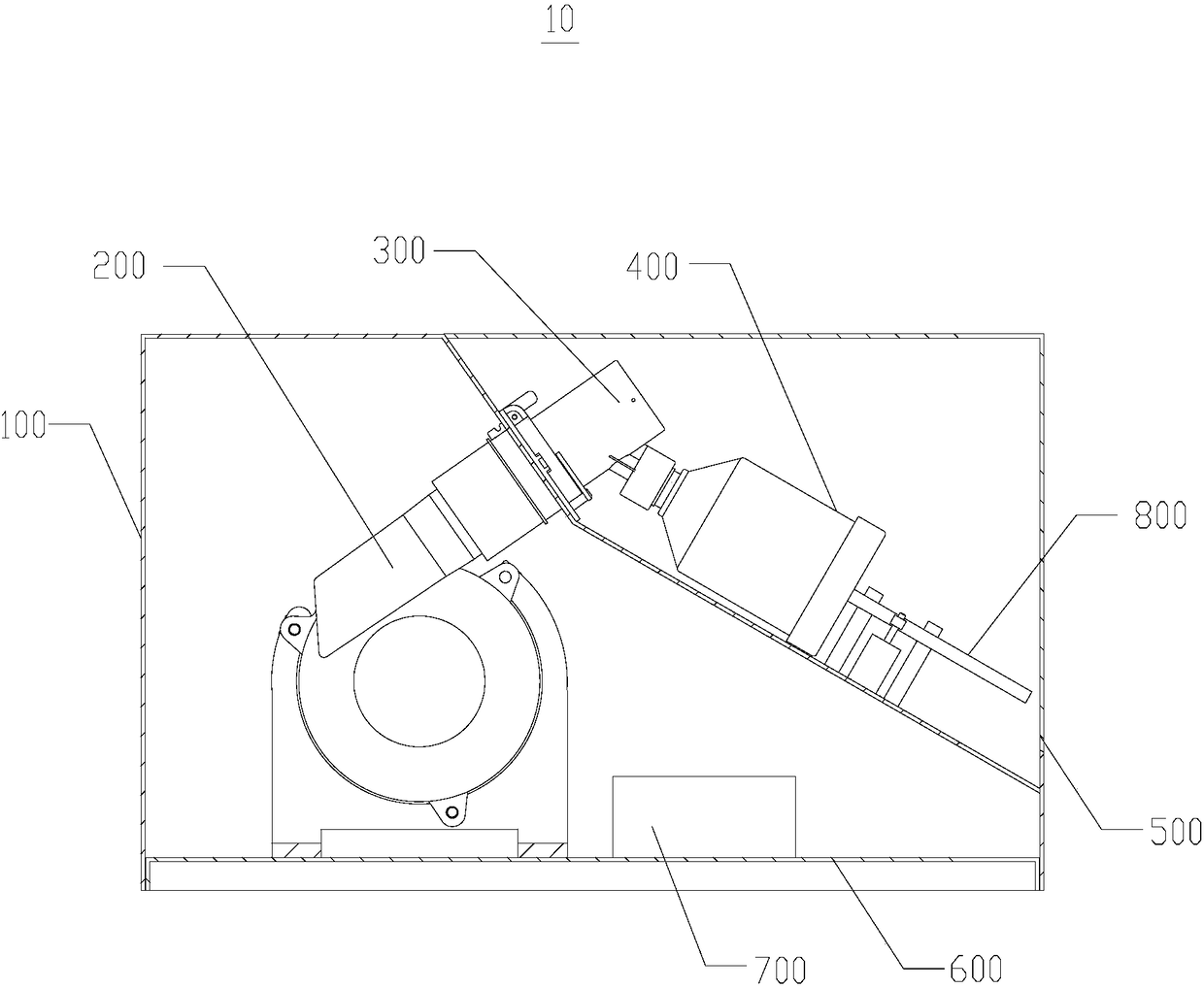

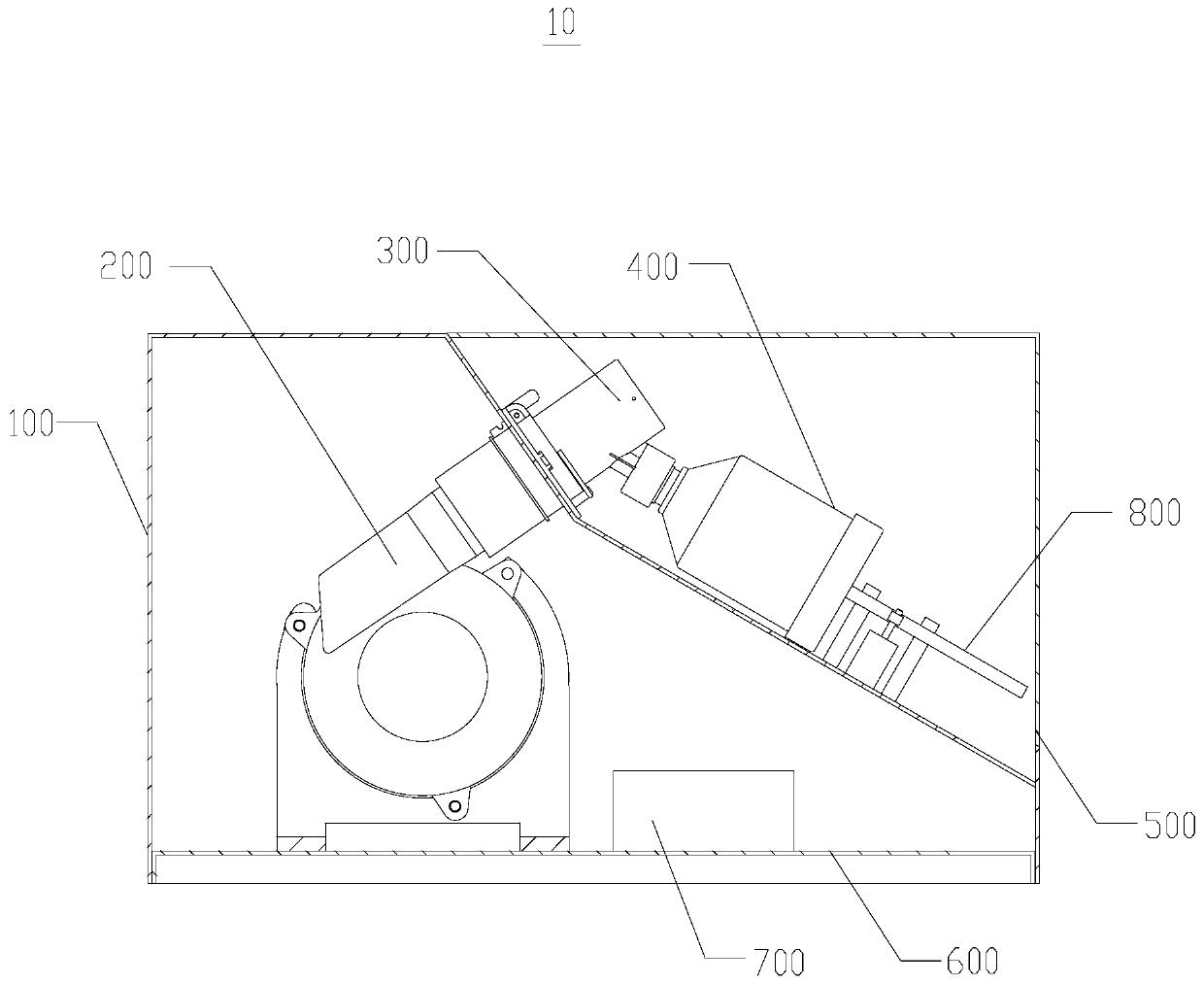

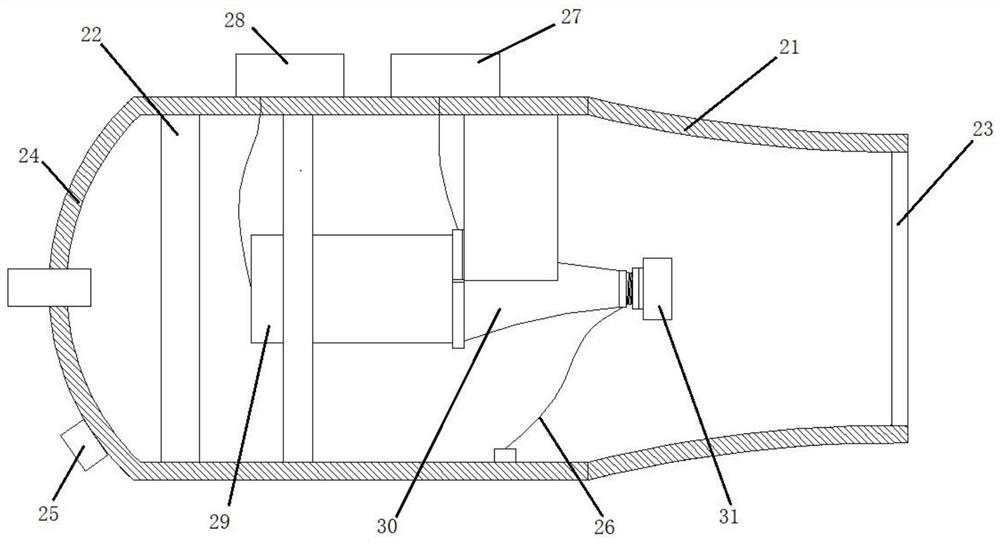

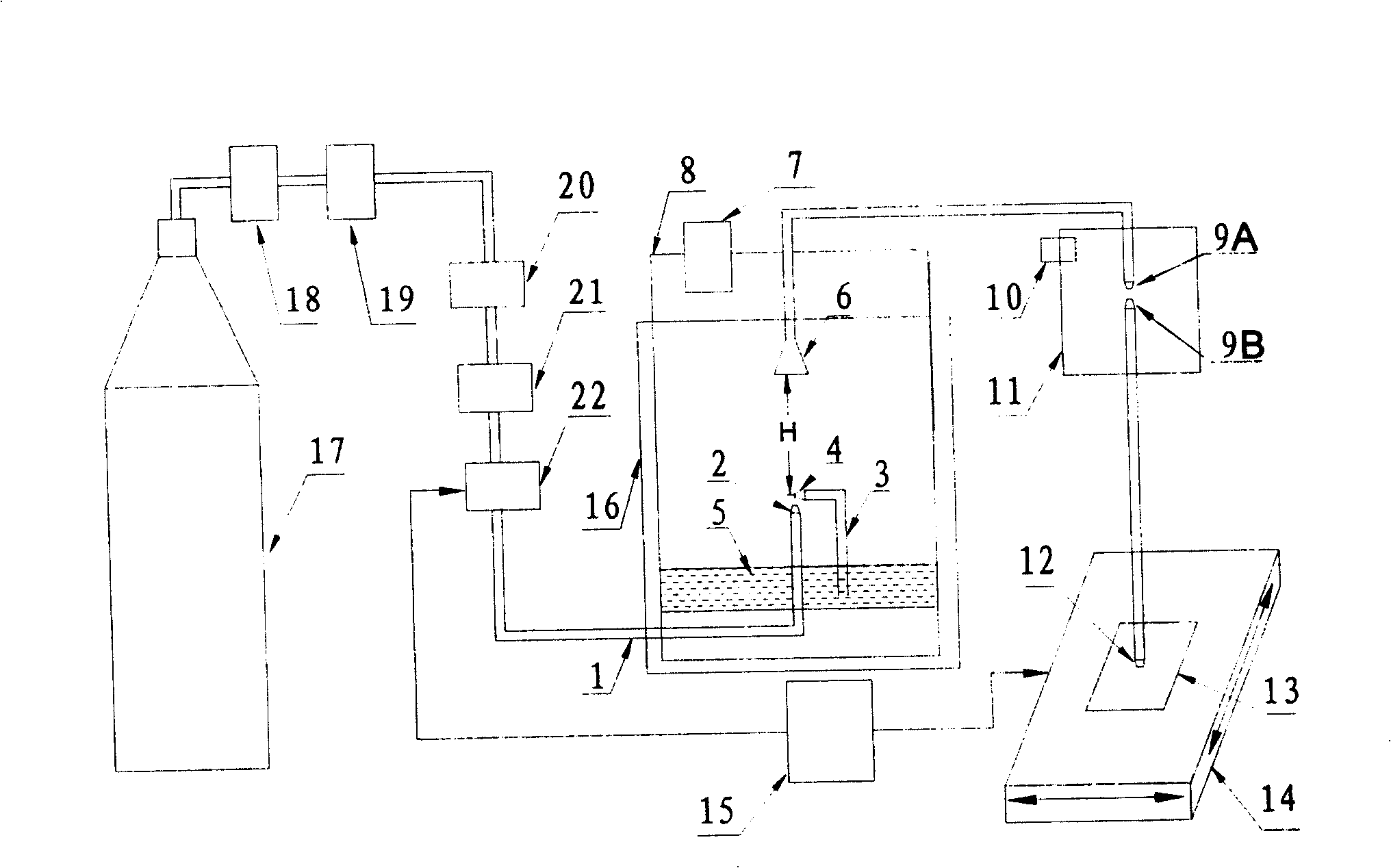

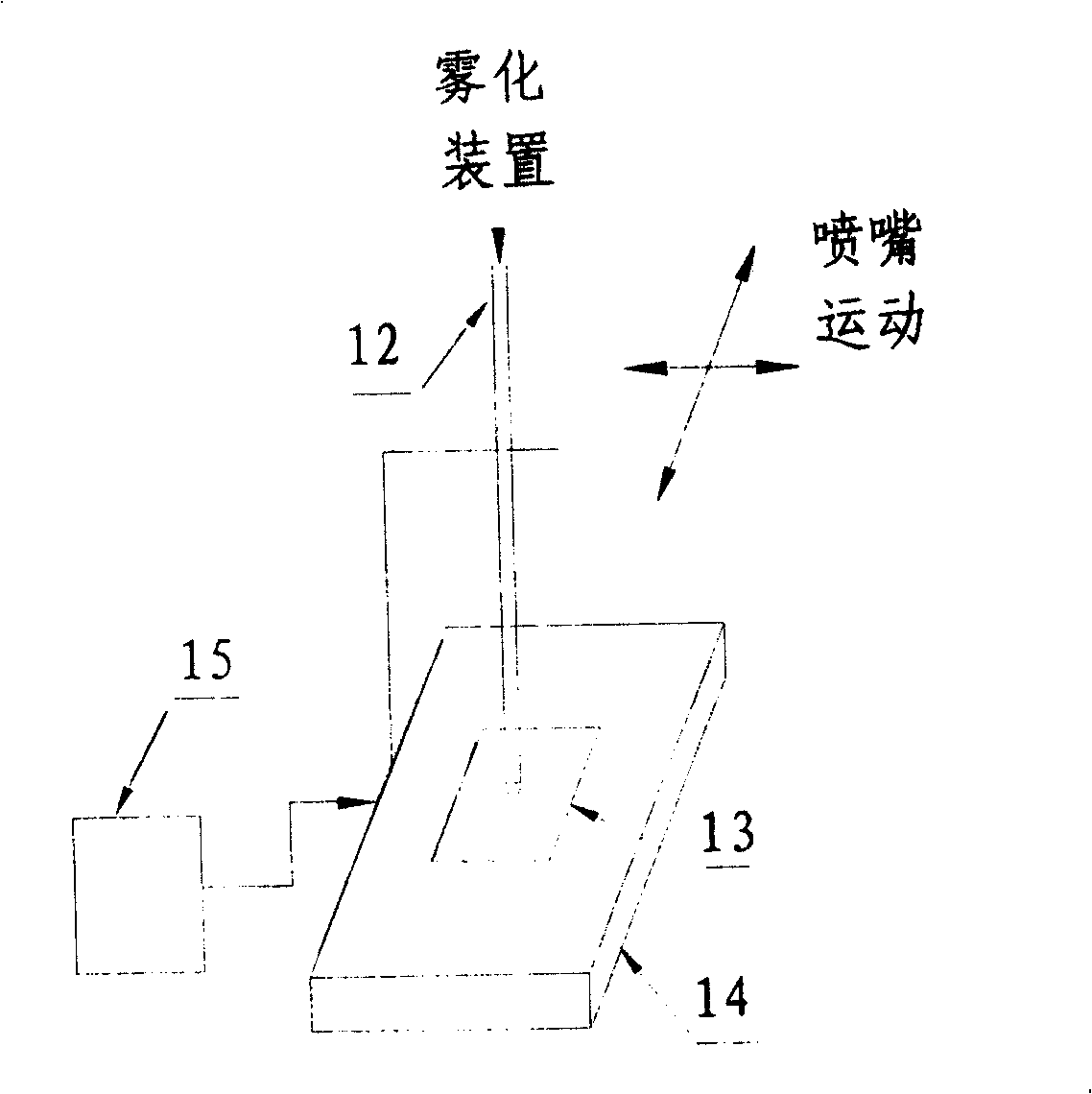

Programmed type electrostatic spraying device

ActiveCN105170359ASmooth slurry flow controlIncrease profitLiquid spraying plantsEngineeringHigh pressure

The invention provides a programmed type electrostatic spraying device. The programmed type electrostatic spraying device comprises a box, a control mainboard and a switching power supply. The programmed type electrostatic spraying device is characterized in that the programmed type electrostatic spraying device further comprises a high-voltage electrostatic spraying nozzle module, a spraying nozzle movement support, a slurry conveying system, an automatic lifting platform and an air connector; the box comprises a box chamber A and a box chamber B; the control mainboard, the switching power supply, the high-voltage electrostatic spraying nozzle module, the spraying nozzle movement support, the automatic lifting platform and the air connector are arranged in the box chamber A; the slurry conveying system is arranged in the box chamber B; the high-voltage electrostatic spraying nozzle module is arranged on the spraying nozzle movement support; the automatic lifting platform is arranged below the high-voltage electrostatic spraying nozzle module; the slurry conveying system is connected with the high-voltage electrostatic spraying nozzle module through a polytetrafluoroethylene tube; the air connector is arranged on the side wall of the box chamber A and connected with the automatic lifting platform through a hose. The programmed type electrostatic spraying device can remarkably increase the utilization rate of sprayed slurry and reduce the usage quantity of expensive slurry.

Owner:NANJING UNIV +2

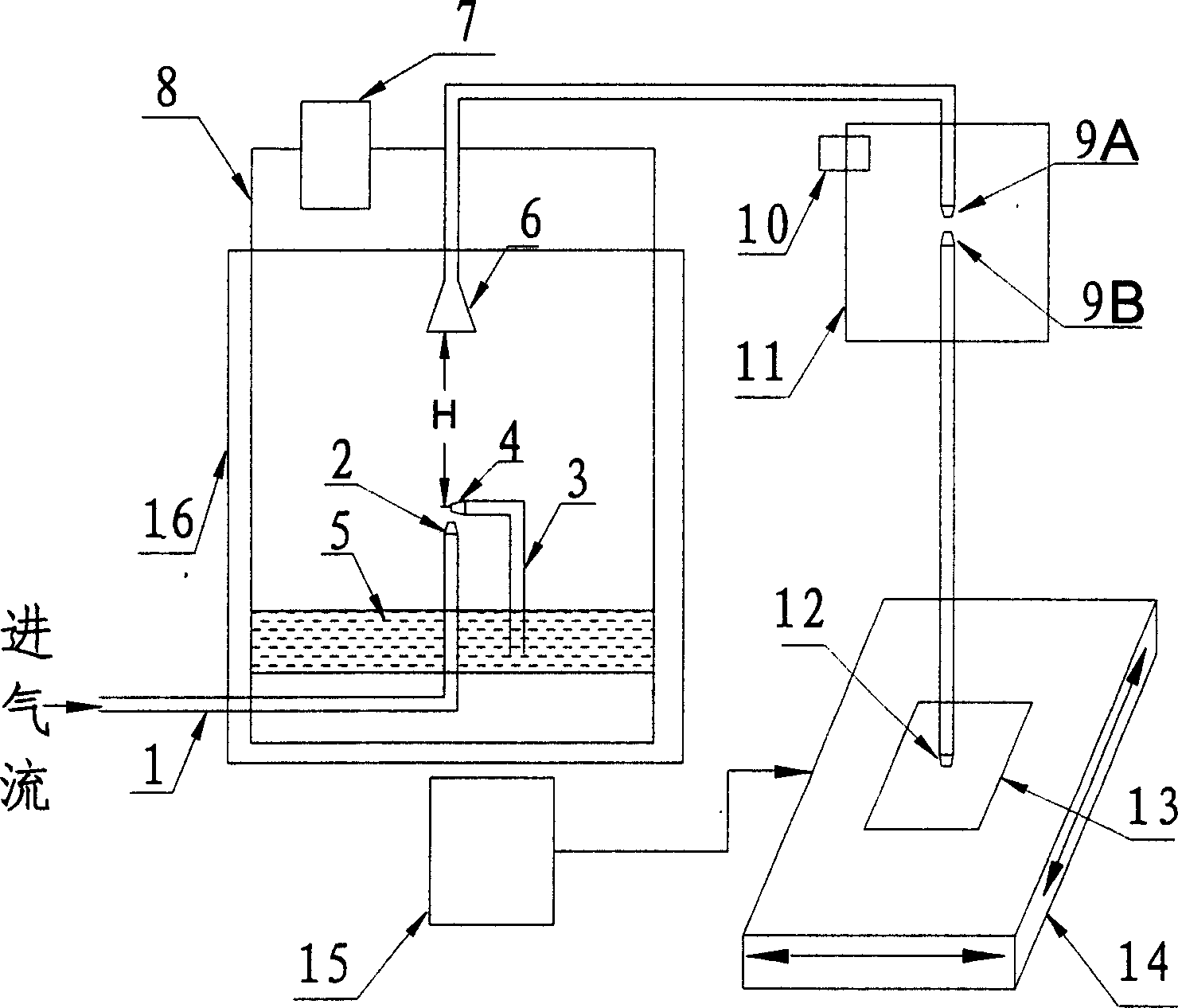

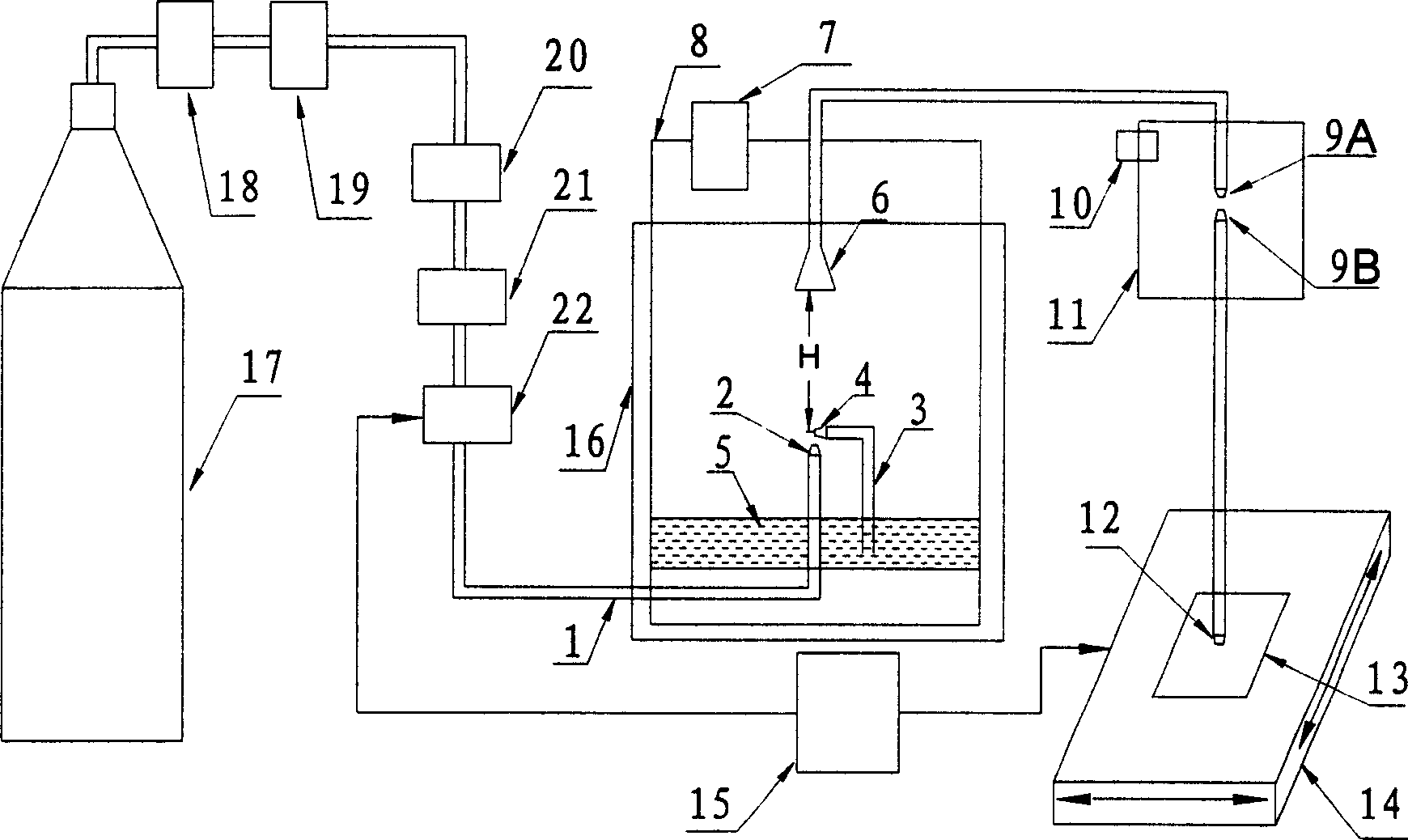

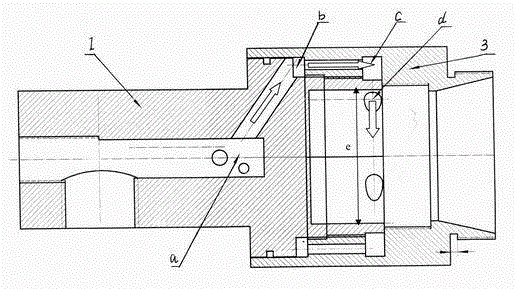

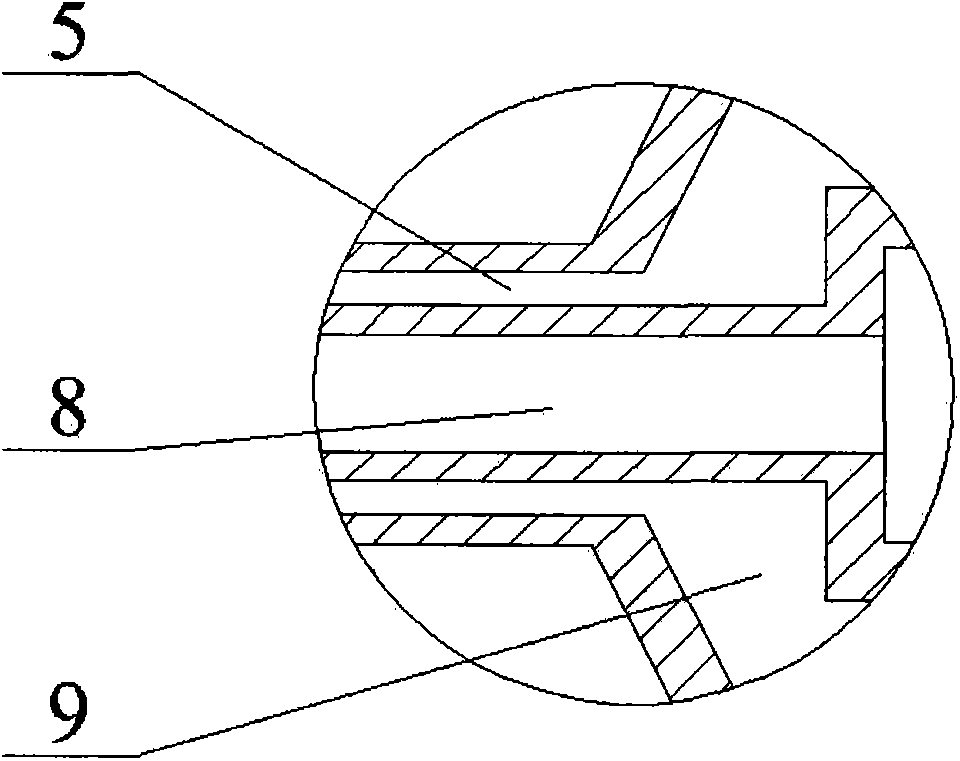

Electronic device for direct slurry atomization and deposition

ActiveCN1876244ASmall inner diameterIncrease air velocityLiquid surface applicatorsSpraying apparatusButt jointSlurry

The disclosed electronic slurry atomization deposition direct-write device comprises: a deposition nozzle, a base plate, a work bench controlled by a controller, two atomizing nozzles every with a gas nozzle connected to gas source and a liquid nozzle connected to slurry pipe end both in the atomization cavity, and a butt-joint jet pipe with co-axial upper and lower jet pipes, wherein arranging a micro-pressure gauge in the cavity, arranging a adjustable valve in the decompression recovery cavity. This invention has well atomization effect, and runs stably and conveniently.

Owner:HUAZHONG UNIV OF SCI & TECH

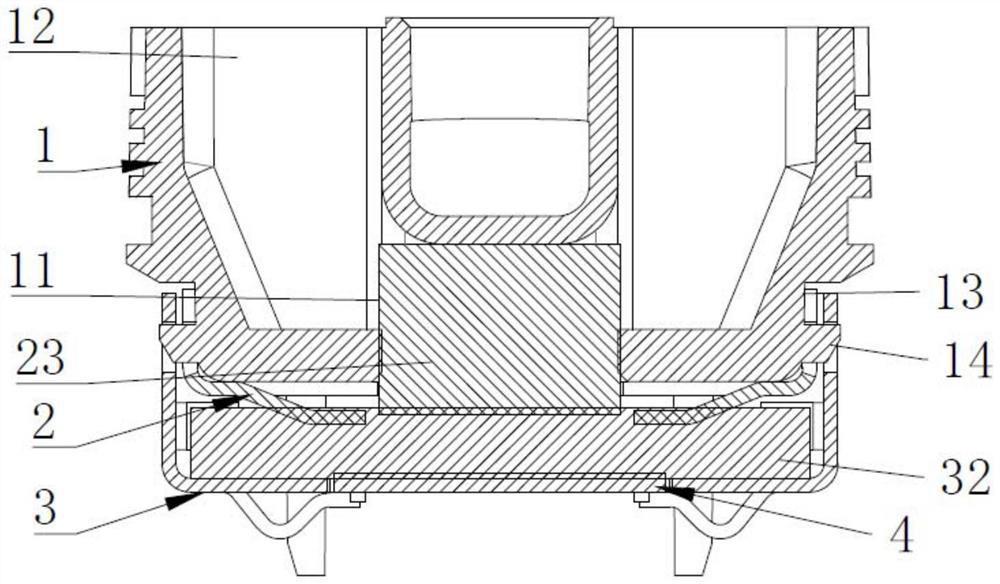

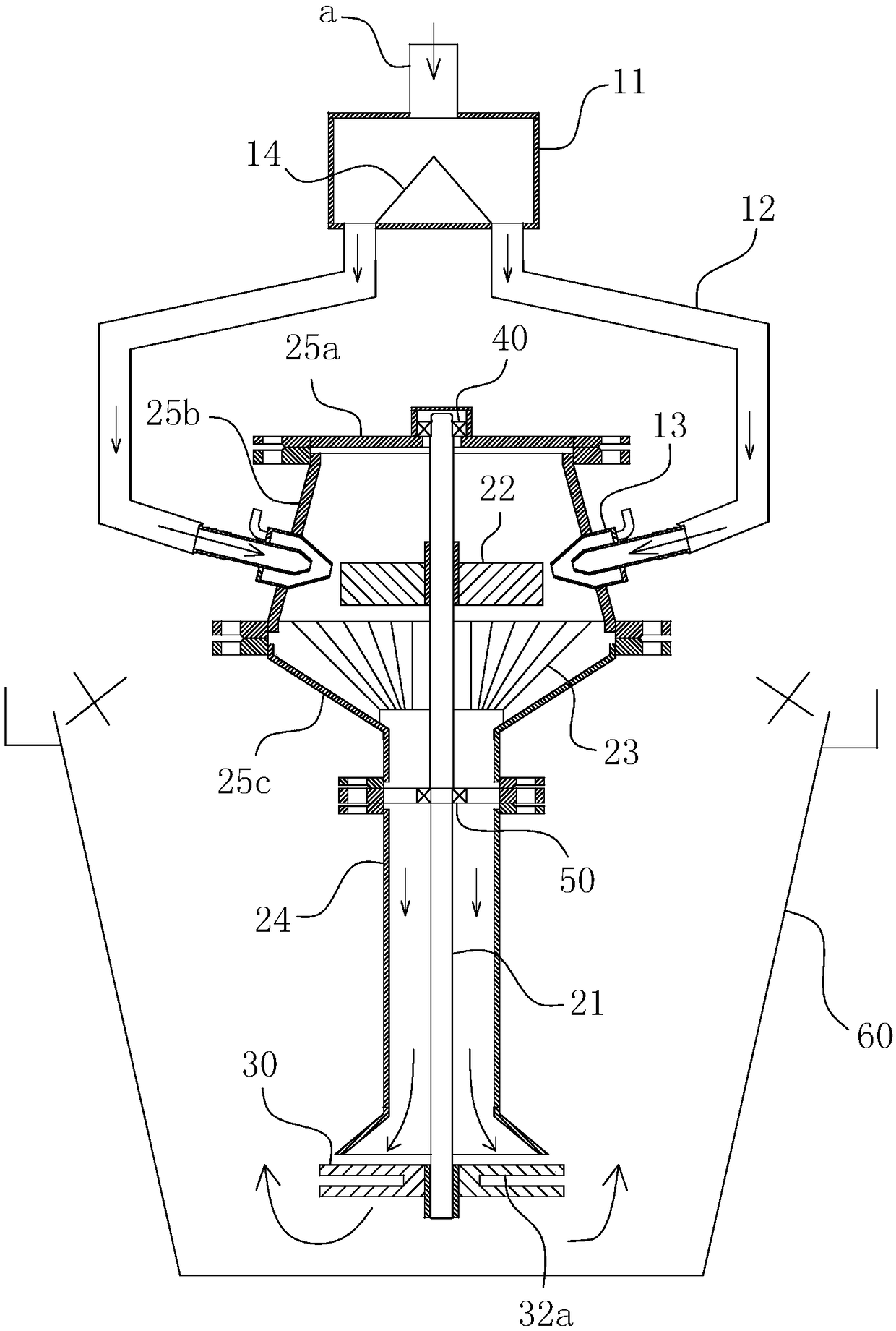

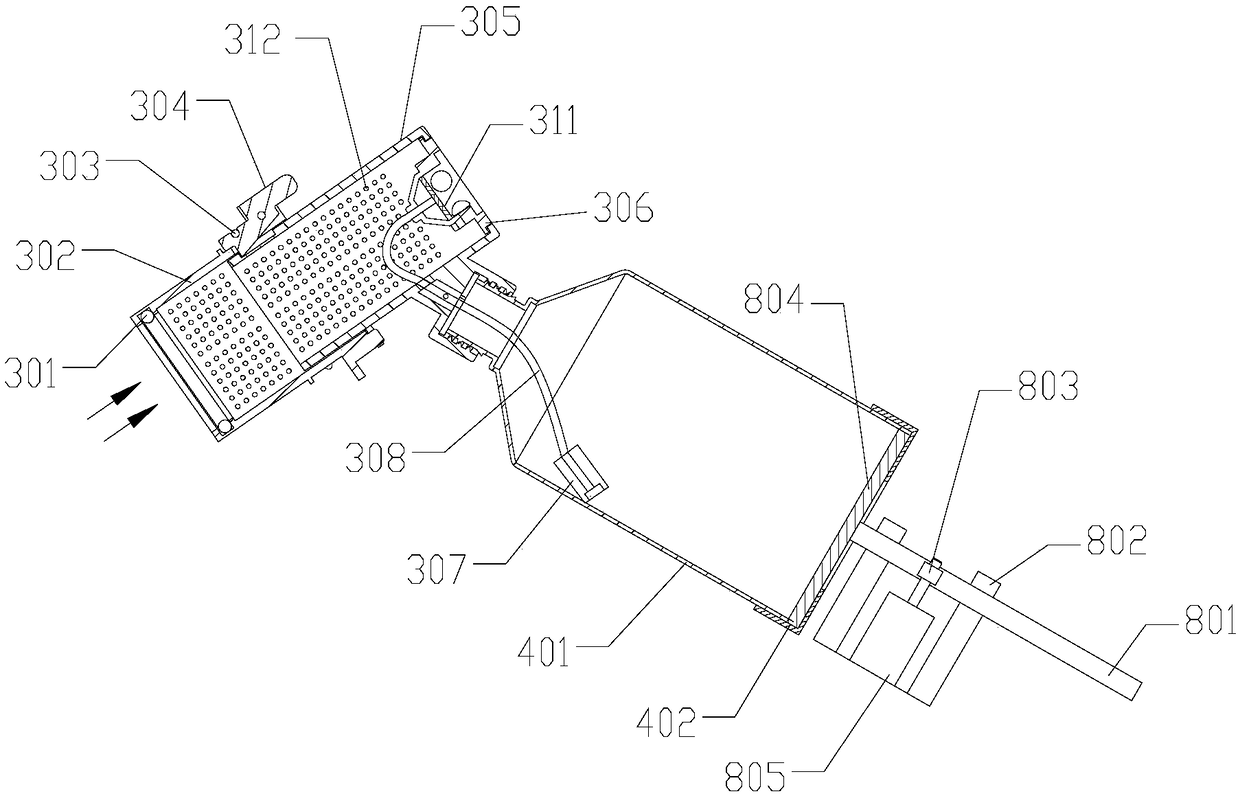

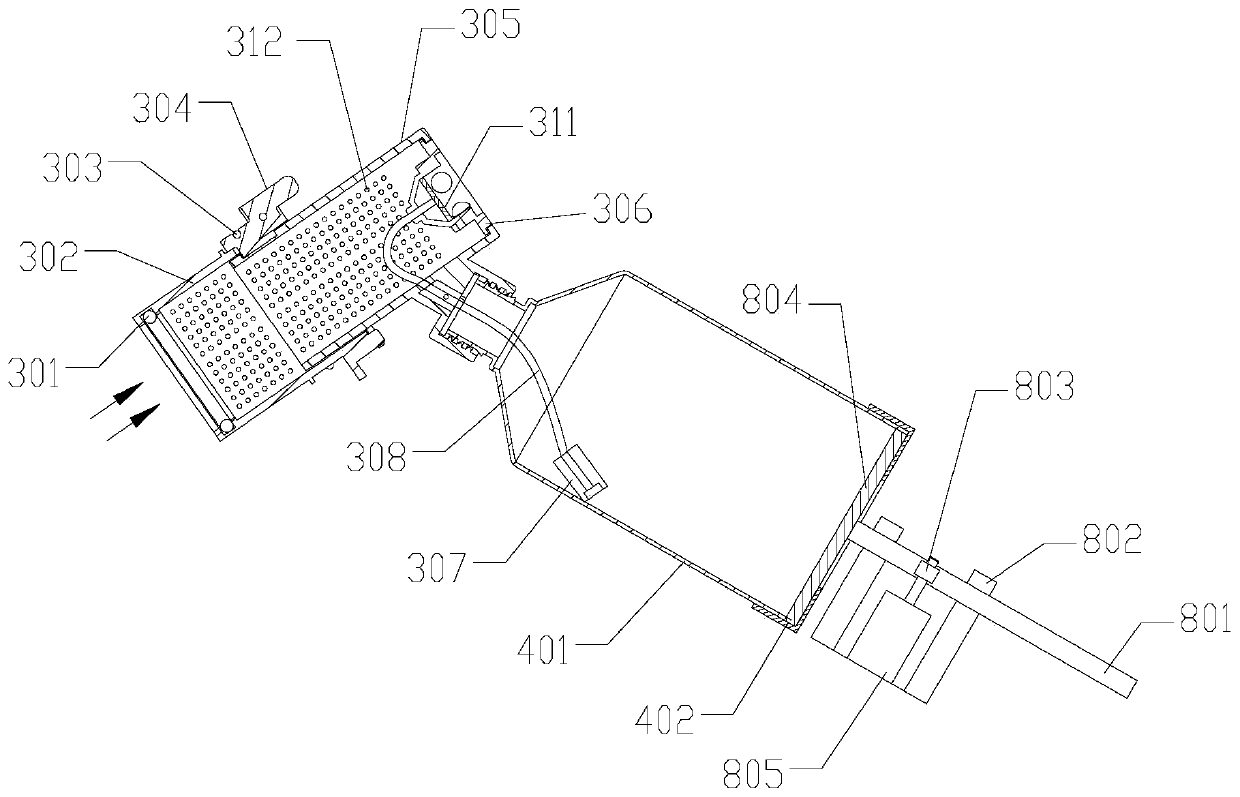

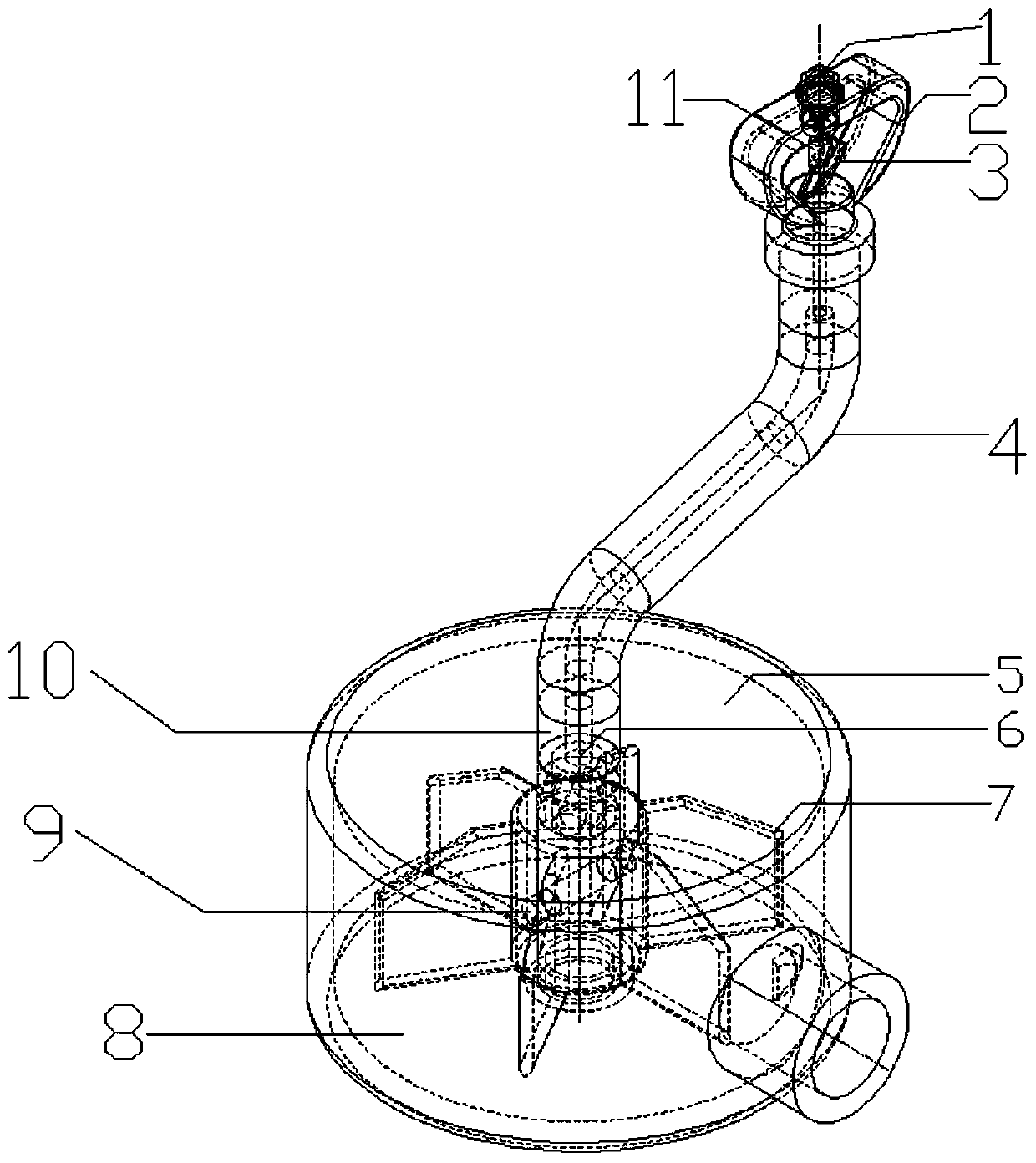

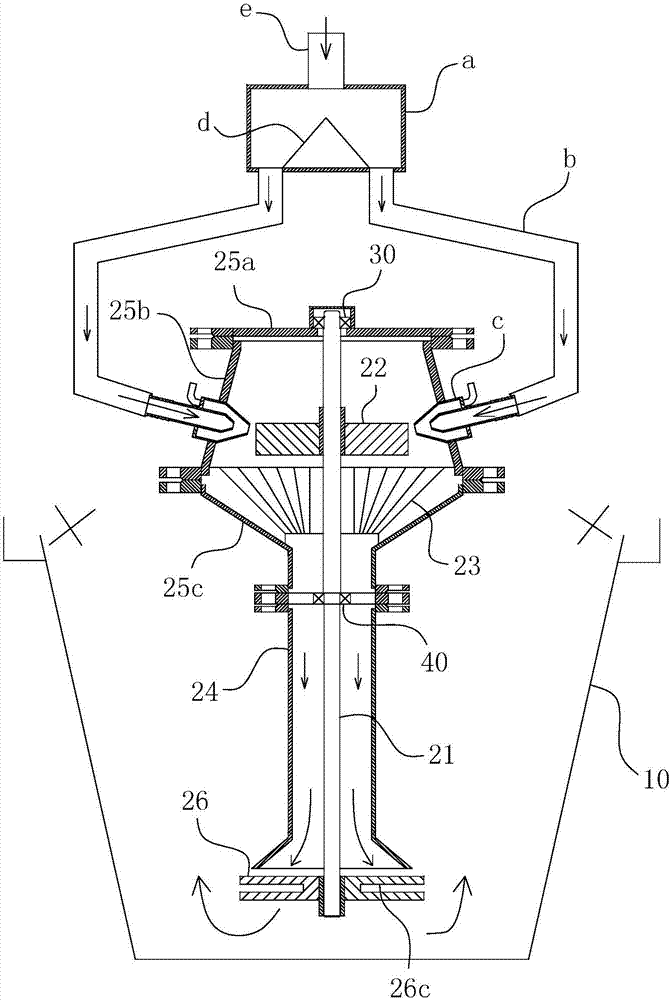

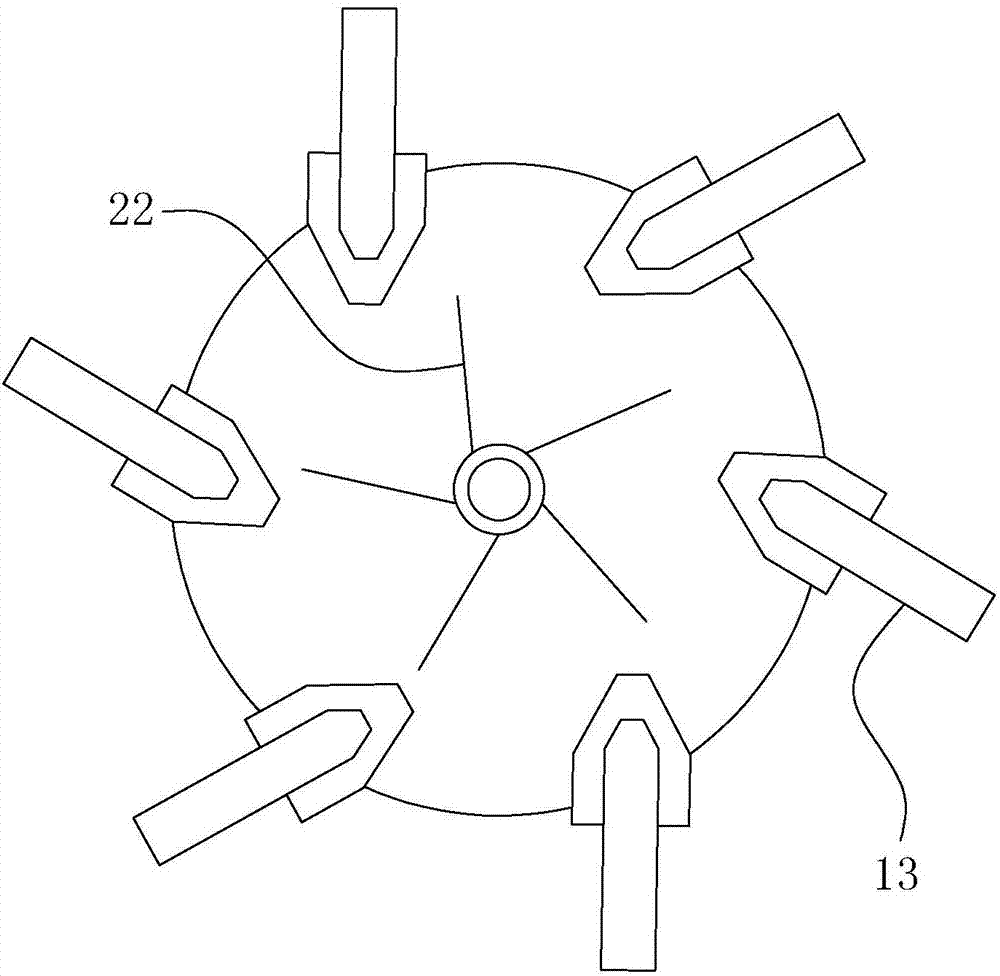

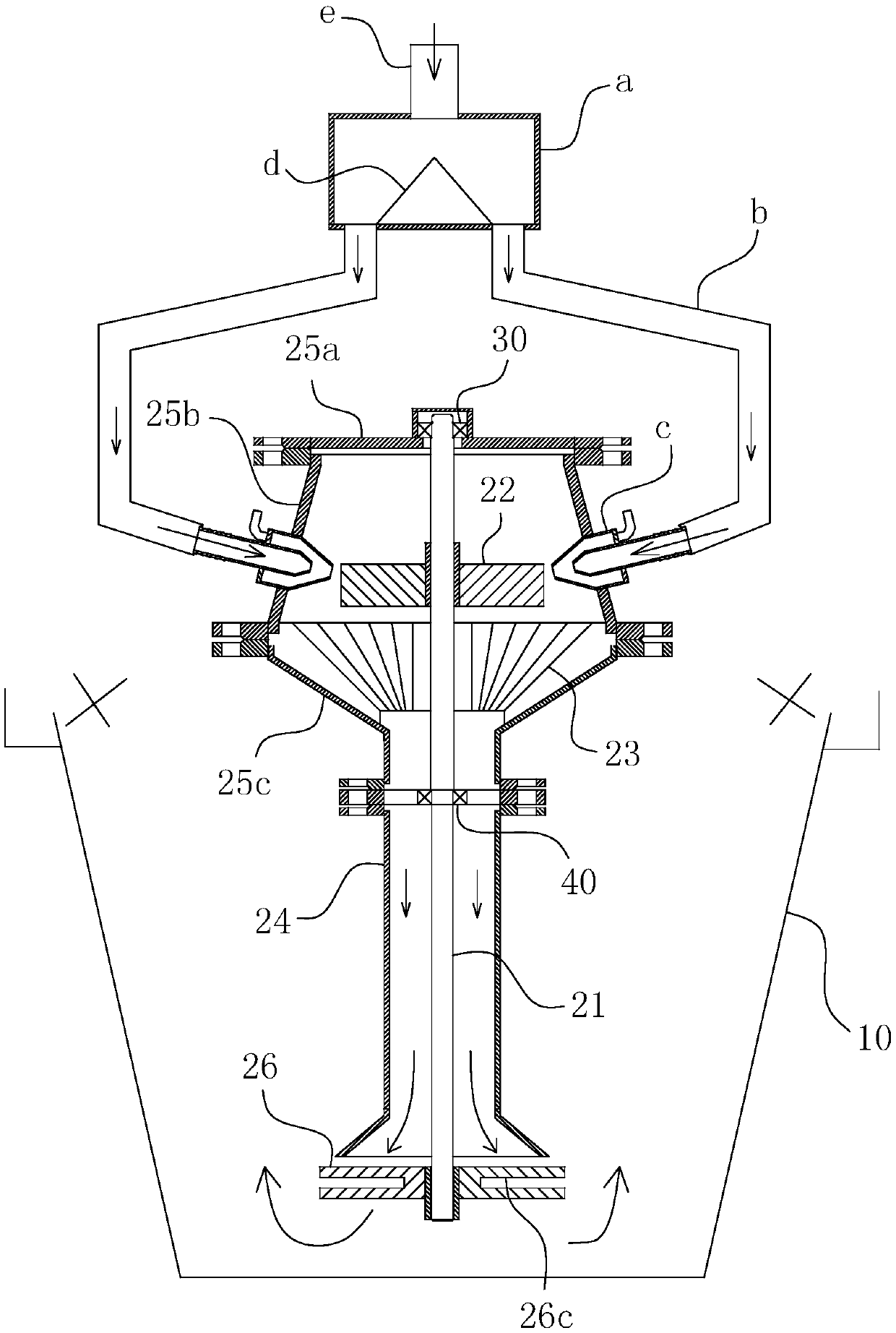

Flotation equipment with pulp self-drive and self-suction functions

ActiveCN107159471AReduce maintenanceEfficient flotation needsFlotationHigh pressureEnergy consumption

The invention relates to the field of pulp-mixing and flotation treatment of coal slime, in particular to flotation equipment with pulp self-drive and self-suction functions. The flotation equipment comprises a flotation tank, a flow distribution assembly for achieving a jet flow mixing function, a high-pressure jet assembly for achieving a turbulent flow mixing function and a lower stirring assembly for achieving a stirring and mixing function. The flotation equipment integrates pulp mixing and flotation and has the beneficial effects of being low in energy consumption, low in maintenance capacity, good in self-suction and sorting effects and capable of reducing the equipment input in the early stage of a coal preparation plant while the efficient flotation requirement of pulp is achieved efficiently and controllably and thus effectively lowering the actual production cost of the coal preparation plant.

Owner:ANHUI UNIV OF SCI & TECH

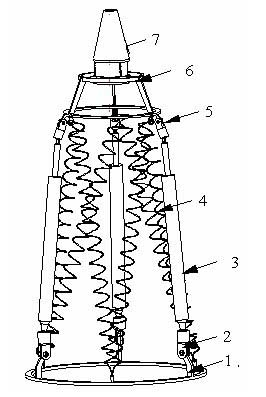

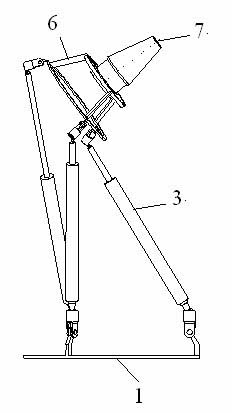

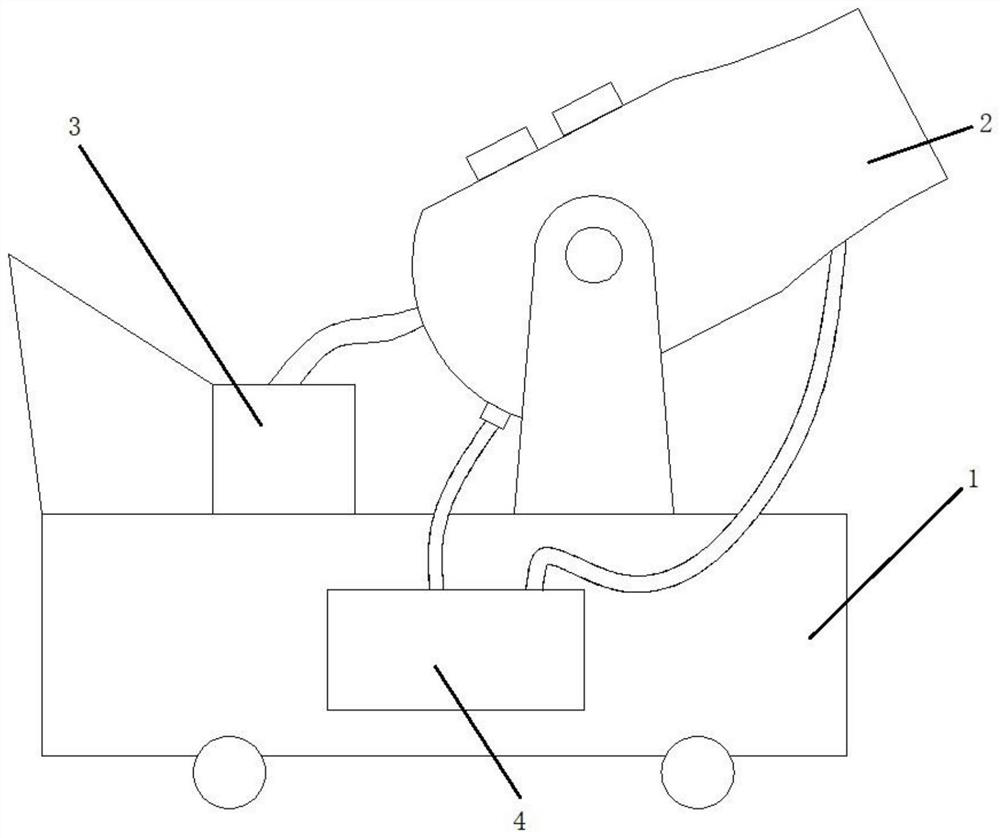

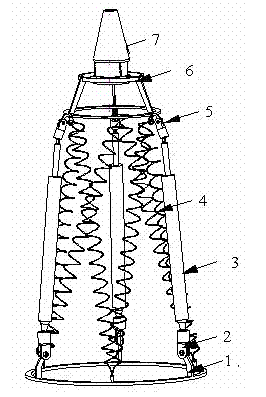

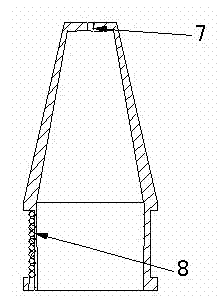

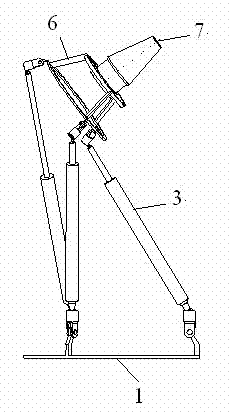

Four-DOF fire-fighting spray gun

InactiveCN102029036AImprove atomization abilityReduce the amount of waterFire rescueEngineeringStructural engineering

The invention relates to a four-DOF (Degree-of-Freedom) fire-fighting spray gun; the bottom end of a hydraulic cylinder is connected with a bottom connecting base through a pin shaft to form a revolute pair; the bottom connecting base is in 120-degree connection with a bottom bracket; the piston rod of the hydraulic cylinder is in spherical corner connection with a top connecting base to form a spherical movement pair; the top connecting base is in 120-detgree connection with a top bracket; the top bracket is symmetrically connected with the bottom bracket together by six tension springs; every two tension springs are installed at an angle of 120 degrees from one another; the center of the top bracket is connected with a fire-fighting faucet through three rows of support balls in 120 degrees; flow guide pores are designed inside the fire-fighting faucet; and the hydraulic cylinder is connected with a controller. The four-DOF fire-fighting spray gun has the following advantages: firstly, the spray gun is small in volume and light in weight, thereby strengthening fire-fighting ability; secondly, long-time fire-fighting extinguishment can be realized so that automatic fire-fighting extinguishment becomes possible.

Owner:NANCHANG UNIV

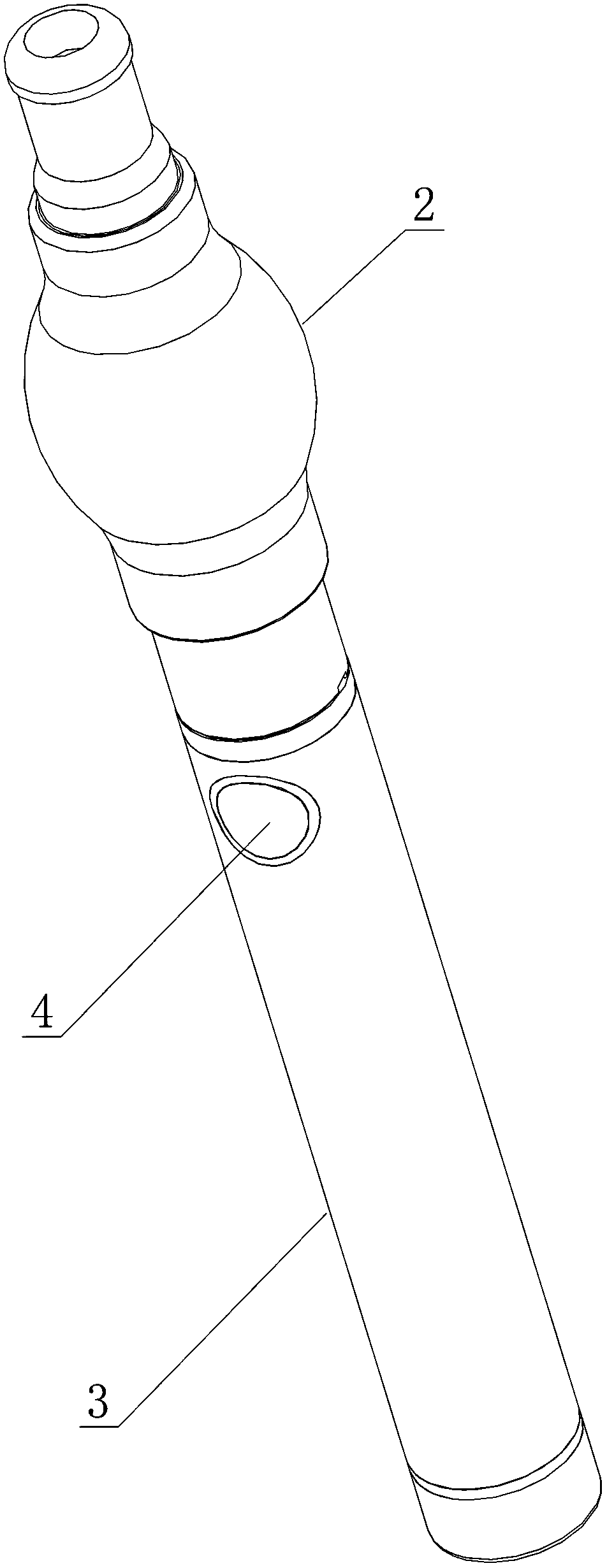

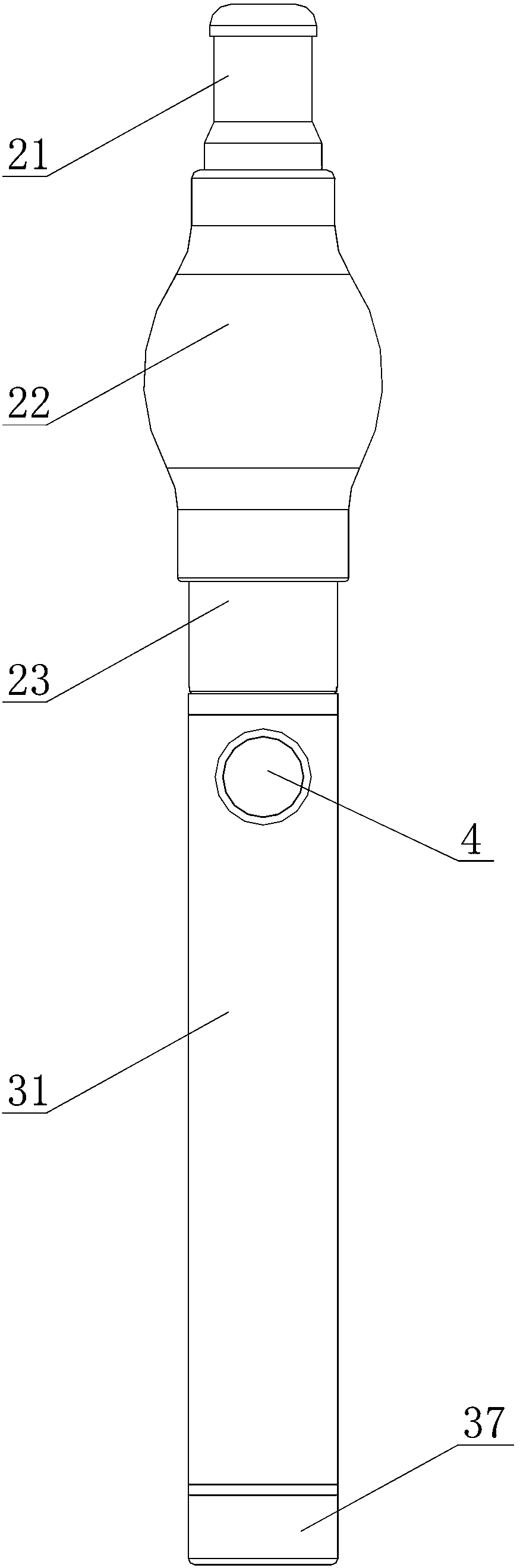

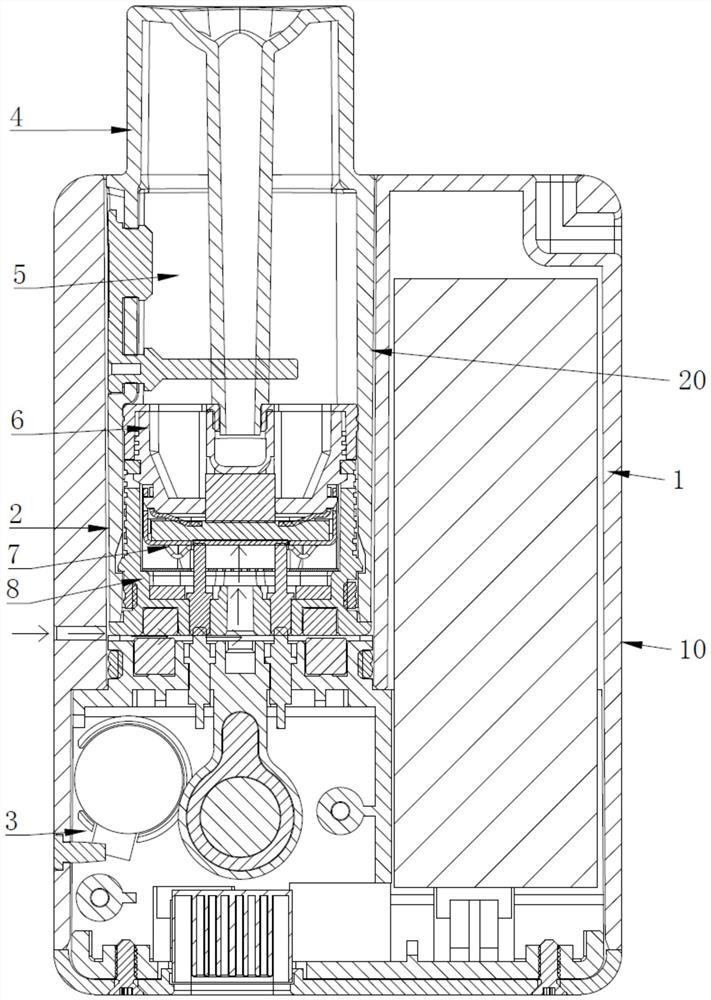

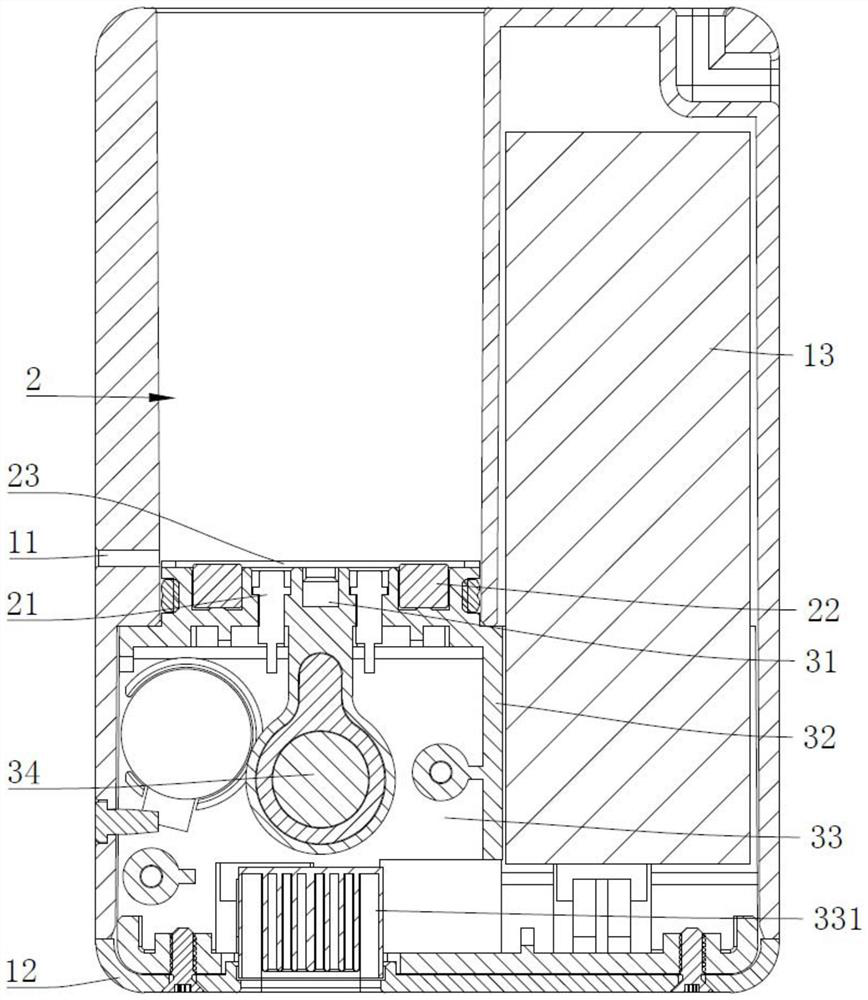

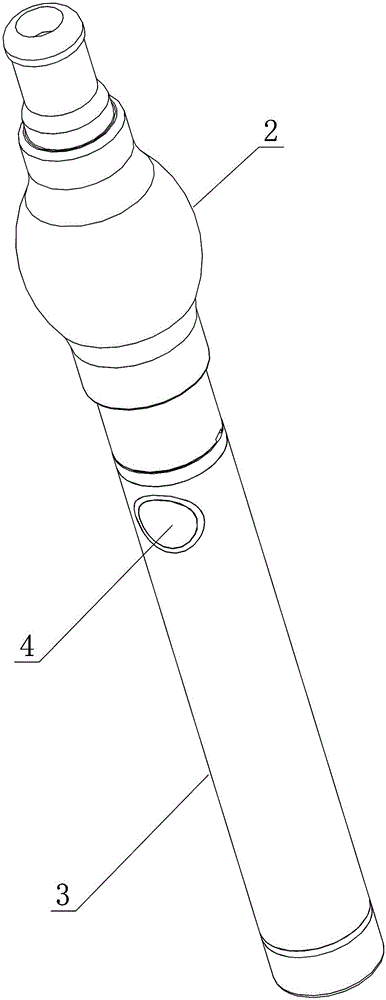

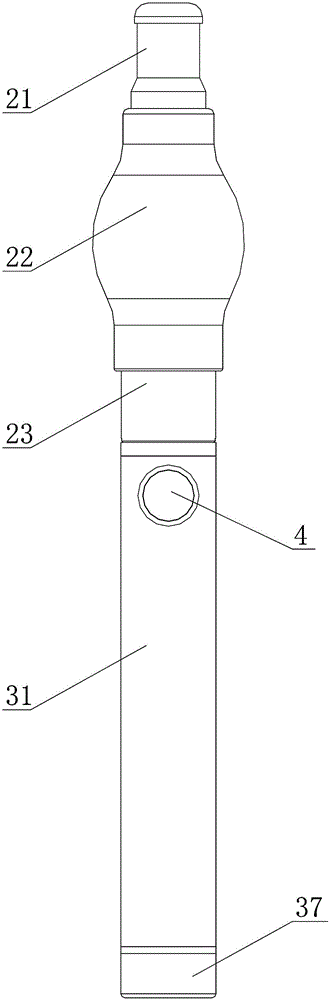

Electronic atomizer

PendingCN114747807AStructural connection is stableImprove atomization effectTobaccoElectrical connectionEngineering

The invention relates to the technical field of electronic atomization, in particular to an electronic atomizer which comprises a main machine, and the main machine comprises a shell, a matching slot formed in the shell, an electric control assembly arranged in the shell and located below the matching slot and a power source installed on one side of the shell and electrically connected with the electric control assembly. The atomizer comprises a shell, an oil storage cavity formed in the shell, an oil guide seat arranged in the shell and communicated with the oil storage cavity, an atomization assembly connected to the oil guide seat and a sealing base, the sealing base is provided with a first electrode, and the first electrode makes contact with the atomization assembly; the oil storage cotton and the oil guide cotton are fixed through cooperation of the first fixing elastic piece and the second fixing elastic piece, the atomization piece is also directly arranged on the second fixing elastic piece, and in the using process, structural connection is stable, installation is matched with the atomization piece, oil guide is stable, and the atomization effect is good.

Owner:东莞市克莱鹏雾化科技有限公司

Spraying process of ultrafine powder paint

The invention discloses a spraying process of ultrafine powder paint, and relates to the technical field of paint spraying. The spraying process selects metal plate punching parts and fluorine carbonultrafine powder paint with a particle size of 15-25 microns for surface treatment by adopting high-pressure fresh water flushing, ultrasonic acid corrosion and vitrification; then, a vacuum electrostatic spraying method is used for spraying; and a temperature of 220-250 DEG C is used for baking and curing. The spraying process adopts ultrasonic auxiliary citric acid for surface corrosion of workpieces to achieve an effect of activating the surfaces of the workpieces, adopts vitrification to replace traditional phosphating to realize no-phosphorus treatment, reduces emission of waste slag andwaste water, reduces such costs as manpower and equipment maintenance, adopts the vacuum electrostatic spraying process, has the advantages of low energy consumption and environmental protection, is higher in atomization effect and more smooth and uniform in coating, and generates no water spot and gas spot.

Owner:WUHU XIECHENG METAL PROD

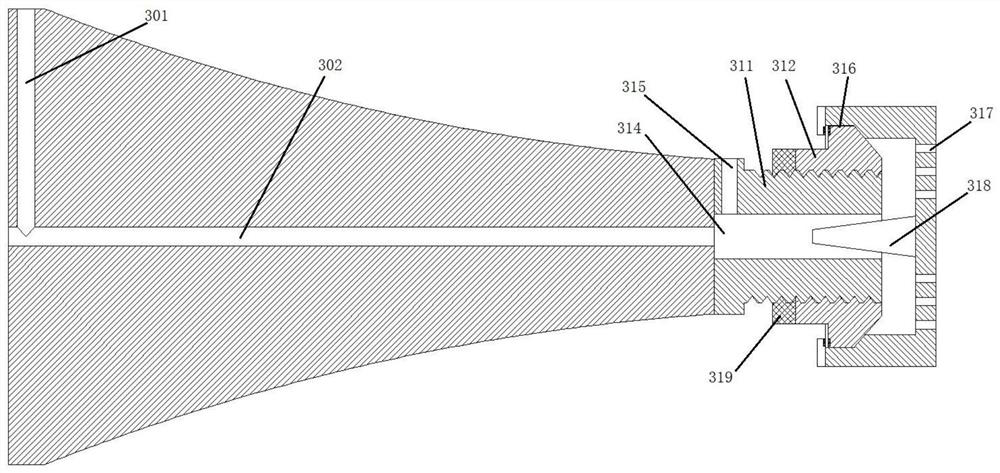

Spiral-flow type supersonic speed electric arc spraying gun

InactiveCN102974486AGood effectImprove stabilityMolten spray coatingElectric arc sprayingSpray coatingSpray nozzle

The invention discloses a spiral-flow type supersonic speed electric arc spraying gun, which comprises a gun body, wherein a contact tip is connected onto a conducting wire; airflow holes are uniformly distributed on a radial airflow channel arranged in the gun body; a spiral-flow ring is connected with the gun body through screw threads; spiral-flow holes are uniformly distributed on the periphery of the spiral-flow ring; an air gathering hood is fixed with the spiral-flow ring through screw threads; a ceramic nozzle is pressed in the spiral-flow ring through the air gathering hood; and an inner cavity of the ceramic nozzle and an inner cavity of the air gathering hood are combined to form a Laval nozzle. According to the technical scheme, spiral-flow atomization and supersonic speed atomization are combined, the effect and the stability of jet flow atomization are enhanced through a spiral-flow structure and a Laval spray pipe, secondary acceleration of jet flow is realized, and the speed of jet flow is further improved, so that the spray coating particle hole atomization effect is stronger, nanometer refinement is achieved, flying speed achieves supersonic speed, and the prepared coating layer is obviously improved. The spiral-flow type supersonic speed electric arc spraying gun is not only suitable for coating equipment for precision parts, but also suitable for large-area coating preparation.

Owner:新乡市布瑞林特机械再制造有限责任公司

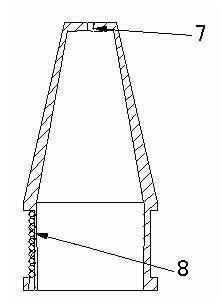

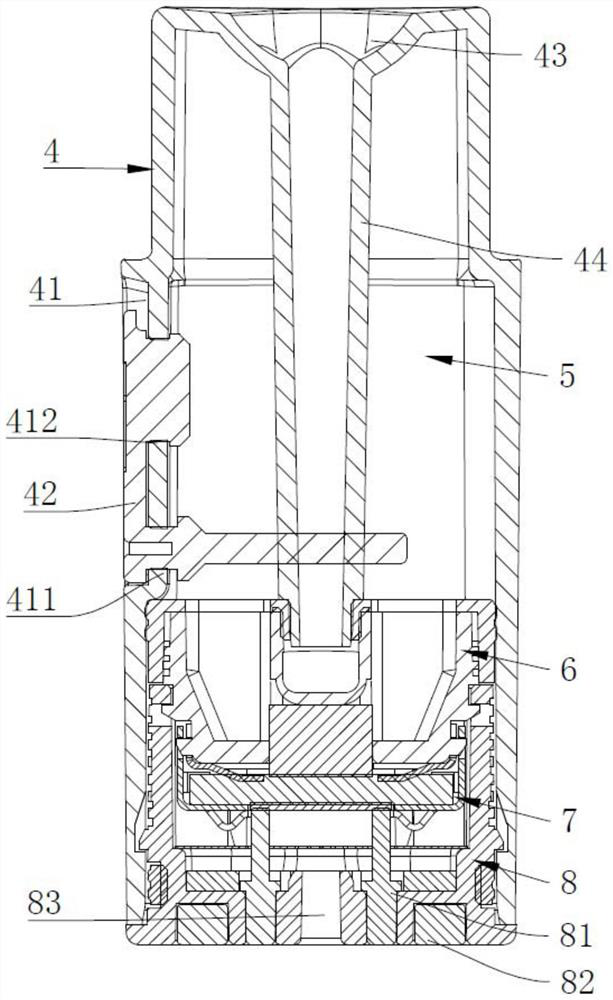

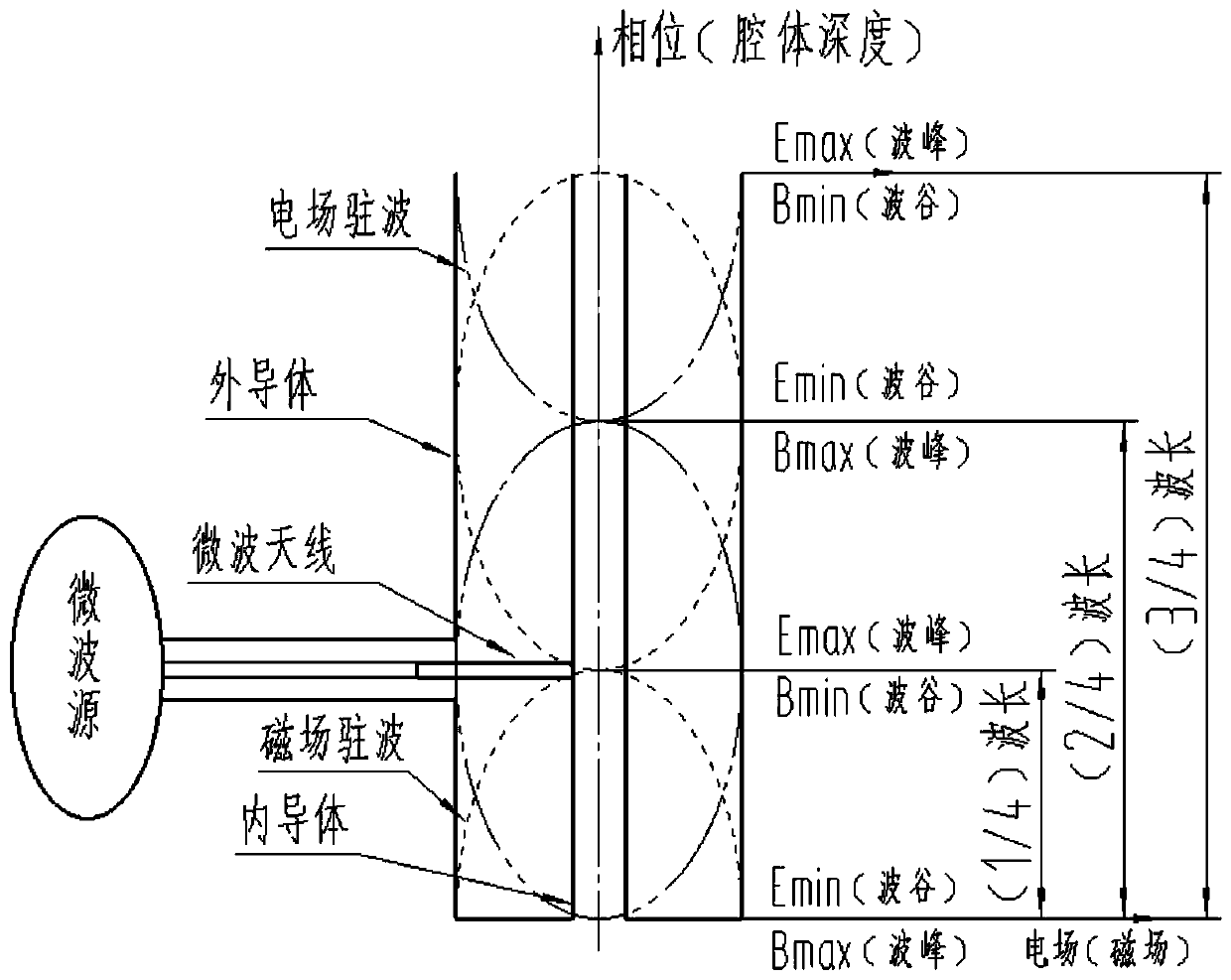

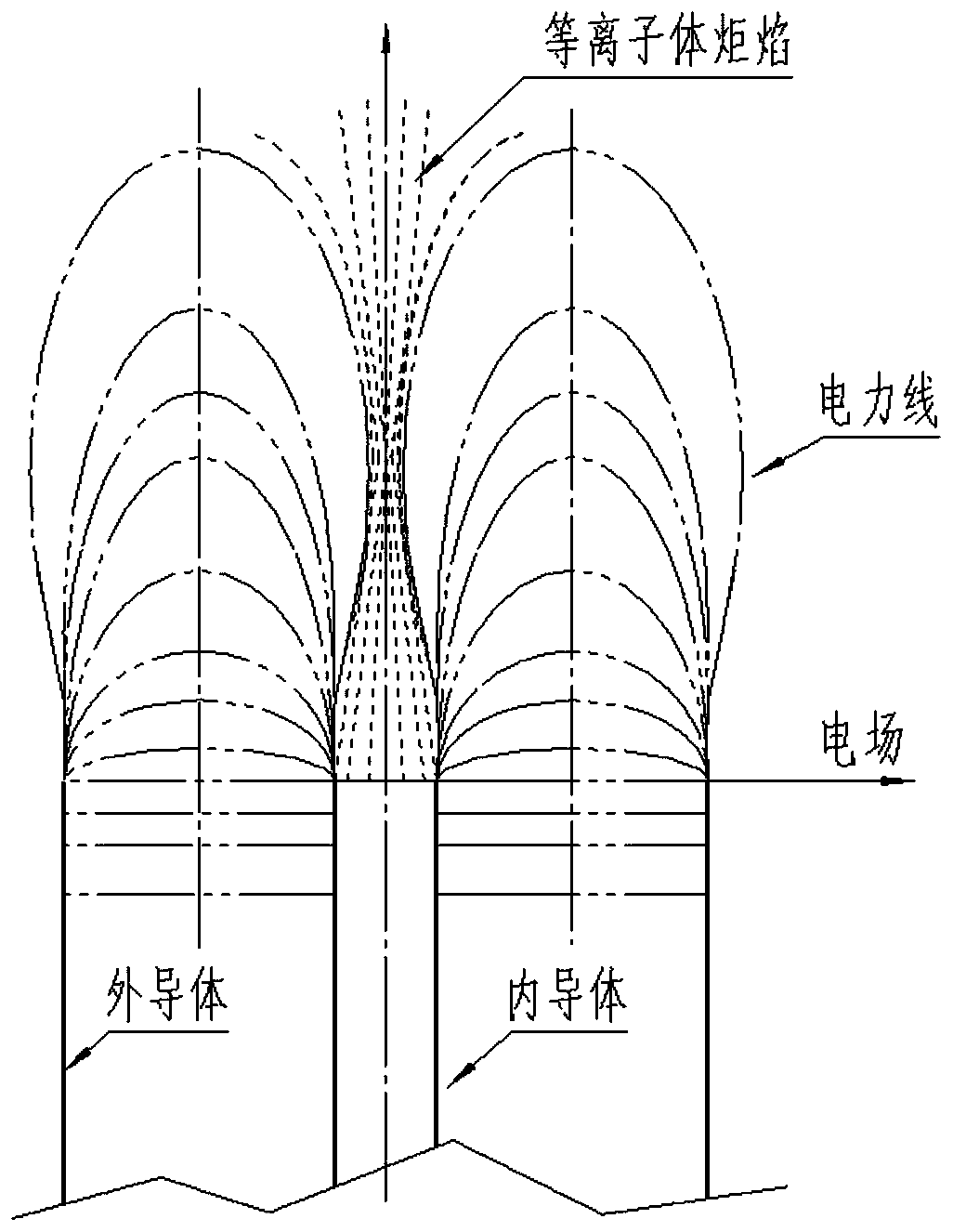

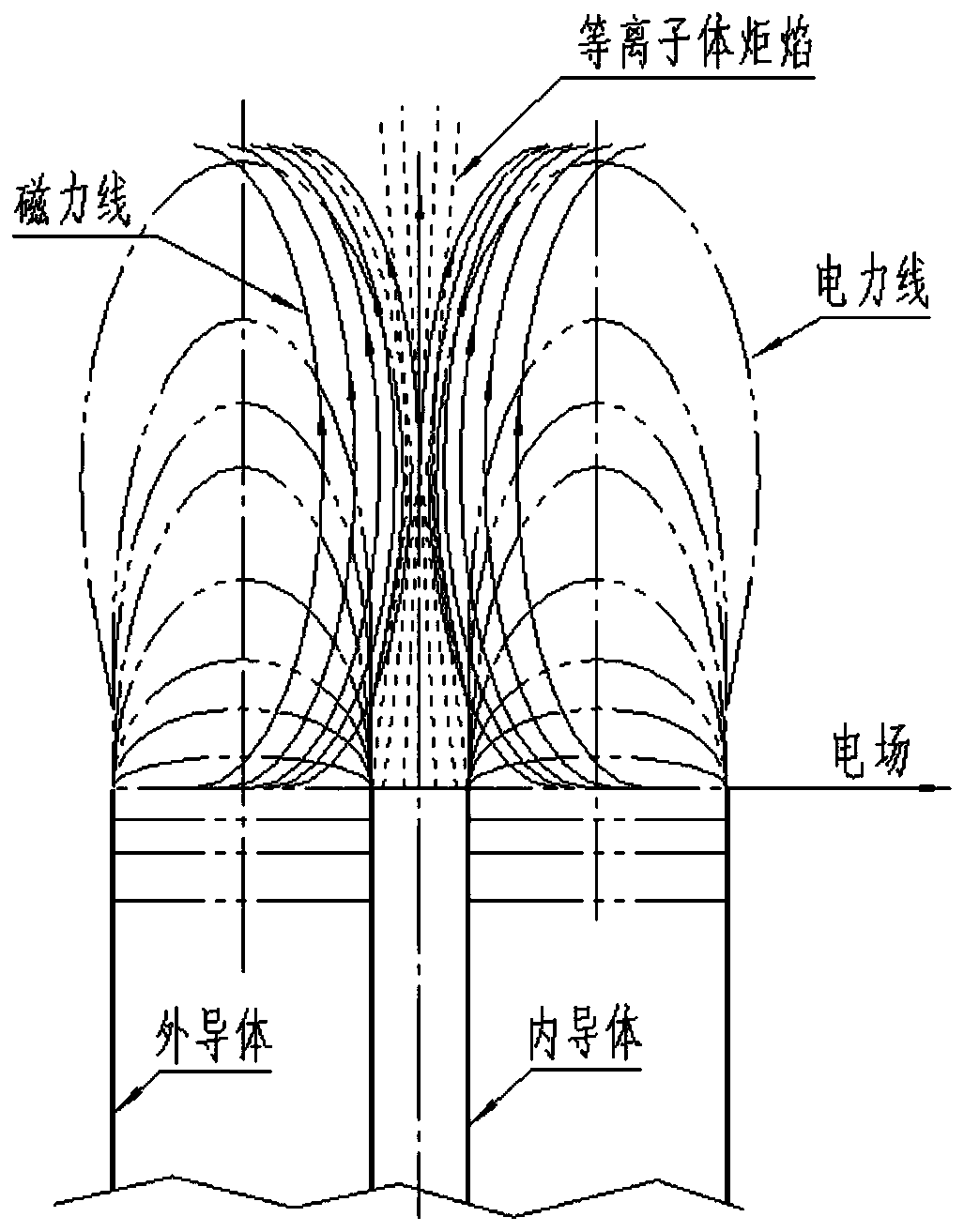

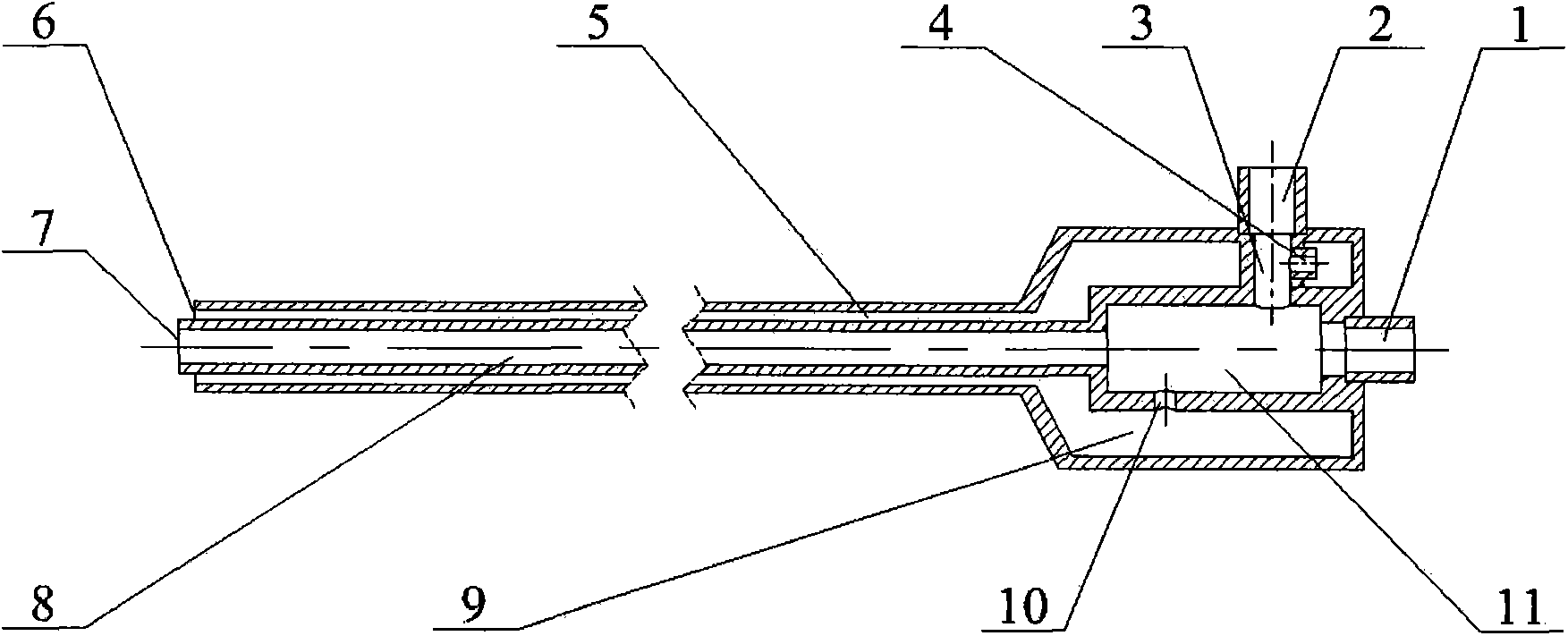

Microwave coupled plasma generating device with electromagnetic energy dual-excitation function

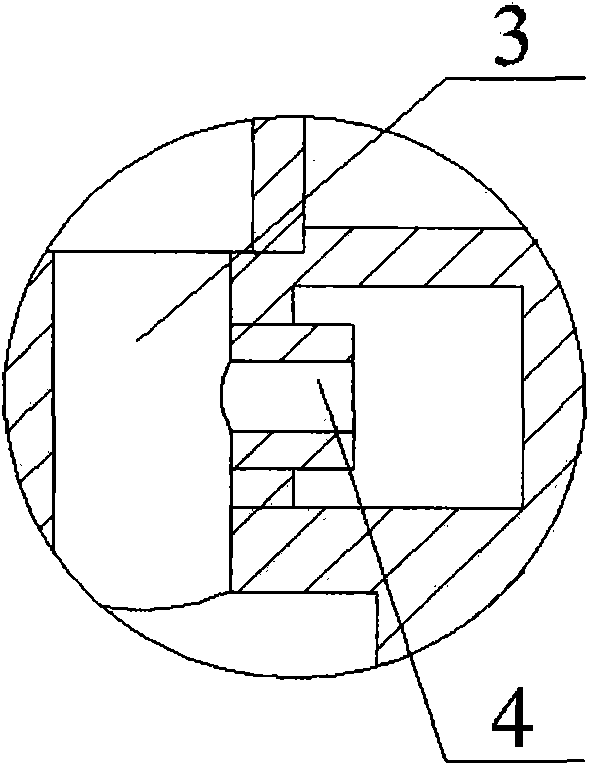

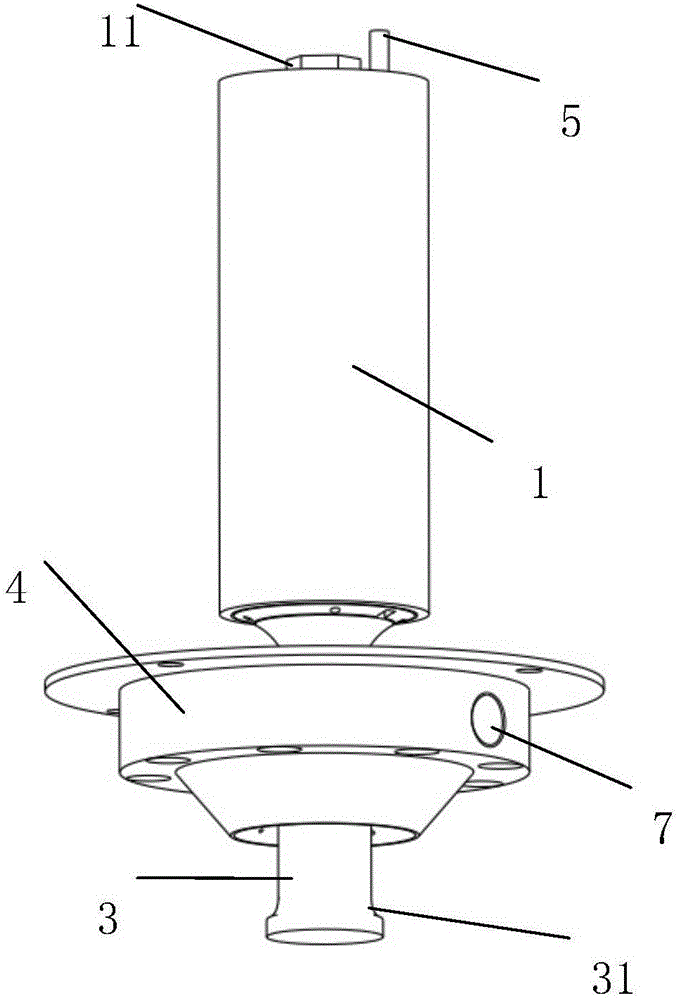

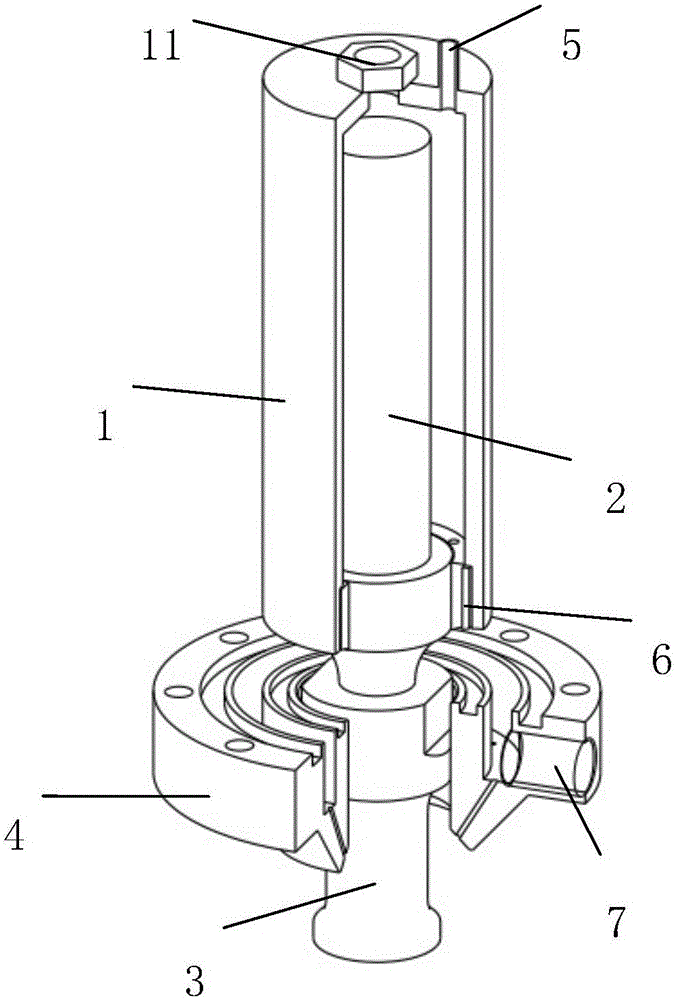

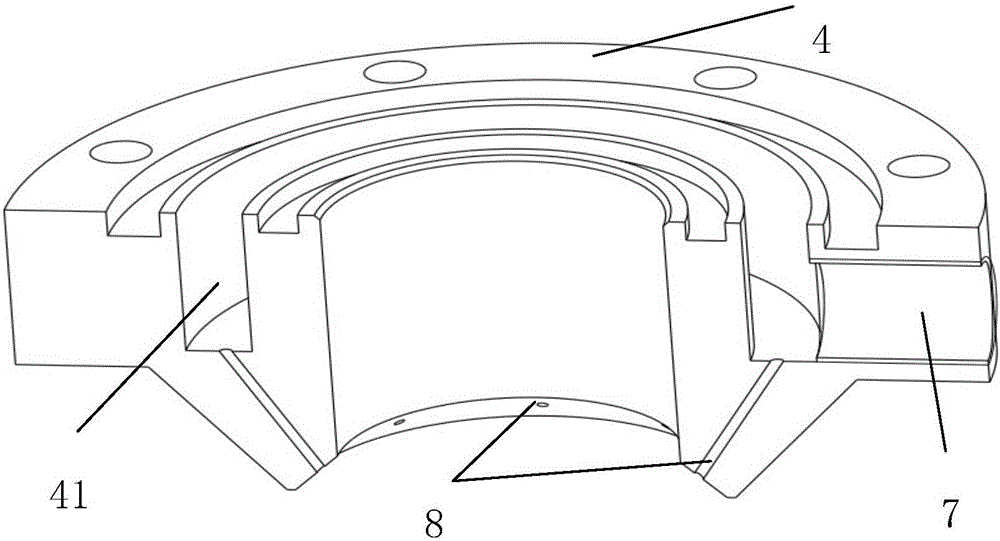

The invention discloses a microwave coupled plasma generating device with an electromagnetic energy dual excitation function, and belongs to the technical field of microwave energy application. The microwave coupled plasma generating device is composed of a microwave coaxial resonant cavity part and a magnetic field generating part, wherein the microwave coaxial resonant cavity part comprises an outer conductor (1), a microwave antenna (2), an inner conductor (3), a middle tube (4), an inner tube (5), a sample tube (6) and an impedance matching cylinder (7), and the magnetic field generating part consists of an excitation lower part (8), an excitation middle part (9) and an excitation upper part (10). Compared with the prior art, the device of the invention has the advantages of improvingthe electron density of the plasma, improving the utilization efficiency of microwave energy, improving the atomization capacity of the plasma and the like.

Owner:JILIN UNIV

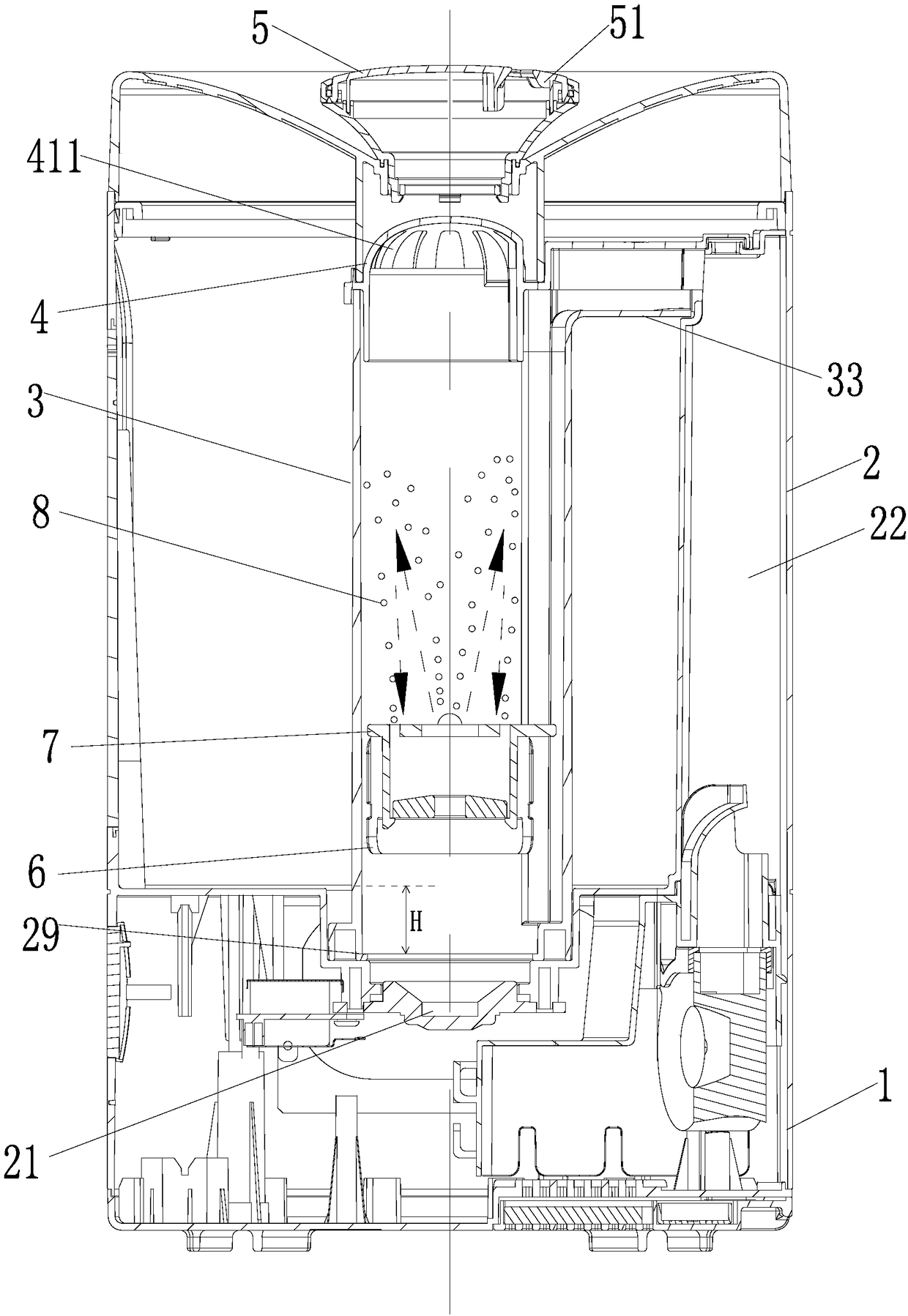

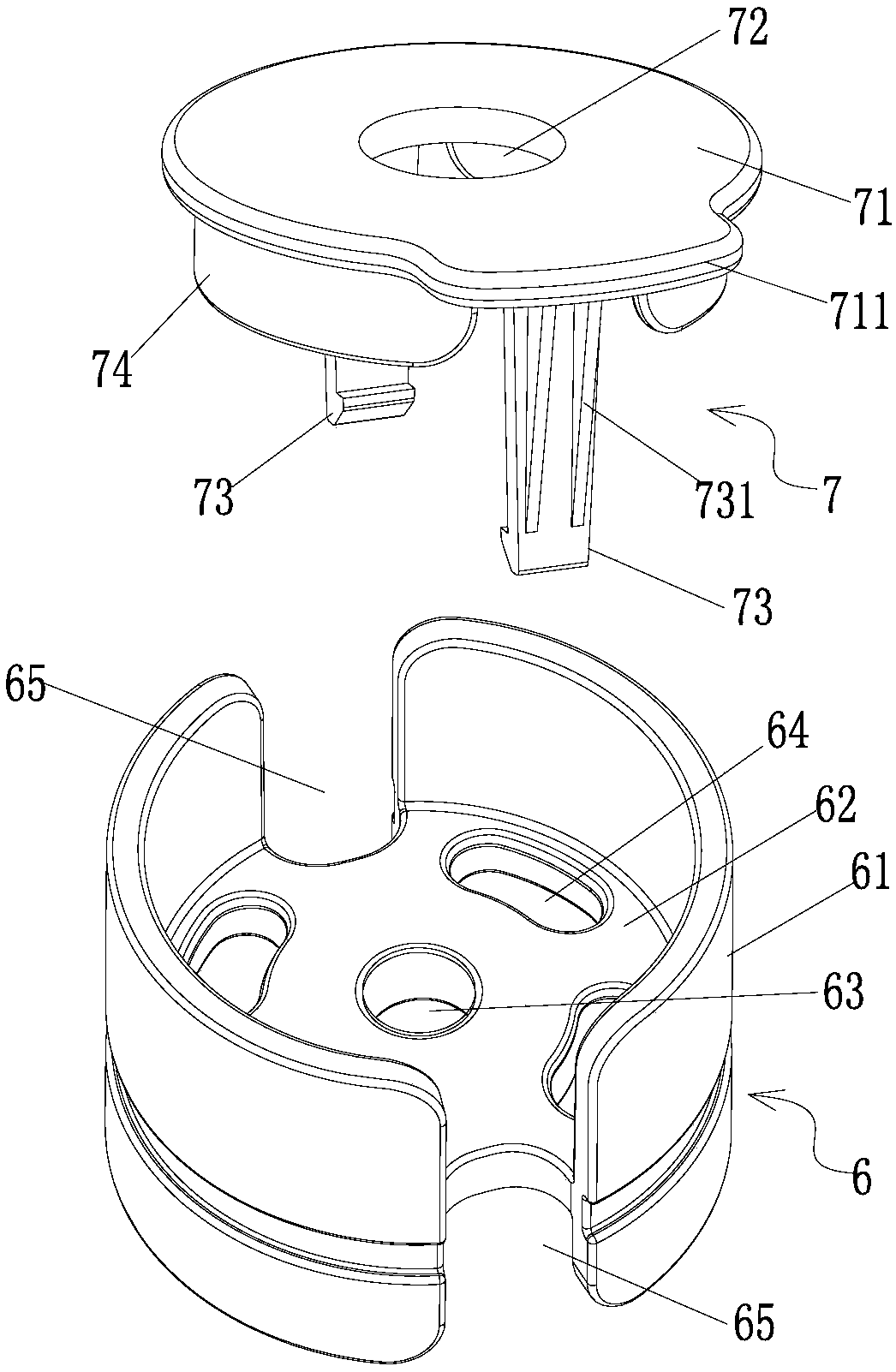

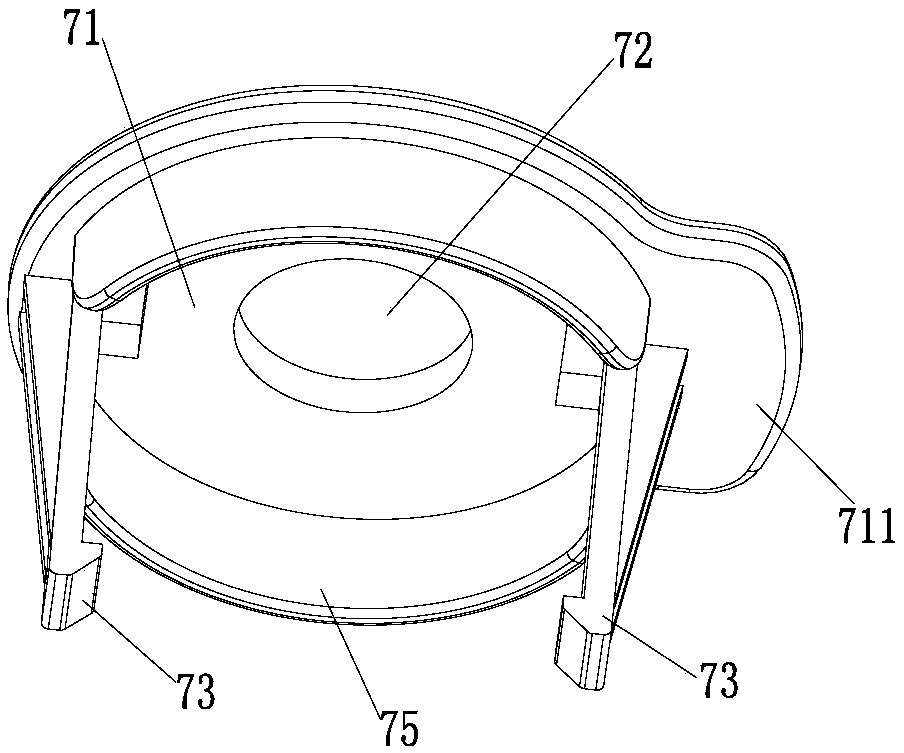

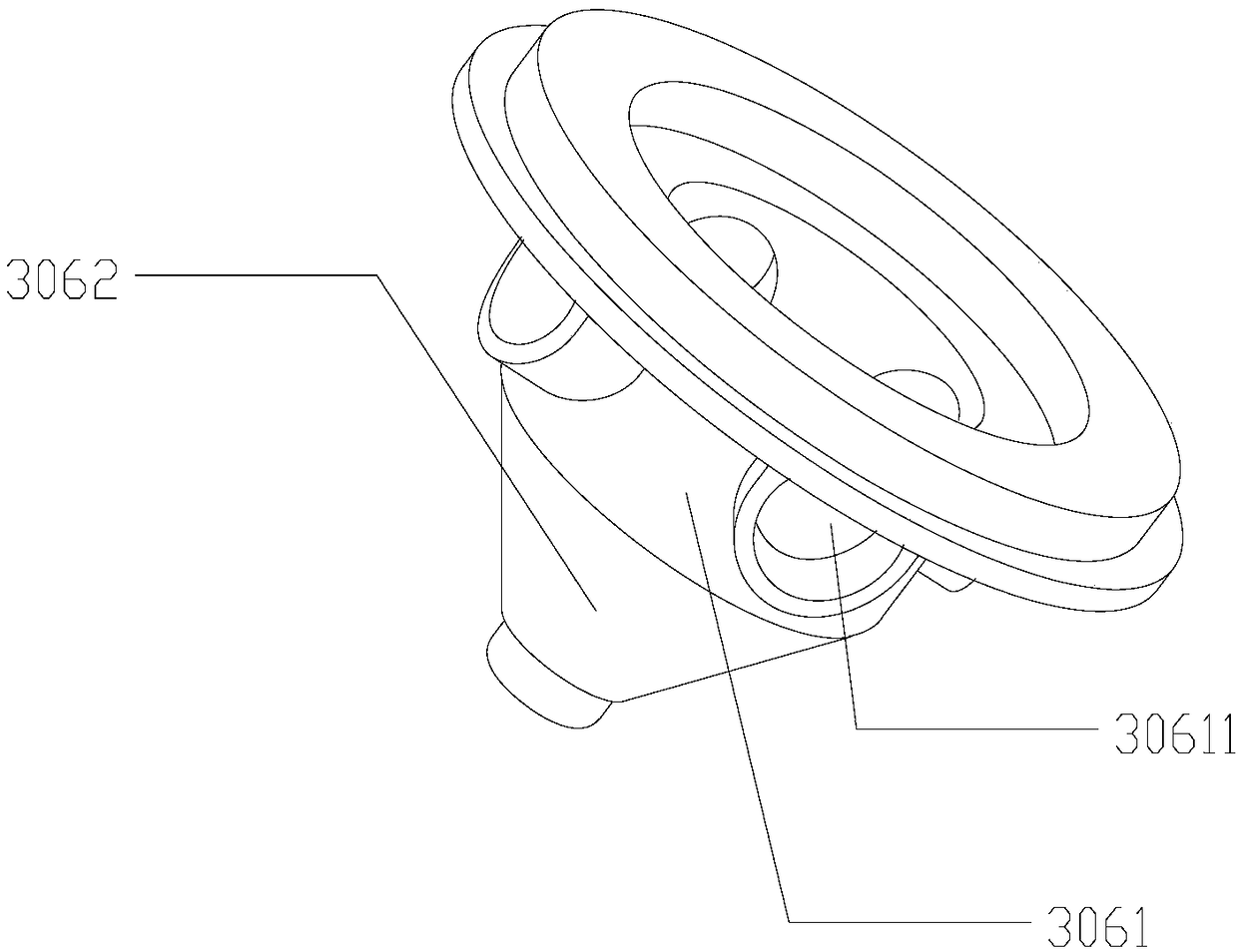

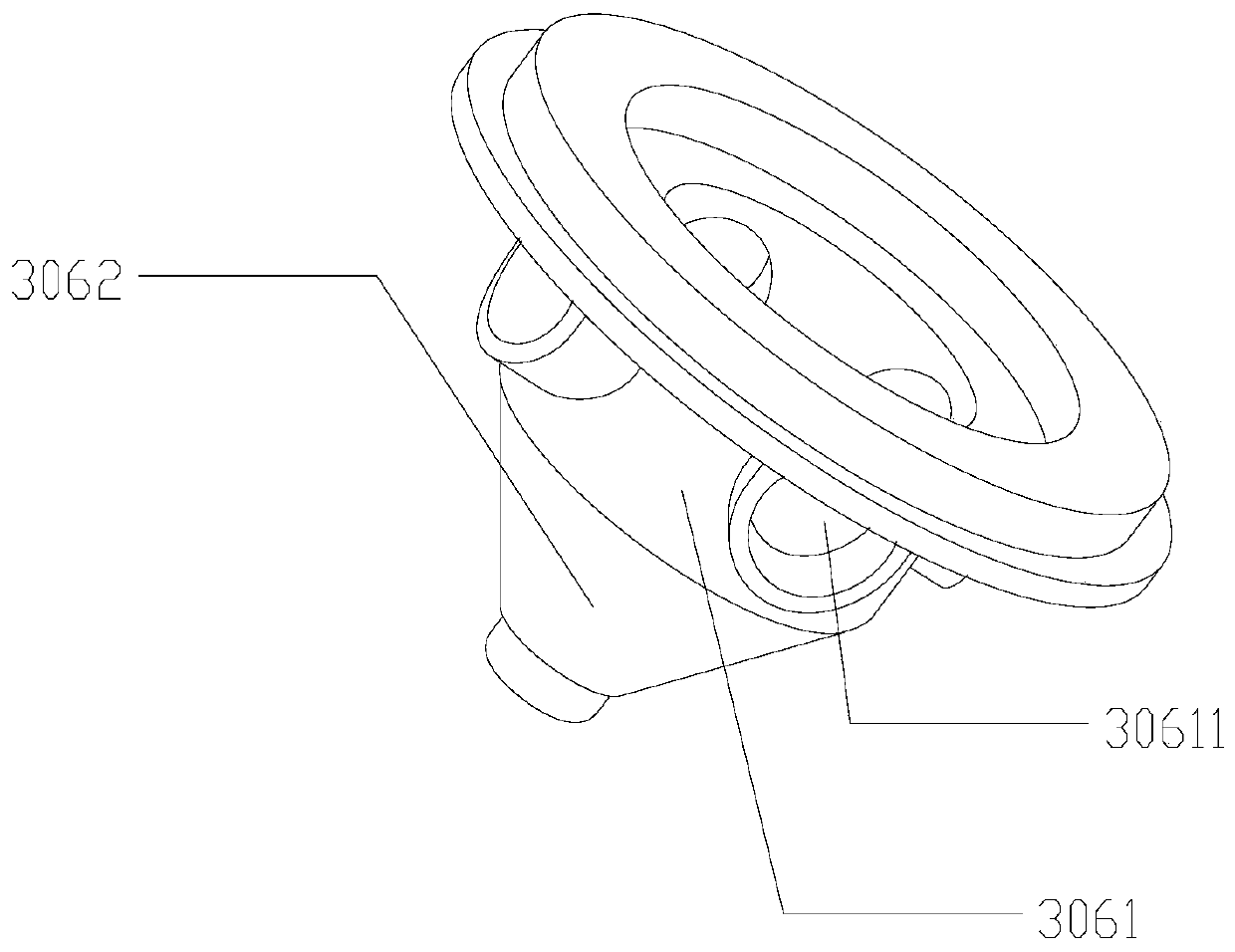

Humidifier and energy gathering device of humidifier

PendingCN109186056AReduce noiseImprove atomization abilityLighting and heating apparatusSpace heating and ventilation detailsTransducerEngineering

The invention discloses a humidifier and an energy gathering device of the humidifier. The energy gathering device comprises an energy gathering cylinder (61) which is located right above a transducer(21) and longitudinally arranged, a partition plate (62) which is transversely arranged in the energy gathering cylinder (61), an energy gathering through hole (63) which is formed in the center position of the partition plate (62), a top cover (71) which is arranged on the upper end surface of the energy gathering cylinder (61) and a mist outlet hole (72) which is formed in the center position of the top cover (71), the size of the hole diameter of the mist outlet hole (72) is larger than the size of the hole diameter of the energy gathering through hole (63). According to the humidifier andthe energy gathering device of the humidifier, the structure is simple, the atomization efficiency is high, moreover, the atomization noise is relatively small, the use is simple, and follow-up cleaning and maintenance are facilitated.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

Atomization device and electronic atomizer

PendingCN114680385AStructural connection is stableImprove atomization effectTobaccoEngineeringPhysics

The invention relates to the technical field of electronic atomizers, in particular to an atomization device and an electronic atomizer, the atomization device comprises an oil guide fixing base, a first fixing elastic piece, a second fixing elastic piece and an atomization piece, and fixing buckles are arranged on the two sides of the oil guide fixing base; the first fixing elastic piece is provided with a first fixing clamping groove, the first fixing clamping groove is clamped to the fixing buckle, the first fixing elastic piece is provided with a first fixing cavity, and the first fixing cavity is provided with oil storage cotton; the second fixing elastic pieces are provided with second fixing clamping grooves, the second fixing clamping grooves are clamped to the fixing buckles and attached to the first fixing clamping grooves, second fixing cavities are formed between the second fixing elastic pieces, the second fixing cavities are provided with oil guiding cotton, the oil guiding cotton is attached to the oil storage cotton, and the second fixing elastic pieces are located on the lower sides of the oil guiding cotton and provided with mounting brackets. The atomizing sheet is arranged on the mounting bracket and is attached to the oil guide cotton; the structure is stable in connection, the wafer heating body acts on the atomization piece, and the service life is long.

Owner:东莞市克莱鹏雾化科技有限公司

Flotation equipment with pulp self-driving and self-absorbing functions

The invention relates to the field of pulp-mixing and flotation treatment of coal slime, in particular to flotation equipment with pulp self-drive and self-suction functions. The flotation equipment comprises a flotation tank, a flow distribution assembly for achieving a jet flow mixing function, a high-pressure jet assembly for achieving a turbulent flow mixing function and a lower stirring assembly for achieving a stirring and mixing function. The flotation equipment integrates pulp mixing and flotation and has the beneficial effects of being low in energy consumption, low in maintenance capacity, good in self-suction and sorting effects and capable of reducing the equipment input in the early stage of a coal preparation plant while the efficient flotation requirement of pulp is achieved efficiently and controllably and thus effectively lowering the actual production cost of the coal preparation plant.

Owner:ANHUI UNIV OF SCI & TECH

A surface acoustic wave electronic cigarette system

ActiveCN108030153BImprove particle size uniformitySmall particle sizeMaterial analysis using sonic/ultrasonic/infrasonic wavesTobacco treatmentElectricityEngineering

Owner:CHINA TOBACCO YUNNAN IND

Dry fog atomizer and atomizing agent bottle

ActiveCN108176526AImprove atomization abilityReduce wind resistanceSpray nozzlesLiquid spraying apparatusEngineeringBottle

The invention provides a dry fog atomizer and an atomizing agent bottle. The dry fog atomizer comprises a base, a fan arranged on the base and a Venturi tube arranged at an air outlet of the fan, wherein the Venturi tube comprises a first air outlet nozzle and a second air outlet nozzle; the first air outlet nozzle is connected with the fan; one end of the second air outlet nozzle is provided witha spraying opening used for spraying fog-type materials, and the other end is connected with the first air outlet nozzle; a sprayer is arranged at the spraying opening of the second air outlet nozzleand comprises a ventilation post and an air assistant device; one end of the ventilation post is arranged close to the spraying opening, and the other end is connected with the air assistant device;the ventilation post is a cylindrical hollow pipe; multiple through holes are formed in a side surface of the ventilation post; and a cross section of one end, which is connected to the ventilation post, of the air assistant device is larger than that of one end, which is far away from the ventilation post, of the air assistant device.

Owner:黄宇

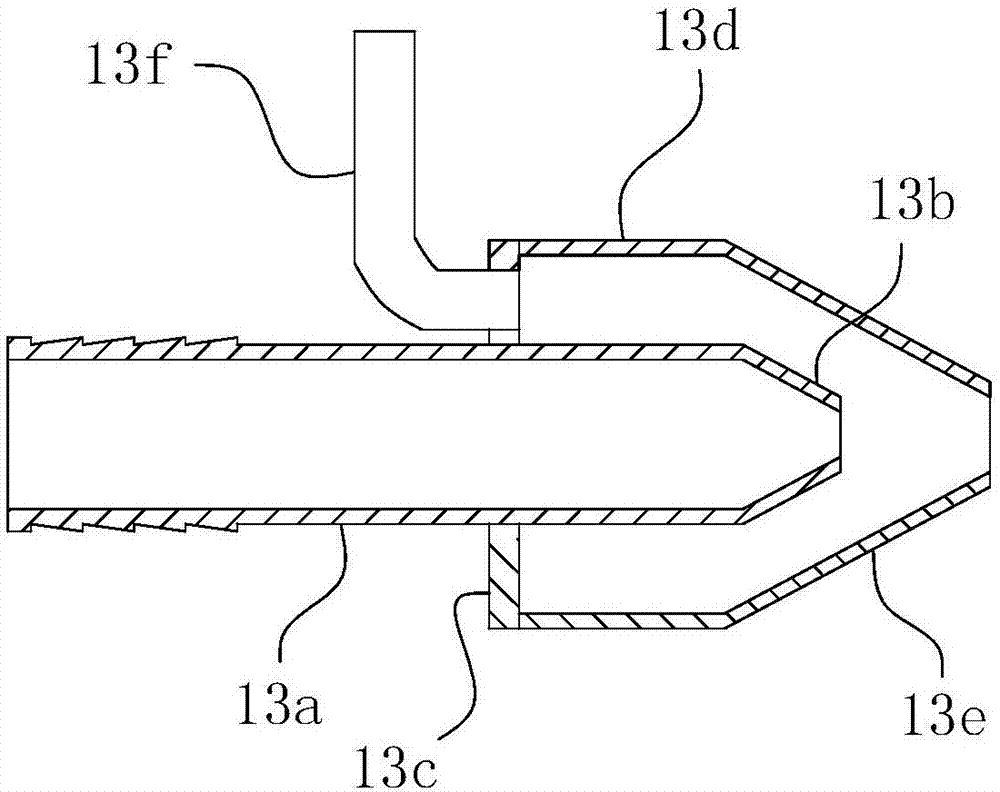

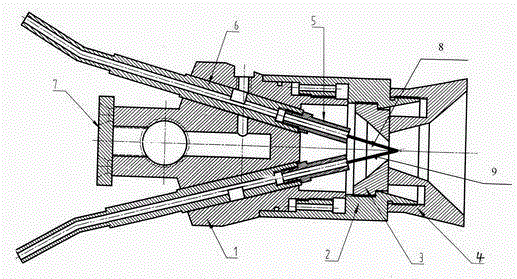

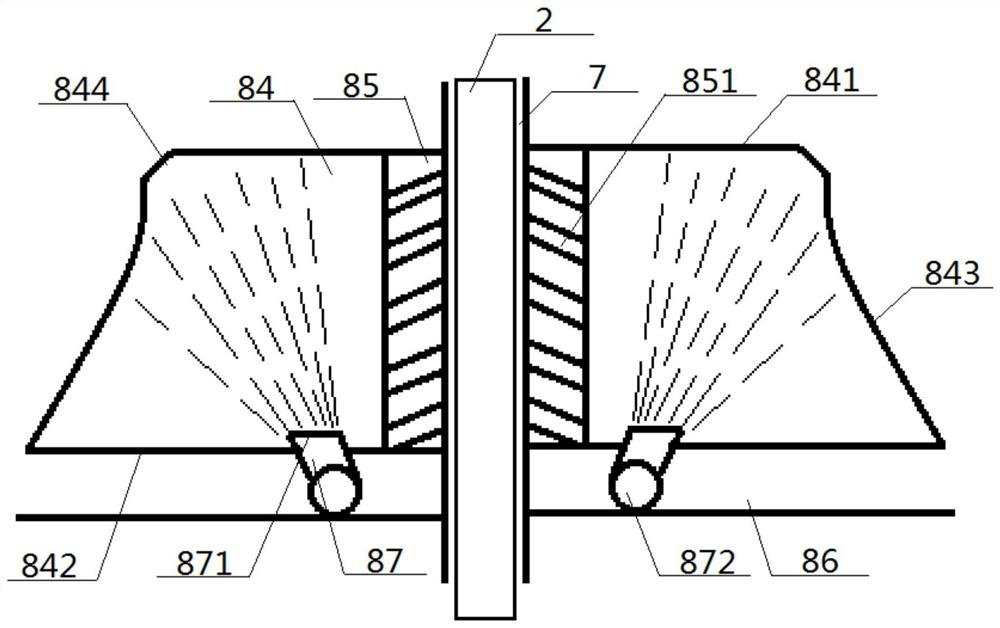

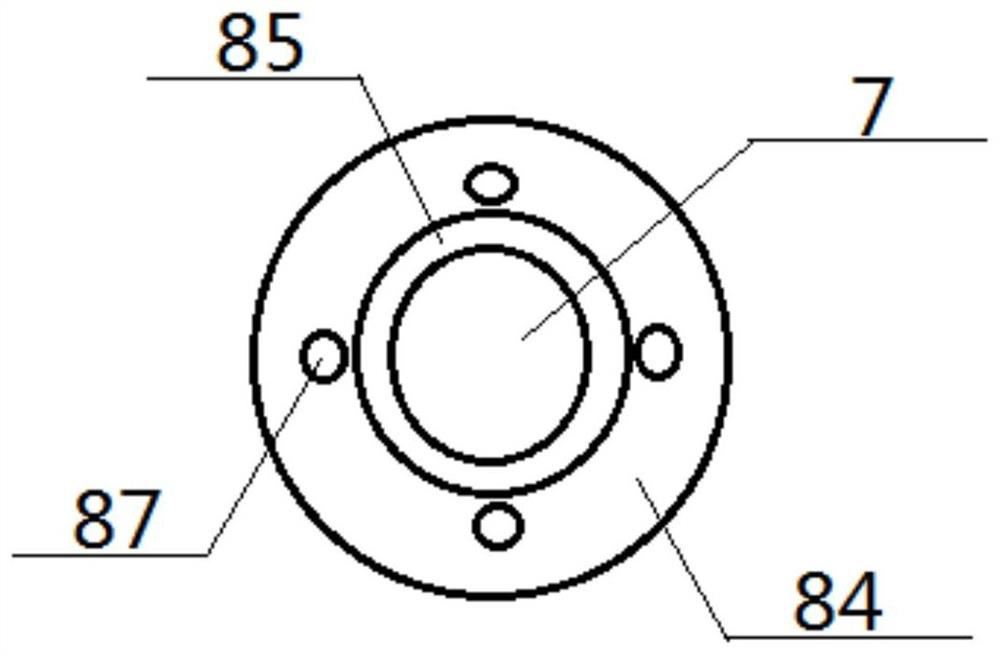

SNCR flue gas denitration spray gun and double-cavity mixing double-layer injection technology thereof

InactiveCN103506234AAvoid interactionStrong penetrating powerDispersed particle separationLiquid spraying apparatusFlue gasEngineering

Provided are an SNCR flue gas denitration spray gun and a double-cavity mixing double-layer injection technology thereof. The spray gun is composed of a central injection pipe, an outer-layer annular injection pipe, a central mixing cavity and an outer-layer mixing cavity. The spray gun is characterized in that the injection technology includes the steps that a reducing agent entering from a reducing agent conveying pipe section and compressed gas entering from a compressed gas conveying pipe section are mixed in a first mixing cavity, and most gas-liquid mixture enters the central injection pipe and is sprayed in flue gas to be treated through a central injection opening; a part of the gas-liquid mixture in the first mixing cavity enters a second mixing cavity through a one-way communicating pipe, a part of compressed air entering from the compressed air conveying pipe section does not pass through the first mixing cavity and enters the second mixing cavity directly through a communicating pipe, and a gas-liquid mixture in the second mixing cavity is sprayed in the flue gas to be treated through the outer-layer annular injection pipe. The SNCR flue gas denitration spray gun and the double-cavity mixing double-layer injection technology of the SNCR flue gas denitration spray gun have the advantages that two gas-liquid mixtures containing the reducing agent and the compressed air can be obtained by the adoption of double-cavity mixing so as to complete different spraying effects, and double layers of sleeves can prevent the two gas-liquid mixtures from influencing mutually.

Owner:CECEP L&T ENVIRONMENTAL TECH

Ultrasonic atomization device used for suspension liquid

ActiveCN106583139AImprove atomization abilityImprove atomization efficiencyLiquid spraying apparatusEngineeringUltrasound

The invention discloses an ultrasonic atomization device used for suspension liquid. The ultrasonic atomization device comprises a transducer shell, a transducer, an atomization tool head, a liquid spraying ring, an air inlet hole, an air outlet hole, a liquid inlet and liquid outlet holes. The transducer shell wraps the transducer. The transducer is connected with an ultrasonic power supply through a wire interface located on the top of the transducer shell. The atomization tool head is connected with the transducer. The transducer is connected with the liquid spraying ring in a clamping and buckling mode. The air outlet hole is formed in the bottom of the transducer shell. A gap between the transducer shell and the transducer is filled with heat conducting glue. The air inlet hole is formed in the upper portion of the transducer shell. Compressed air enters the interior of the transducer shell through the air inlet hole, and flows rapidly in the transducer shell cavity. According to the ultrasonic atomization device, the atomization ability and atomization efficiency of the ultrasonic atomization device are improved, the atomization of the suspension liquid and a solution is achieved, in addition, the device is not limited by liquid storage and the liquid level and can work continuously, and the ultrasonic atomization device has wide application prospects in the field of thermal power plant flue gas desulfurization and denitration systems.

Owner:杭州瑞利声电技术有限公司

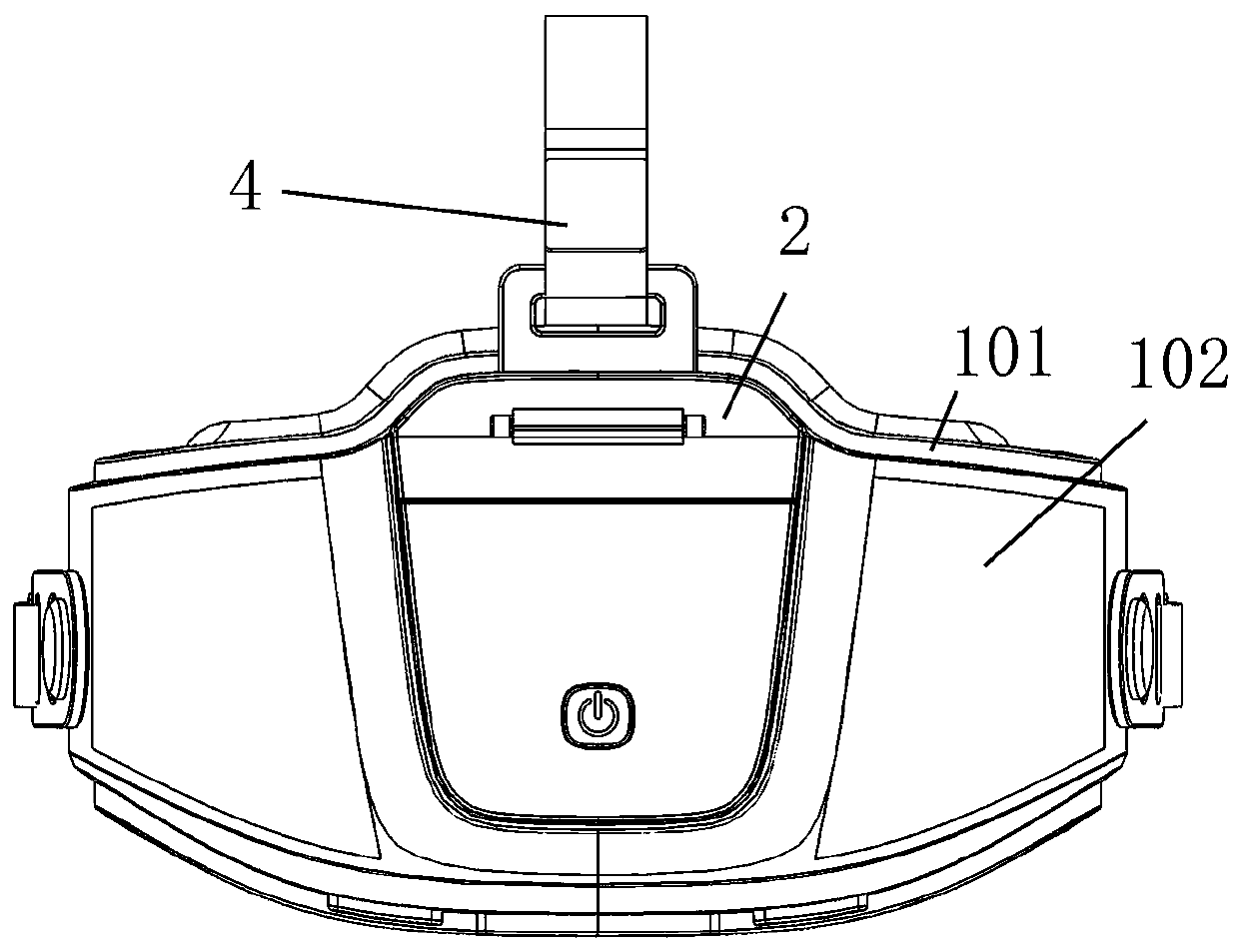

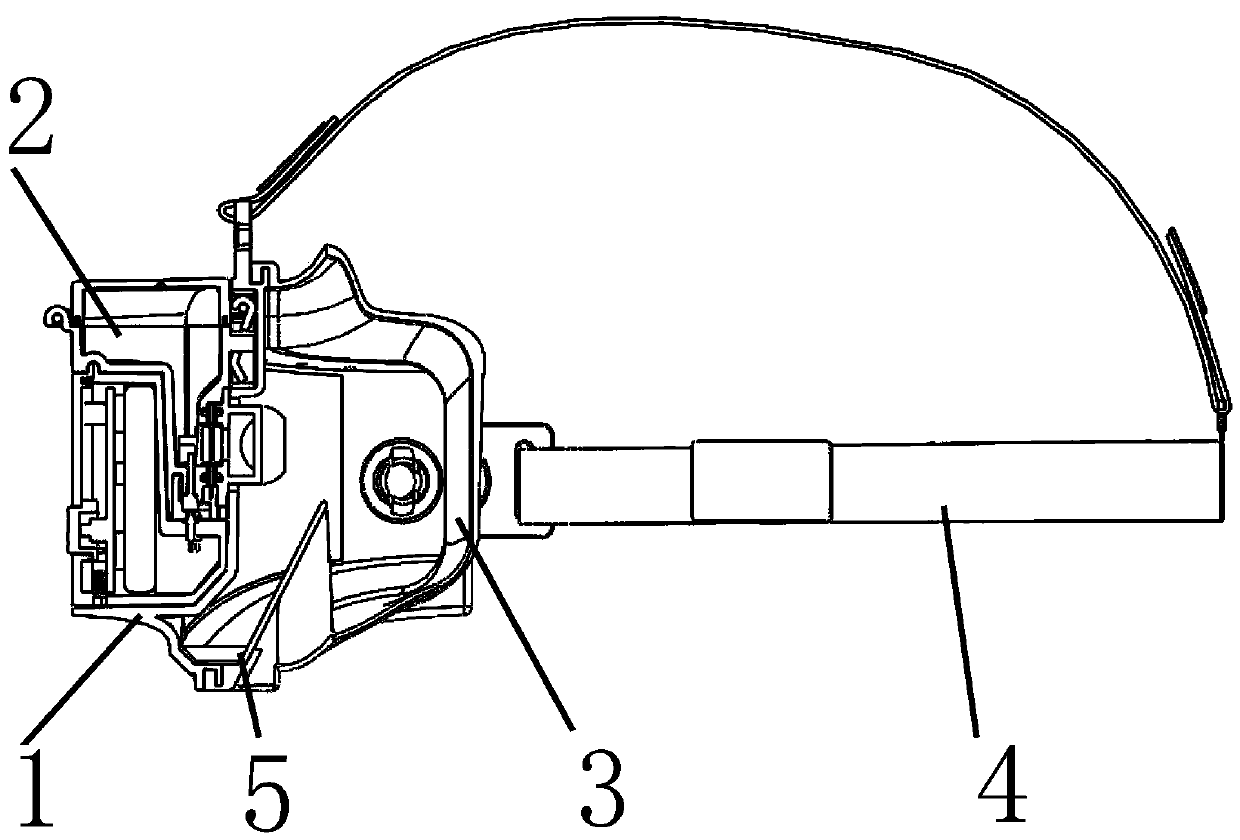

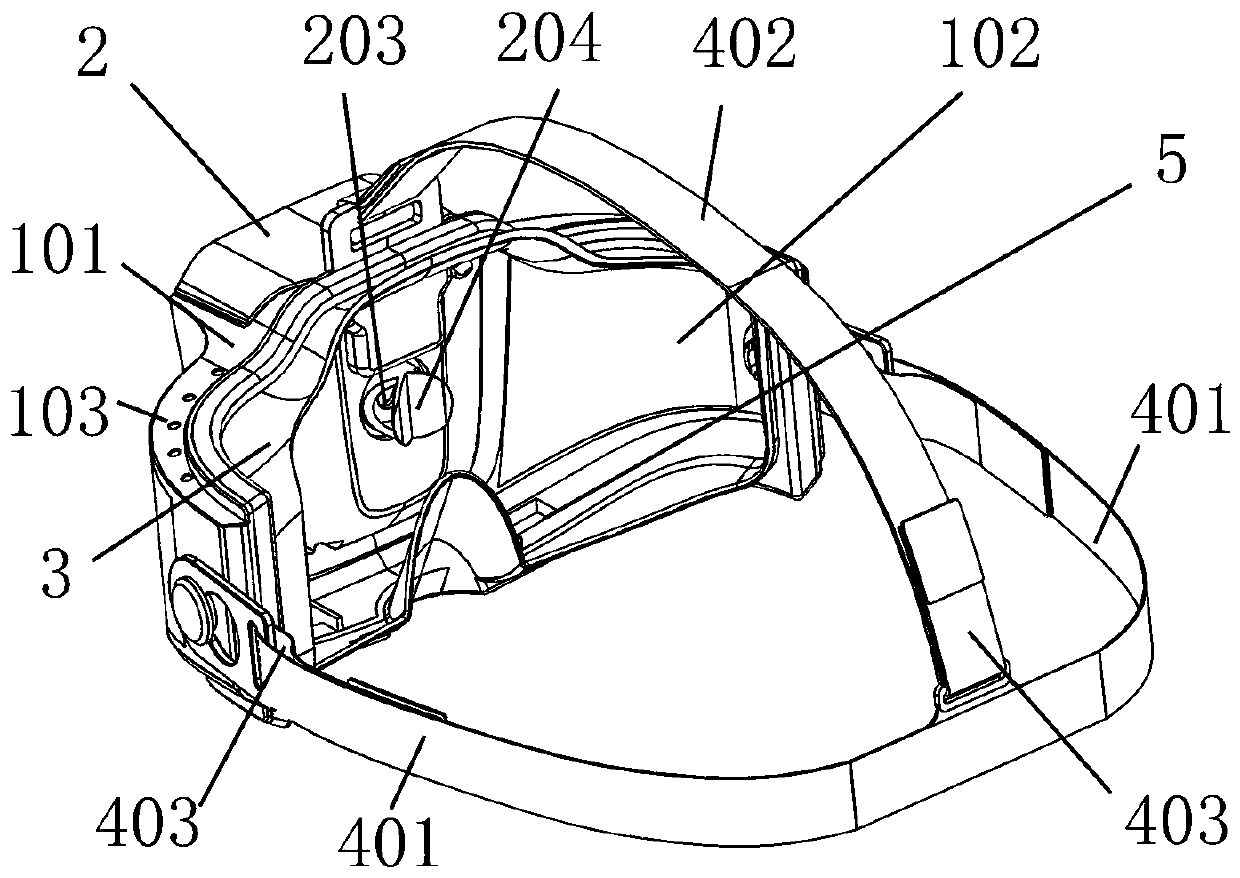

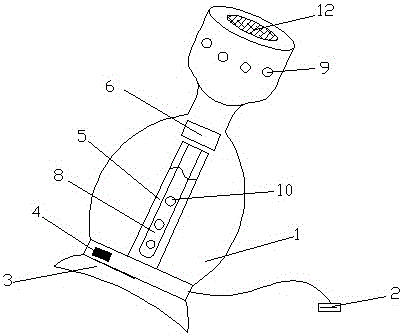

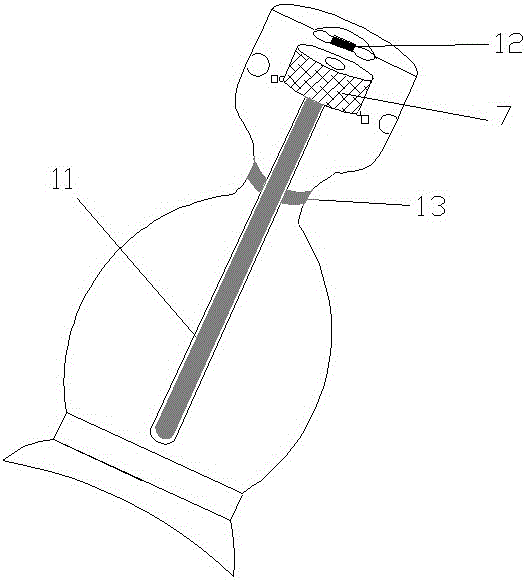

Ultrasonic atomization eye protector

PendingCN111012984AImprove atomization abilityGood careMedical devicesMedical applicatorsEye FatigueEngineering

The invention discloses an ultrasonic atomization eye protector, relates to an eye care instrument, and concretely relates to an instrument for protecting eyes by using ultrasonic waves to atomize a care solution to act on eyes. The ultrasonic atomization eye protector has the effects of relieving eye fatigue and assisting in treatment of ophthalmic diseases. The ultrasonic atomization eye protector comprises a frame, an ultrasonic atomizer, a sealing ring, a condensate storage device and a fixing device, the ultrasonic atomizer is installed on the frame, the sealing ring is installed on the periphery, making contact with the human face, of the frame, air holes are reserved, the condensate storage device is mounted at the lower portion of the frame, the fixing device for the head is arranged on the frame, and the whole frame is fixed to the head of a person. Single-channel output or double-channel output is adopted to make the care solution sprayed to the left eye and the right eye through a left ultrasonic transducer and a right ultrasonic transducer respectively after being sprayed, and the double-channel output has a higher atomization capability and a better care effect than the single-channel output.

Owner:朱丹

Dry mist nebulizer and nebulizer bottle

ActiveCN108176526BImprove atomization abilityReduce wind resistanceSpray nozzlesLiquid spraying apparatusAerosolizeEngineering

The invention provides a dry fog atomizer and an atomizing agent bottle. The dry fog atomizer comprises a base, a fan arranged on the base and a Venturi tube arranged at an air outlet of the fan, wherein the Venturi tube comprises a first air outlet nozzle and a second air outlet nozzle; the first air outlet nozzle is connected with the fan; one end of the second air outlet nozzle is provided witha spraying opening used for spraying fog-type materials, and the other end is connected with the first air outlet nozzle; a sprayer is arranged at the spraying opening of the second air outlet nozzleand comprises a ventilation post and an air assistant device; one end of the ventilation post is arranged close to the spraying opening, and the other end is connected with the air assistant device;the ventilation post is a cylindrical hollow pipe; multiple through holes are formed in a side surface of the ventilation post; and a cross section of one end, which is connected to the ventilation post, of the air assistant device is larger than that of one end, which is far away from the ventilation post, of the air assistant device.

Owner:黄宇

Multifunctional trolley for construction site

PendingCN112538835AAdd air purification functionImprove atomization abilityDispersed particle filtrationRoad cleaningStructural engineeringMechanical engineering

The invention discloses a multifunctional trolley for the construction site. The trolley comprises a movable trolley body, a warning indicator, an atomizer and a dust remover, wherein the warning indicator, the atomizer and the dust remover are all arranged on the movable trolley body and move along with the movable trolley body, the atomizer is connected with the dust remover, the atomizer is obliquely arranged, the atomizer is used for improving air humidity, and the dust remover is used for filtering dust in air; the warning indicator is used for warning the position of the multifunctionaltrolley for the construction site; the dust remover comprises a filtering box body, the filtering box body is connected with the end of the atomizer through a connecting pipe, a suction cylinder is arranged on the side, away from the atomizer, of the filtering box body, and a fan is arranged in the atomizer. According to the multifunctional trolley for the construction site, wind energy is provided through the draught fan, air enters the filtering box body from the suction cylinder to be filtered and then enters the atomizer through the connecting pipe to be secondarily filtered, and thereforethe air purification function of the multifunctional trolley for the construction site is enhanced.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

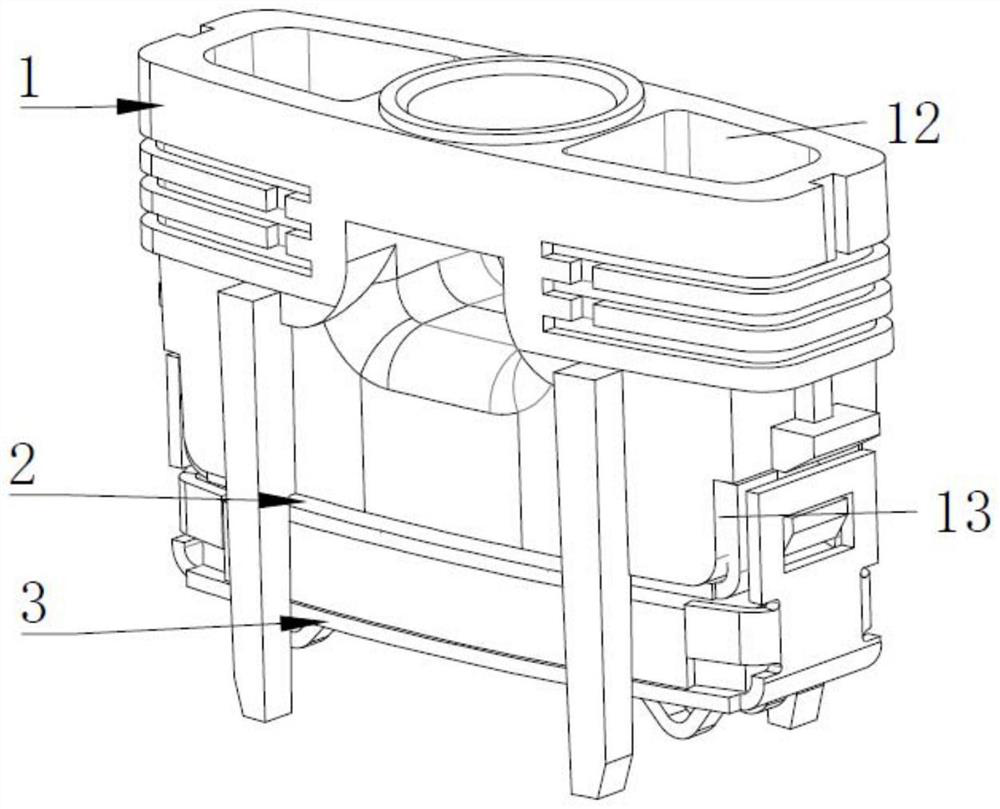

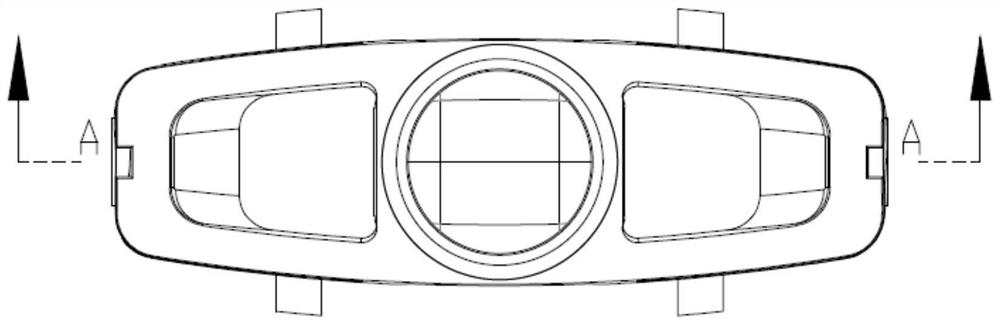

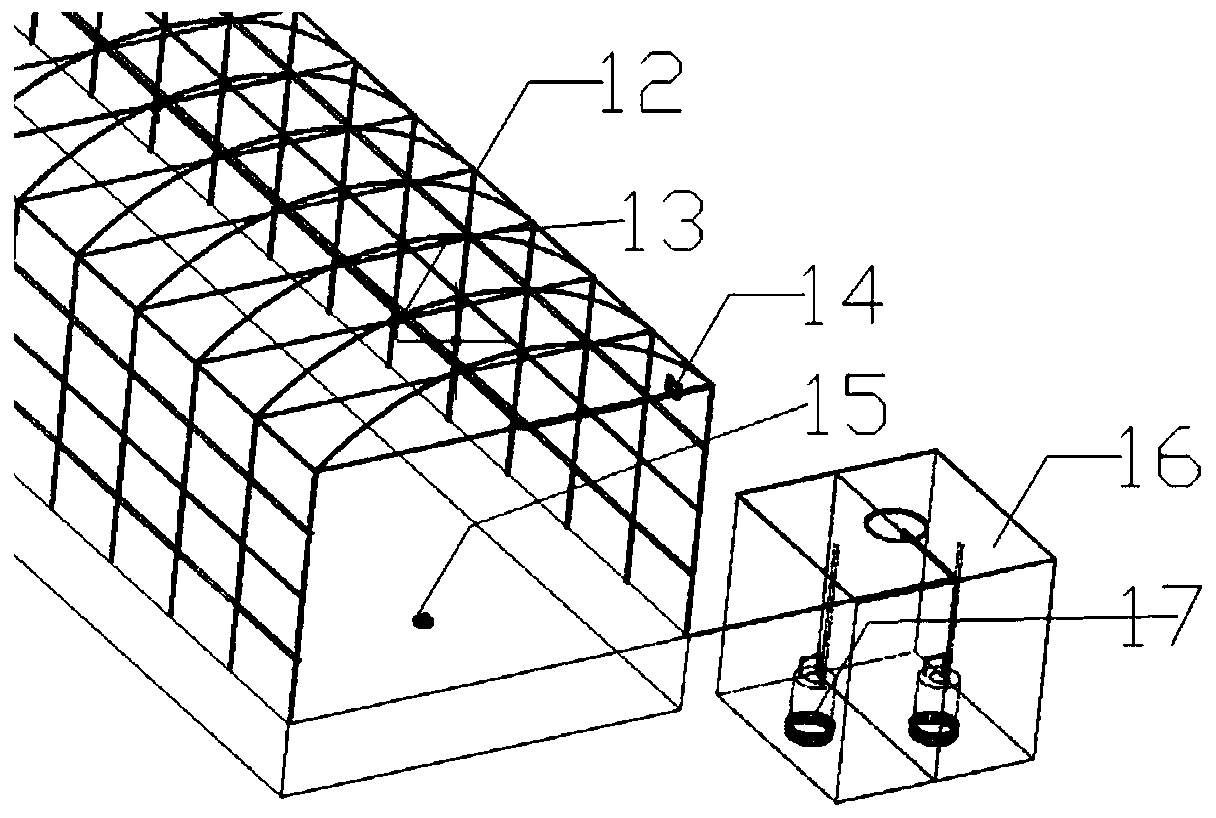

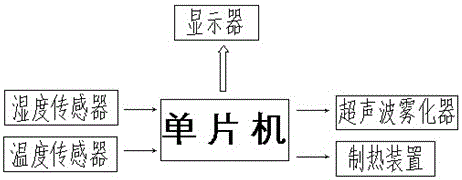

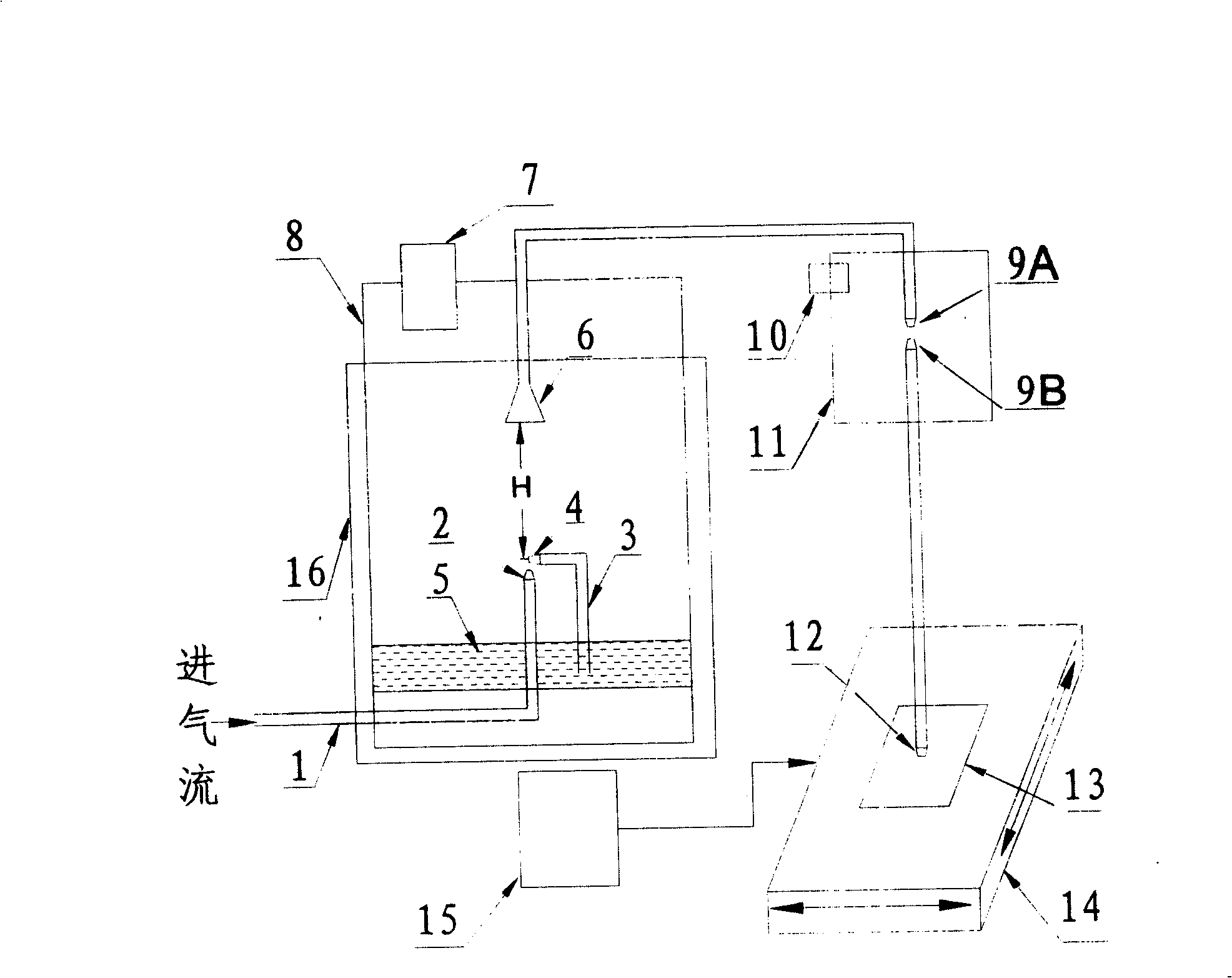

Full-automatic pesticide spraying and irrigation combined system for greenhouse

InactiveCN110521462AExpand the spraying areaImprove atomization abilityClimate change adaptationGreenhouse cultivationElectricityControl system

The invention discloses a full-automatic pesticide spraying and irrigation combined system for a greenhouse. The system comprises a spraying device, the greenhouse (12), a pipeline system (13), a control panel (14), a humidity sensor (15), an underground water tank (16) and a water pump (17), wherein one end of the water pump (17) is communicated with the underground water tank (16), and the otherend of the water pump (17) extends along a frame of the greenhouse (12) through the pipeline system (13) and is communicated with the spraying device. The humidity sensor (15) is arranged in the greenhouse (12), and the control panel (14) is mounted on the side wall of the greenhouse (12) and electrically connected with the pipeline system (13), the humidity sensor (15) and the water pump (17) soas to control the start or shutdown of the full-automatic pesticide spraying and irrigation combined system. The full-automatic pesticide spraying and irrigation combined system has the advantages oflarge spraying area, strong atomization effect, convenient operation and high working efficiency.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Intelligent vehicle-mounted humidifier and application system thereof

InactiveCN106394189AReduce volumeImprove atomization abilityAir-treating devicesIn vehicleEngineering

The invention discloses an intelligent vehicle-mounted humidifier and an application system thereof. The intelligent vehicle-mounted humidifier comprises a humidifier body and a USB power line. A base of the humidifier body is provided with a suction cup and a switch. The humidifier body is provided with perspective glass and a water adding port. An ultrasonic atomizer is arranged inside the humidifier and connected with a water absorption bar, and a row of exhaust holes are formed in the upper portion of the humidifier. The humidifier is researched, developed and designed according to the climatic environment and the internal structure of a vehicle, control can be conducted through a display screen in the vehicle by inserting the USB power line into a USB interface in the vehicle, and an automatic adjustment and control mode is adopted; and the intelligent vehicle-mounted humidifier is small in size, high in atomization capacity and high in humidifying speed, and can create a comfortable in-vehicle environment for people.

Owner:开平市仕冠贸易有限公司

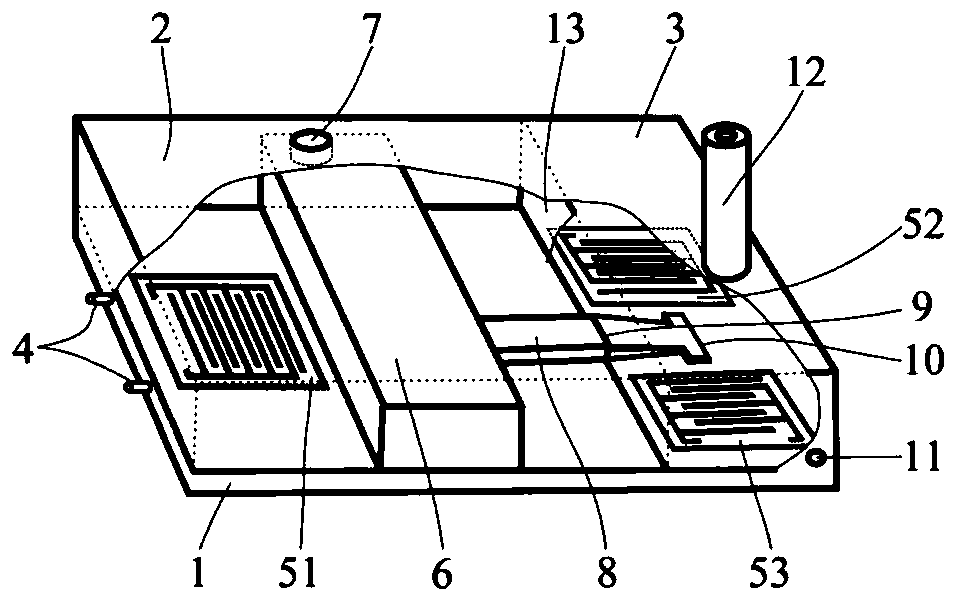

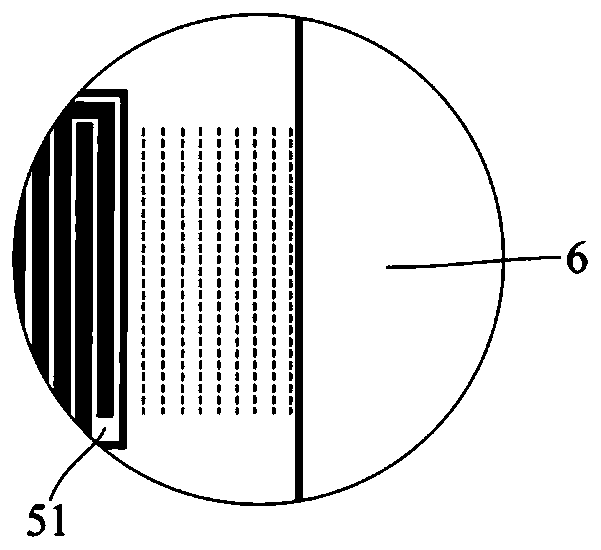

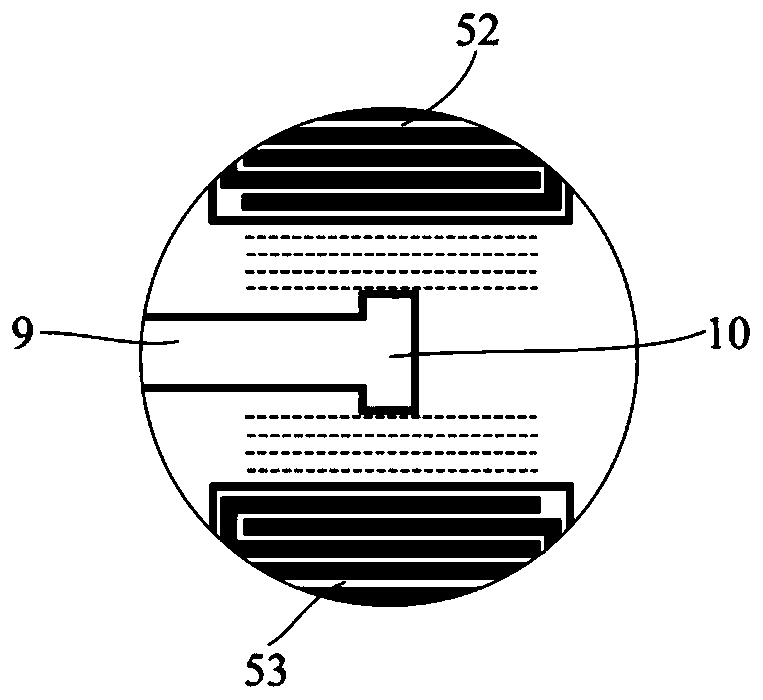

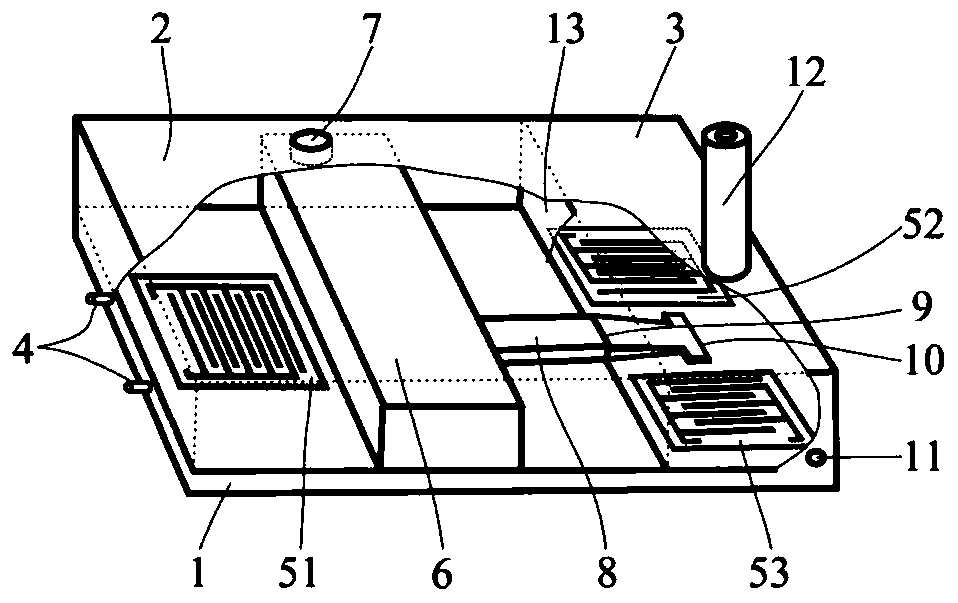

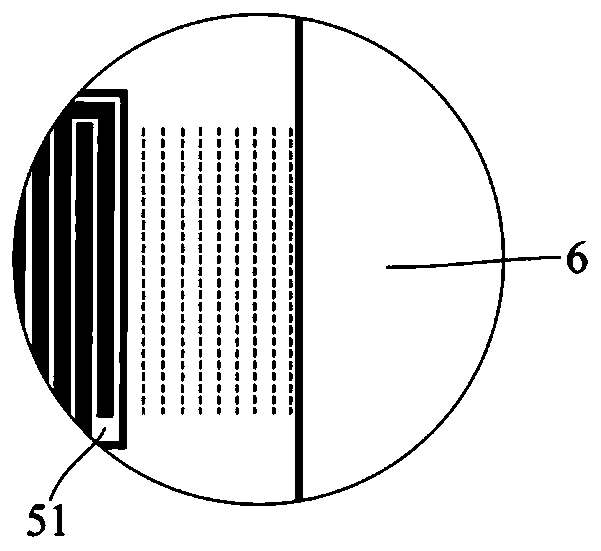

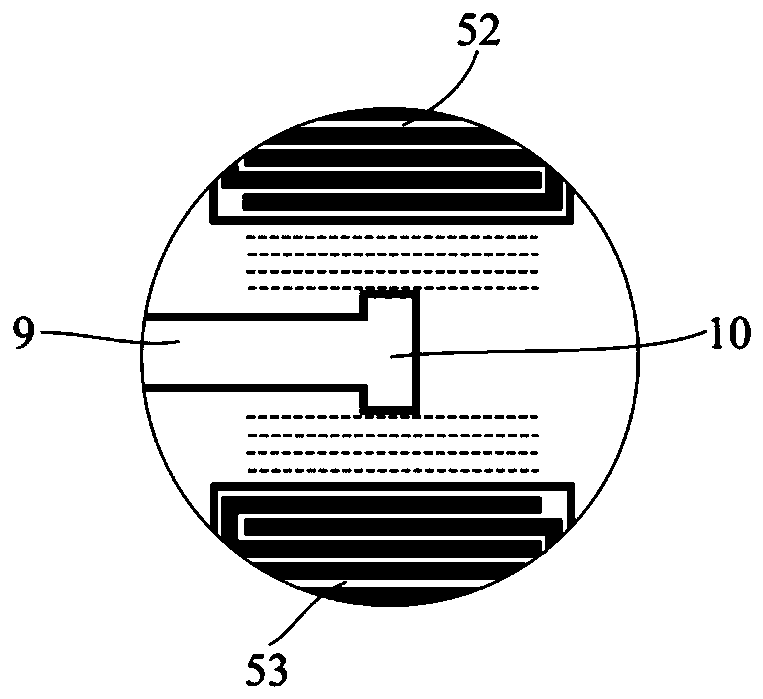

A surface acoustic wave non-contact atomization device

ActiveCN108158042BImprove particle size uniformitySmall particle sizeTobacco devicesElectricityFiber

The invention discloses a surface acoustic wave non-contact atomization device. The surface acoustic wave non-contact atomization device comprises a piezoelectric substrate (1), T-shaped fiber paper (10), a second interdigital transducer (52) and a third interdigital transducer (53), wherein the second interdigital transducer (52) and the third interdigital transducer (53) are placed on the two sides of the T-shaped fiber paper (10), and the T-shaped fiber paper (10), the second interdigital transducer (52) and the third interdigital transducer (53) closely fit the surface of the piezoelectricsubstrate (1). The surface acoustic wave non-contact atomization device has a strong E-liquid atomization capability and can generate a large amount of smoke per unit time, and a user can quickly obtain a sense of satisfaction in smoking.

Owner:CHINA TOBACCO YUNNAN IND

Four-DOF fire-fighting spray gun

InactiveCN102029036BImprove atomization abilityReduce the amount of waterFire rescueHydraulic cylinderClassical mechanics

The invention relates to a four-DOF (Degree-of-Freedom) fire-fighting spray gun; the bottom end of a hydraulic cylinder is connected with a bottom connecting base through a pin shaft to form a revolute pair; the bottom connecting base is in 120-degree connection with a bottom bracket; the piston rod of the hydraulic cylinder is in spherical corner connection with a top connecting base to form a spherical movement pair; the top connecting base is in 120-detgree connection with a top bracket; the top bracket is symmetrically connected with the bottom bracket together by six tension springs; every two tension springs are installed at an angle of 120 degrees from one another; the center of the top bracket is connected with a fire-fighting faucet through three rows of support balls in 120 degrees; flow guide pores are designed inside the fire-fighting faucet; and the hydraulic cylinder is connected with a controller. The four-DOF fire-fighting spray gun has the following advantages: firstly, the spray gun is small in volume and light in weight, thereby strengthening fire-fighting ability; secondly, long-time fire-fighting extinguishment can be realized so that automatic fire-fighting extinguishment becomes possible.

Owner:NANCHANG UNIV

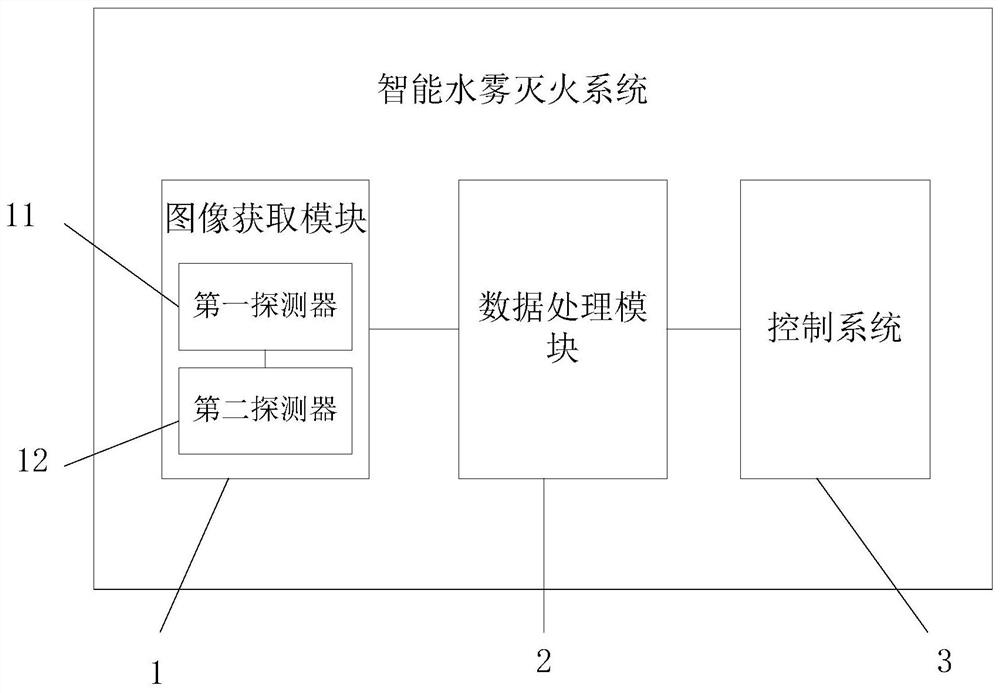

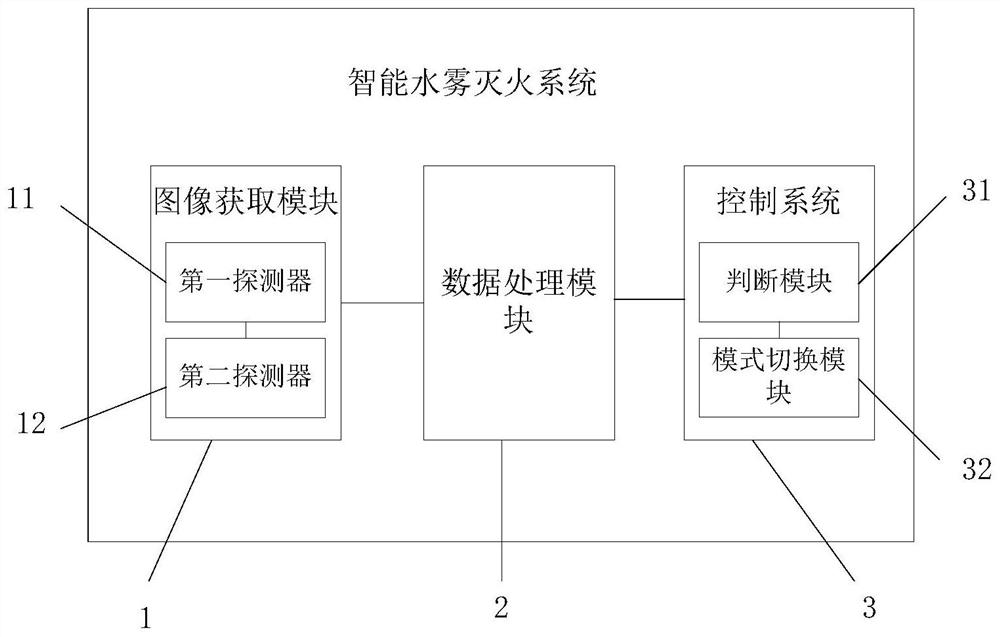

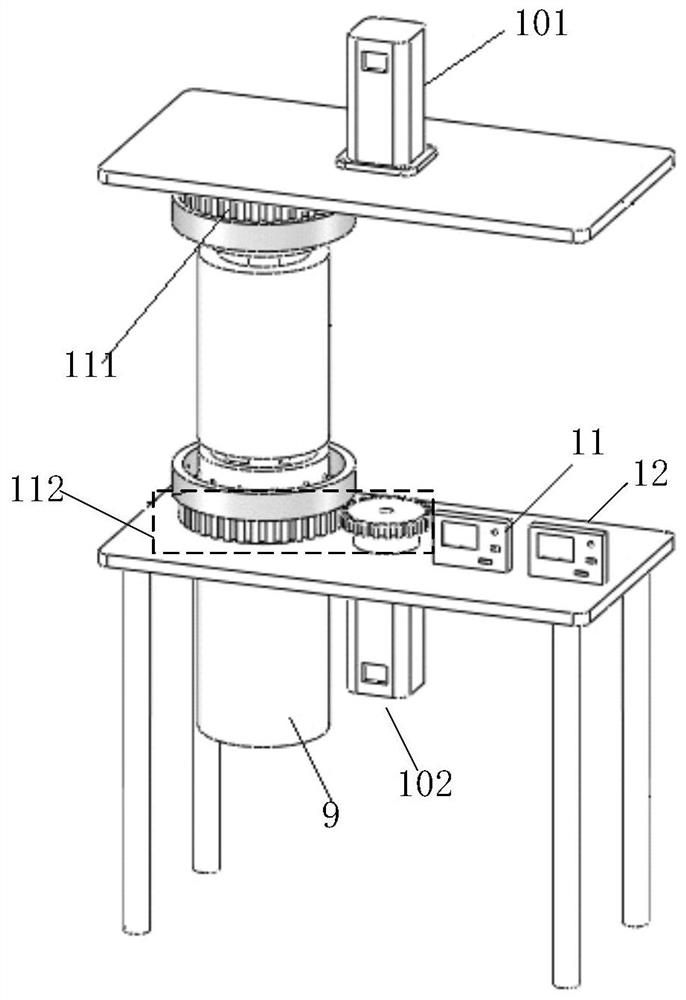

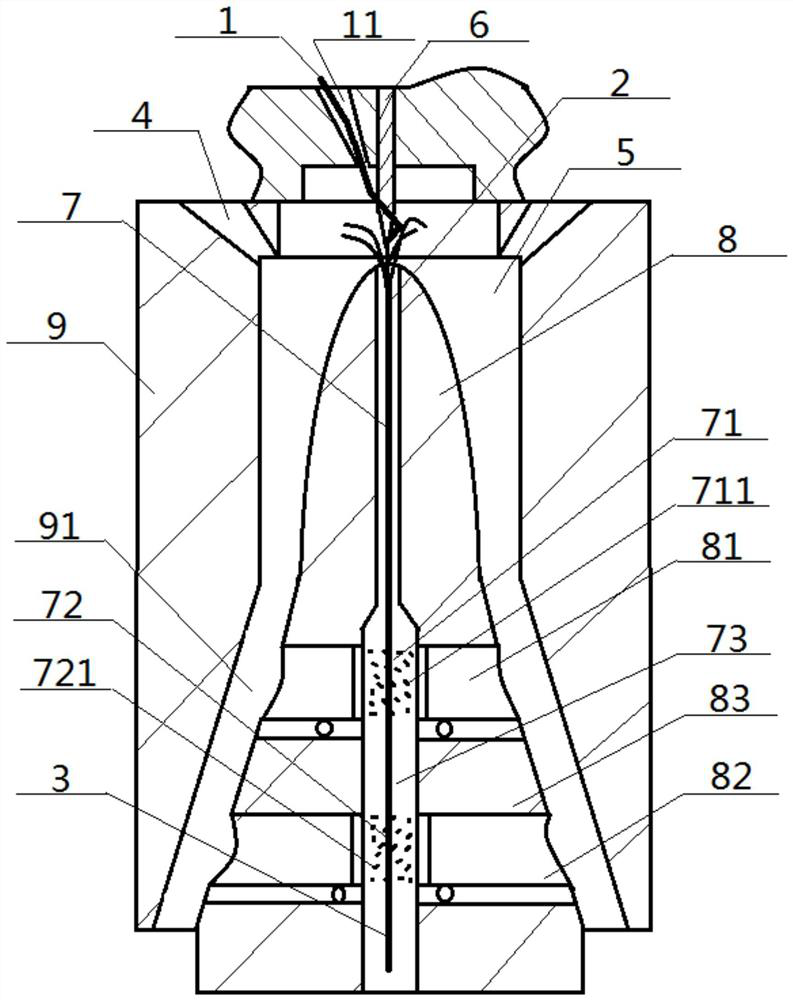

An intelligent water mist fire extinguishing system

ActiveCN110975206BImprove fire extinguishing effectLarge axial momentumFire rescueControl systemEnvironmental engineering

Owner:北京南瑞怡和环保科技有限公司

Air-jet vortex spinning process and product for making antibacterial yarn

ActiveCN113201832BStable structureImprove washing resistanceBiochemical fibre treatmentContinuous wound-up machinesYarnPolymer science

An air-jet vortex spinning process for making antibacterial yarn. Firstly, the pressurized gas is injected into the vortex chamber from the air jet hole to form a swirling airflow, and then the fiber bundle is input into the fiber channel, and the fiber bundle enters the vortex chamber under the action of the guide needle. , a part of the fiber bundle enters the yarn-drawing channel to become the core fiber, and the rest rotates with the airflow to wrap the core fiber to form the primary yarn. Among them, the primary yarn goes through the cation coating area and the anion coating area in turn to obtain the antibacterial yarn, the non-coating area is between the cation and anion coating areas, and the cation and anion coating areas are distributed in the cation and anion coating areas. , Anion mist. This design can not only produce antibacterial yarn through air-jet vortex spinning, but also has relatively high uniformity and strong atomization effect.

Owner:HUBEI FENGSHU THREAD MFG +1

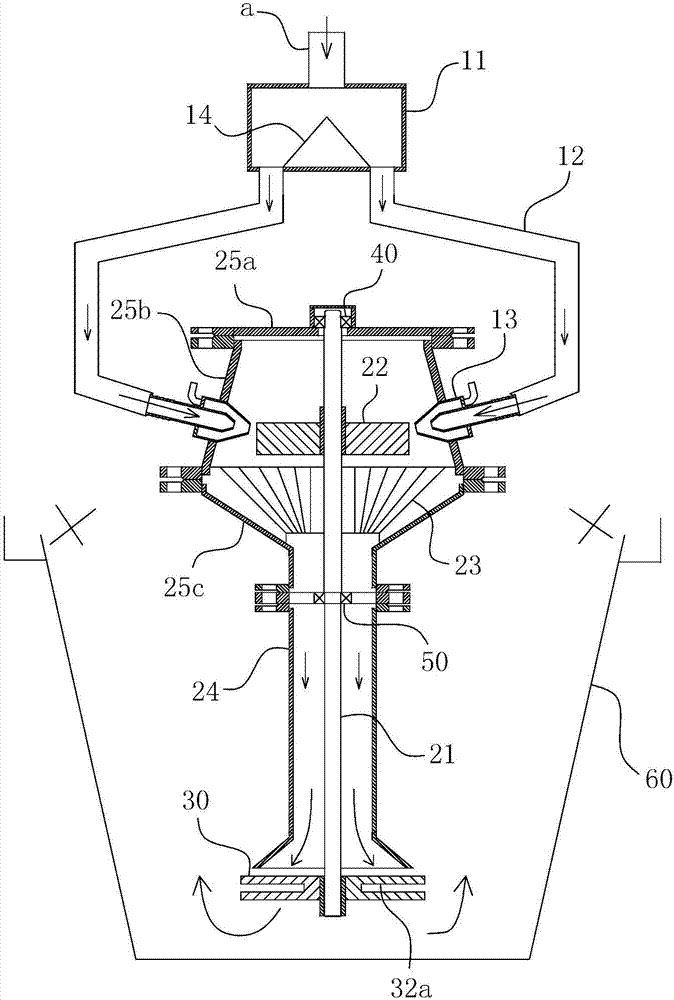

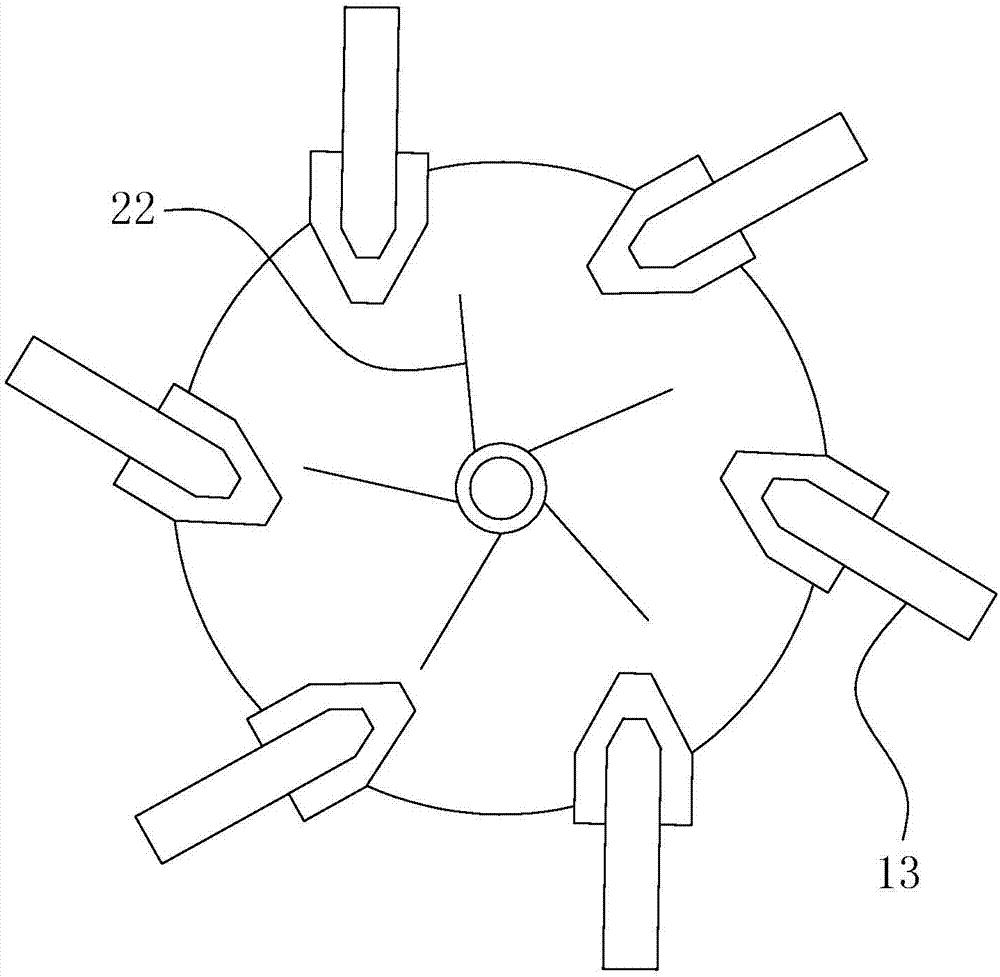

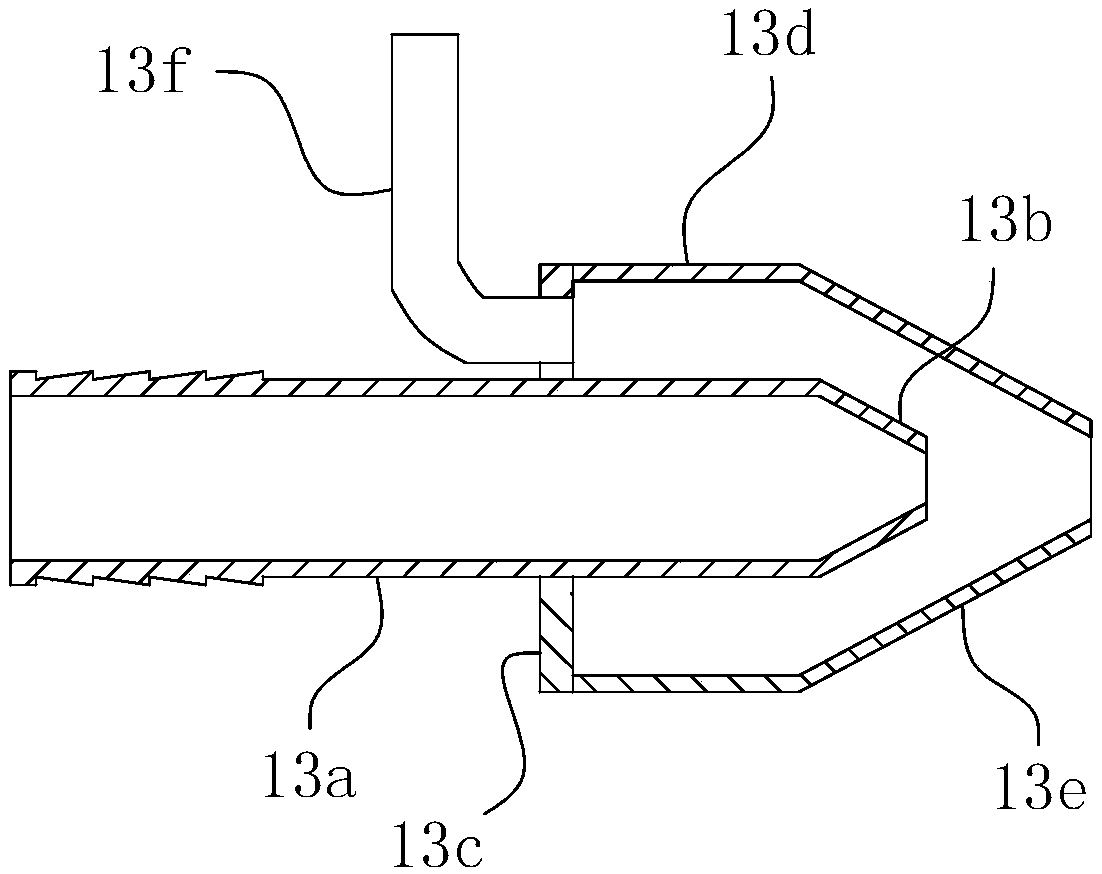

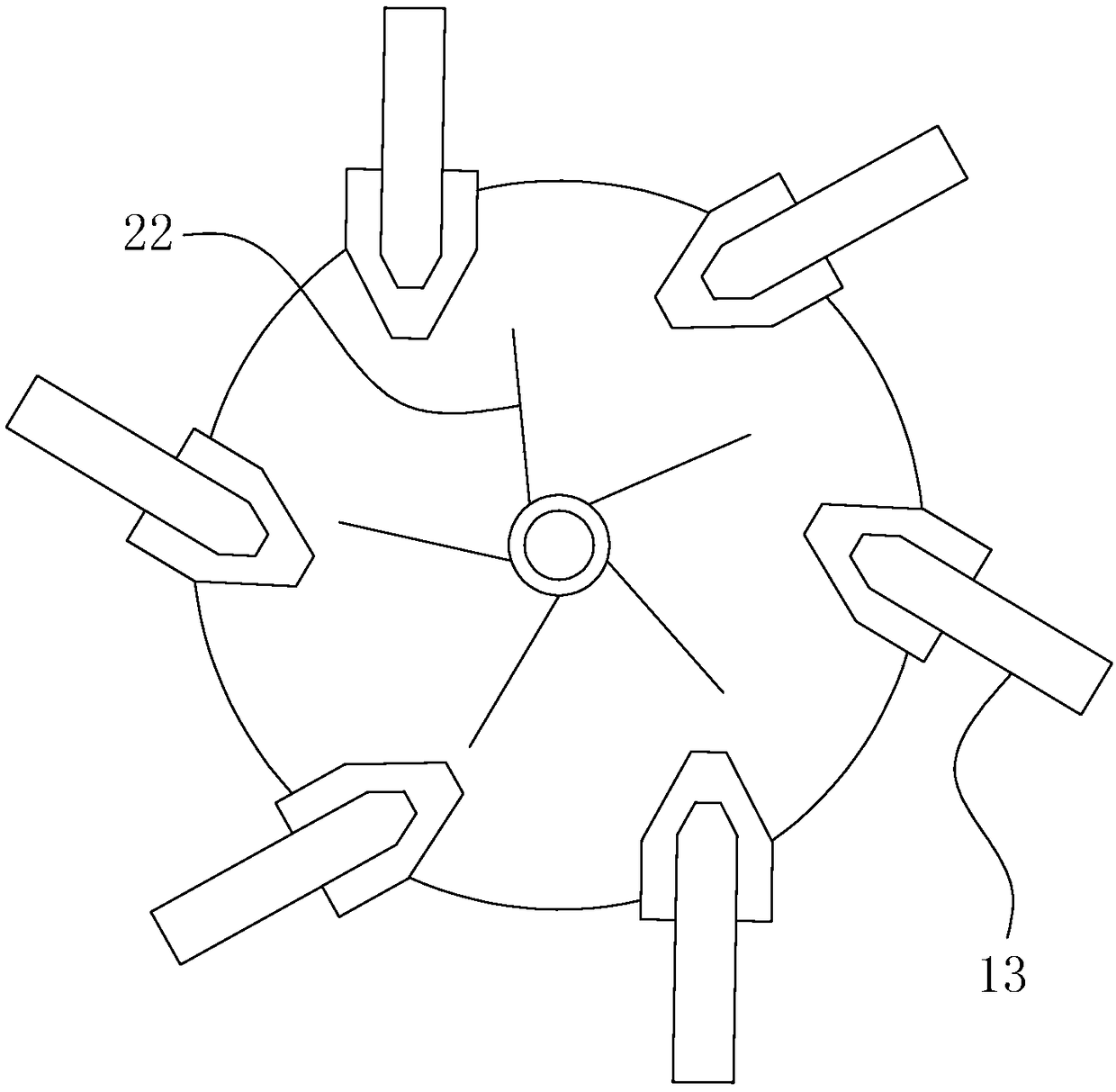

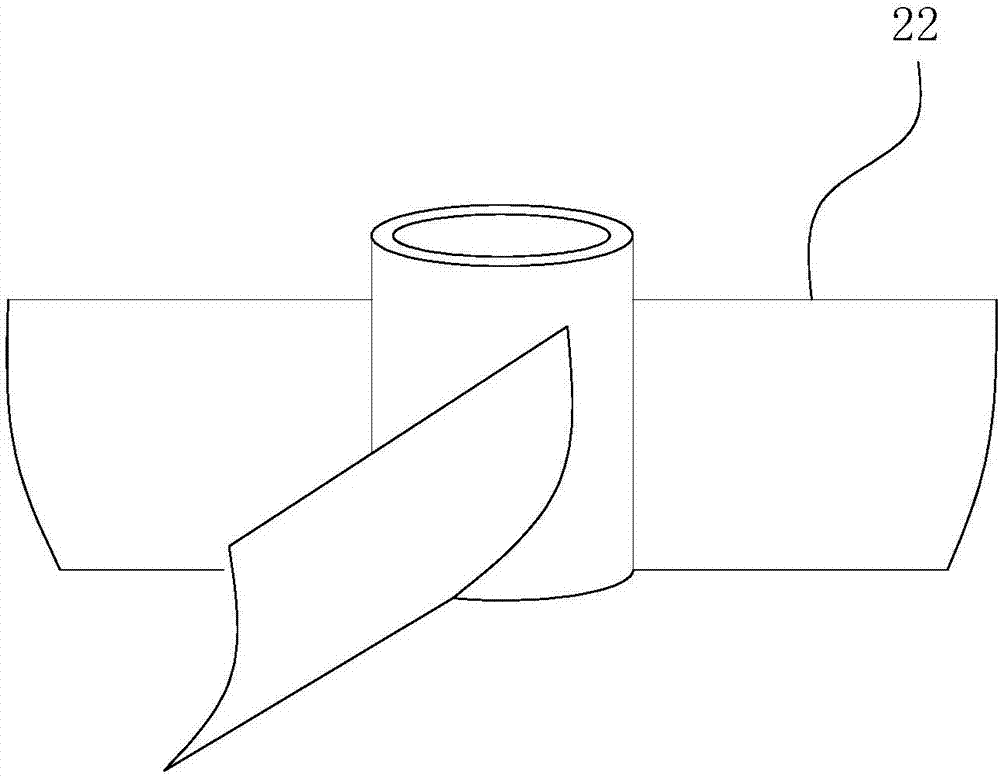

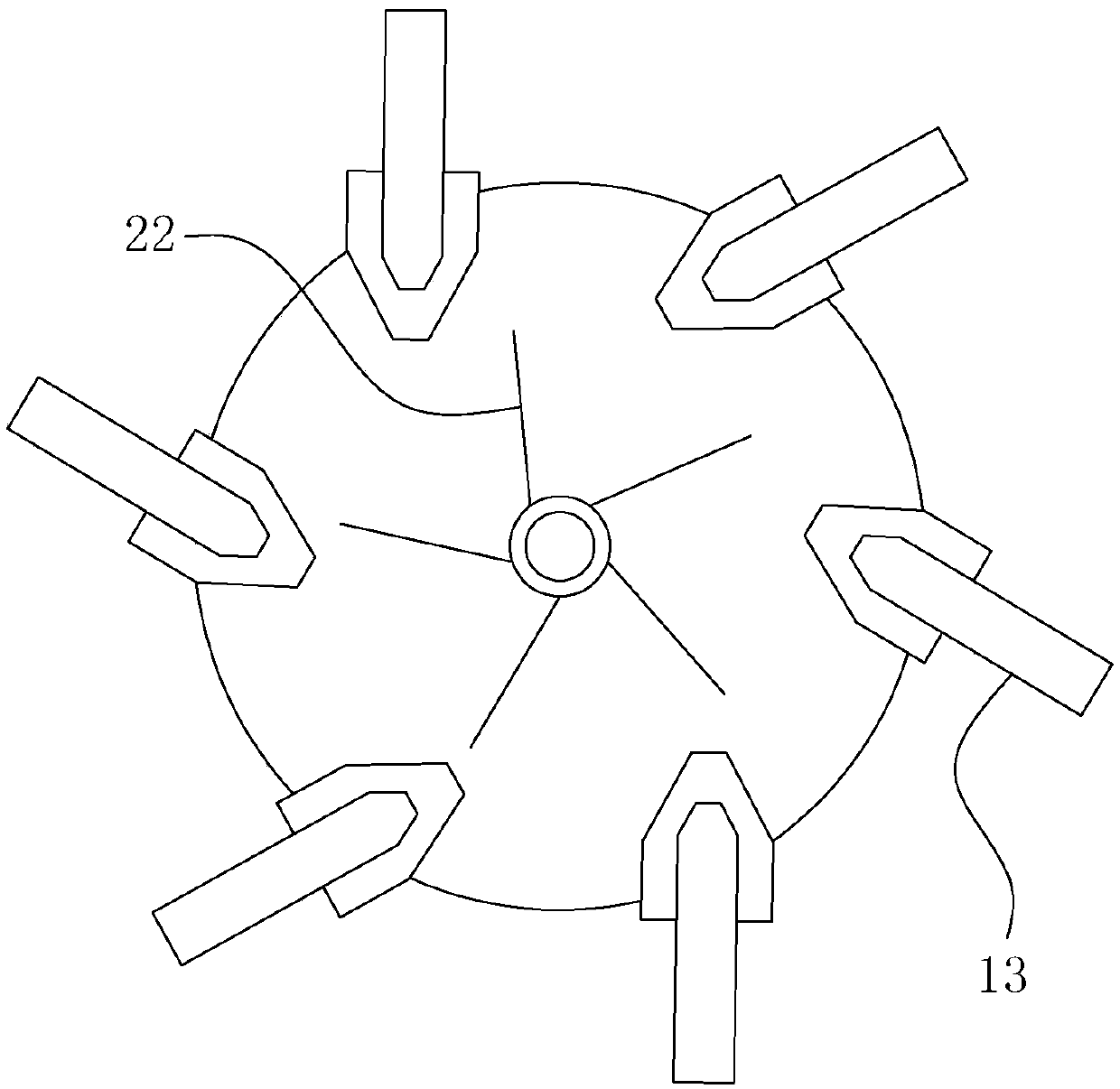

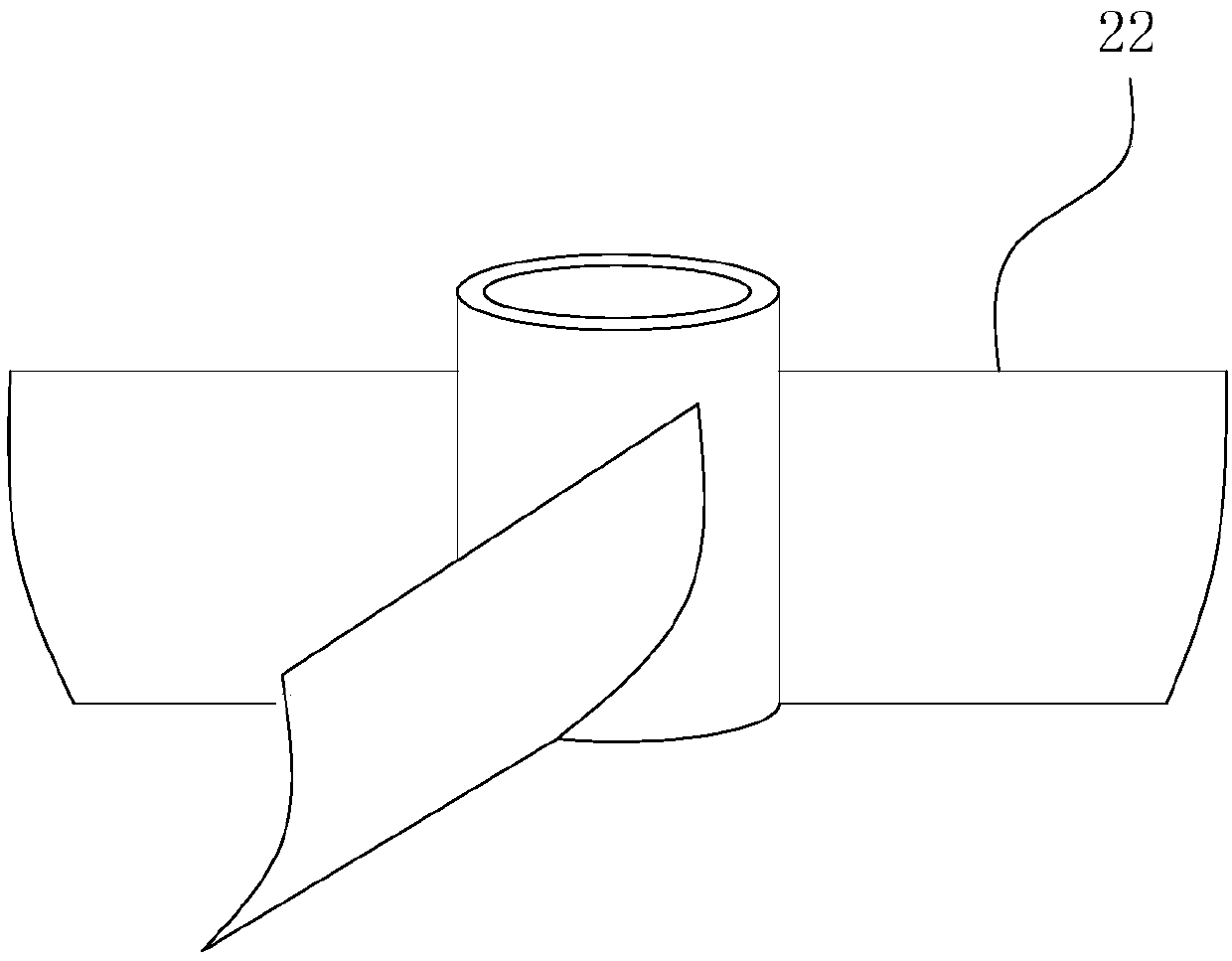

Ore-pulp self-driving-type flotation device with high-pressure jet-flow stirring function

The invention relates to the field of coal slime pulp-mixing flotation treatment, in particular to an ore-pulp self-driving-type flotation device with a high-pressure jet-flow stirring function. The device comprises a flotation tank, a stirring part is arranged in the flotation tank and comprises a high-pressure cavity, a rotating shaft is vertically arranged in the high-pressure cavity in the axial vertical direction, and an upper driving wheel is fixed on the rotating shaft; jet orifices are formed in the circumferential direction of the high-pressure cavity, the outlet ends of the jet orifices point to the position of the paddle surface of the upper driving wheel, and a pulp-mixing retainer is arranged under the upper driving wheel; and a discharging cylinder extending downwards is coaxially located at the bottom end of the high-pressure cavity, an outlet of the lower portion of the pulp-mixing retainer communicates with and points to the feeding end of the discharging cylinder, the stirring part further comprises a lower stirring wheel coaxially fixed at the shaft end of the bottom of the rotating shaft, and a discharging path of the discharging cylinder is located within the wheel blade stirring range of the lower stirring wheel. The ore-pulp self-driving-type flotation device with the high-pressure jet-flow stirring function has the advantages that the energy consumption is low, the maintenance amount is low, and the separation effect is good, the high-efficiency flotation demand of the ore-pulp can be achieved efficiently and controllably, and the early equipment investment of a coal preparation plant can be reduced.

Owner:ANHUI UNIV OF SCI & TECH

A self-driven flotation device for ore pulp with high-pressure jet stirring function

The invention relates to the field of coal slime pulp-mixing flotation treatment, in particular to an ore-pulp self-driving-type flotation device with a high-pressure jet-flow stirring function. The device comprises a flotation tank, a stirring part is arranged in the flotation tank and comprises a high-pressure cavity, a rotating shaft is vertically arranged in the high-pressure cavity in the axial vertical direction, and an upper driving wheel is fixed on the rotating shaft; jet orifices are formed in the circumferential direction of the high-pressure cavity, the outlet ends of the jet orifices point to the position of the paddle surface of the upper driving wheel, and a pulp-mixing retainer is arranged under the upper driving wheel; and a discharging cylinder extending downwards is coaxially located at the bottom end of the high-pressure cavity, an outlet of the lower portion of the pulp-mixing retainer communicates with and points to the feeding end of the discharging cylinder, the stirring part further comprises a lower stirring wheel coaxially fixed at the shaft end of the bottom of the rotating shaft, and a discharging path of the discharging cylinder is located within the wheel blade stirring range of the lower stirring wheel. The ore-pulp self-driving-type flotation device with the high-pressure jet-flow stirring function has the advantages that the energy consumption is low, the maintenance amount is low, and the separation effect is good, the high-efficiency flotation demand of the ore-pulp can be achieved efficiently and controllably, and the early equipment investment of a coal preparation plant can be reduced.

Owner:ANHUI UNIV OF SCI & TECH

Surface heating atomizer and electronic cigarette with the atomizer

The invention discloses a surface heating atomizer and an electronic cigarette with the atomizer. The atomizer includes a base connected to each other and a heating element. The heating element includes a ceramic seat. The storage tank for e-liquid or e-liquid, the outside of the ceramic seat is wrapped with a nano-titanium metal heating material film; the electronic cigarette includes an interconnected atomizer assembly and a smoke rod assembly, and the atomizer assembly includes a mouthpiece, an atomizer, and an atomizer that are connected in sequence. The device tube, the first electrode connection assembly and the aforementioned atomizer, the cigarette rod assembly includes a battery tube and a second electrode connection assembly, a battery, and a control board respectively arranged in the battery tube, and the second electrode connection assembly is connected to the battery through the control board , the battery tube is provided with a key switch for connecting with the control board, and the first electrode connection assembly is connected to the second electrode connection assembly. The invention has the advantages of large heating area, good atomization performance, more smoke oil atomized each time of heating, no carbon deposit in use, long service life, energy saving and environmental protection.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

Electronic device for direct slurry atomization and deposition

ActiveCN100413598CSmall inner diameterIncrease air velocityLiquid surface applicatorsSpraying apparatusButt jointSlurry

The disclosed electronic slurry atomization deposition direct-write device comprises: a deposition nozzle, a base plate, a work bench controlled by a controller, two atomizing nozzles every with a gas nozzle connected to gas source and a liquid nozzle connected to slurry pipe end both in the atomization cavity, and a butt-joint jet pipe with co-axial upper and lower jet pipes, wherein arranging a micro-pressure gauge in the cavity, arranging a adjustable valve in the decompression recovery cavity. This invention has well atomization effect, and runs stably and conveniently.

Owner:HUAZHONG UNIV OF SCI & TECH

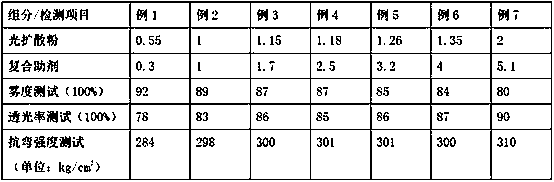

Preparation process of composite diffusion plate

The invention relates to the technical field of illumination, in particular to a preparation process of a composite diffusion plate; the preparation process comprises the following steps: step 1, PS or PP is selected as raw materials, and 1 to 1.35 parts of light diffusion powder and 1 to 4 parts of a composite additive are added into the raw materials by weight, and mixing and stirring are performed to form 100 parts of mixture by weight; step 2, an extrusion process is adopted, and the mixture is added into an extrusion forming machine to be extruded to form a diffusion plate; step 3, an embossing roller with suitable decorative patterns is selected to carry out knurling processing on the diffusion plate; step 4, light diffusion coating is coated on the diffusion plate through a coatingmachine; and step 5, the light diffusion coating is cured and shaped by adopting a UV coating process and is compounded with the diffusion plate to form the composite diffusion plate. The light diffusion coating is compounded with the diffusion plate after being subjected to UV curing to form the composite diffusion plate, so that the structure of the existing double-layer composite diffusion plate having the diffusion plate and the diffusion sheet is replaced, and the cost is lowered; and the prepared composite diffusion plate is higher in structural stability, high in light transmittance andhigh in atomization effect.

Owner:DONGGUAN XINJU OPTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com