Ultrasonic atomization device used for suspension liquid

An atomization device and ultrasonic technology are applied in the fields of liquid spray devices, flue gas desulfurization and denitrification systems of thermal power plants, and ultrasonic atomization devices. Achieve the effect of improving atomization efficiency, broad application prospects and improving atomization capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with accompanying drawing:

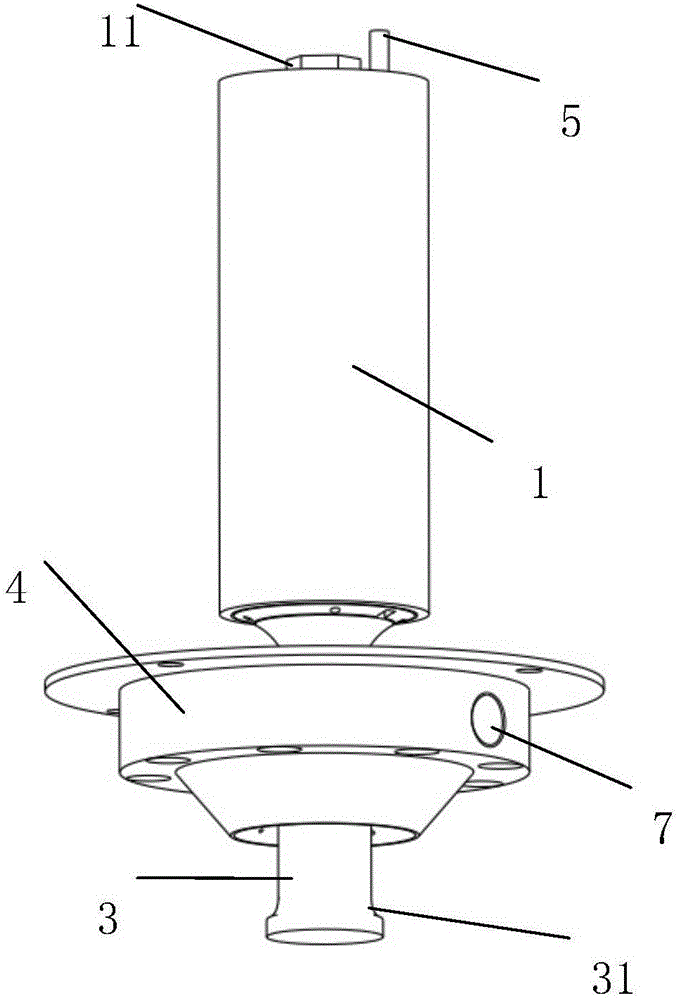

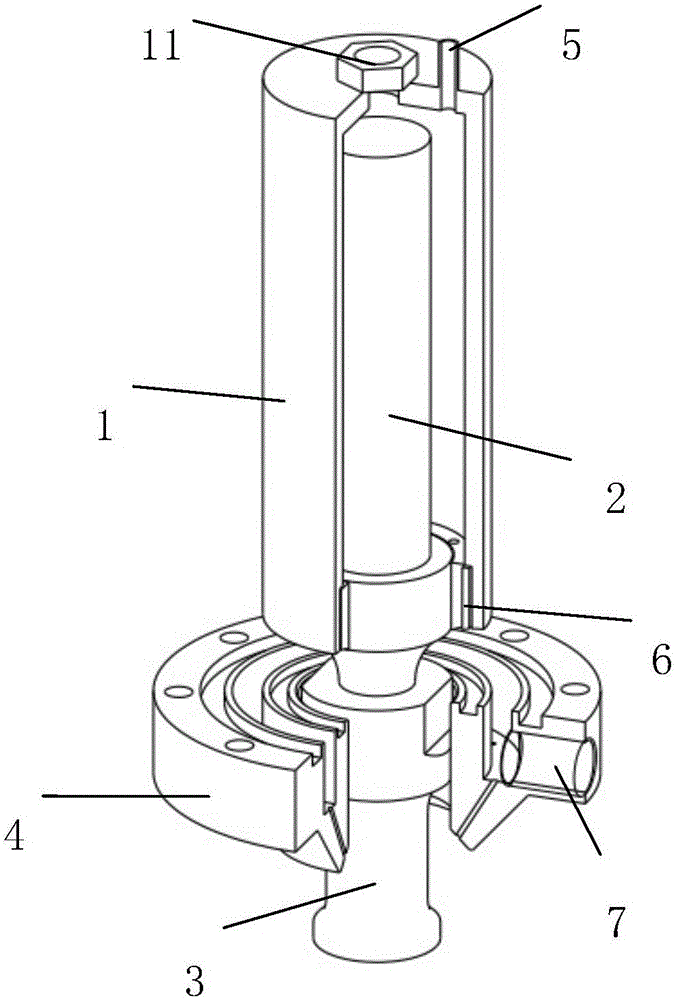

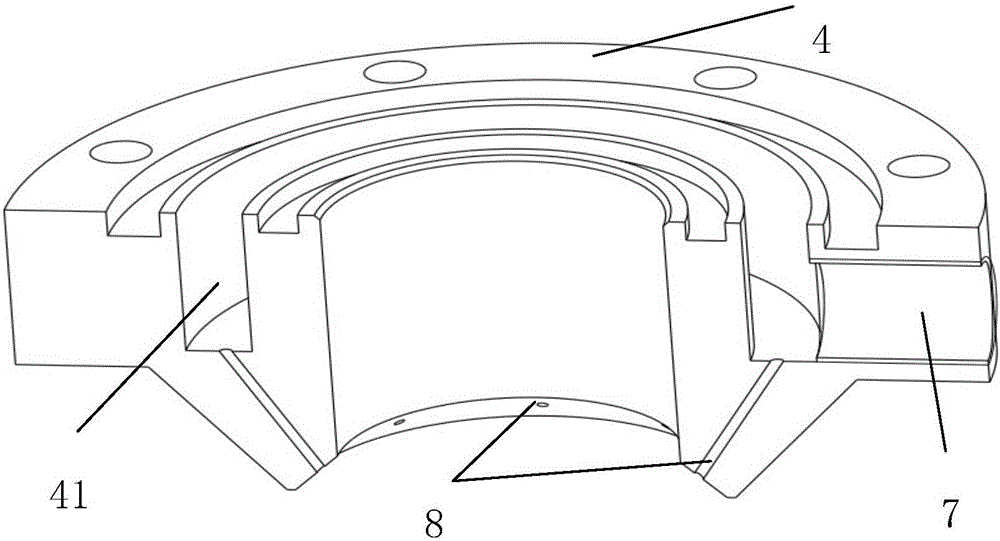

[0017] As shown in the figure, this ultrasonic atomization device for suspension is characterized in that it includes a transducer housing 1, a transducer 2, an atomization tool head 3, a liquid spray ring 4, and an air inlet 5. The air outlet hole 6, the liquid inlet hole 7 and the liquid outlet hole 8, the transducer housing 1 is covered on the outside of the transducer 2, and the transducer 2 is connected through the wire interface 11 at the top of the transducer housing 1 Ultrasonic power supply; the atomizing tool head 3 is connected to the transducer 2 through screws, and the transducer 2 passes through the central hole of the baffle and is snap-connected with the spray ring 4 . There is an air outlet 6 at the bottom of the transducer shell 1, and the gap between the transducer shell 1 and the transducer 2 is filled with heat-conducting glue; on the one hand, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com