Multifunctional trolley for construction site

A construction site, multi-functional technology, applied in the direction of construction, dispersed particle filtration, liquid injection devices, etc., can solve the problems of dust emission, impact on the environment, and insufficient dust reduction effect, etc., to achieve strong atomization effect and enhanced air purification function , Improve the effect of dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

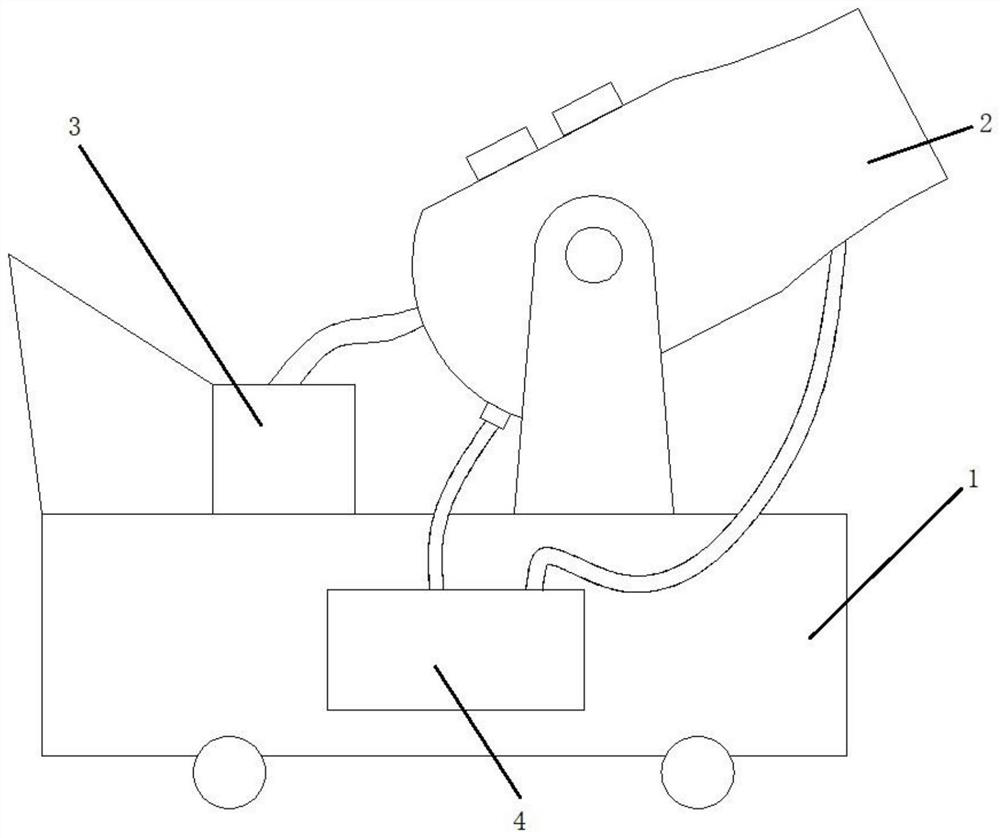

[0029] Such as figure 1 as shown, figure 1 It is a structural view of the multifunctional trolley for the construction site; the multifunctional trolley for the construction site of the present invention includes a mobile body 1, a warning device, an atomizer 2, and a dust collector 3, and the warning device, the atomizer The device 2 and the dust collector 3 are all arranged on the mobile car body 1, and move with the mobile car body 1, the atomizer 2 is connected with the dust collector 3, and the atomizer 2 uses To improve the air humidity, make the dust in the air humidify and reduce dust and further realize the improvement of the humidity of the construction ground to avoid the occurrence of dust; the dust collector 3 is used to filter the dust in the air to improve the visual clarity of the construction site, and the warning device Generally, it is a warning light or / and a buzzer, which reminds the site personnel of the location of the construction site multifunctional ...

Embodiment 2

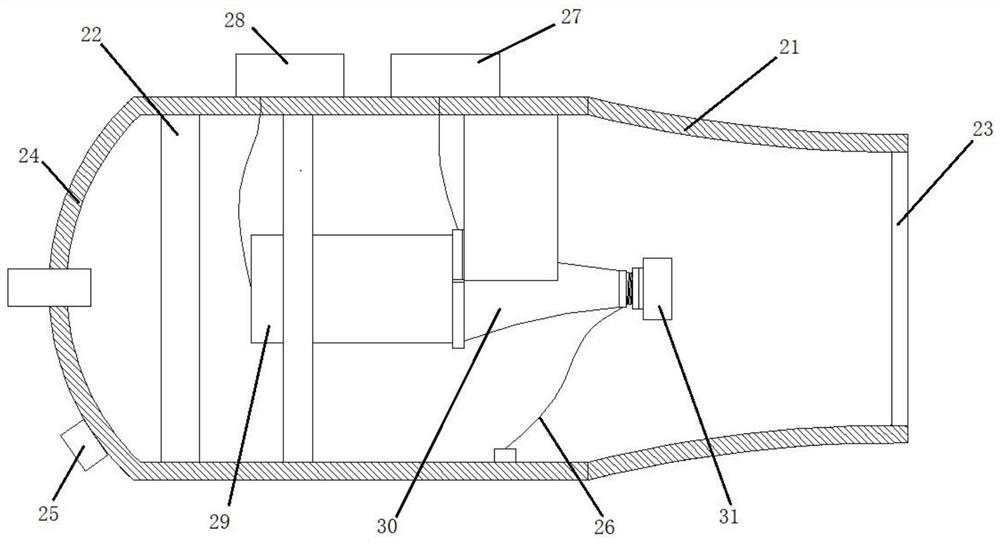

[0035] Such as figure 2 as shown, figure 2 It is a structural view of the atomizer; the atomizer 2 of the present invention includes a housing 21, an atomization assembly, the fan 22 and a blocking plate 23, and the housing 21 is a cylindrical structure with a cavity inside , one end of the casing 21 is set as the air inlet end in the closed state, and the other end is the discharge end in the open state, the atomization assembly and the fan 22 are both set in the placement cavity, the connecting pipe is The inlet end communicates with the placement cavity, and the barrier plate 23 is arranged on the discharge end. Powered by the blower 22 , the air preliminarily filtered by the dust collector 3 enters the placement cavity, and is discharged into the external environment through the barrier plate 23 together with the water mist generated by the atomization assembly.

[0036] Generally, the casing 21 is arranged obliquely on the mobile vehicle body 1, and the discharge end ...

Embodiment 3

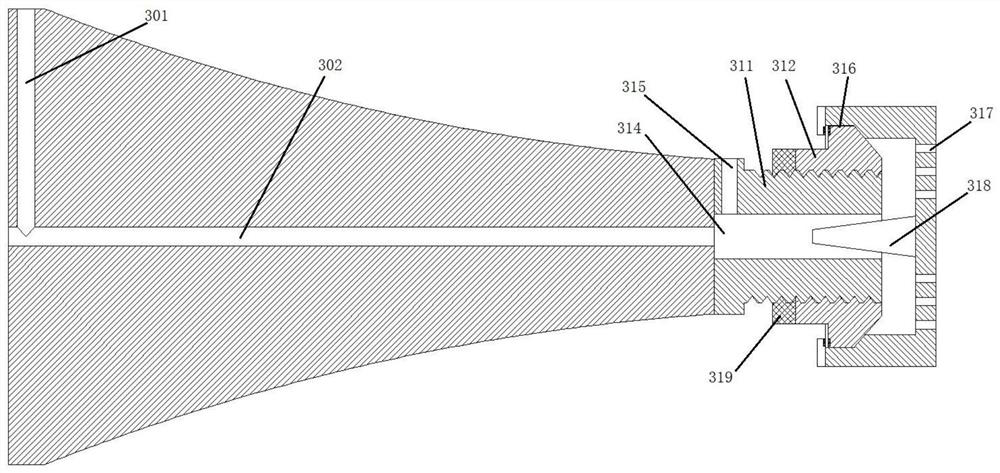

[0044] The atomization assembly includes a fixing part and an atomization production part, the atomization production part is detachably connected to the fixing part, and the fixing part is fixedly arranged on the housing 21; the atomization production part includes The transducer 29, the horn 30 and the atomizing head 31, the atomizing head 31 is connected with the transducer 29 through the horn 30, and the transducer 29 is fixed on the fixed part The atomization production part is arranged on the axis of the housing 21, from the direction of the inlet end to the discharge end, the transducer 29, the horn 30 and the atomization head 31 in sequence. Generally, the transducer 29 and the horn 30 are arranged in the straight section, and the atomizing head 31 is arranged in the variable diameter section.

[0045] The power supply part 28 is connected to the transducer 29 , the air source supply part 27 is connected to the horn 30 , and the water tank 4 is connected to the atomiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com