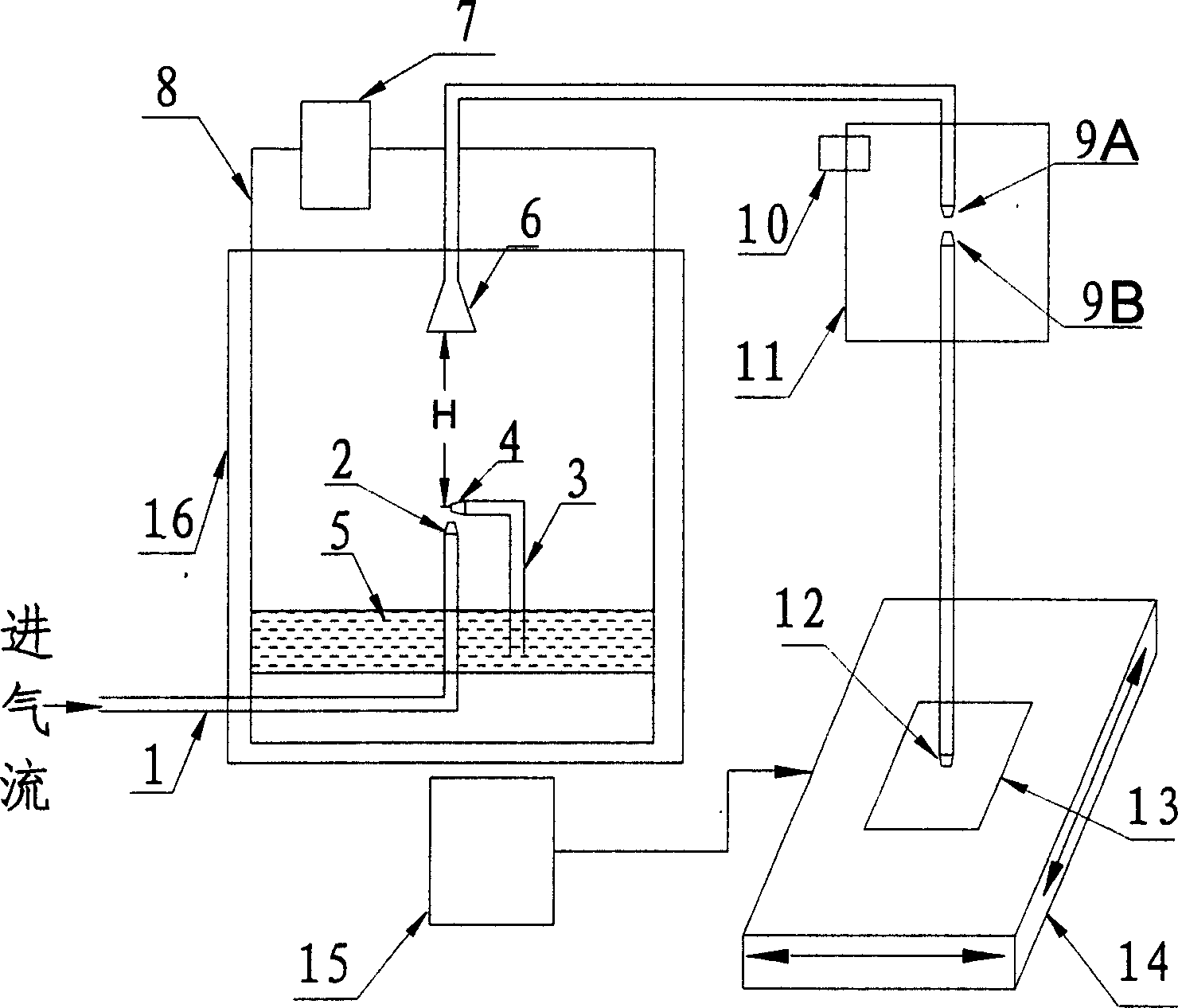

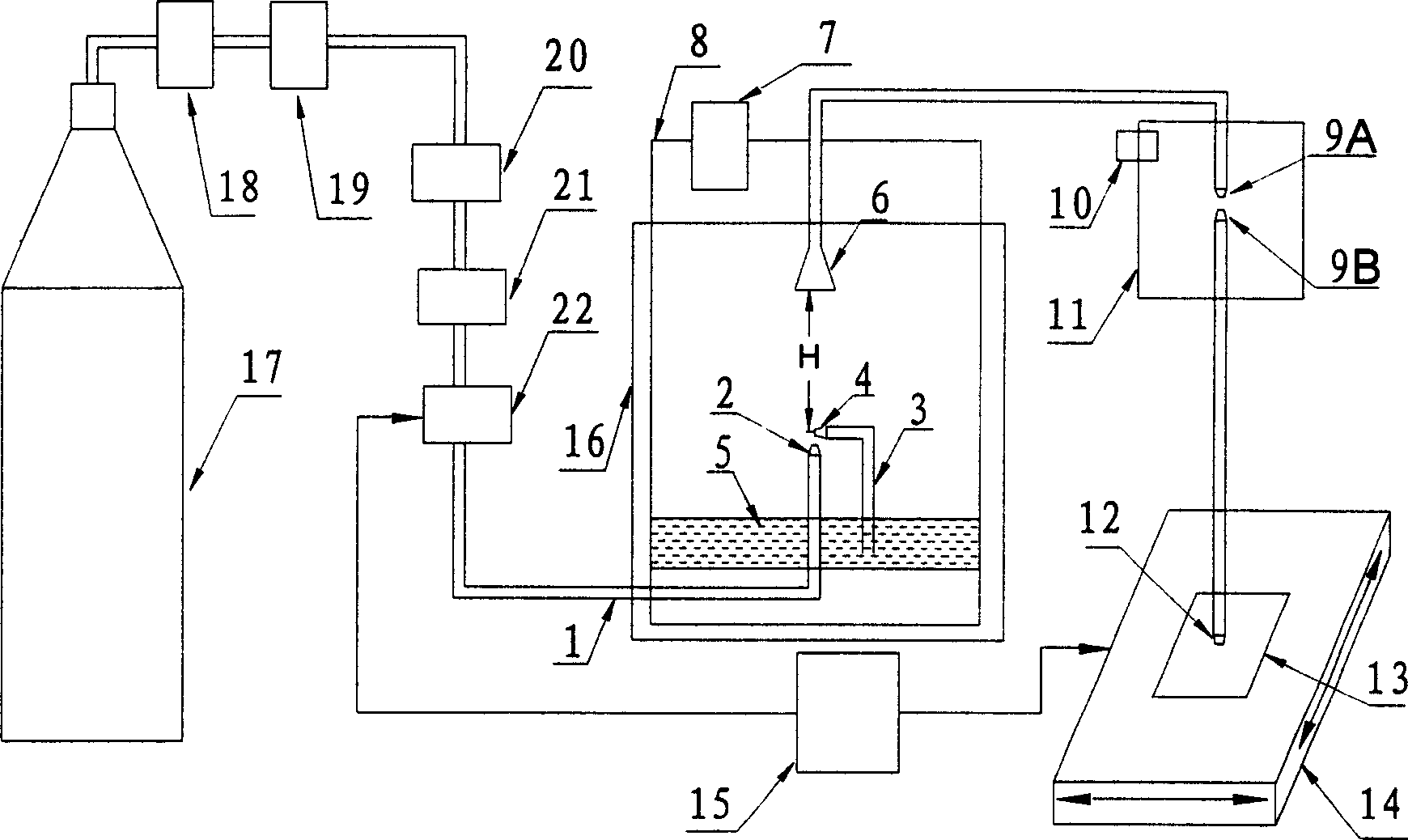

Electronic device for direct slurry atomization and deposition

A technology of atomization deposition and electronic slurry, which is applied in spraying devices, devices for coating liquid on the surface, circuits, etc., can solve the problems of high cost and complex equipment composition, achieve convenient operation, improve electrical performance, and be easy to replace Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

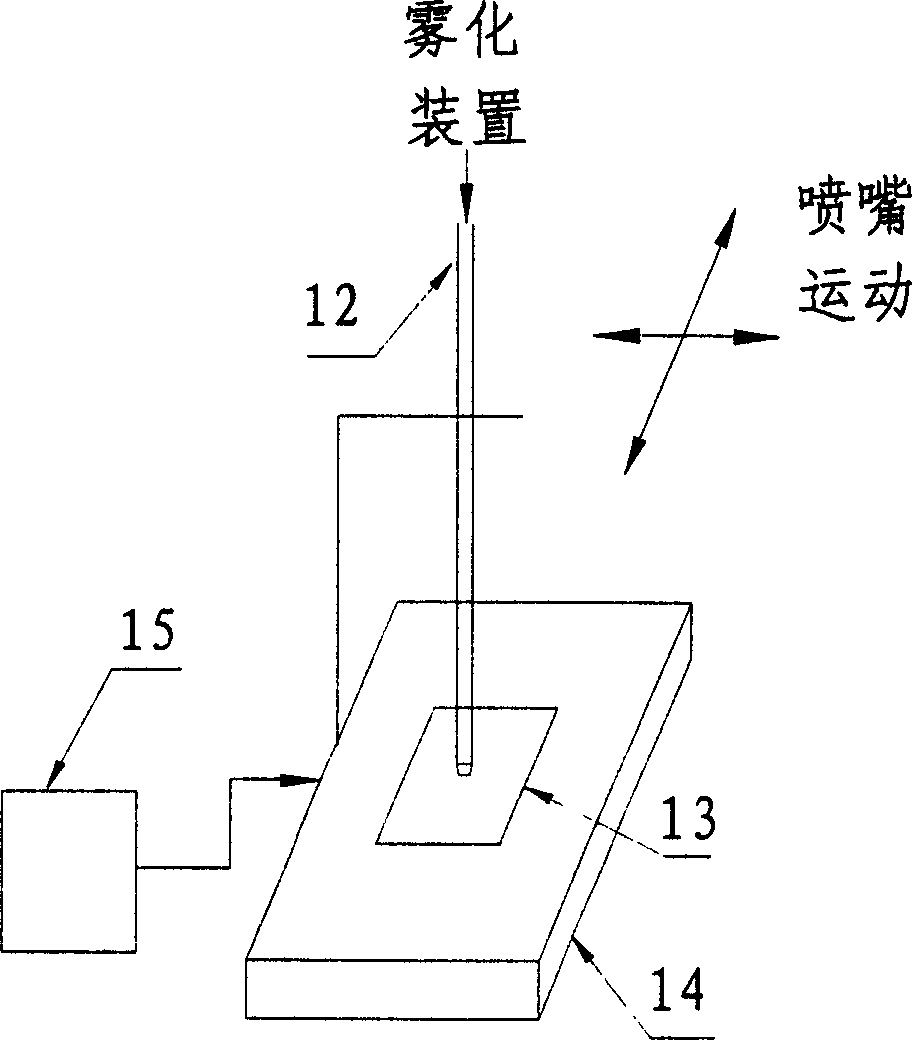

Method used

Image

Examples

Embodiment 1-3

[0038] Embodiment 1-3 is in ceramic (Al 2 o 3 , 96wt%) deposited direct-write high-temperature Ag conductor on the substrate. Among the two-fluid atomizing nozzles, the diameter of the gas nozzle is Φ0.22mm, the diameter of the liquid nozzle is Φ0.5mm, the diameter of the deposition nozzle is Φ0.4mm, and the viscosity of the slurry is 2Pa.S. Other parameters are shown in Table 1.

[0039] example

Embodiment 4-6

[0041] Examples 4-6 deposited direct-write Ag conductors on Si substrates. In the two-fluid atomizing nozzle, the diameter of the gas nozzle is Φ0.20mm, the diameter of the liquid nozzle is Φ0.50mm, the diameter of the deposition nozzle is Φ0.10mm, the viscosity of the slurry is 2Pa.S, and other parameters are shown in Table 2

[0042] example

[0043] The electronic slurry direct writing technology proposed by the present invention uses the atomizing nozzle to atomize the electronic slurry into fine particles, and then transports the electronic slurry to the nozzle along the pipeline under the guidance of the air flow, and deposits it on the substrate through the nozzle to form a preset circuit graphics. Among them, the deposition path is controlled by the control command issued by the numerical control workbench. The electronic paste includes conductive paste, resistive paste, dielectric paste or other electronic paste. The substrate can be ceramic, glass, silicon,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com