Spiral-flow type supersonic speed electric arc spraying gun

A supersonic arc and swirling technology, which is applied in arc spraying, coating, spraying device and other directions, can solve the problems of unstable spraying jet, rough surface, poor jet clustering, etc., to achieve enhanced effect and stability, coating Boost, speed boost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

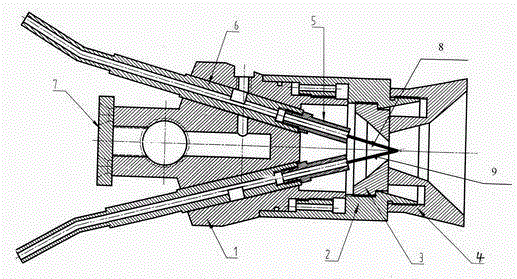

[0008] Describe embodiment in detail in conjunction with above accompanying drawing, see figure 1 The guide wire tube 2 shown is assembled in the rob body 1, the conductive tip 4 is connected to the guide wire tube, the swirl ring 3 is connected with the rob body through threads, the gas gathering cover 6 is fixed with the swirl ring through threads, and the ceramic nozzle 5 passes through The gas gathering cover is pressed in the swirl ring, the inner cavity of the ceramic nozzle and the inner cavity of the gas gathering cover are combined with a Laval nozzle structure, the ceramic nozzle and the front end are respectively connected with the positive electrode 8 of the spraying wire and the negative electrode 9 of the spraying wire, and the external body 7 is passed through the bolt It is connected with the rob body and connected with the external spraying rob fixing device, and a sealing ring is arranged between the external body 7 and the rob body 1 .

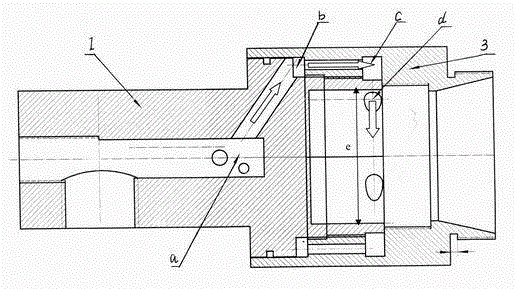

[0009] See figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com