Flotation equipment with pulp self-drive and self-suction functions

A self-driven, self-aspirated technology, applied in flotation, solid separation, etc., can solve the problems of excessive turbulence in the flow field, affecting the flotation effect, particle shedding, etc., to ensure work efficiency, easy bubble mineralization, foam layer stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

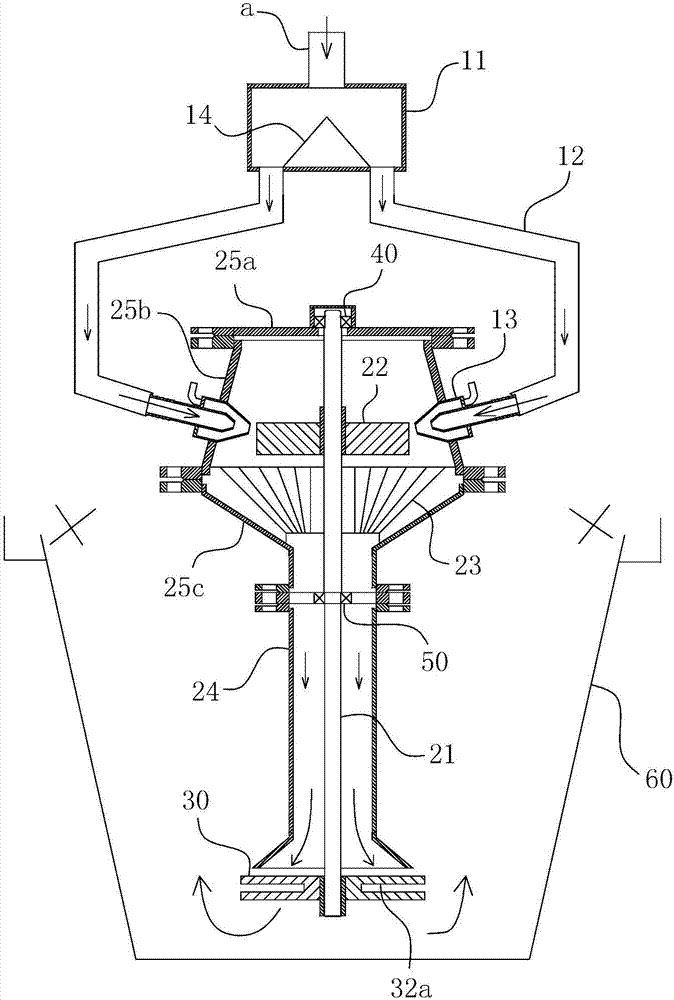

[0042] For ease of understanding, combined here Figure 1-7 , the specific embodiments of the present invention are further described as follows:

[0043] The specific components of the present invention are divided into several major modules, including: flotation cell 60, flow diversion assembly, high-pressure injection assembly and lower stirring assembly, which are described one by one below:

[0044] 1. Flotation cell

[0045] As a conventional flotation device, the flotation cell 60 can be equipped with auxiliary flotation operation structures such as bubble scraping mechanism, so as to realize its inherent flotation function.

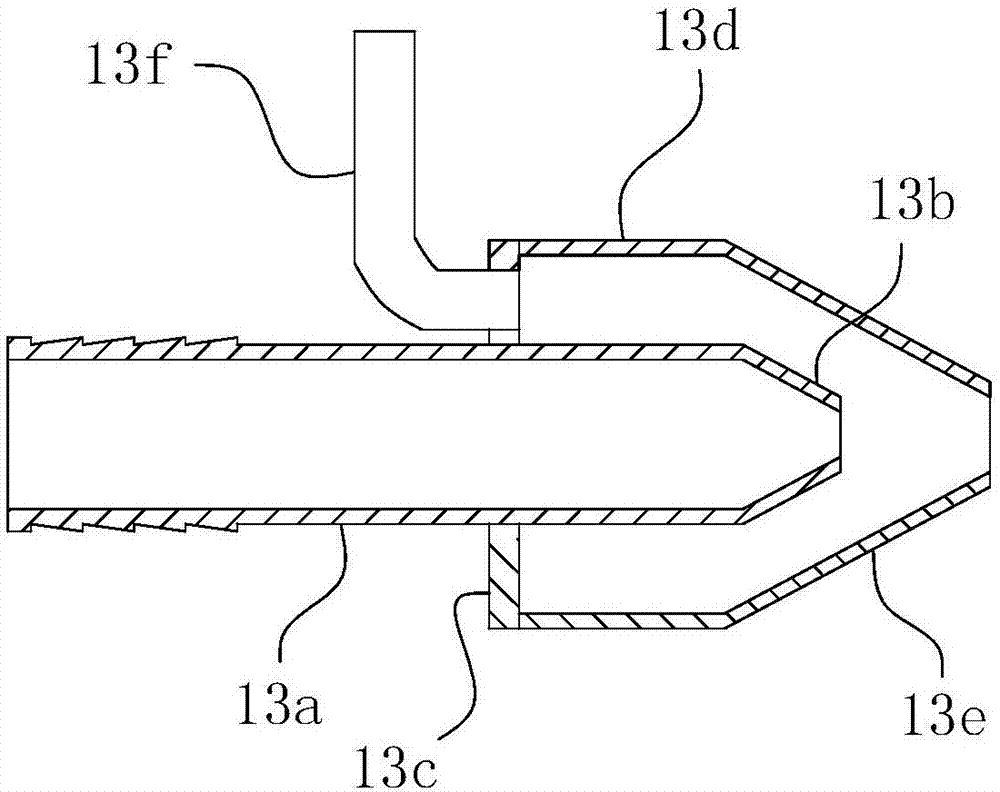

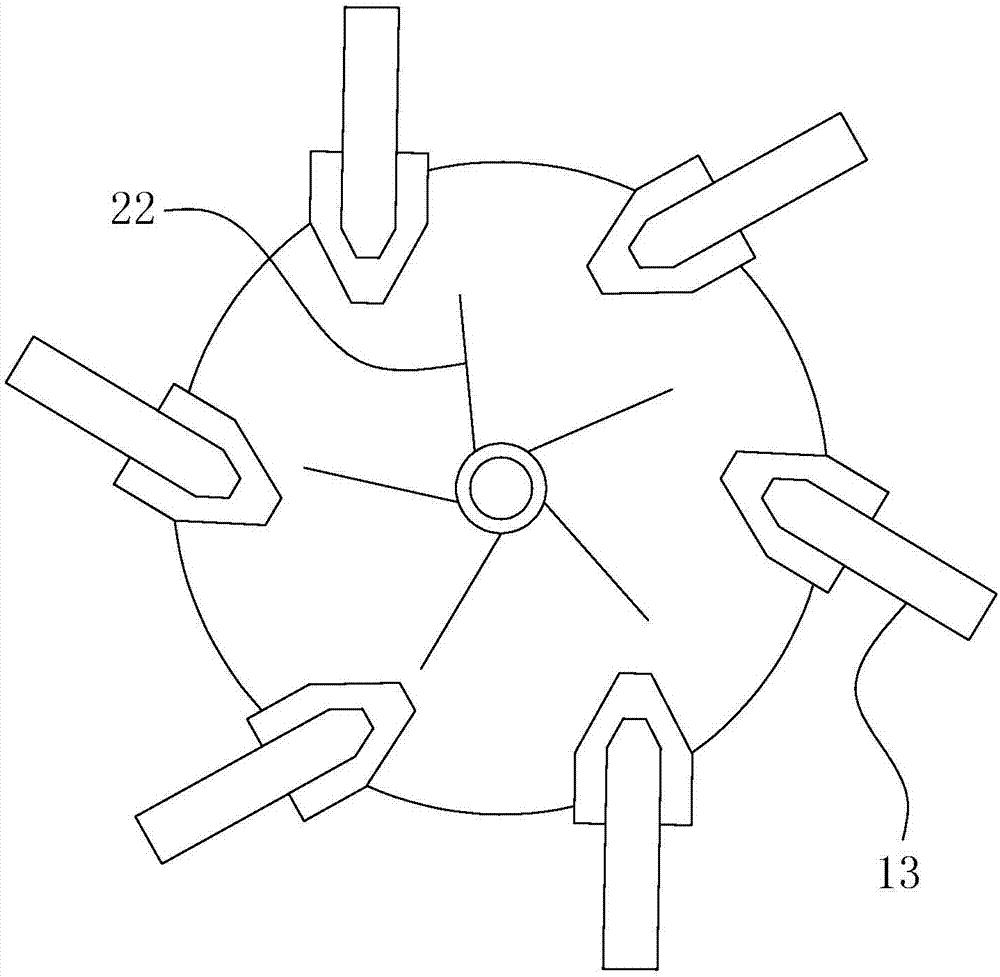

[0046] 2. Shunt component

[0047] shunt components to Figure 1-2 and Figure 7 When the structure shown is a specific embodiment, it is mainly subdivided into a sextant and a jet nozzle 13 connected to the end of the branch pipe 12 of the sextant.

[0048] As the main part of the diversion assembly, the sextant is set up to divide the flota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com