Hydraulic clamp side plate adjusting mechanism

A technology of adjusting mechanism and hydraulic clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below through specific examples.

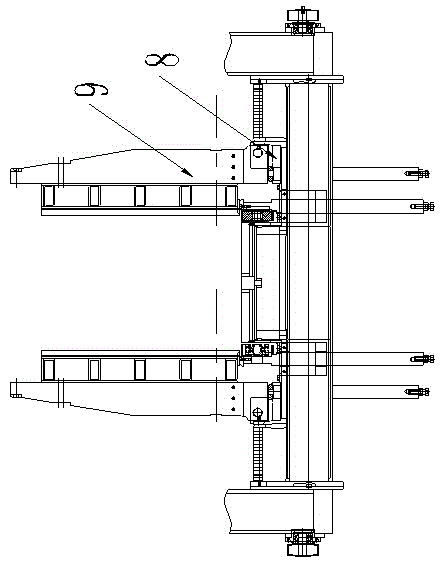

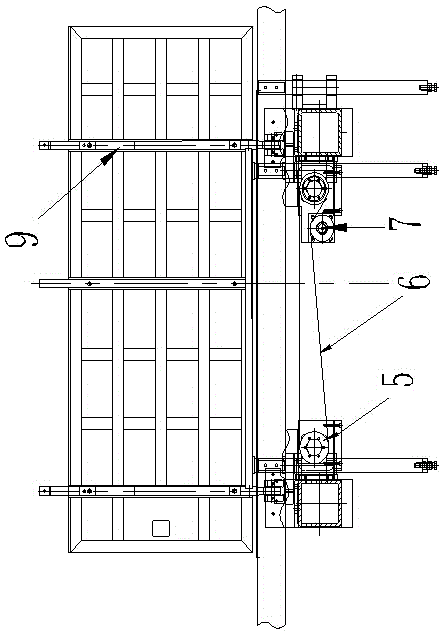

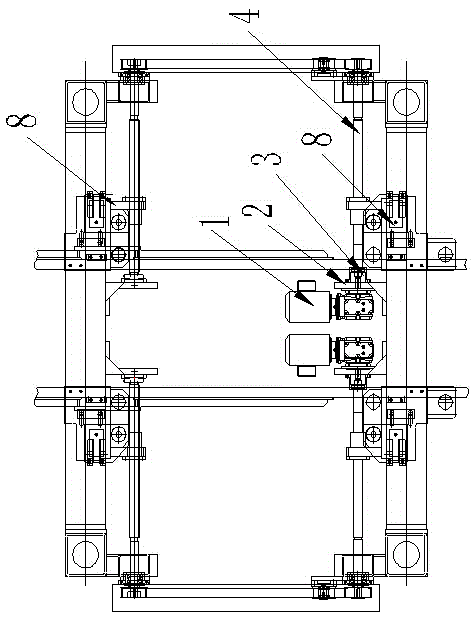

[0017] A hydraulic fixture side plate adjustment mechanism, which includes two vertical side plates 9, a horizontal sliding seat 8, a motor mounting seat 2 for installing and fixing a motor, and a servo motor mounted on the motor mounting seat 2. The motor 1, the coupling 3 connected with the servo motor 1, the other end of the coupling 3 is connected with the trapezoidal screw 4, the trapezoidal screw 4 is connected with the side plate 9 through the sliding seat 8, and the drive adjustment is carried out, and the output of the servo motor The synchronous pulley is driven, and the speed is transmitted through the synchronous belt between the synchronous pulleys, and adjusted by the tensioning pulley.

[0018] The synchronous pulley, synchronous belt, and tensioning pulley are to ensure the synchronous displacement of the front and rear points on the side plate.

[0019] The basic princ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com