Direct connection type shaftless lock up structure

A direct-connected, shaftless technology, used in printing, printing machines, general parts of printing machinery, etc., can solve the problems of troublesome adjustment, complex structure, equipment stability and overprinting accuracy, etc., to improve stability, increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

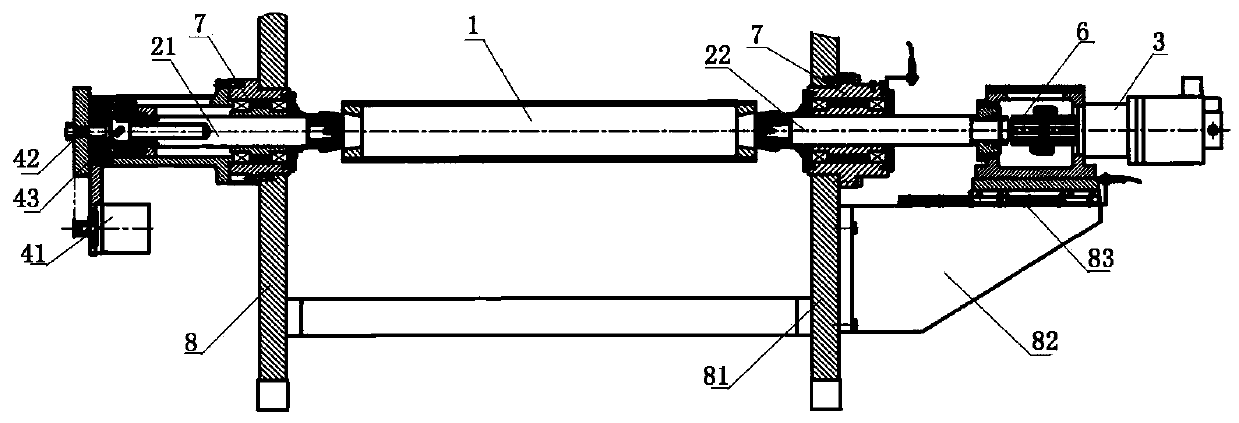

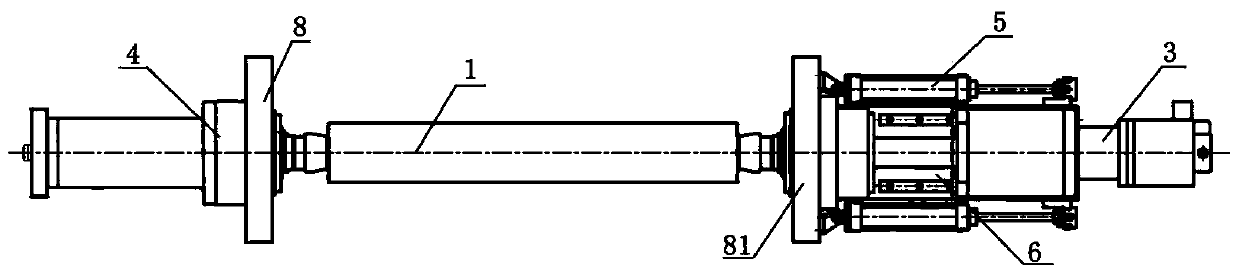

[0017] refer to Figure 1~2 , is shown as the structural representation of the present invention. A direct-connected shaftless plate loading structure, comprising: a printing plate roller 1, a printing plate shaft 2 and a printing plate drive motor 3, the left and right ends of the printing plate roller 1 are connected to the printing plate shaft 2, and the left printing plate shaft The outer end of 21 is provided with a correction motor unit 4, and the outer end of the right printing plate shaft 22 is provided with a cylinder 5, which drives the right printing plate shaft 2 and the printing plate drive motor 3 to move, and the correction motor unit 4 and the cylinder 5 cooperate with each other , so that the printing plate roller 1 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com