Solar energy power machine

A power machine and solar energy technology, which is applied in the direction of generating mechanical power with solar energy, solar thermal power generation, and mechanisms for generating mechanical power. The effect of less transmission clearance and simple transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

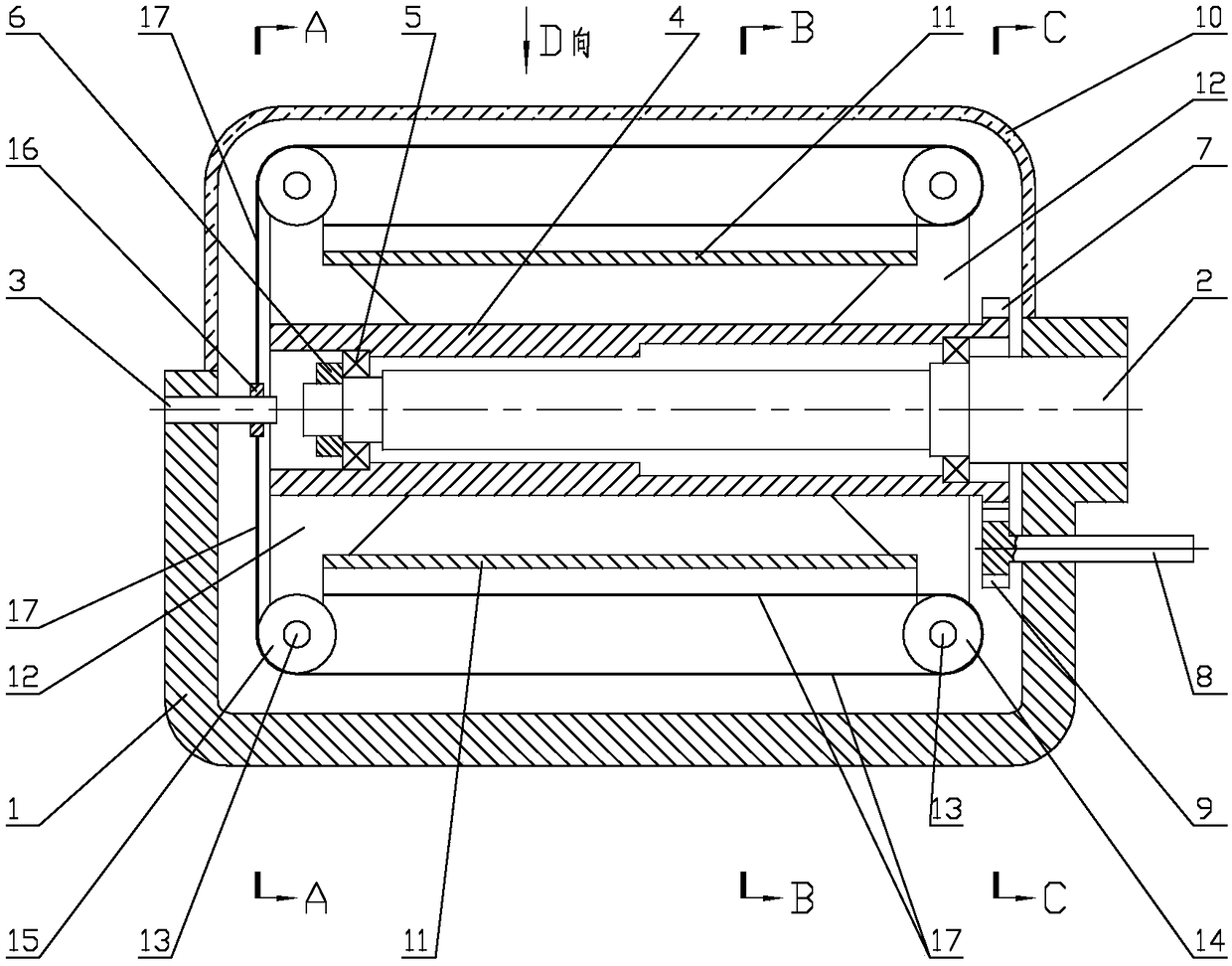

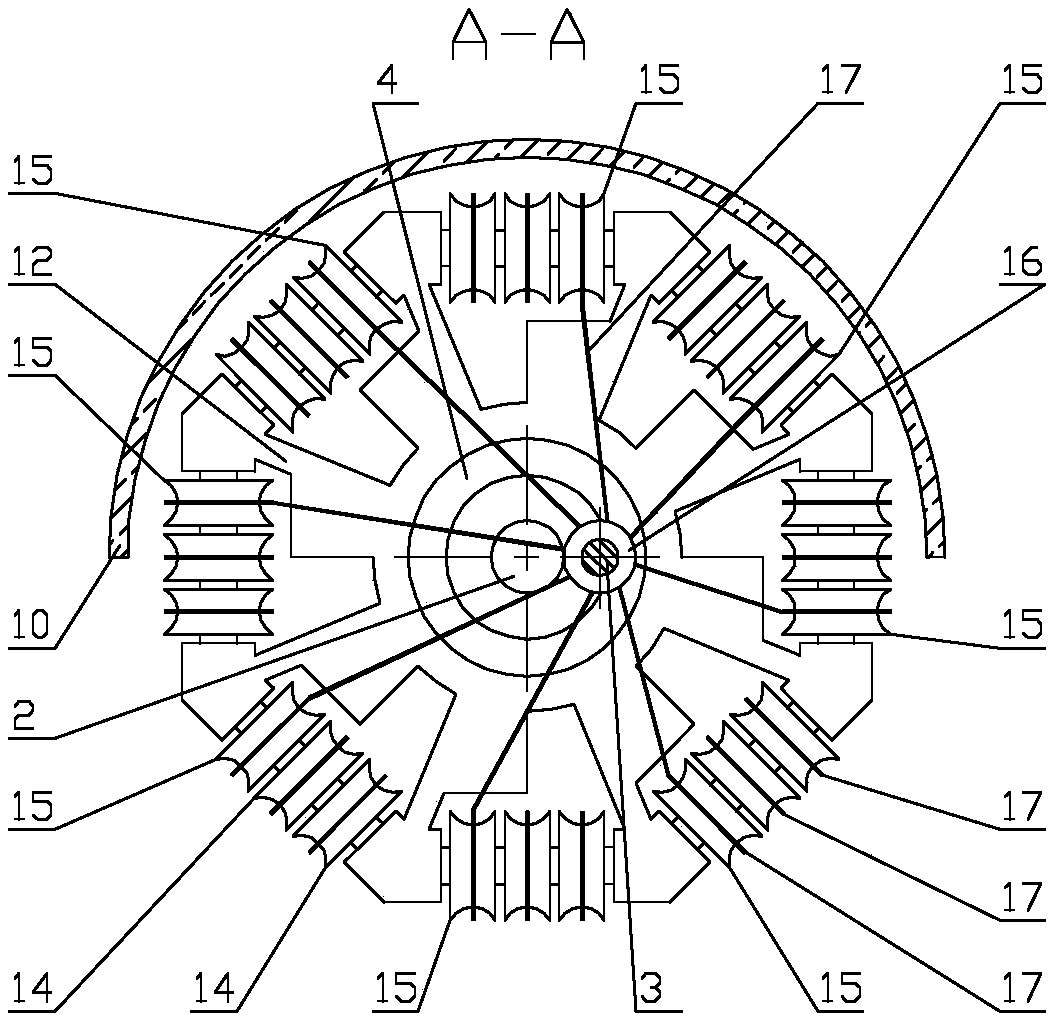

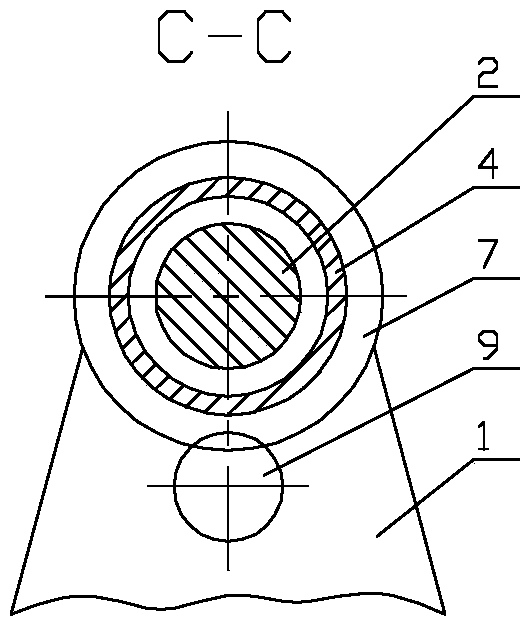

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the solar power machine described in the present embodiment includes: frame 1, main shaft 2, support shaft 3, rotating drum 4, bearing 5, nut 6, bull gear 7, output shaft 8, pinion 9, telescopic mechanism and exposure Type heat collecting cover 10.

[0031] see figure 1 , on the opposite two walls of the open frame 1, the main shaft 2 and the support shaft 3 are respectively provided in the form of a cantilever, and the free end of the main shaft 2 is opposite to the free end of the support shaft 3. The frame 1 of the embodiment is U-shaped, and the main shaft 2 and the supporting shaft 3 are respectively arranged on two opposite walls of the U-shaped frame 1 in the form of a cantilever. The form that the main shaft 2 is located on the frame 1 is preferably fixed. see figure 2 , the axis of the support shaft 3 is parallel to and staggered with the axis of the main shaft 2, the axis of the support shaf...

Embodiment 2

[0047] In order to improve the power output of the solar power machine, on the basis of the solar power machine described in embodiment 1, a steering mechanism is also added, please refer to Figure 7 , Figure 8 , Steering mechanism includes: steering shaft 19 and bogie frame 20.

[0048] see Figure 7 , Figure 8 , the steering shaft 19 is fixed on the frame 1 and the steering shaft 19 is coaxial with the output shaft 8, the steering shaft 19 is suitable for connecting to an external servo drive device, and the steering frame 20 is provided with a supporting On the base of the ground, the bogie frame 20 is respectively provided with holes that are pivotally hinged with the output shaft 8 and pivotally hinged with the steering shaft 19 .

[0049] The working principle and beneficial effects of the steering mechanism: see Figure 7 , Figure 8 , in order to make the solar power machine of the present invention maintain a higher power output, the heat collecting cover 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com