Geometric design method for cross shaft straight-teeth conical gear pair with changeable transmission ratio

A technology of straight bevel gears and variable transmission ratios, applied in transmissions, gear transmissions, belts/chains/gears, etc., can solve the problems of approximation evaluation, short transmission ratio change period, and small transmission ratio change range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

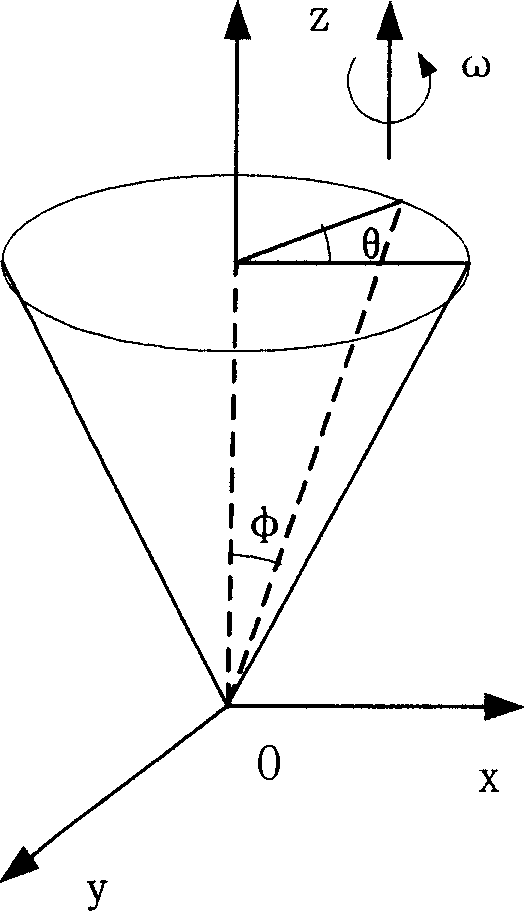

Method used

Image

Examples

Embodiment 1

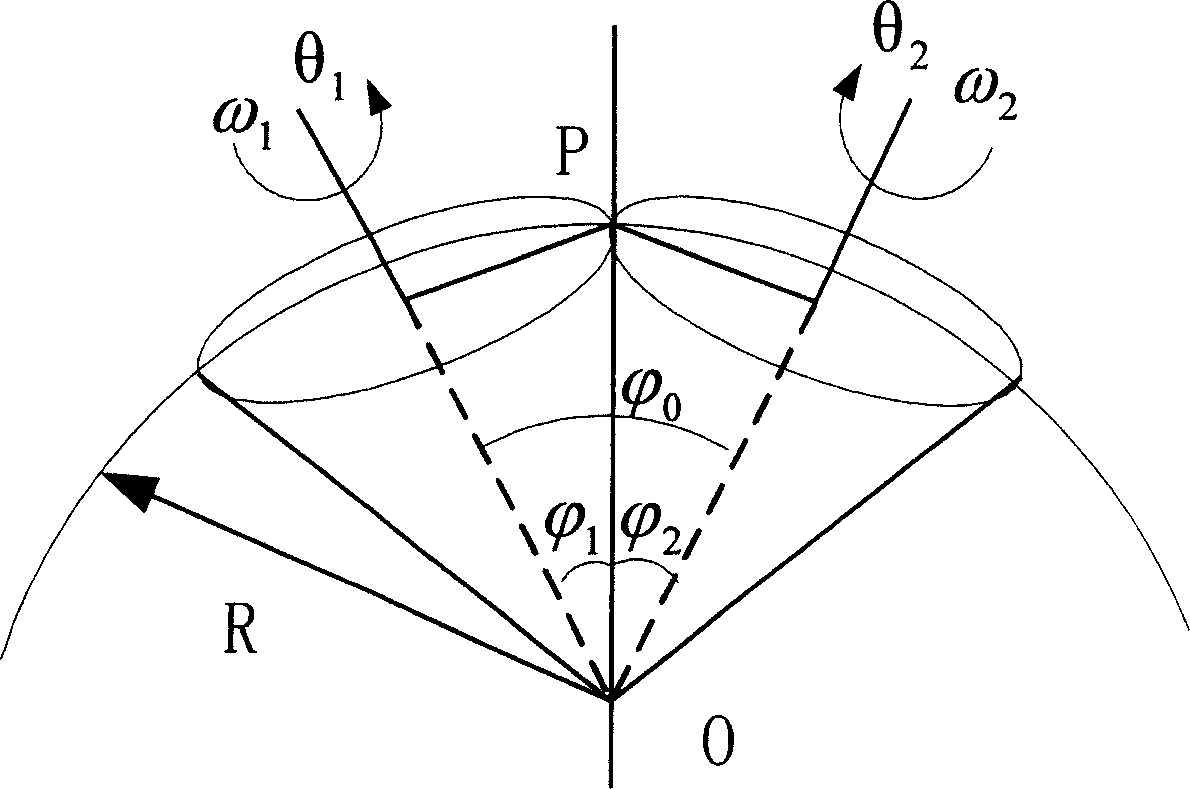

[0077] Embodiment 1: Parameter design, solid modeling and rapid prototyping of a pair of non-conical gears Take a non-conical gear pair with an included angle of 60° and satisfy the following transmission relationship as an example: f(θ 1 )=1.1558+0.5795cos(2θ 1 )

[0078] From step (1), the equations of the pitch cone surfaces of the driving and passive wheels can be expressed as:

[0079]

[0080] From step (2), the number of teeth is selected as z=21, the coefficient of addendum height is f=1, the coefficient of backlash is c=0.2, and the die angle is α m = π 20 , The entire nodal surface is convex.

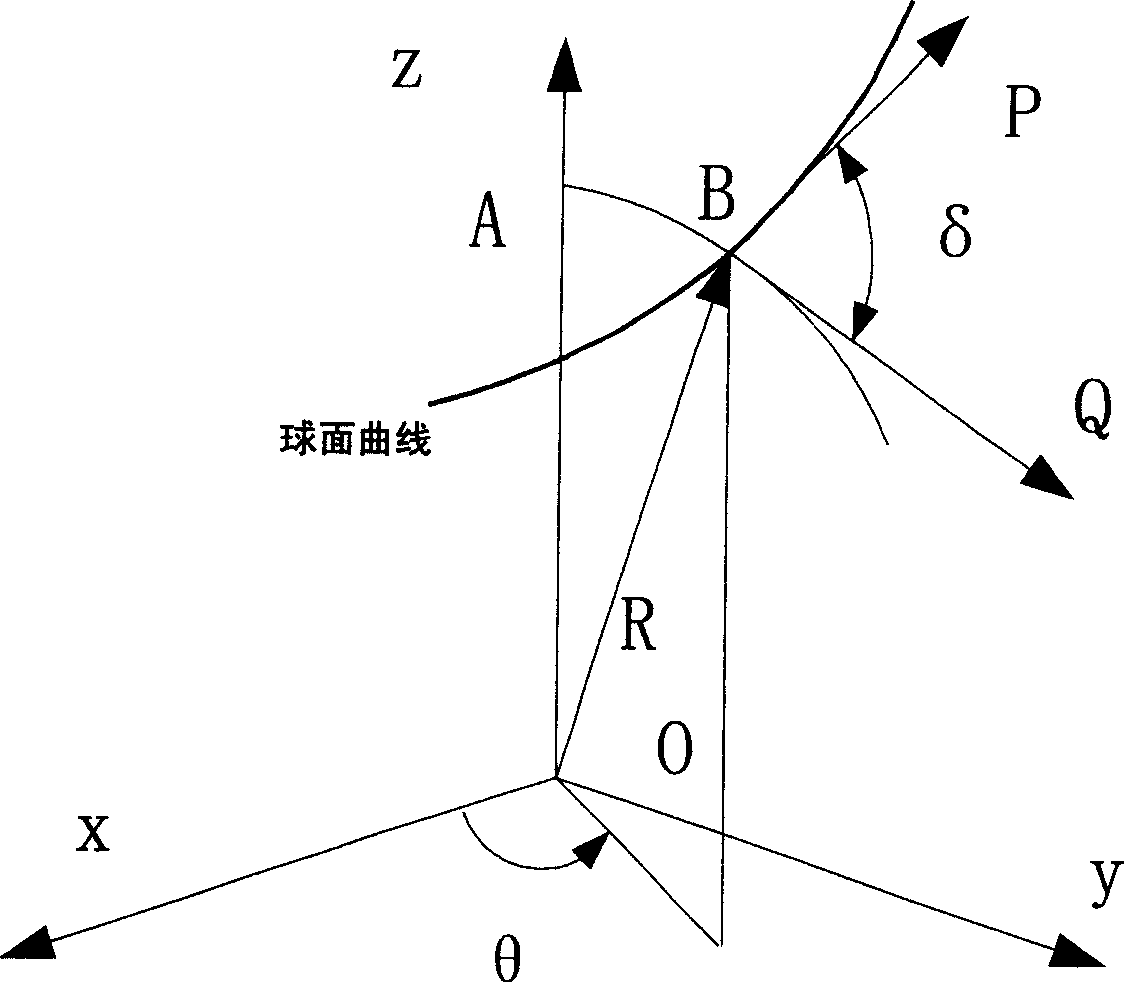

[0081] By numerical calculation in step (3), the pitch cone, tooth top cone and tooth bottom cone curves of the non-conical gear on a certain spherical surface can be obtained (such as Figure 8 ) and tooth profile distribution (such as Figure 9 ).

[0082] From step (4...

Embodiment 2

[0084] Embodiment 2: Parameter design and solid model generation of non-conical gear differential

[0085] Here non-bevel gears are used to design the side gears and planetary gears of the differential. Taking the transmission ratio function relationship of n-stage bevel gears as a reference, and considering the symmetry of the differential mechanism, the side gears are 3-stage bevel gears, and the planetary gears are 2-stage bevel gears (oval gears). The designed transmission ratio relationship is as follows:

[0086] f ( θ 1 ) = 2 3 ( 1 + 2 e cos ( 3 θ 1 ) + e ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com