Method and device for printing substrates

A technology for printing materials and printing machines, which is applied to printing devices, general parts of printing machinery, printing, etc., and can solve problems such as the quality influence of ink volume and ink strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

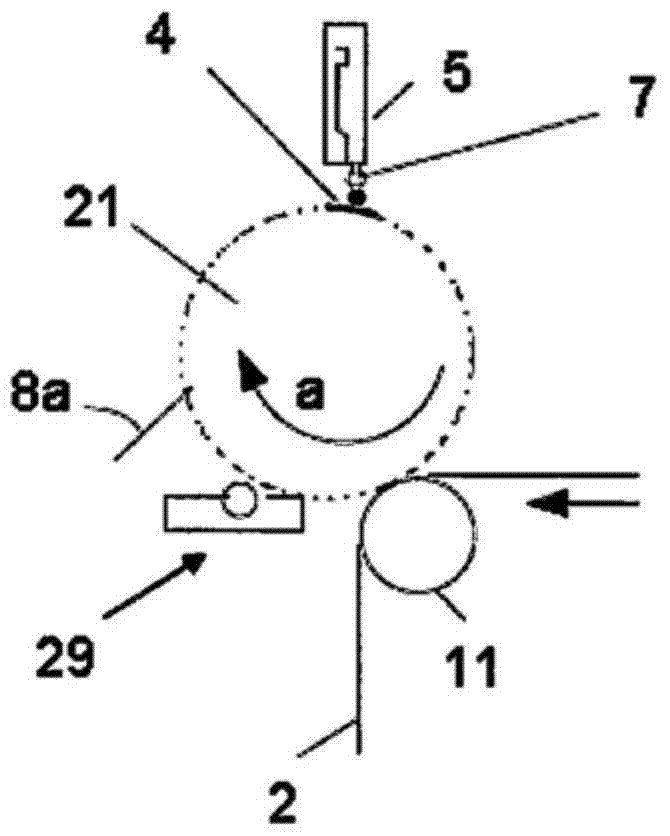

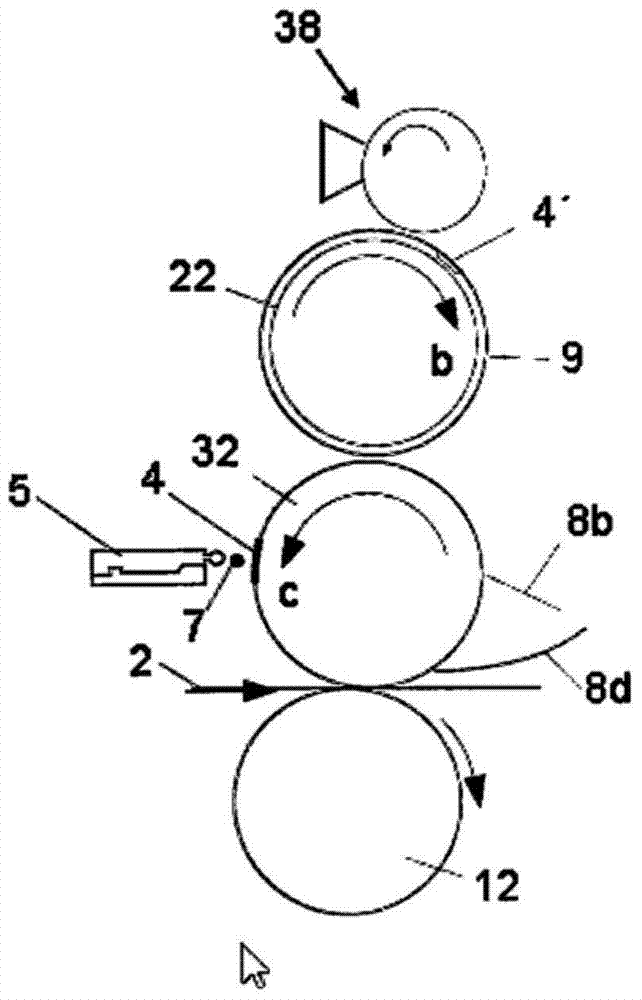

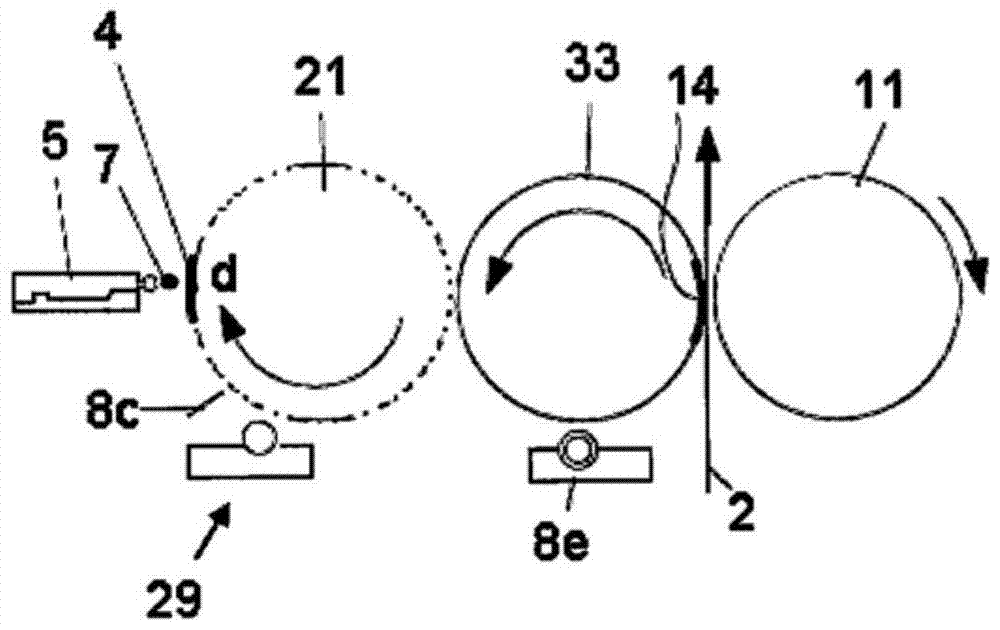

[0032] Such as figure 1 As shown, a first printing press cylinder in the form of an impression cylinder 11 and a second printing press cylinder in the form of an intaglio printing cylinder 21 cooperate in an intaglio printing unit, through which the printing material web 2 passes in a known manner. Between two printing press cylinders. The gravure printing cylinder 21, which rotates in the region of the schematically shown inking unit 29 for inking the cylinder, has on its surface a plurality of pit-shaped depressions, not shown in detail, which are formed during the inking process. The ink unit 29 receives ink therein, which is transferred to the printing material web 2 to produce a first immutable printed image. The intaglio printing cylinder 21 also has on its surface an ink-free circumferential section 4 in which no depressions or wells are formed to receive printing ink in the inking unit 29 . Here, if figure 1 As shown schematically in the figure, when the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com