Concave surface high-precision repeated overprinting method and blind hole printing machine

A high-precision, printing press technology, used in printing presses, rotary printing presses, general-purpose parts of printing machinery, etc., can solve the problems of low overprinting accuracy, and the center point cannot be highly overlapped, and achieve the effect of high overprinting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

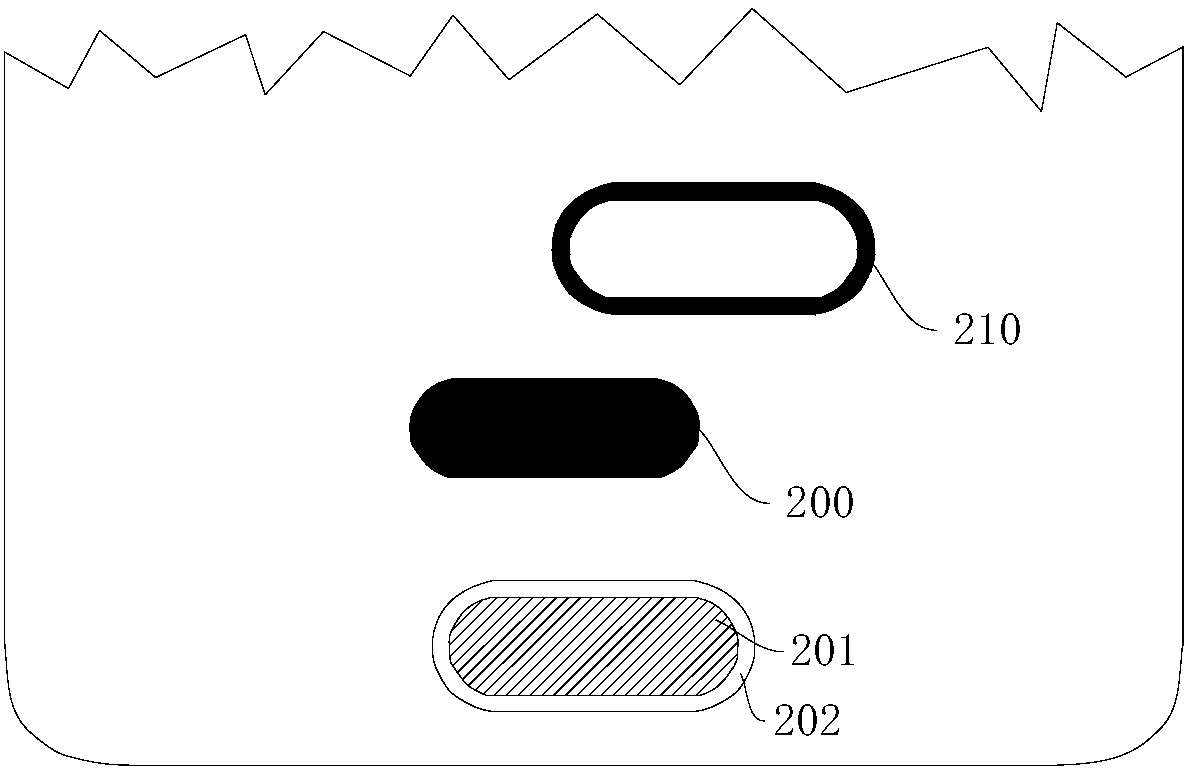

[0080] refer to figure 1 , Embodiment 1 of the present invention provides a method for repeated overprinting of concave surfaces with high precision. The method is mainly aimed at blind holes on cover plates of electronic products. The method includes the following steps:

[0081] Wherein, the steps of printing the first pattern are:

[0082] Step S1, using the blind hole positioning mechanism to grab the bottom of the blind hole or the aperture halo, and automatically record its first center coordinates X00, Y00 and R00;

[0083] Step S2, collect the first pattern 210 matching the bottom 201 of the blind hole from the ink-taking mechanism, and print it on the cover plate of the electronic product;

[0084] Step S3, using the blind hole positioning mechanism to capture the data of the second center coordinates X1, Y1 and R1 of the first pattern 210 on the cover;

[0085] Step S4, obtain the difference between the second center coordinates X1, Y1, R1 of the first pattern 210 ...

Embodiment 2

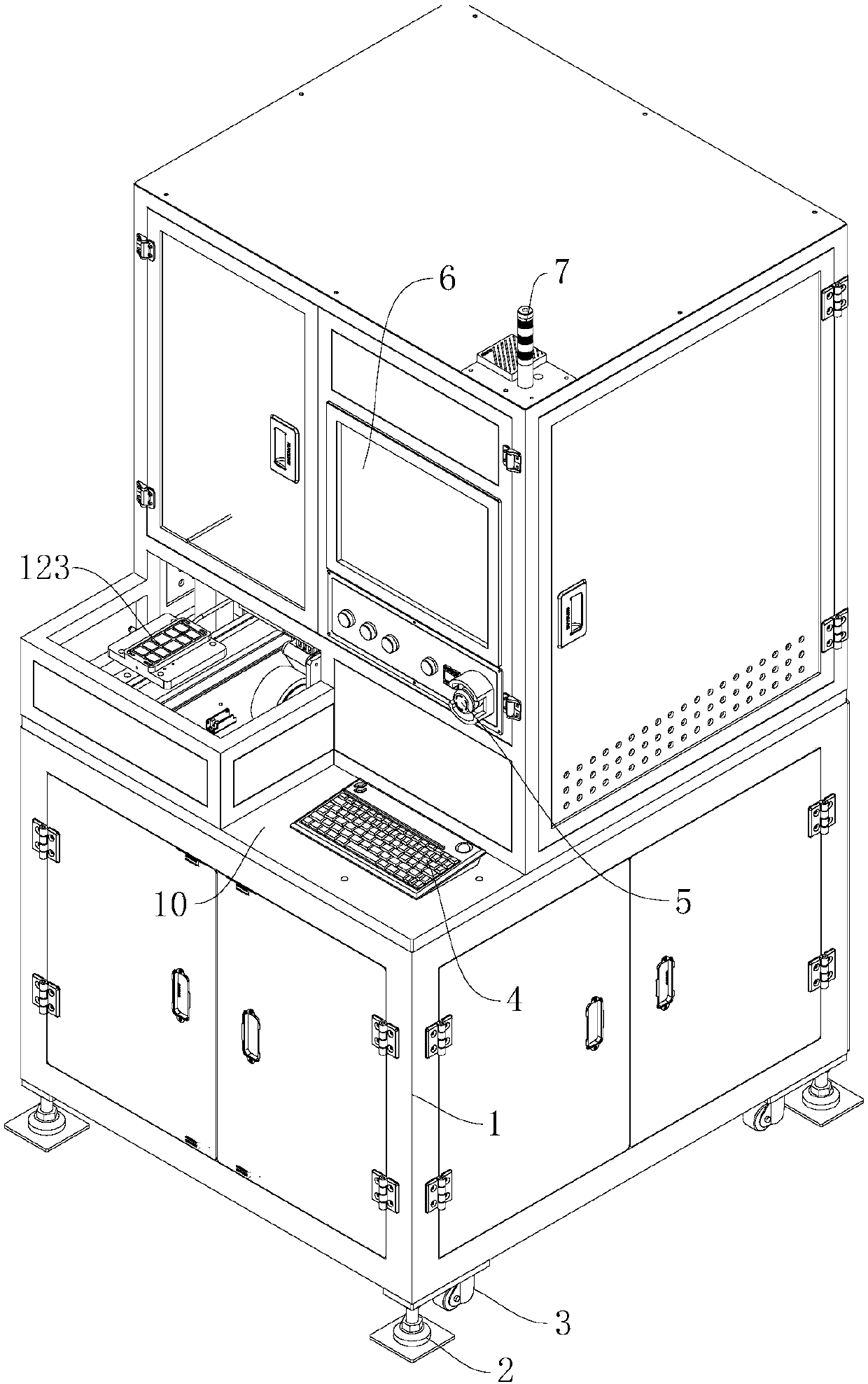

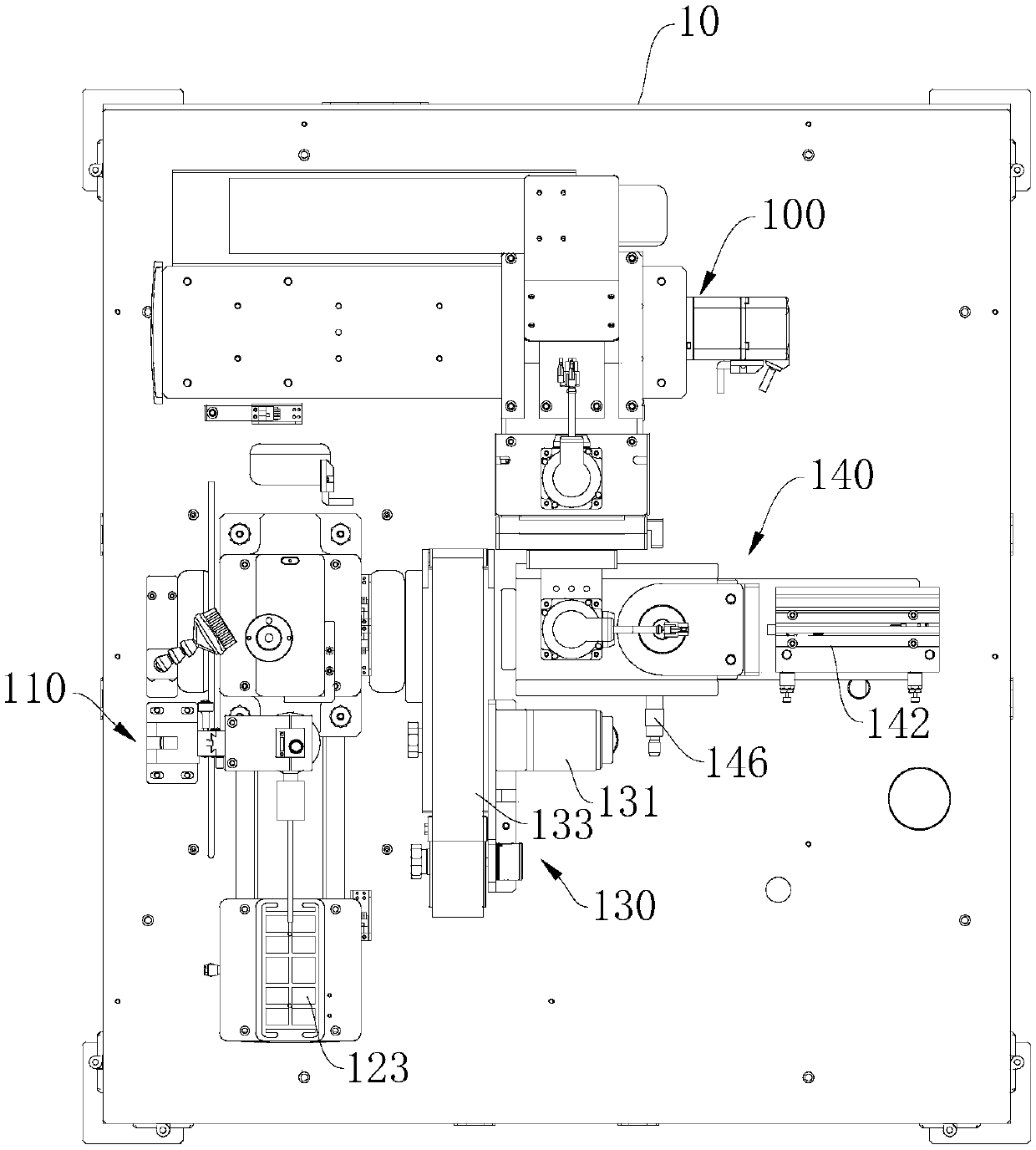

[0098] combine figure 2 , image 3 , Figure 4 and Figure 5 The embodiment of the present invention also provides a blind hole printing machine, which includes a frame 1, a support table 10, a Y-axis linear module, a workbench 123, a blind hole positioning mechanism 110, an ink taking mechanism 140, a moving Printing mechanism 100 and rubber head cleaning mechanism 130. Wherein, the frame 1 is a basic component of the blind hole printing machine, and it is used for installing the support table 10 . In addition, the blind hole printing machine also includes support feet 2, transfer pulleys 3, keyboard 4, emergency stop button 5, touch screen 6, three-color indicator light 7, and the support feet 2 and transfer pulleys 3 are arranged on the far side of the frame 1. One side of the support platform 10, the keyboard 4 is installed on the support platform 10, the emergency stop button 5 is used for the emergency stop operation of the blind hole printing machine, and the touch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com