A bottle silk screen printing process using a circular conveying line

A cycle conveying and working line technology, applied in printing, printing device, printing post-processing, etc., can solve problems such as low work efficiency, transmission errors, high failure rate, etc., and achieve high overprint accuracy, safety, reliability, noise, and low failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described further with specific embodiment below:

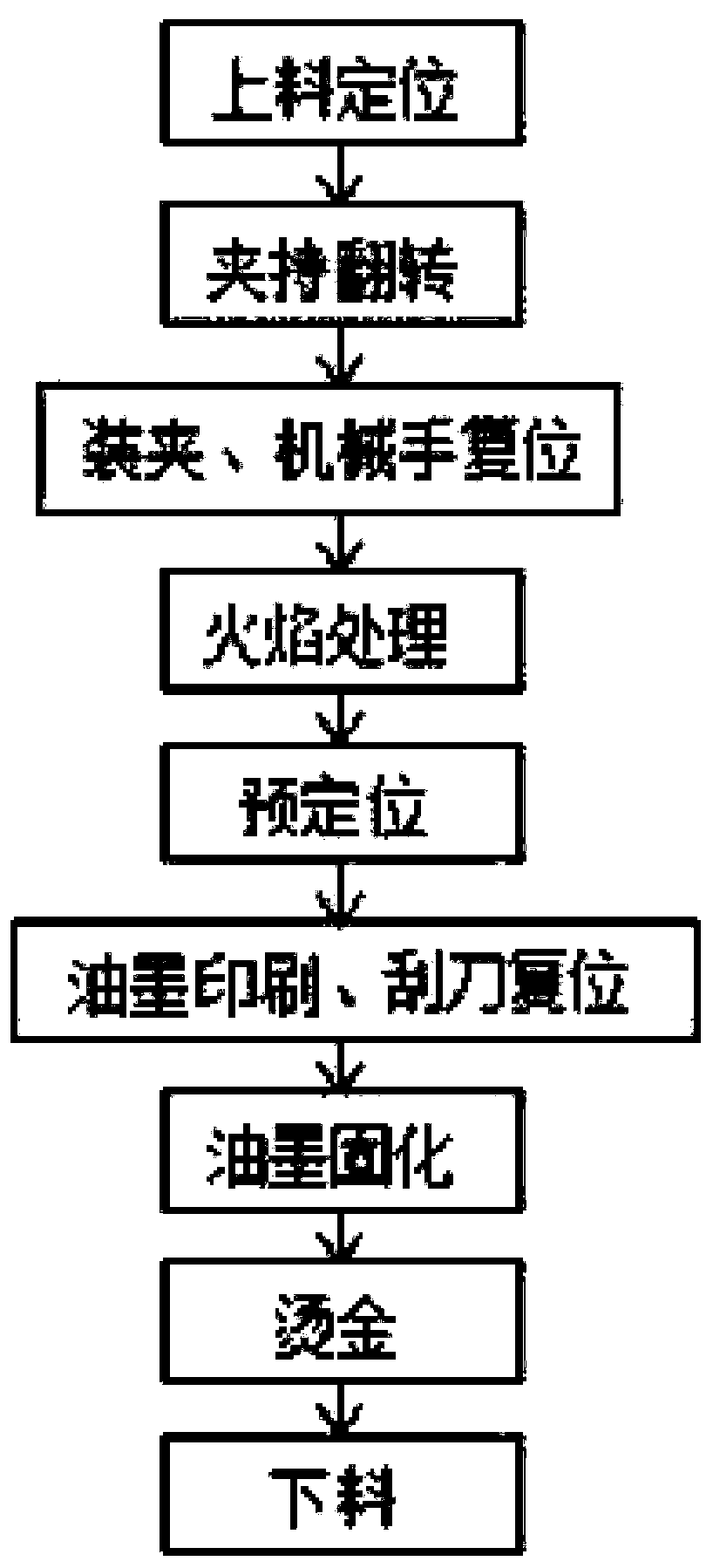

[0029] see figure 1 Shown, a kind of bottle body silk screen printing process that uses circular conveying work line, it comprises the following steps:

[0030] a, Loading positioning: place the bottle to be printed vertically on the conveyor belt, and the bottle to be printed will move along the conveyor belt to the circular conveying line. The body is still at the position of taking the bottle;

[0031] b. Clamping and flipping: the feeding manipulator set at the end of the conveyor belt stretches out to hold the bottle to be printed, and after holding the bottle to be printed, the feeding manipulator returns and turns the bottle to the top of the circulating conveying line;

[0032] c. Clamping and manipulator reset: There is a mover on the circulating conveying line, and the fixture installed on the mover is opened. When the feeding manipulator loads the bottle to be printed to the fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com