Cooling flat-type bronzing machine with three colored tapes

A hot stamping machine, flat technology, applied in printing presses, rotary printing machines, printing and other directions, can solve the problems of complex and heavy structure, low work efficiency, poor color registration accuracy, etc., to improve the hot stamping speed, good hot stamping effect, vibration small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with specific examples.

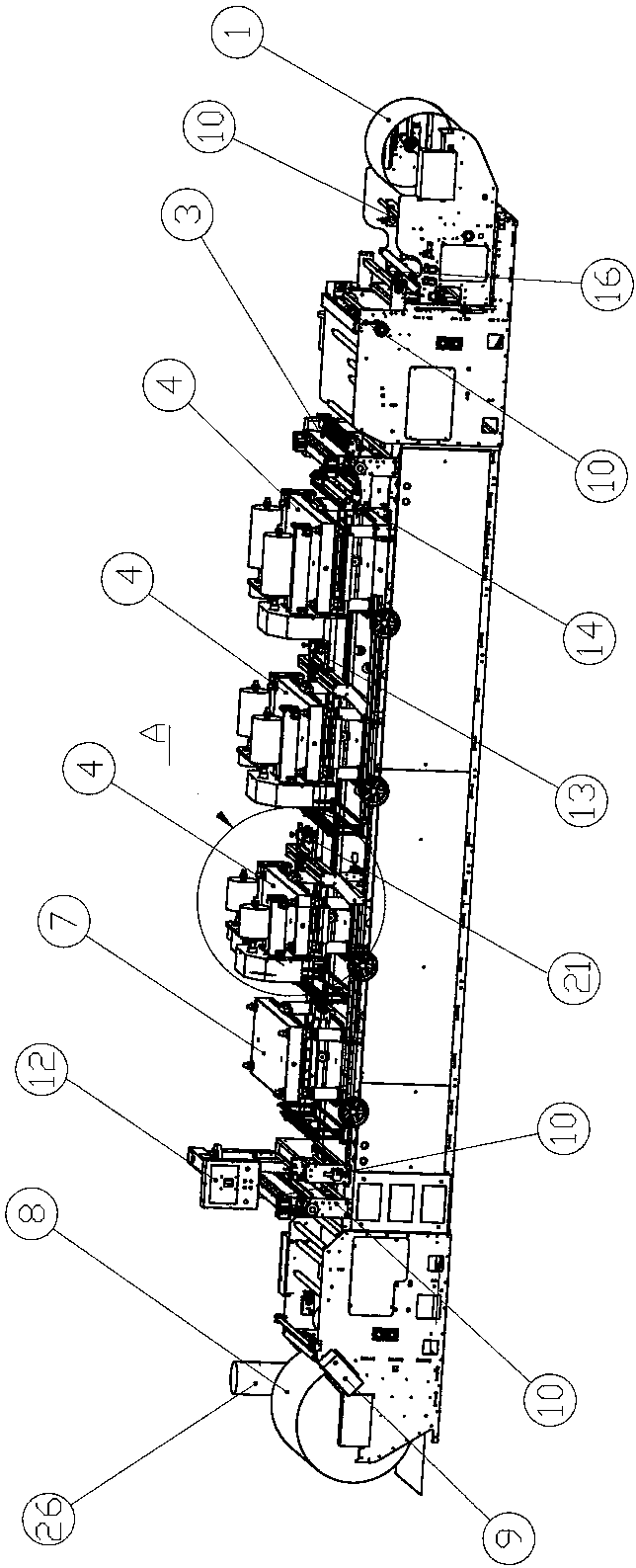

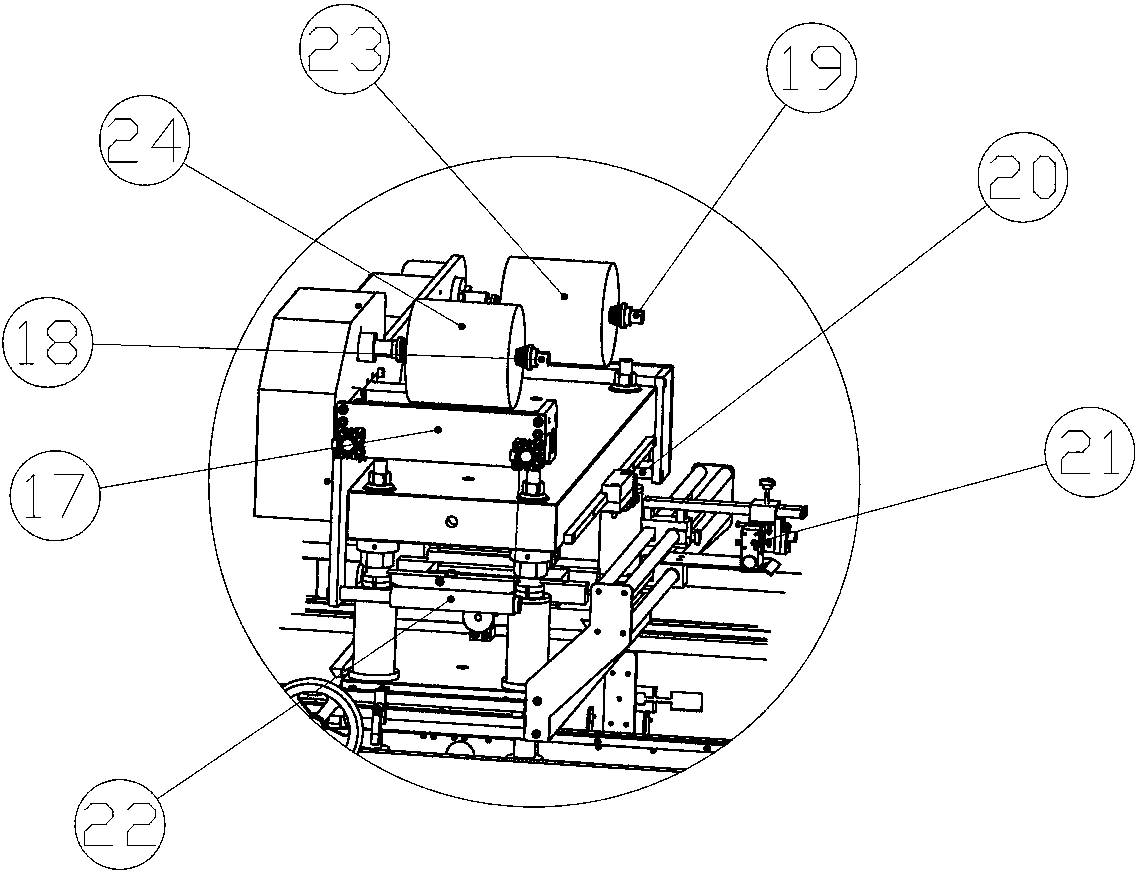

[0012] Such as Figure 1-2 As shown, the three-color belt cooling flat stamping machine, the main frame body 30 is fixed on the unwinding 1 and the winding 8 and the conveying roller 10 between the unwinding 1 and the winding 8, and is driven by the motor 26 to transport the bronzing Paper, three hot stamping parts 4 and cooling parts 7 are fixed sequentially on the main frame along the traveling direction of the paper to be hot stamped. The upper part of the hot stamping part 4 is provided with an unwinding shaft 19 and a winding shaft 18 in parallel, and the lower part is provided with a first separating roller 20 and a second Two separating rollers 22, a drawing roller 17 is arranged under the winding shaft 18, and a heating unit and a drying unit are built in the bronzing part 4. The front end of the unwinding 1 is provided with a deviation correction sensor 16 adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com