A kind of water-based anodized aluminum adhesive resin with high adhesion and high temperature resistance and preparation method thereof

A kind of anodized aluminum, high temperature resistant technology, applied in the direction of adhesive type, nitrile copolymer adhesive, ester copolymer adhesive, etc., can solve the problem of poor heat resistance stability and bonding and curing performance, which affects anodized aluminum Problems such as hot stamping performance, sticky peeling strength and the range of applicable substrates, etc., to reduce the phenomenon of implosion and gelation, broaden the range of applicable substrates, and ensure the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

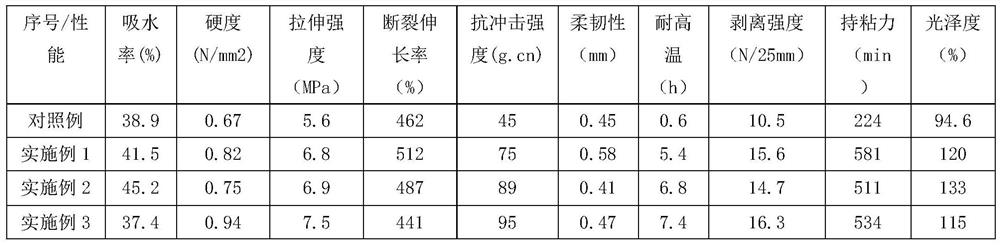

Examples

Embodiment 1

[0018] A kind of preparation method of water-based anodized aluminum adhesive resin with high adhesion and high temperature resistance, wherein, its preparation method is as follows:

[0019] (1) Add 25 parts of acrylonitrile, 34 parts of diethylaminoethyl methacrylate, 43 parts of hydroxypropyl acrylate, 5 parts of emulsifier, and 11 parts of deionized water into the stirring tank by mass fraction. It is composed of alkylphenol polyoxyethylene ether and polyoxyethylene dodecylphenyl ether in a mass ratio of 1:1, stirred and mixed at 230r / min for 40min, and emulsified into a seed pre-emulsion;

[0020] (2) under nitrogen atmosphere, add mass ratio and account for seed pre-emulsion total amount 10% seed pre-emulsion, mass fraction be 7 parts of deionized water and the initiator that mass fraction is 0.08 part in polymerizer, be warming up to 65°C and constant temperature, reflux reaction for 35min;

[0021] Raise the temperature to 82°C and add the remaining seed pre-emulsion ...

Embodiment 2

[0023] A kind of preparation method of water-based anodized aluminum adhesive resin with high adhesion and high temperature resistance, wherein, its preparation method is as follows:

[0024] (1) Add 21 parts of acrylonitrile, 24 parts of diethylaminoethyl methacrylate, 52 parts of hydroxypropyl acrylate, 6 parts of emulsifier, and 10 parts of deionized water into the stirring tank by mass fraction. It is fatty alcohol polyoxyethylene polyoxypropylene ether, stirred and mixed at 240r / min for 50min, and emulsified into seed pre-emulsion;

[0025] (2) under nitrogen atmosphere, add mass ratio and account for seed pre-emulsion total amount 10% of seed pre-emulsion, mass fraction be 6 parts of deionized water and the initiator that mass fraction is 0.04 part in polymerizer, be warming up to 70°C and constant temperature, reflux reaction for 40min, the initiator is composed of potassium persulfate and ammonium bisulfite in a mass ratio of 1:1;

[0026] Raise the temperature to 83°...

Embodiment 3

[0028] A kind of preparation method of water-based anodized aluminum adhesive resin with high adhesion and high temperature resistance, wherein, its preparation method is as follows:

[0029] (1) Add 29 parts of acrylonitrile, 27 parts of diethylaminoethyl methacrylate, 38 parts of hydroxypropyl acrylate, 4 parts of emulsifier, and 13 parts of deionized water into the stirring tank by mass fraction. It is composed of polyoxyethylene dodecyl phenyl ether and polyoxyethylene octyl phenol ether in a mass ratio of 1:1, stirred and mixed for 30 minutes at 210r / min, and emulsified into a seed pre-emulsion;

[0030] (2) under nitrogen atmosphere, add mass ratio and account for seed pre-emulsion total amount 10% of seed pre-emulsion, mass fraction be 6 parts of deionized water and the initiator that mass fraction is 0.06 part in polymerizer, be warming up to 65°C and constant temperature, reflux reaction for 35 minutes, the initiator is composed of sodium persulfate, potassium persulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com