Pearlescent transfer film as well as preparation method and application thereof

A transfer film and pearlescent technology, which is applied in the field of preparation and application of pearlescent transfer film and its preparation method, can solve the problems of limiting the scope of high-demand applications, poor surface scratch resistance, and difficulty in meeting market demands, etc. Excellent adhesion, good water resistance, brilliant color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

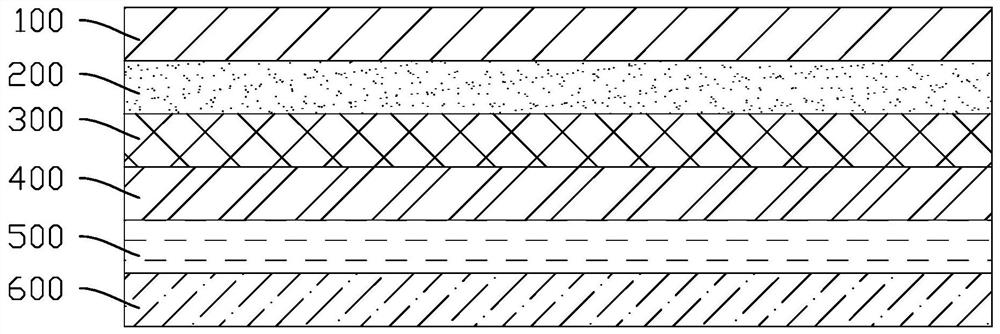

[0057] The pearly luster transfer printing film of embodiment 1-4, from top to bottom is substrate layer 100, UV release layer 200, stabilizer layer 300, pearly luster graphic layer 400, ink graphic layer 500, adhesive layer 600; The material layer 100 is a PET film; the UV release layer 200 is made of UV varnish; the stabilizer layer 300 is made of a stabilizer; the pearlescent graphic layer 400 is made of a pearlescent binder; the ink graphic layer 500 is made of ink; the adhesive layer 600 Constructed of hot melt adhesive.

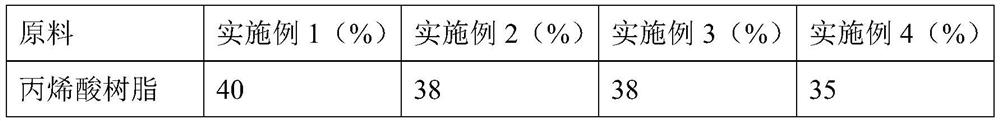

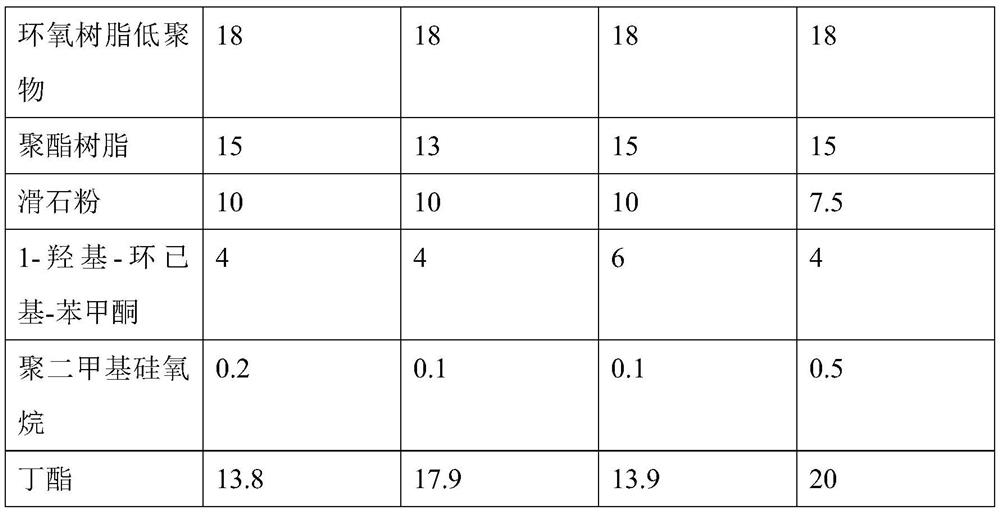

[0058] The UV varnish of embodiment 1-4 is carried out by the component of weight percent shown in table 1:

[0059] Table 1

[0060]

[0061]

[0062] The preparation method of the UV varnish of embodiment 1-4, comprises the following steps:

[0063] (1) Add resin monomers including acrylic resin, epoxy oligomer and polyester resin, 1-hydroxy-cyclohexyl-benzophenone and butyl ester into the reaction kettle, and set the reaction temperature at 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com