Satellite intaglio printing method

A gravure printing and satellite technology, applied in the field of textile printing, can solve the problems of multi-color and precise overprinting that cannot meet the direct printing process, and achieve the effects of saving the use of OPP film, simple printing process, and high overprinting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

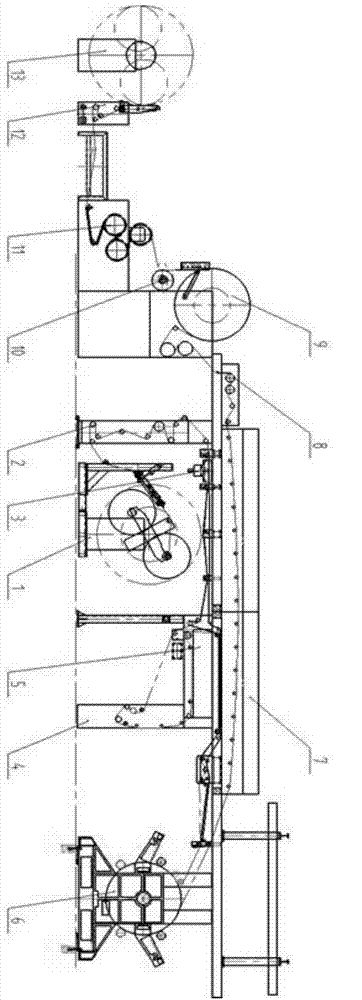

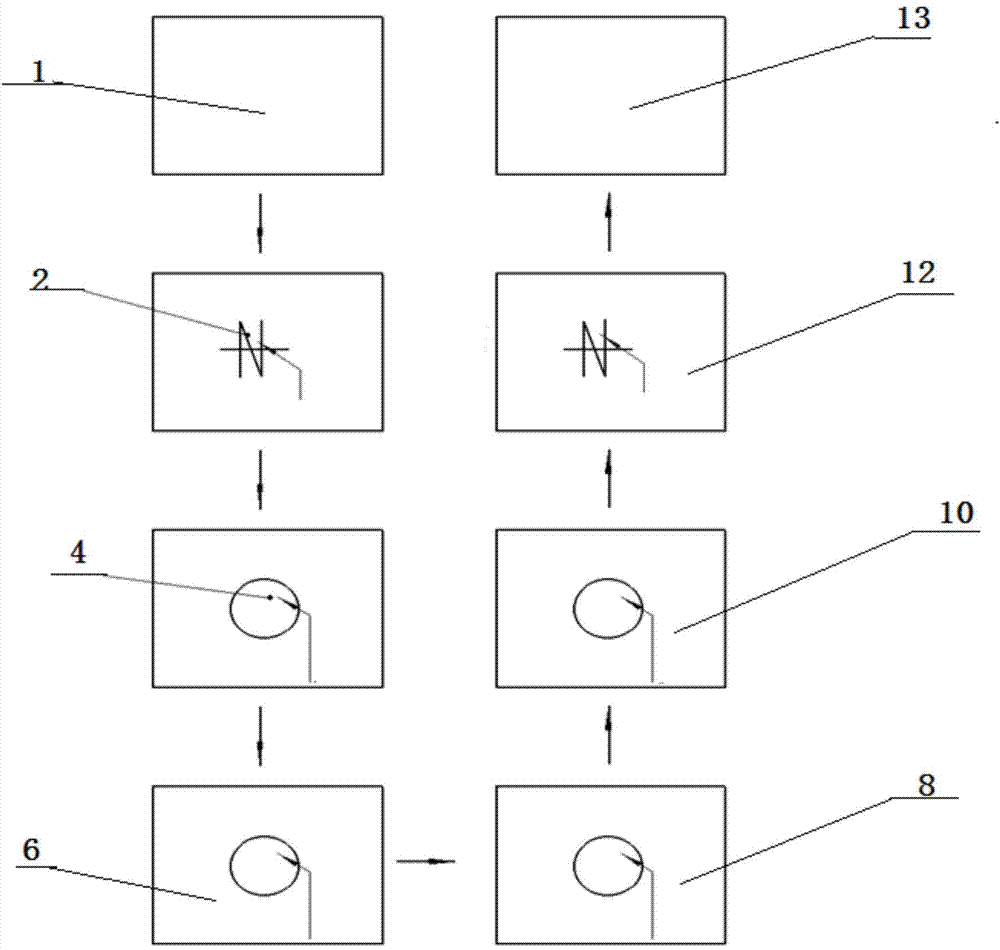

[0017] Satellite gravure printing method of the present invention, as figure 1 and figure 2 As shown, it includes the following steps, the substrate passes through the pendulum roller 14 in the traction unit 2 from the discharge unit 1, enters the corona treatment unit 3 after the tension reaches a predetermined state, and then enters the separate coating unit 4 for corona treatment. The substrate is printed with the background color, and then the coating drying unit 5 dries it, and the substrate with the background color enters the satellite gravure printing unit 6 for four-color printing, and then the top drying unit 7 dries the substrate. After the substrate is dried and passed through the top water cooling unit 8 to lower its temperature, it is then subjected to deep embossing treatment through the deep embossing unit 10. The deep embos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com