Automatic precise punching device and operation method thereof

A punching device and precise technology, applied in metal processing and other directions, can solve the problems of affecting printing efficiency, low punching accuracy, etc., to improve printing efficiency and automation, reduce manual overprinting instability problems, and overprint accurate effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

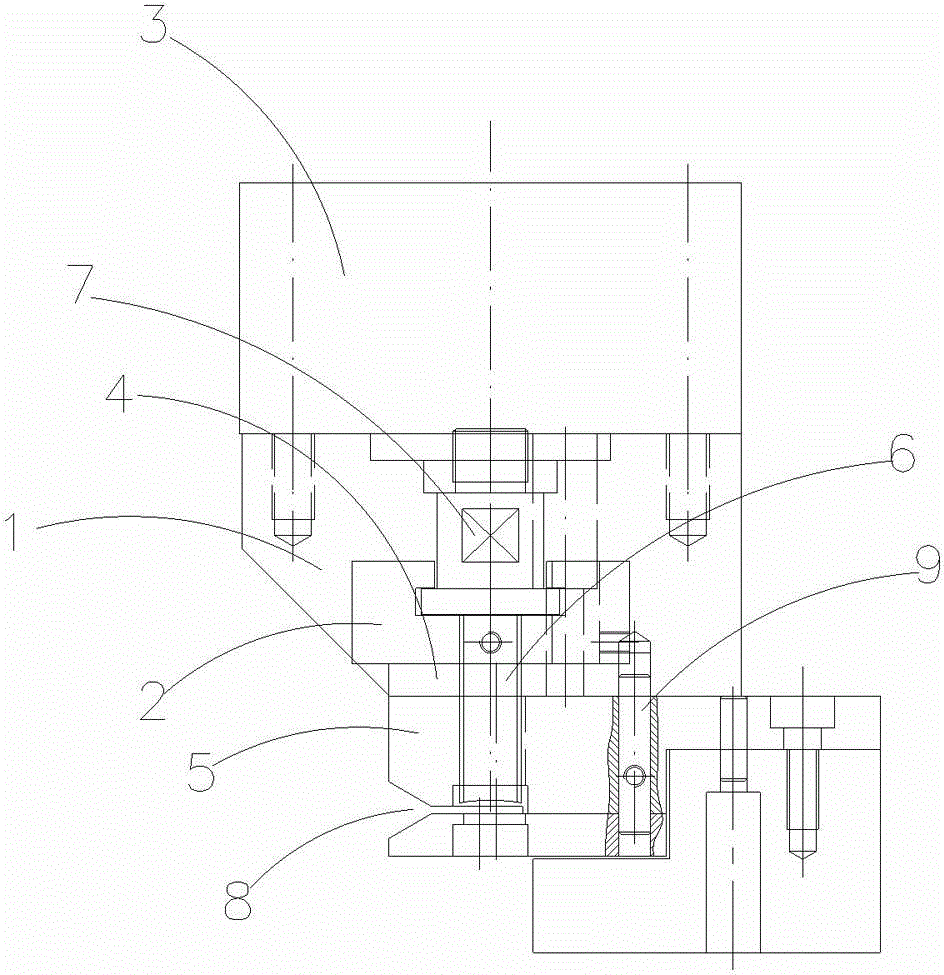

[0025] Embodiment 1: as figure 1 As shown, an automatic precision punching device includes a punching die connecting side plate 1 and a punching cylinder connecting plate 2, the upper end of the punching die connecting side plate 1 is provided with a punching cylinder 3, and the punching cylinder connecting plate 2 is located at the lower end of the die connecting side plate 1, the bottom of the punching cylinder connecting plate 2 is fixedly connected with the die upper plate 4, the bottom of the die upper plate 4 is provided with a die lower plate 5, and the The upper die plate 4 and the lower die plate 5 are provided with a punch 6, the upper end of the punch 6 is fixedly connected with the punching cylinder 3 through a connecting screw 7, and the lower die plate 5 is provided with a punching hole for positioning Horizontal groove 8.

[0026] The lowest end of the punch 6 is located above the punching positioning transverse groove 8, and the movable gaps between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com