Method for manufacturing colorful flexible printing corrugated paper box

A manufacturing method and technology of flexo printing tiles, which are applied in the field of corrugated cartons, can solve problems such as difficulty in satisfying color stability and fullness, insufficient overprinting accuracy of printed products, and low vividness of printed products, and achieve stable and full color, glossy The effect of good degree and clear printing pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

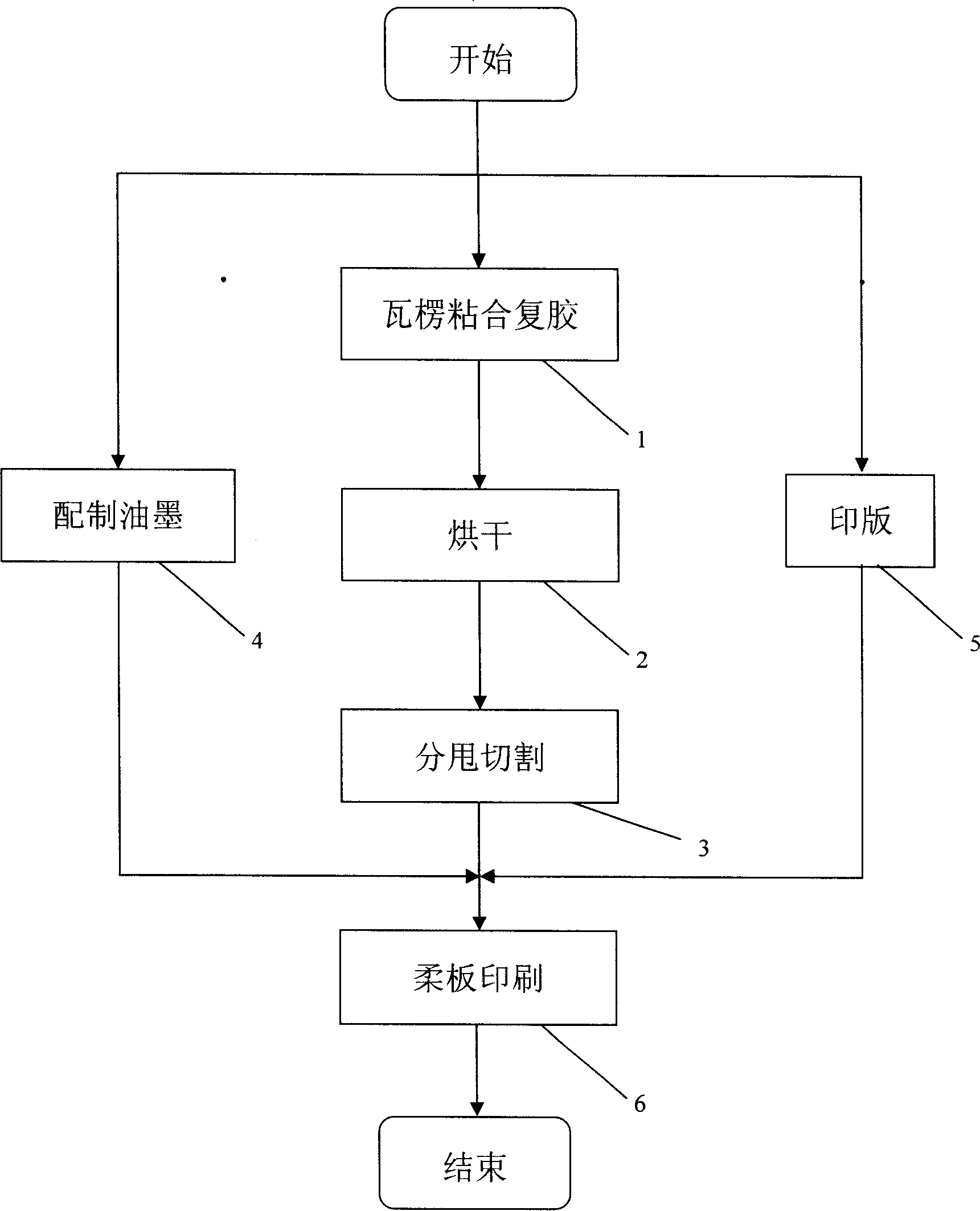

[0022] figure 1 It is a flow chart of the manufacturing method of the color flexo printing corrugated cardboard box of the present invention. Including the following steps:

[0023] Corrugated adhesive compounding glue 1: select surface paper weight ≥ 250g / m 2 , transverse folding resistance ≥ 50 times, water content 8 ± 2%, water absorption not greater than 60g / m 2 Corrugated cardboard, three-layer, five-layer or seven-layer corrugated board is bonded with adhesive and then glued;

[0024] Drying 2: send the glued corrugated cardboard into the drying box for drying;

[0025] Separation and cutting 3: Cut the corners of the dried corrugated cardboard neatly and divide them into required sizes;

[0026] Prepare ink 4: prepare ink with a viscosity of 15 seconds, a coloring rate of 90-100%, a fineness of ≤25, and a pH value of 7-9; the prepared ink is a transparent water-based ink.

[0027] Printing plate 5: Make a film according to the designed pattern, and then print the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com