PCB clamping mechanism

A technology of PCB board and clamping mechanism, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of inconvenient loading and unloading of PCB boards, affect the detection structure, and reduce work efficiency, so as to achieve simple structure and ensure the shooting of images , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

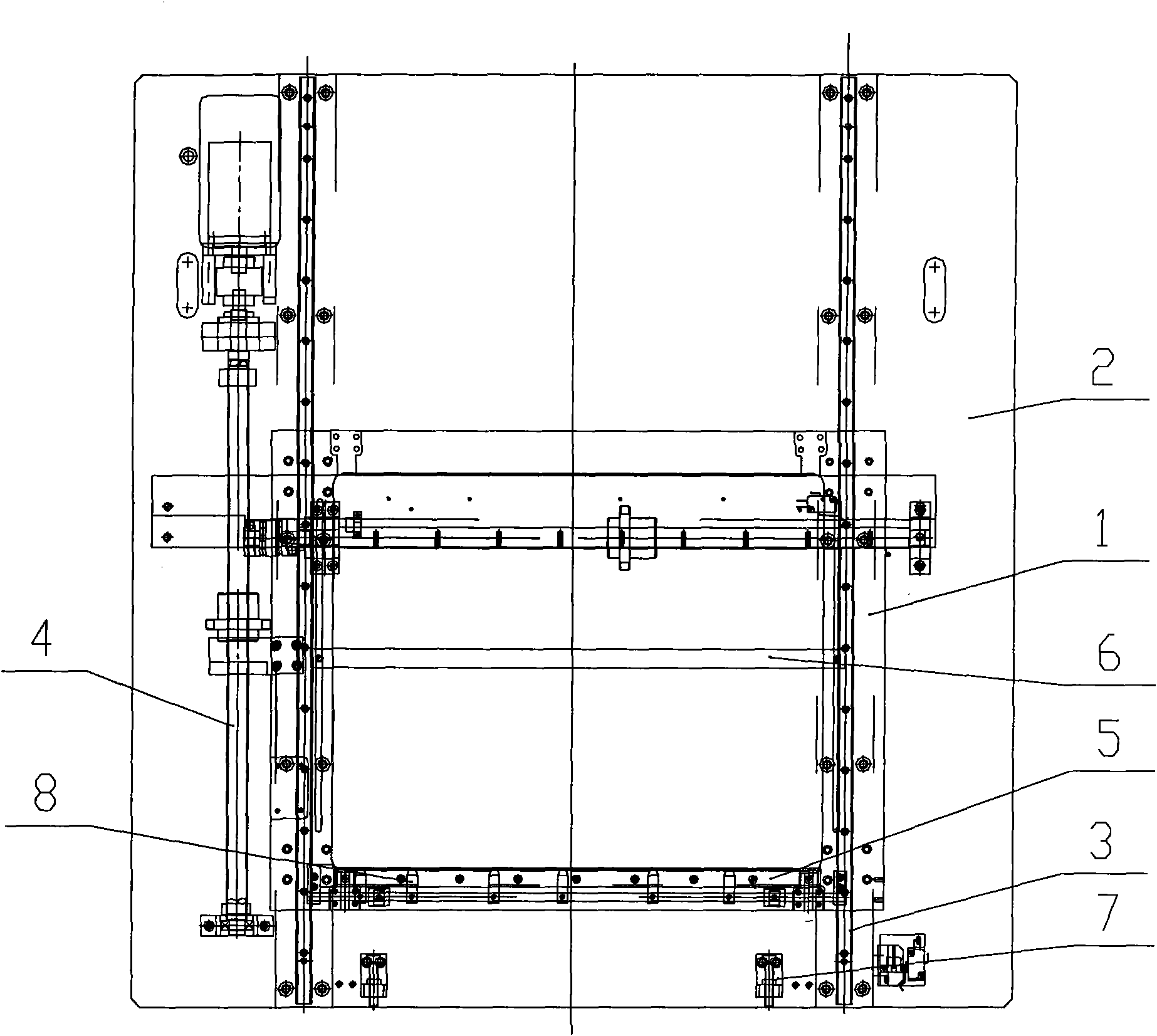

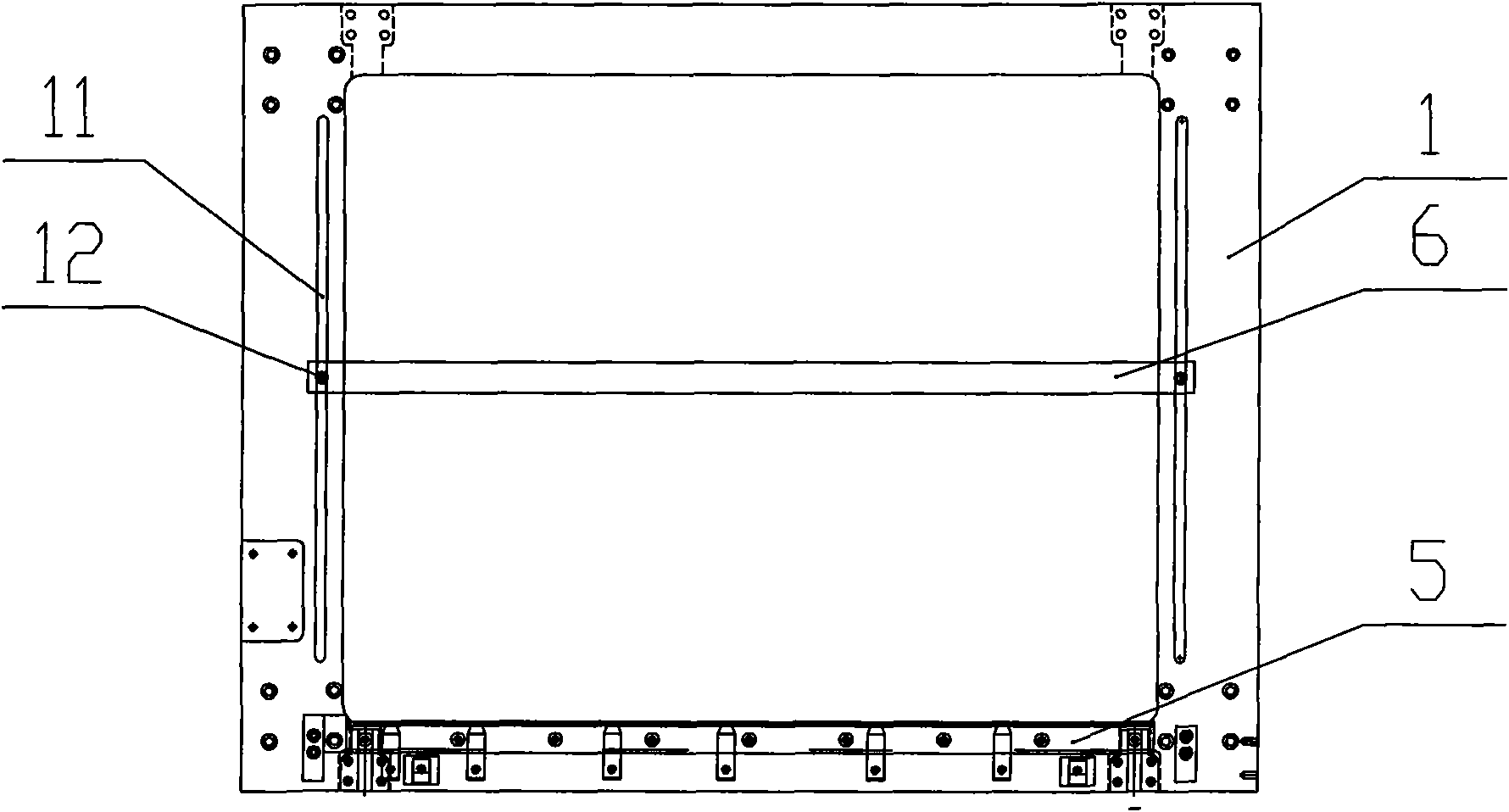

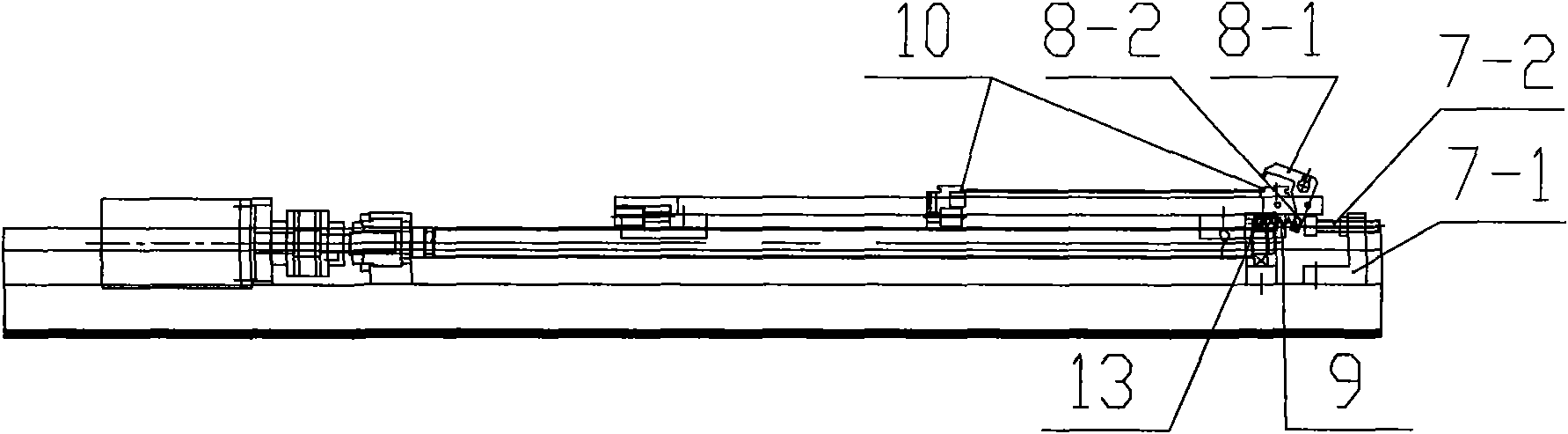

[0016] like figure 1 , figure 2 A PCB board clamping mechanism shown has a fixed base 1, the fixed base 1 is arranged on the guide rail 3 of the machine base 2, and a wire for driving the fixed base 1 to move back and forth on the guide rail 3 is provided on one side of the fixed base 1. Rod 4 is provided with a PCB board clamping mechanism on the fixed seat 1, and the PCB board clamping mechanism includes a front stop bar 5 and a rear stop bar 6 which are horizontally mounted on the fixed seat 1 and a rear stop bar 6 which is fixedly installed on the machine base 2 The ejector rod device 7, the front stop bar 5 is fixedly connected with the fixed seat 1, the rear stop bar 6 is slidably connected with the fixed seat 1, and at least one clamp 8 is pinned on the front stop bar 1, such as image 3 As shown, the clamp 8 is composed of a chuck 8-1 arranged above the front bar 5 and a top block 8-2 arranged below the front bar 5, and a spring 9 is arranged below the front bar 5, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com