Satellite type electron-beam curing ink offset press

A technology of electron beam curing and offset printing machine, which is applied to printing presses, rotary printing machines, lithographic rotary printing machines, etc. It can solve the problems of polluting the air environment and low accuracy of offset printing structure overprinting, achieving low pollution and improving overprinting accuracy , Promote the effect of quick drying of ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

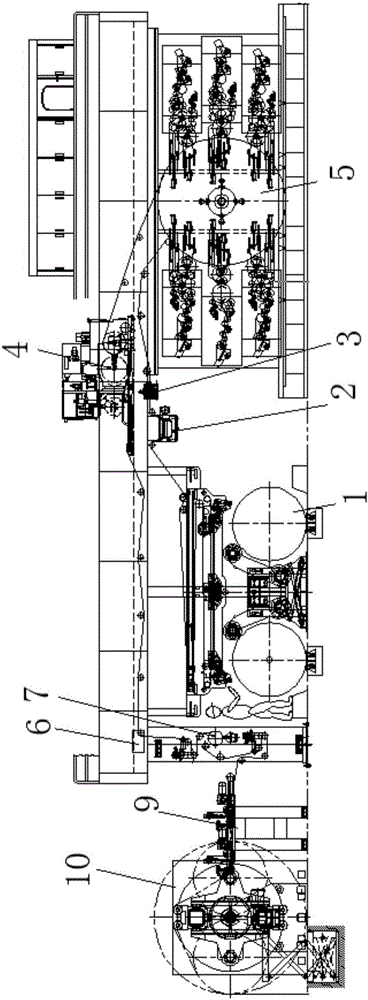

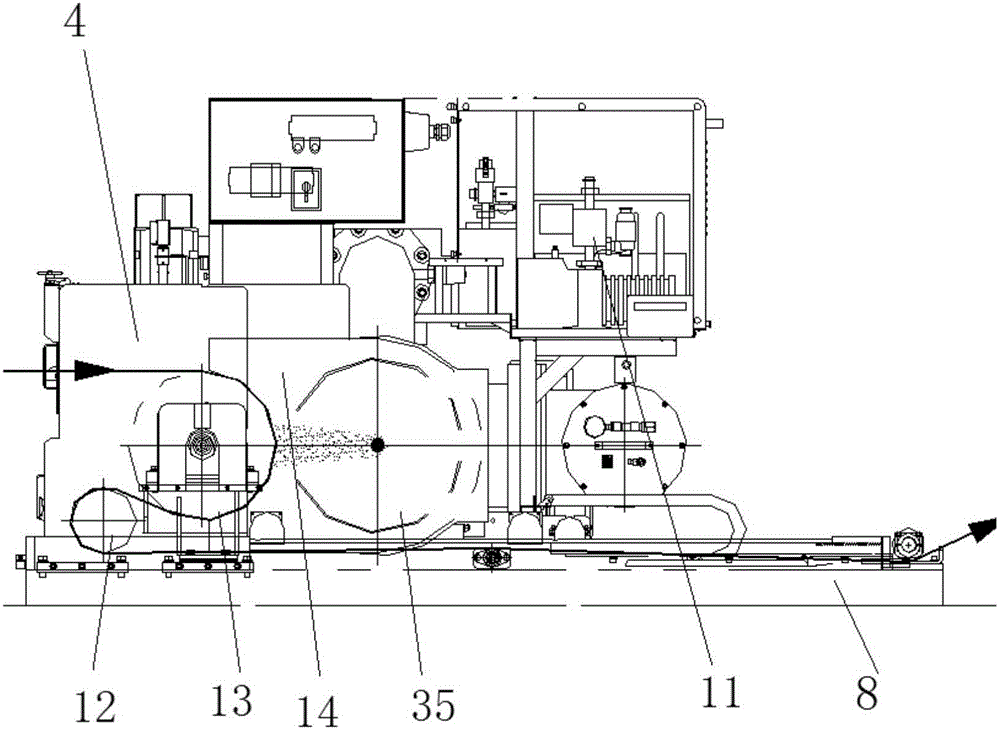

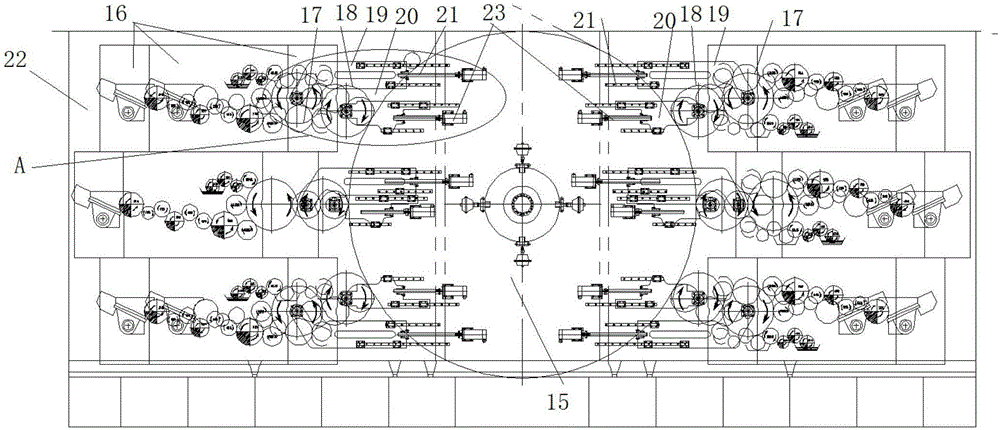

[0030] The invention provides a satellite type electron beam curing ink offset printing machine, such as figure 1 and figure 2 As shown, including the discharge and splicer device 1, the printing material in the form of a roll in the discharge and splicer device 1 passes through the deviation correction device 2, the dust removal device 3, the printing unit 5, the electron beam curing device 4, and the exit deviation correction device 6 1. The receiving traction device 7 and the receiving and cutting device 9 enter the receiving device 10, and it is characterized in that: the electron beam curing device 4 includes a frame 8, and the frame 8 is provided with an electrical cabinet 11, the electrical cabinet 11 and the guide roller 12 , the cooling roll 13, the nitrogen tank 14 and the electron accelerator 35 are connected, and the printing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com