Device capable of improving regulation precision of photogravure press guide roller

A gravure printing machine and a technology for adjusting accuracy, which are applied in the field of guide roller devices, can solve the problems of lack of gear matching accuracy, affecting overprinting accuracy, overprinting deviation, etc., and achieve the effect of improving overprinting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

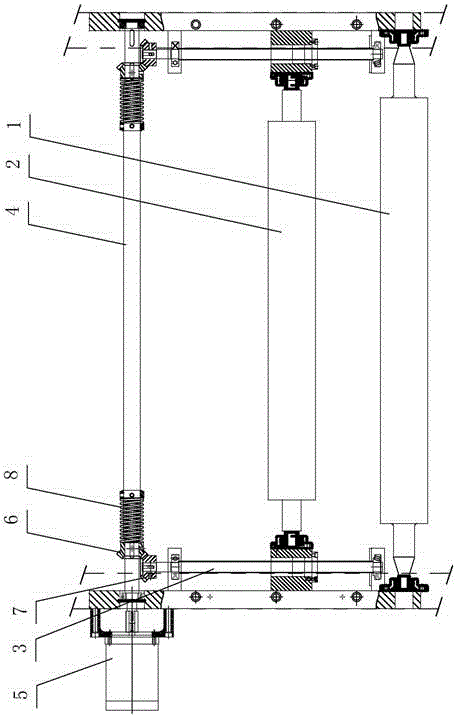

[0007] like figure 1 As shown, a device that can improve the adjustment accuracy of the guide roller of a gravure printing machine includes a guide roller 1, an adjustment guide roller 2 arranged above the guide roller 1, and is installed at both ends of the adjustment guide roller 2 to adjust The ball screw 3 that adjusts the guide roller 2 up and down, the transmission rod 4 that drives the two ball screws 3 to rotate synchronously by connecting the two ball screws 3 through bevel gears, and the motor 5 that drives the transmission rod 4 to rotate. The bevel gear 6 on the transmission rod 4 is axially fixed on the transmission rod 4, and each is equipped with a spring 8 that can press and engage the bevel gear 6 and the bevel gear 7 on the ball screw 3.

[0008] Under the tight pressure of the spring 8, even if there are various problems such as wear or lack of matching accuracy between the bevel gears 6 and 7, the spring 8 will always press the bevel gear 6 on the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com