Manufacturing method of broad-width special holographic mold pressing mother matrix

A production method and holographic technology, applied in the direction of printing plate preparation, printing, etc., can solve the problems of affecting the printing effect, no special plate pattern, discontinuous graphics and text, etc., and achieve the effect of high overprinting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

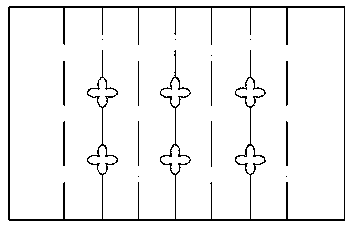

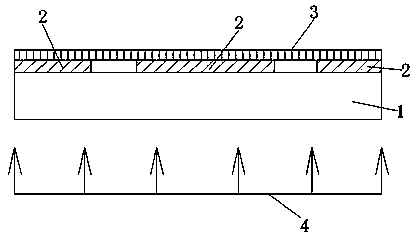

[0026] figure 2 Shown is the holographic embossed master plate of the present invention in which the special edition pattern is nested in the background pattern, and its production method is: image 3 , 4 As shown, take a transparent PC resin board 1 with a thickness of 0.5-2.5mm, cut the size of the transparent PC resin board according to the specifications of the master to be made; according to the pattern design of the master to be made, first make the background pattern separately For offset printing, flexo printing or gravure UV printing plate in the area and special pattern area, use a printing machine equipped with a UV printing plate in the background pattern area, and first print a layer of UV with a thickness of 0.5-2 μm on the surface of the transparent PC resin board. Ink 2, part of the non-background pattern area is hollowed out, the transparent PC resin plate is placed horizontally with the UV oil layer upward, and the holographic film 3 with the background pat...

Embodiment 2

[0028] Figure 5It is a wide-width holographic molded master plate composed of small-area special-edition patterns. Its production method is basically the same as that of Example 1. Take a transparent PC resin board with a thickness of 0.5-2.5 mm, and cut it according to the specifications of the master plate to be produced. The size of the transparent PC resin board is good, and the UV printing plate of offset printing, flexo printing or gravure printing with an area of about 200mmX200mm is used. A printing machine equipped with a UV printing plate is used to print a layer of thickness of 0.5 on the surface of the transparent PC resin board. - 2μm UV ink, put the transparent PC resin board horizontally with the UV oil layer up, and attach the holographic film with the special pattern to the UV ink layer with the pattern down, so that it is compatible with the UV ink on the PC resin board Layers are fully in contact, there can be no bubbles or gaps between the two, the wavel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com