Drying device of multicolor intaglio press oven

A gravure printing machine and drying device technology, which is applied to printing machines, general parts of printing machinery, printing, etc., to achieve good printing effects, stable printing quality, and high overprinting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

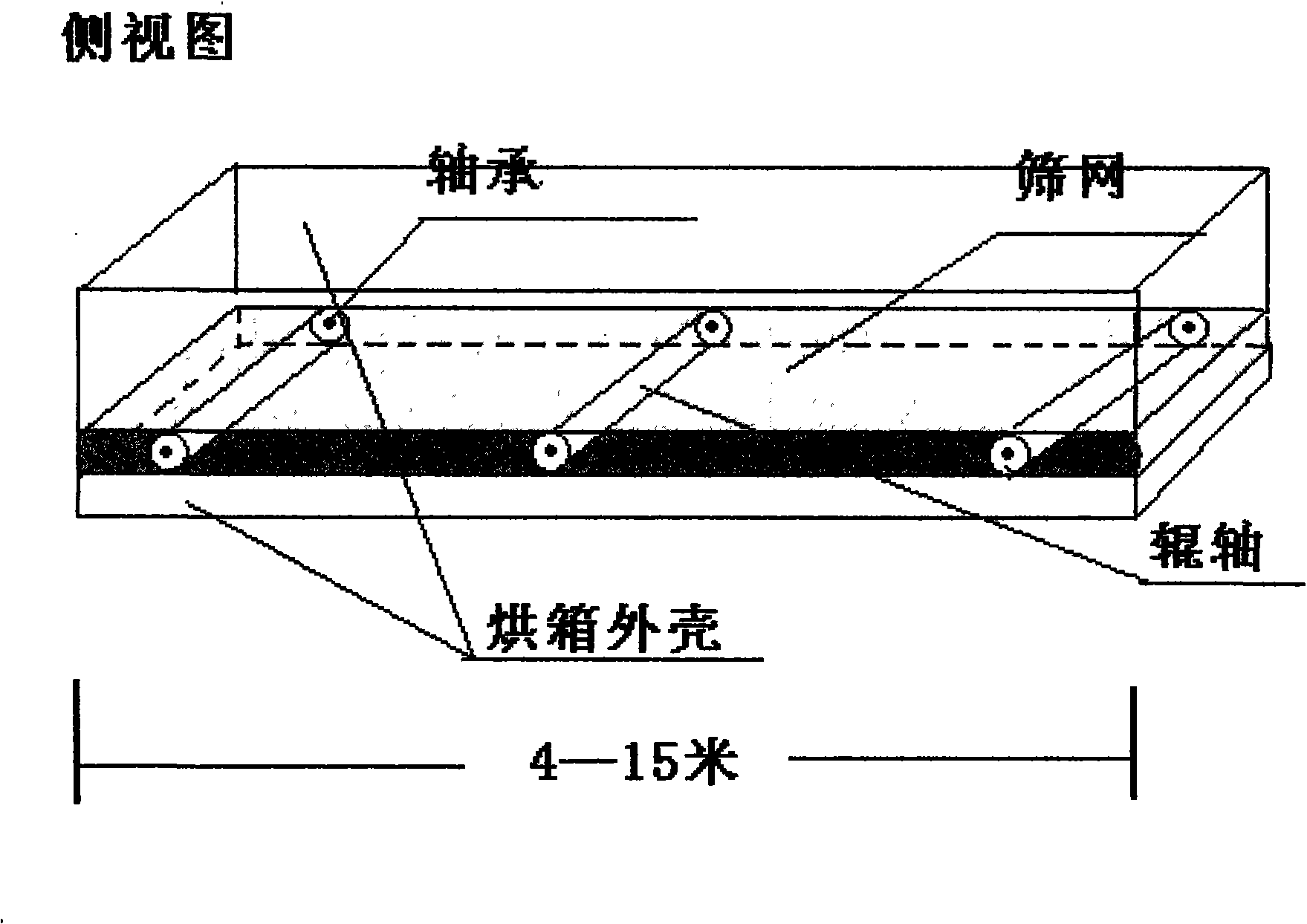

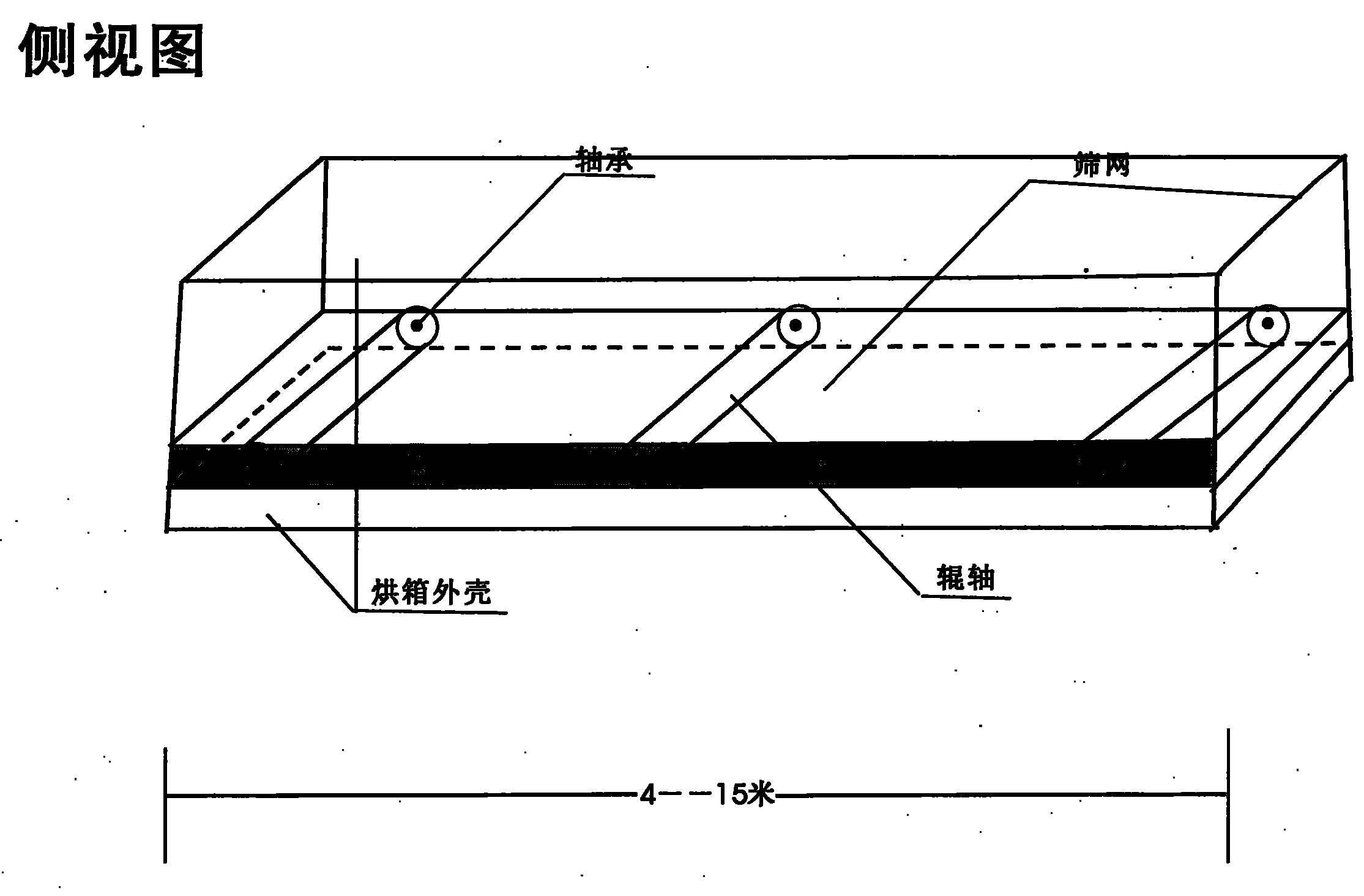

[0009] The structure of the drying device of the multi-color gravure printing machine oven of the present invention, as shown in the figure, the length of the oven is set to 10 meters, the temperature of the oven is positioned at 70 degrees, the printing roller material enters from one end of the oven, and passes through in 4 seconds. Oven, because the rotation of the roller shaft and bearing drives the screen, and the printing material also rotates at the same time, so that the printing material passes through the oven smoothly, so that the printing speed can reach 150 meters per minute.

[0010] The technology of the invention makes the printing color registration of the multi-color gravure printing machine stable, further increases the printing speed, improves the work efficiency, and obtains good printing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com