Gloss oil set printing device for optical variable anti-faking ink offset printing and offset printing online printing method

A technology for optically changing anti-counterfeiting and printing devices, which is applied in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of darkening and blackening of anti-counterfeiting ink, and achieve the effect of reducing damage, small friction coefficient and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

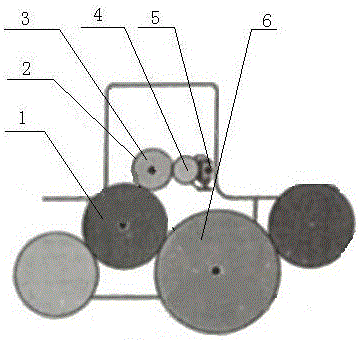

[0062] refer to Figure 1~7 , a kind of varnish group printing device for optically variable anti-counterfeiting ink offset printing of the present embodiment, comprising a conveying device 6, a scraper 5, an anilox roller 4, a plate roller 3 and an impression cylinder 1 sleeved with a resin plate 2; the conveying The device 6 is installed under the impression cylinder 1, and transfers the substrate 7 to the impression cylinder 1; the scraper 5 and the version roller 3 are installed on both sides of the anilox roller 4, and the version roller 3 is installed on the impression cylinder 1, the scraper 5 transfers the optically variable anti-counterfeiting ink to the resin plate 2 covered by the plate roller 3 through the anilox roller 4, and then under the action of the impression cylinder 1, the optically variable anti-counterfeiting ink on the resin plate 2 is transferred Print onto substrate 7.

[0063] The resin plate 2 includes a metal-based substrate 21, an adhesive layer ...

Embodiment 2

[0079] refer to Figure 8 and 9 , compared with embodiment 1, a kind of optically variable anti-counterfeiting ink offset printing varnish group printing device of the present embodiment has the following differences:

[0080] The height of the balance bar 24 protruding from the outer surface of the resin layer 23 is 0.4mm.

[0081] 15mm。 The metal-based substrate 21 is an alloy metal-based thickness of 0. 15mm.

[0082] The hardness of the resin layer 23 is 75 degrees Shore hardness.

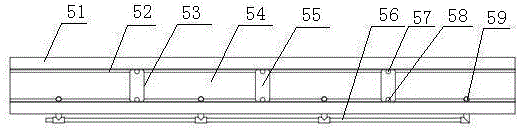

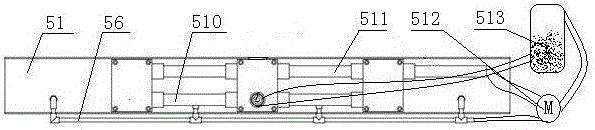

[0083] A mounting frame 515 is also provided on the back of the knife holder 51 .

[0084] The end of the barrier sheet 53 close to the blade 52 is provided with an ink absorbing device 514, which can effectively absorb the ink accumulated on the blade 52 into the ink storage chamber, thereby improving the ink scraping effect of the blade 52.

[0085] The ink absorbing device 514 is a sponge.

[0086] The ink inlet and outlet device comprises an ink feed pipe 510, an ink discharge pipe 511...

Embodiment 3

[0091] refer to Figure 10 , an optically variable anti-counterfeiting ink offset online printing device of the present invention, comprising: a paper feeding device 10, a conveying device 6, 6 color printing units 8 connected in series in sequence, and a varnish group printing device as described in Embodiment 1 and collecting device 8; the transfer device 6 sequentially transfers the substrate 7 from the paper feeding device 10 to the color printing unit 8 for color printing, and then transfers the color printed substrate 7 to the varnish group printing device for varnish printing Change the anti-counterfeiting ink to print, and finally transfer the substrate 7 to the collecting device 8.

[0092] The color printing unit 8 can be a common color printing unit 8 in the market, such as the 6-color printing unit of Heidelberg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com