A pcb board coating and baking all-in-one machine and its control circuit

A technology of PCB board and all-in-one machine, applied in the directions of drying of printed circuit, secondary treatment of printed circuit, coating of non-metallic protective layer, etc., can solve the problems of underutilization, easy sticking of oil on the roller, waste of heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

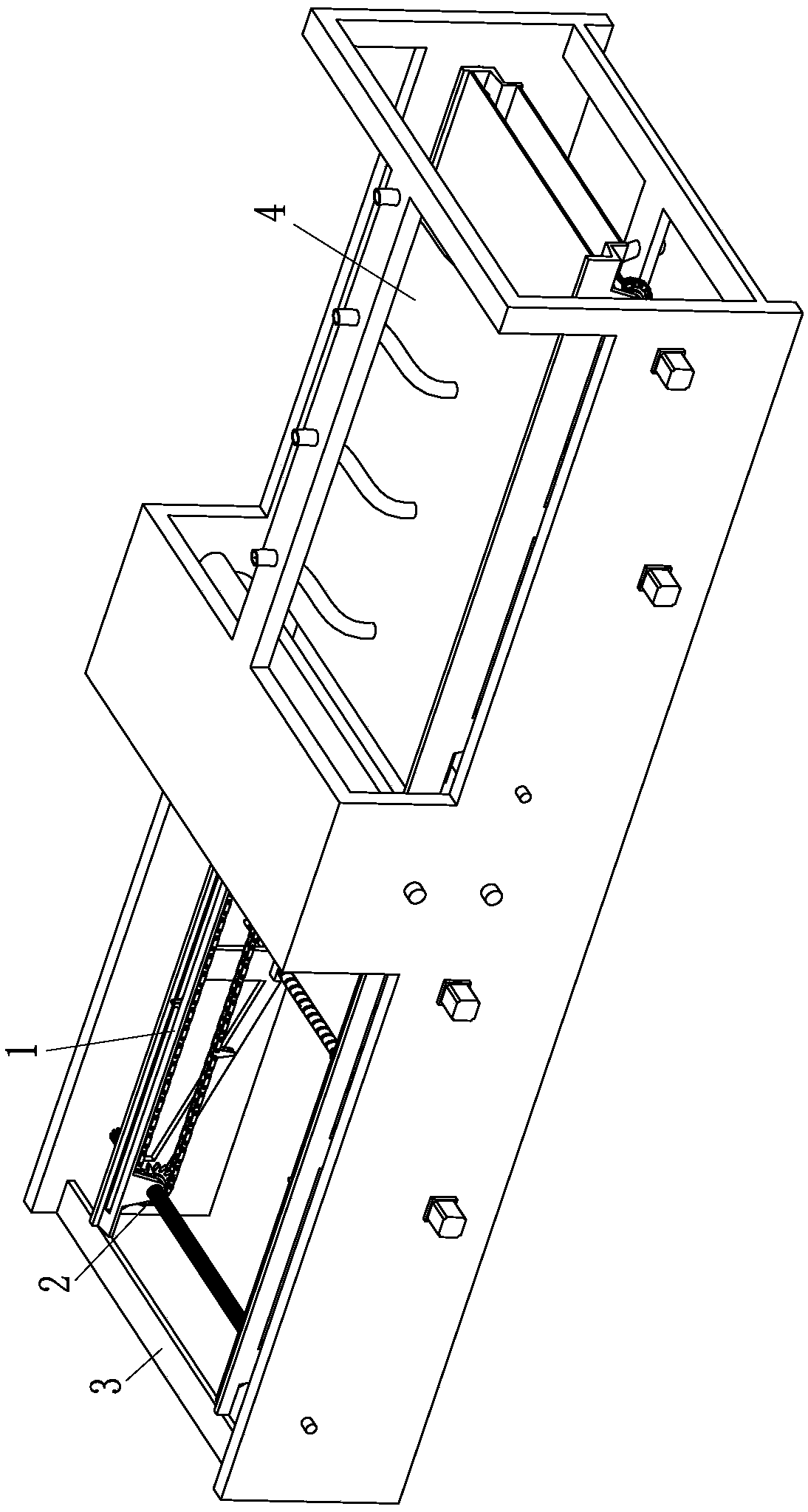

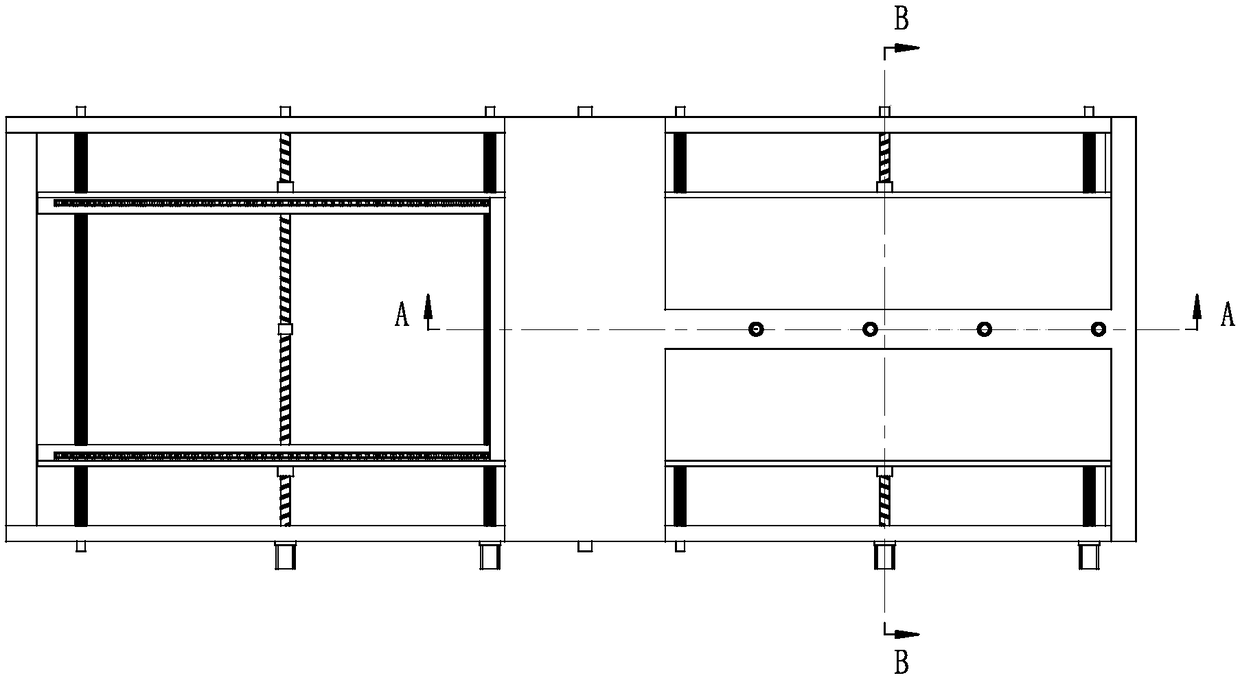

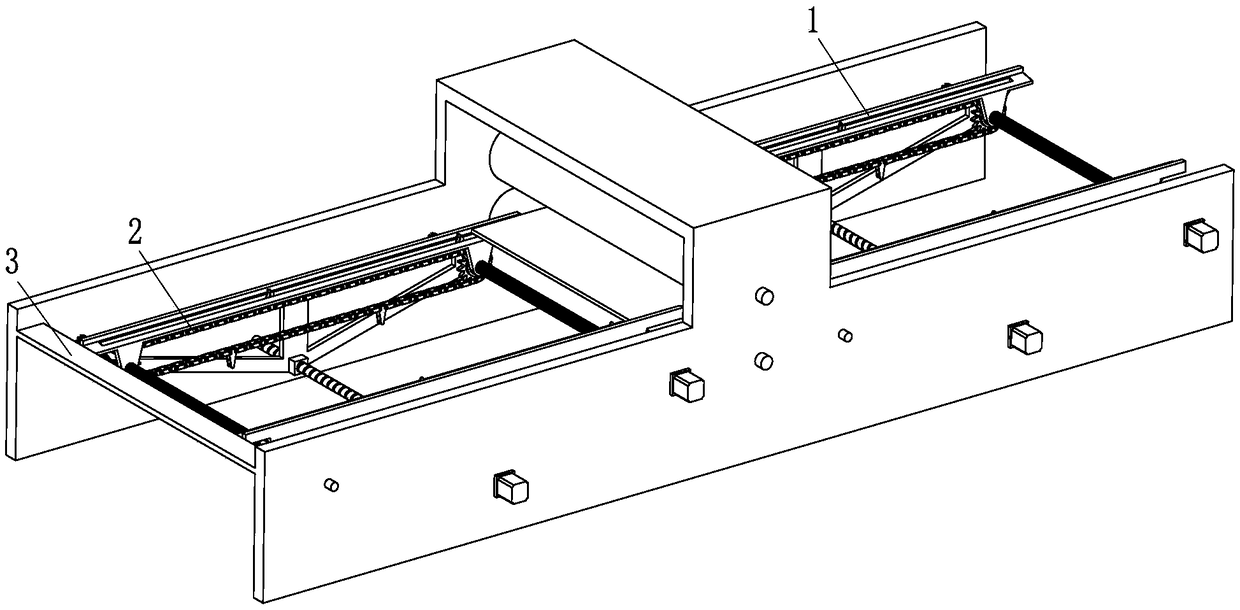

[0063] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 A PCB board coating and baking integrated machine is shown, including a fuselage, a coating roller, a doctor blade, an ink outlet pipe and a control panel, and also includes a supporting mechanism 1, a pushing mechanism 2 and a baking device 4;

[0064] The number of the stretching plate mechanism 1 is two, and the two spreading plate mechanisms 1 are respectively installed on the front and rear sides of the coating roller. , support screw rod 13 and support motor 14;

[0065] A pair of brace bases 11 are symmetrically arranged on the left and right sides of the fuselage, the PCB board can be placed on the pair of brace bases 11, and a pair of support shafts 12 are respectively rotatably installed on the fuselage horizontally. And the front and rear ends of each support plate base 11 are respectively slidably mounted on corresponding support shafts 12;

[0066] The support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com