Film coating machine for two-sided automatic register

A film coating machine, automatic technology, applied in the direction of machining/deformation, etc., can solve the problem that the film coating machine cannot realize automatic double-sided pattern alignment, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

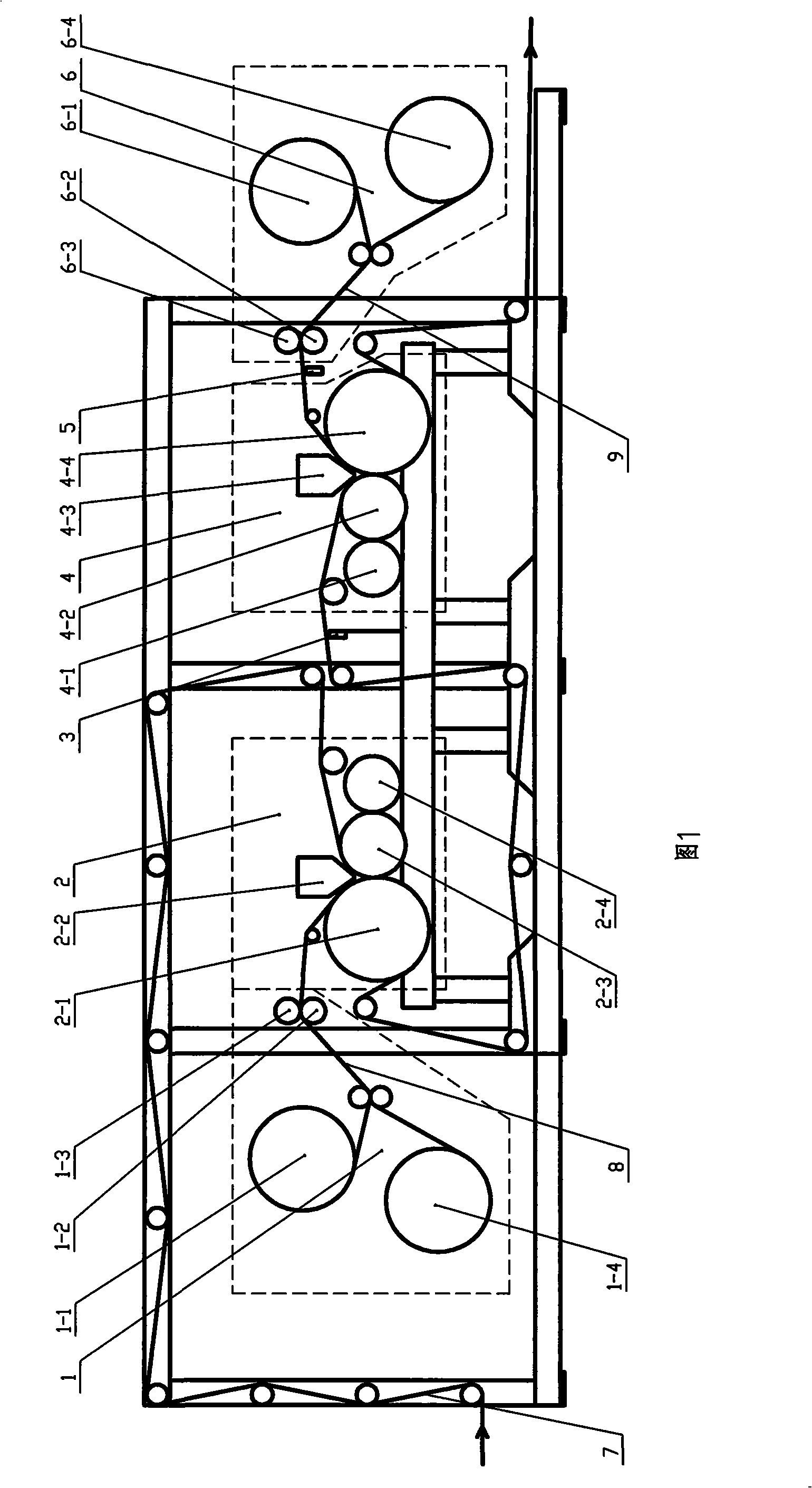

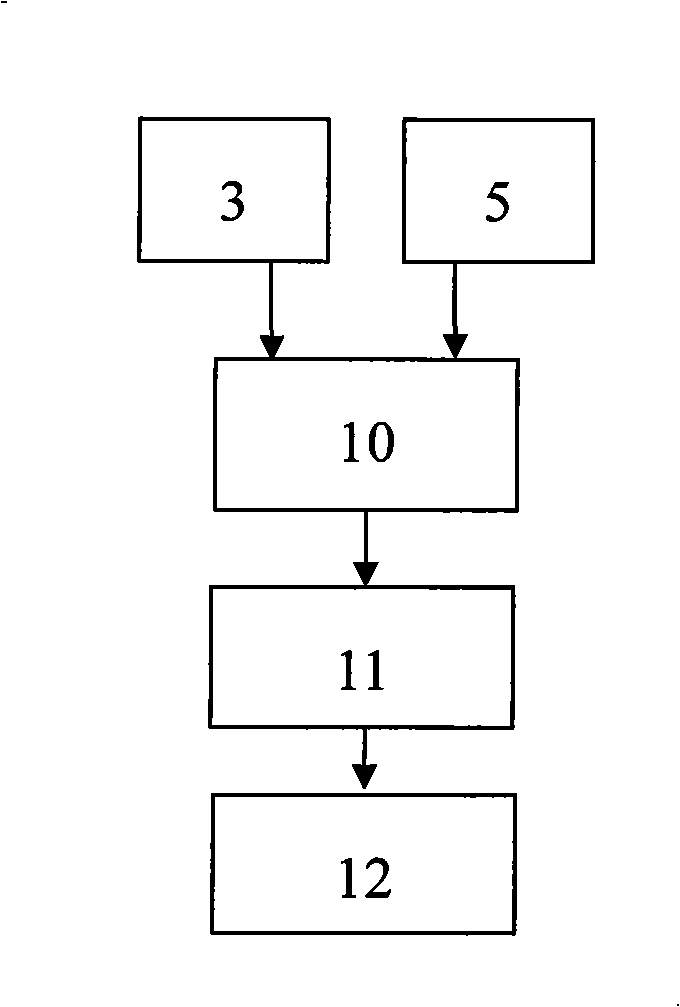

[0012] Figure 1 and figure 2 The best embodiment of the double-sided automatic plate-aligning film coating machine shown in the present invention has a base cloth feeding mechanism, a first substrate feeding mechanism 1, a first composite mechanism 2, and a second substrate feeding mechanism 6. The second compound mechanism 4. The first color mark sensor 3 for real-time monitoring of the position of the pattern color mark on the first substrate 8 on the woven cloth 7 via the first compound mechanism 2 during real-time monitoring. The second color mark sensor 5 of the pattern color mark position on the second substrate 9 released by the second roll feeding mechanism 6, the processor 10 receiving and processing the color mark sensor signal, the servo controller 11 and the servo motor 12, The first substrate feeding mechanism 1 has a first substrate feeding shaft 1-1 driven by a first substrate feeding motor, a first substrate introduction roller 1-2, a first substrate pressing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com