Patents

Literature

73results about How to "Won't relax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

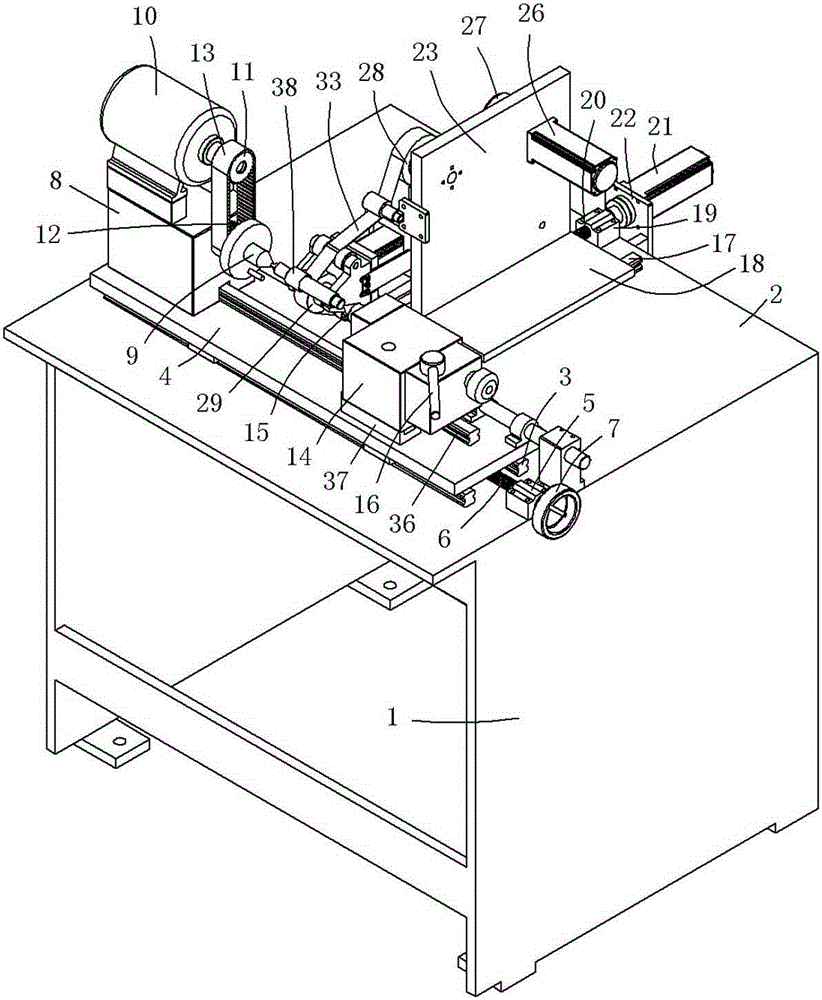

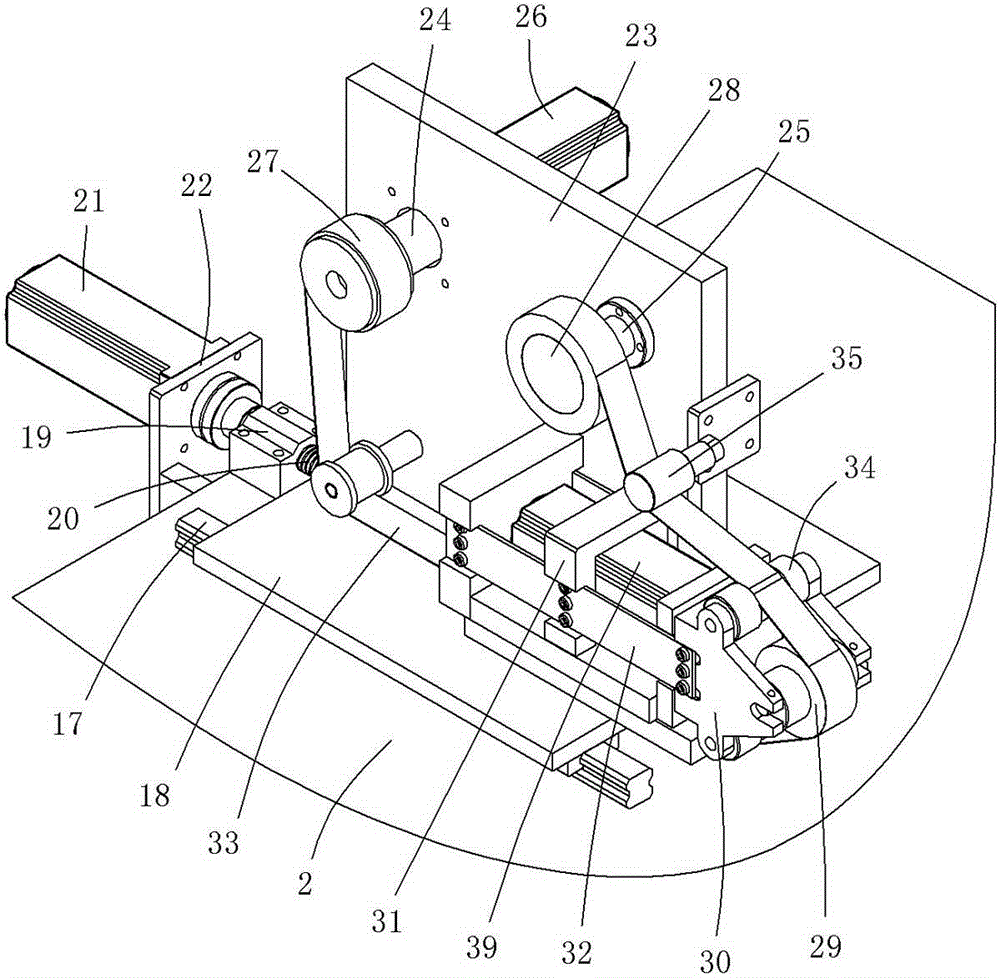

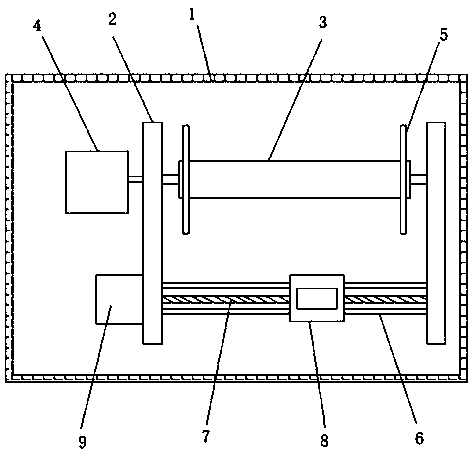

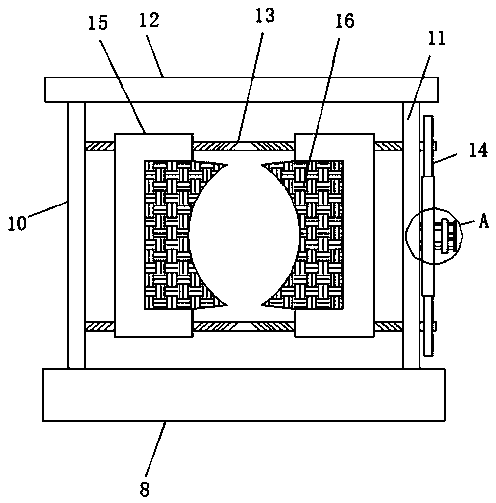

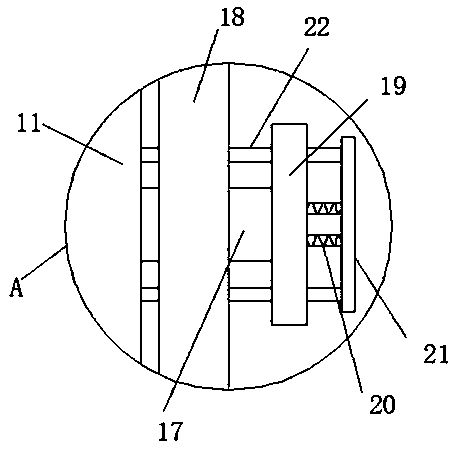

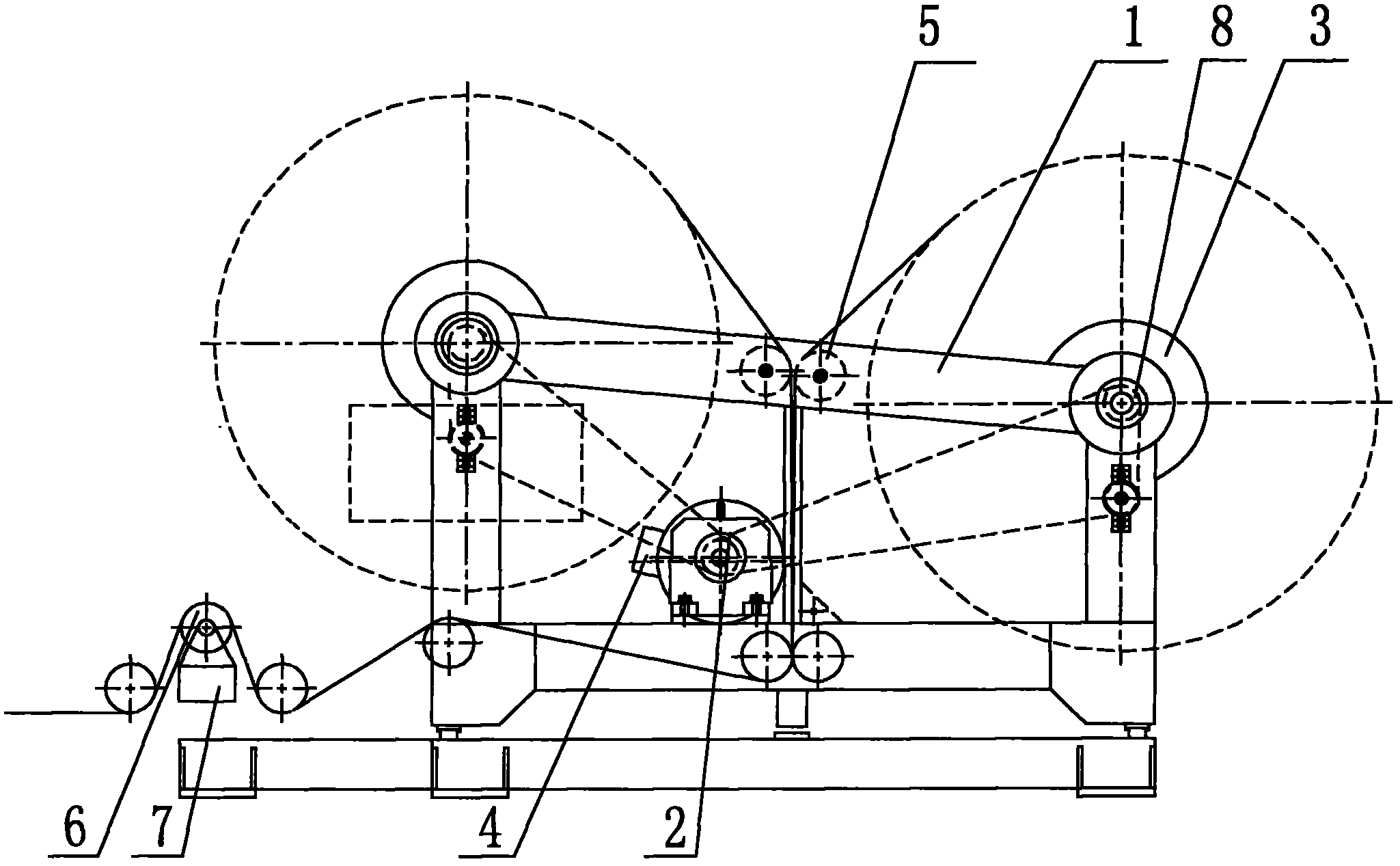

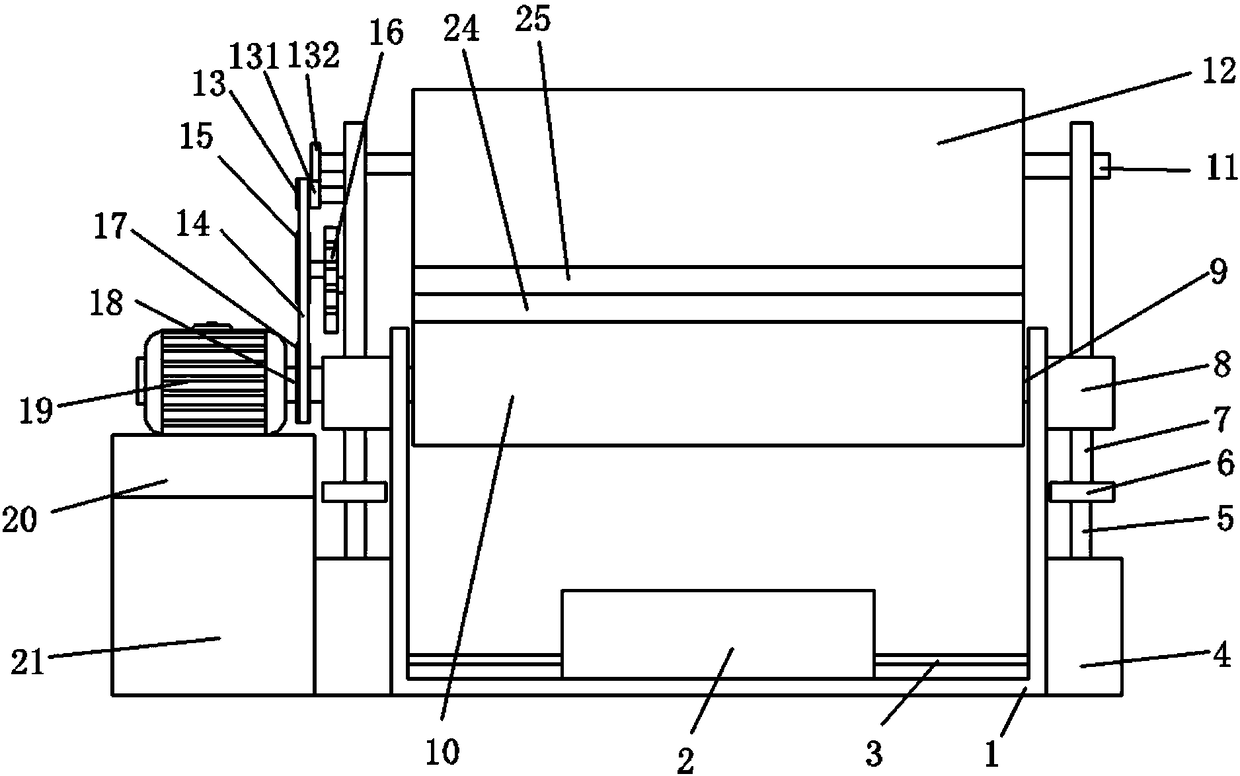

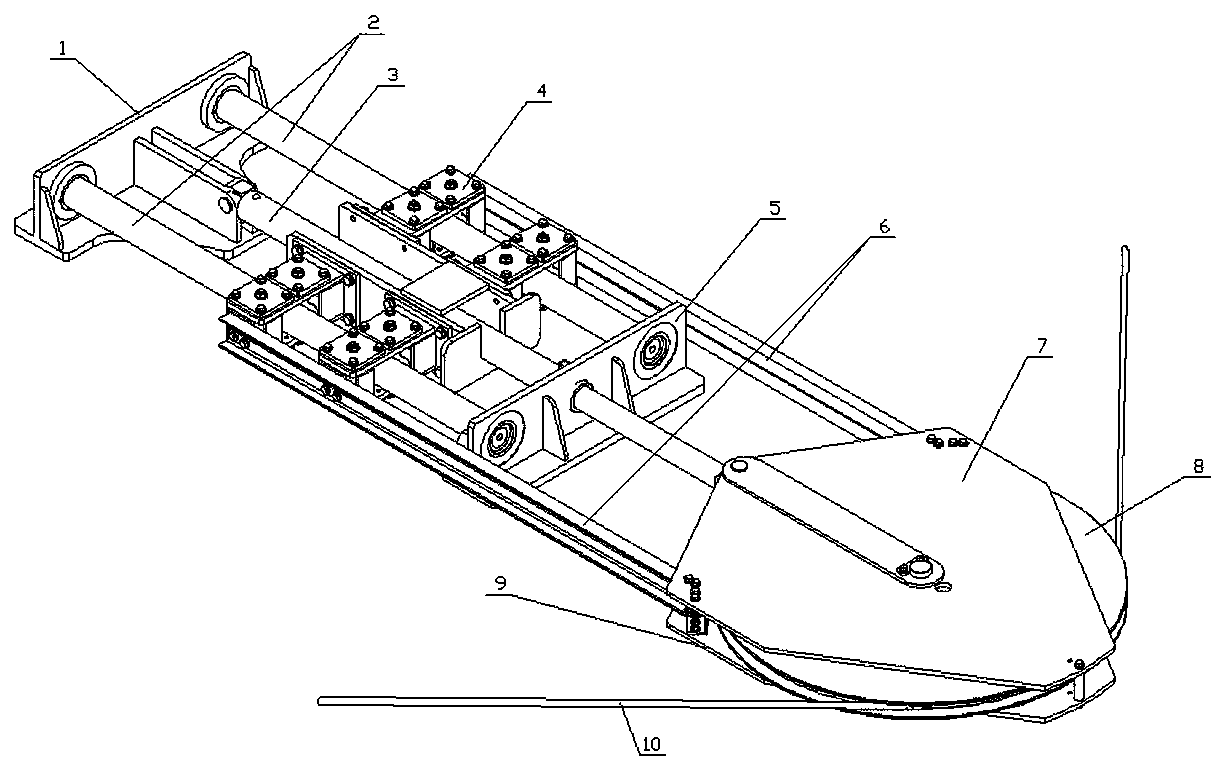

External cylindrical superfinishing machine

The invention provides an external cylindrical superfinishing machine. The machine comprises a frame, a workbench and an abrasive belt, wherein a transverse guide rail, a transverse sliding table, a transverse motion driving mechanism, a longitudinal guide rail, a longitudinal sliding table and a longitudinal motion driving mechanism; a headstock, a headstock center and a rotary driving mechanism are arranged on one side of the transverse sliding table; a tailstock, a sleeve, a tailstock center and a center adjustment mechanism are arranged on the other side of the transverse sliding table; an abrasive belt rack, an abrasive belt driving shaft, an abrasive belt driven shaft, an abrasive belt motor, a rolling abrasive belt wheel, a releasing abrasive belt wheel, a polishing wheel, a polishing wheel rack and a polishing motor are arranged on the transverse sliding table; one end of the abrasive belt winds the releasing belt wheel, and the other end of the abrasive belt moves around the polishing wheel and is fixedly arranged on the releasing abrasive belt wheel. The external cylindrical superfinishing machine has the beneficial effects of simple and compact structure, convenience in operation, integral operation stability and reliability and high processing accuracy, and cannot cause scrap of axial parts.

Owner:宁波华表机械制造有限公司

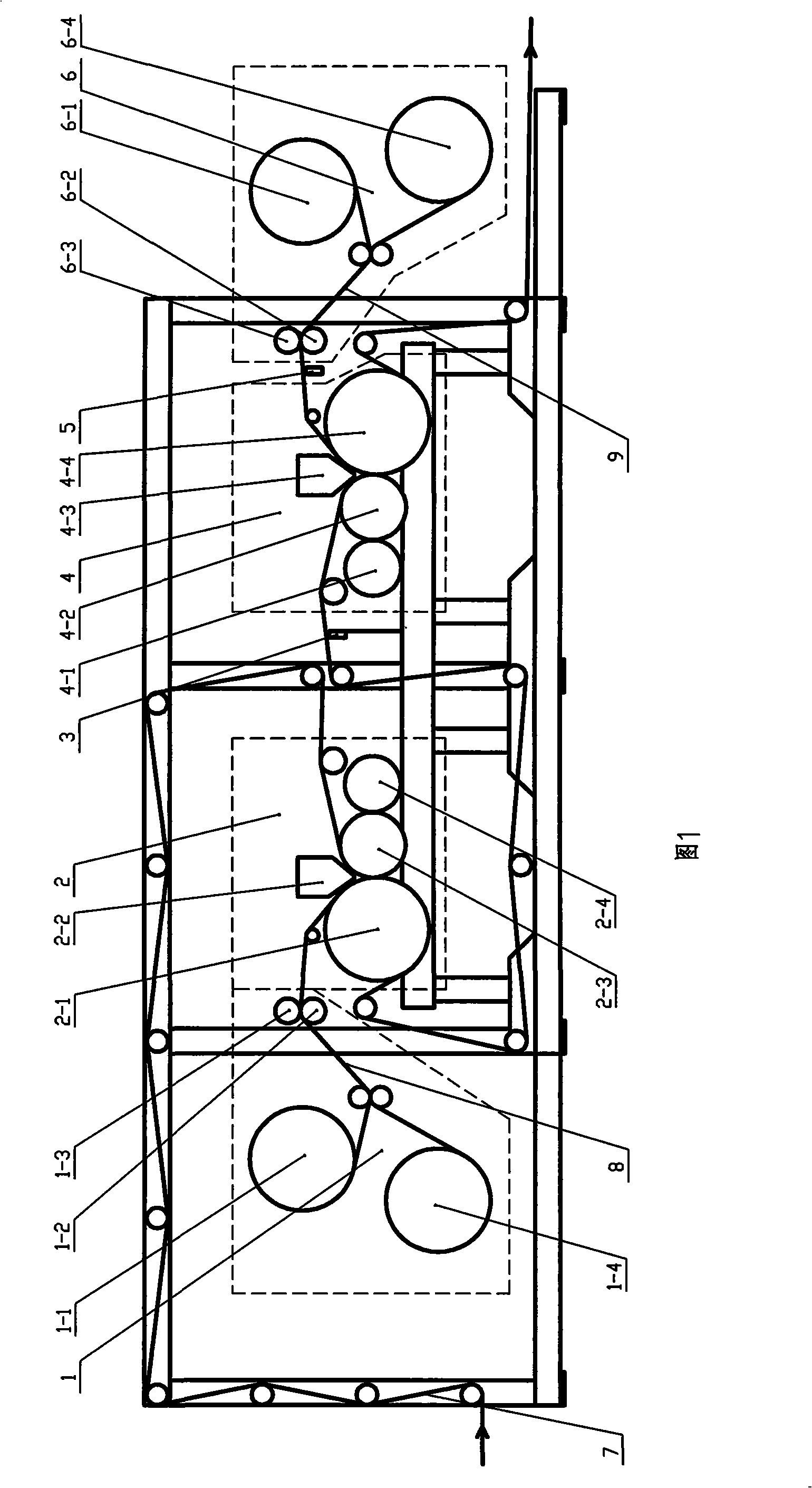

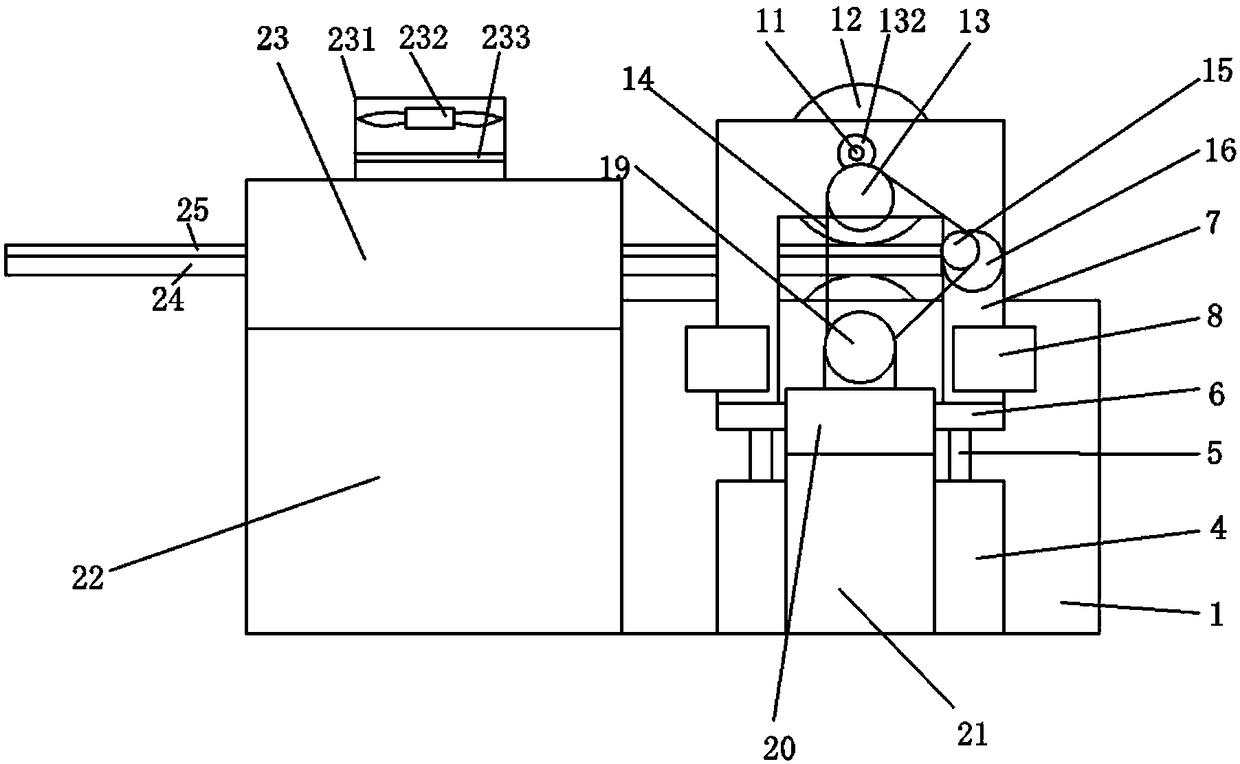

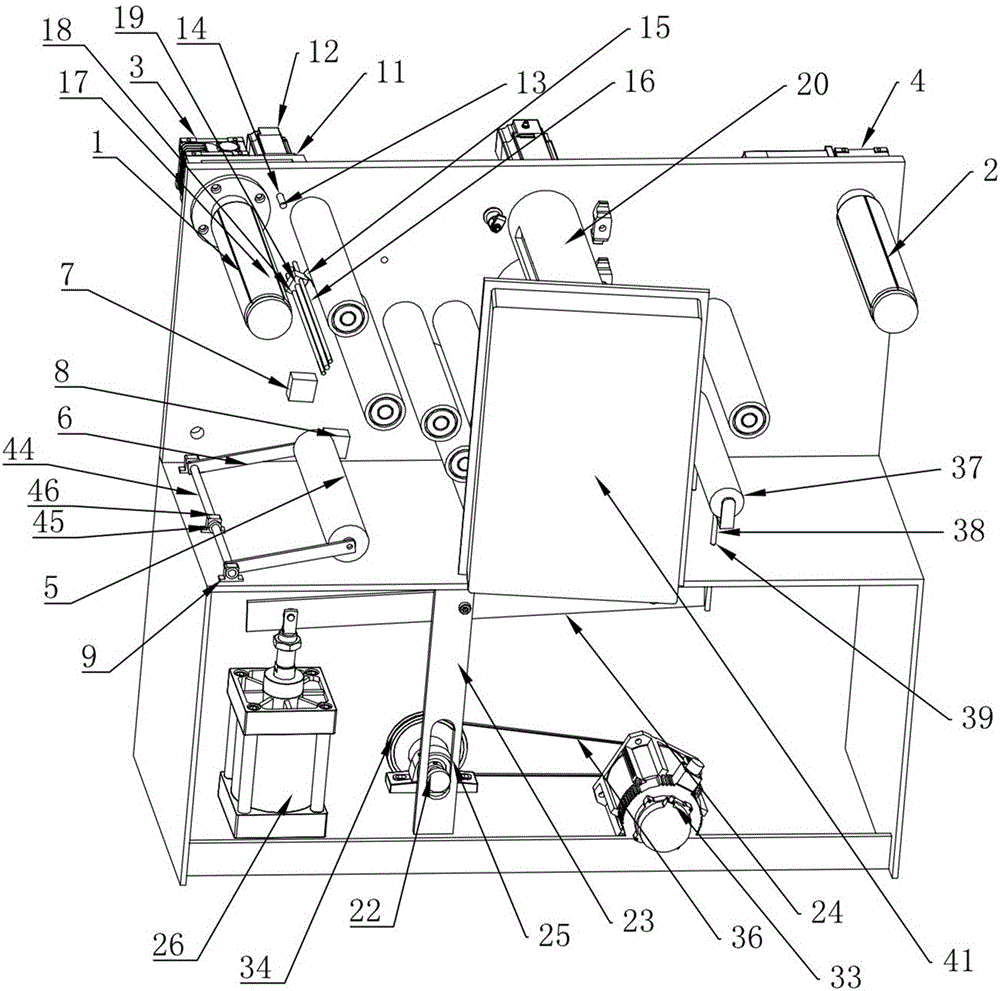

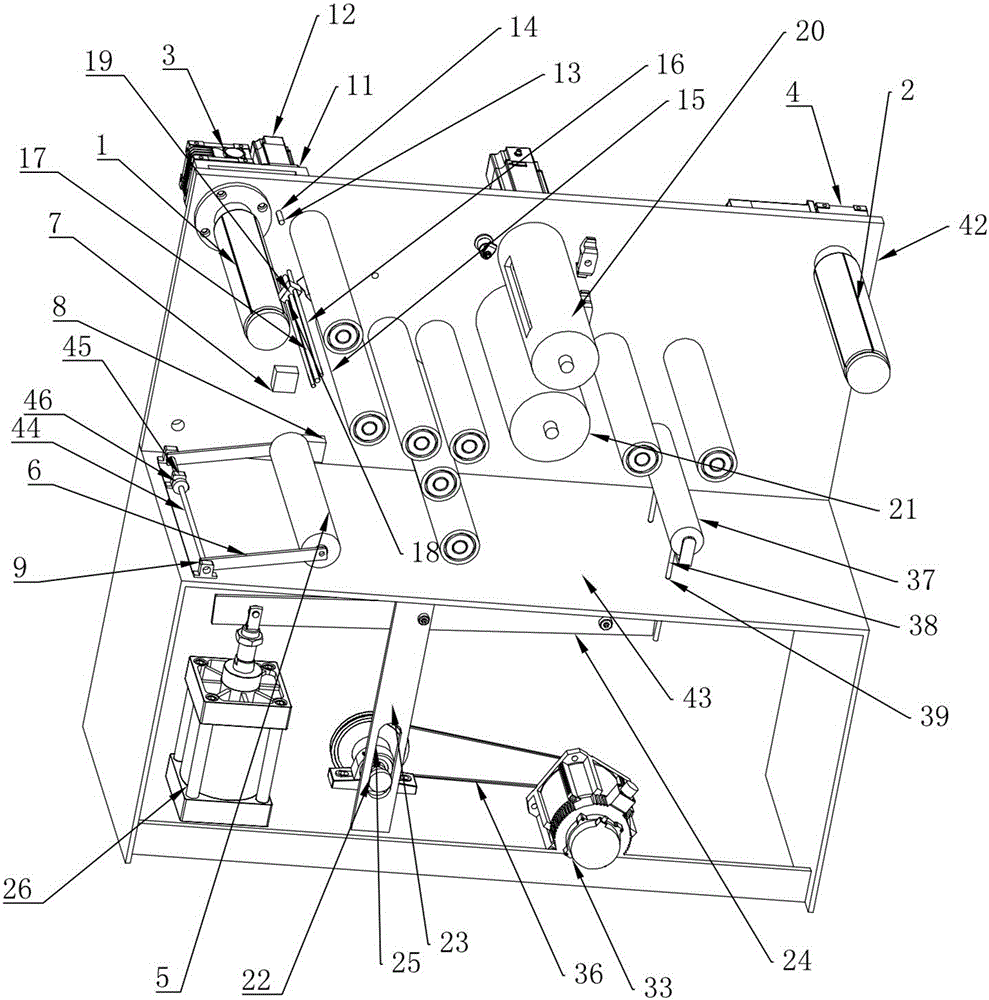

Film coating machine for two-sided automatic register

InactiveCN101269552AIncrease productivityRealize automatic version matching functionMechanical working/deformationRelative displacementMotor drive

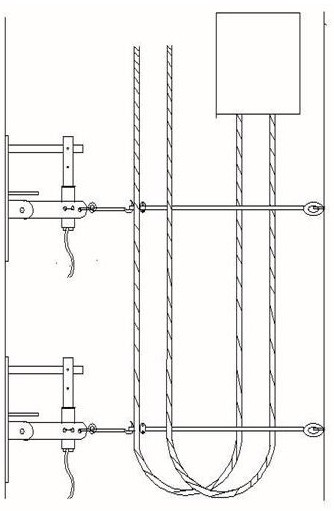

The invention relates to a film coating machine, in particular to a two-sided automatic plate-alignment film coating machine, which is provided with a basic cloth delivery-furl mechanism, a first basic material delivery-furl mechanism, a first composite mechanism, a second basic material delivery-furl mechanism, a second composite mechanism, a first color mark sensor, a second color mark sensor, a processor, a servo controller, and a servo motor; the second basic material delivery-furl mechanism is provided with a second basic material delivery-furl shaft, a second pressing roll, and a second basic material guiding roll which are driven by a second basic material delivery-furl motor; the servo motor drives the second basic material guiding roll; the processor is connected with the servo controller; and the servo controller is connected with the servo motor. The film coating machine has the automatic plate-alignment function of two-sided design, and the delivery-furl composite speed is rapid, the productivity effect is high, even though the basic material adopts an OPP film with very thin thickness, the highest delivery-furl composite speed of the OPP film can reach 80 meters per minute, the relative displacement of the color mark combined on the OPP films of the two sides of the same plastic braided cloth can be controlled within 3 mm.

Owner:CHANGZHOU HUASHENG PLASTIC MACHINERY

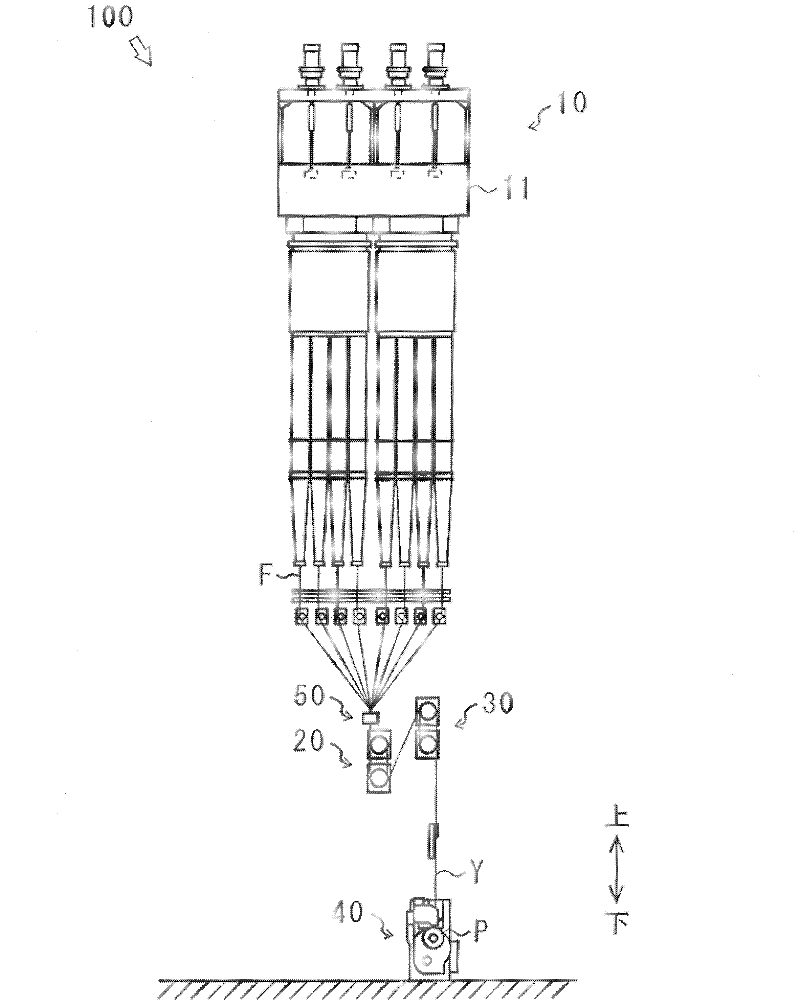

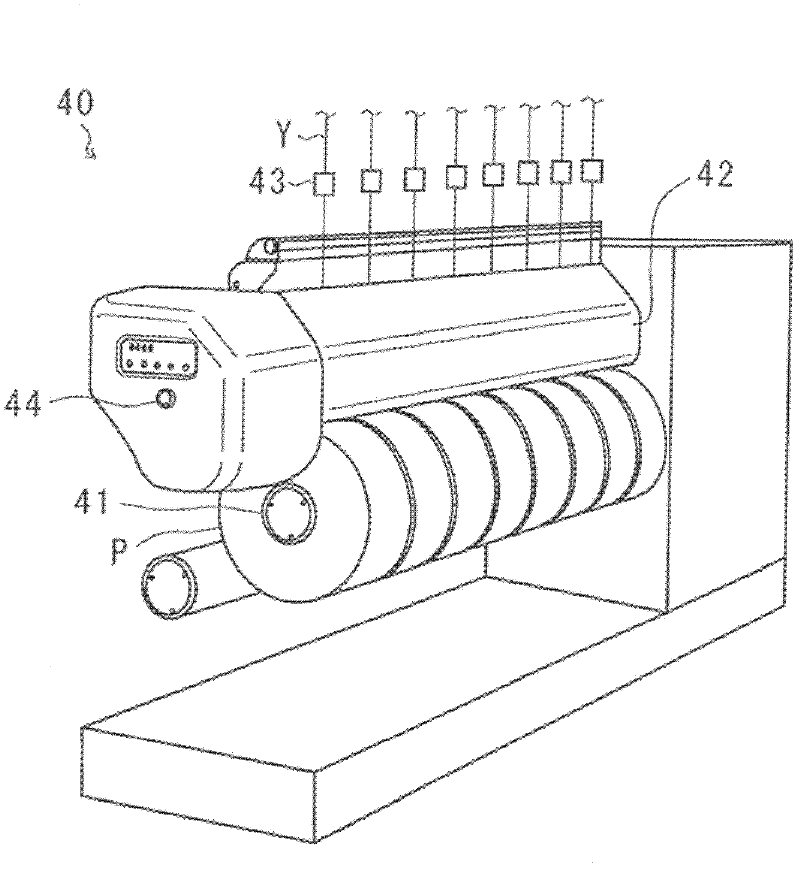

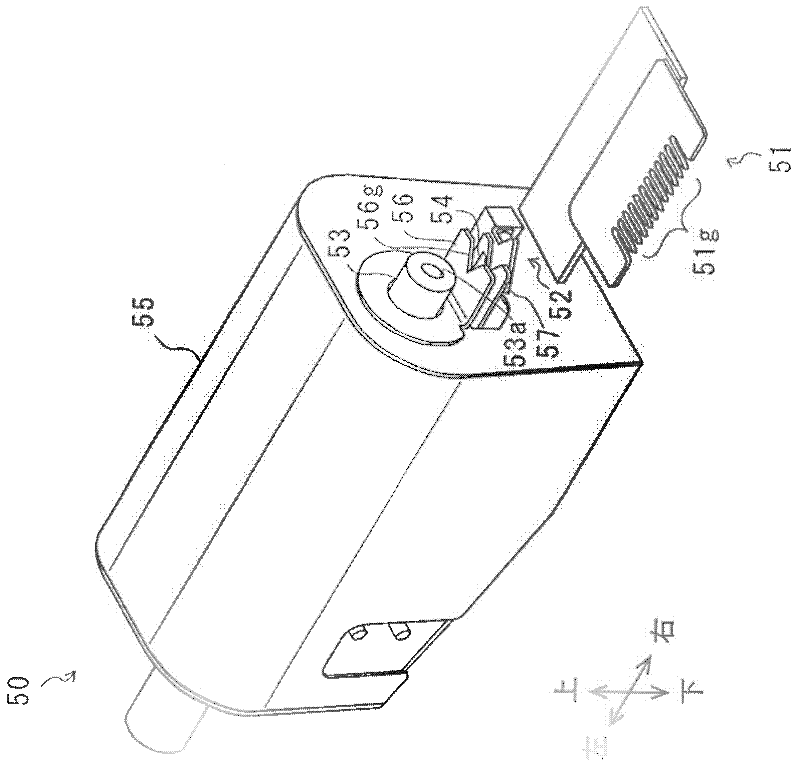

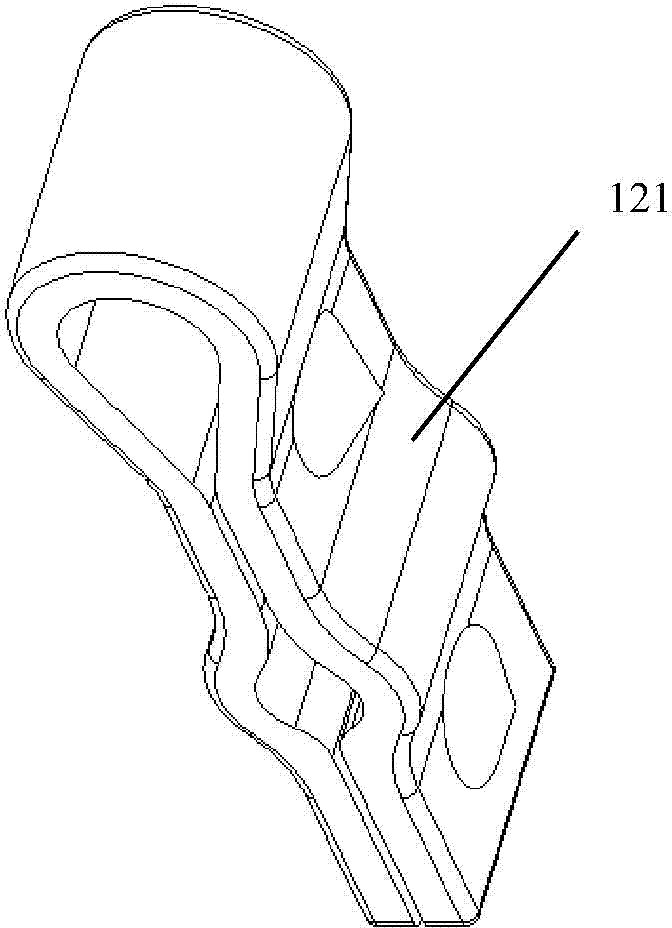

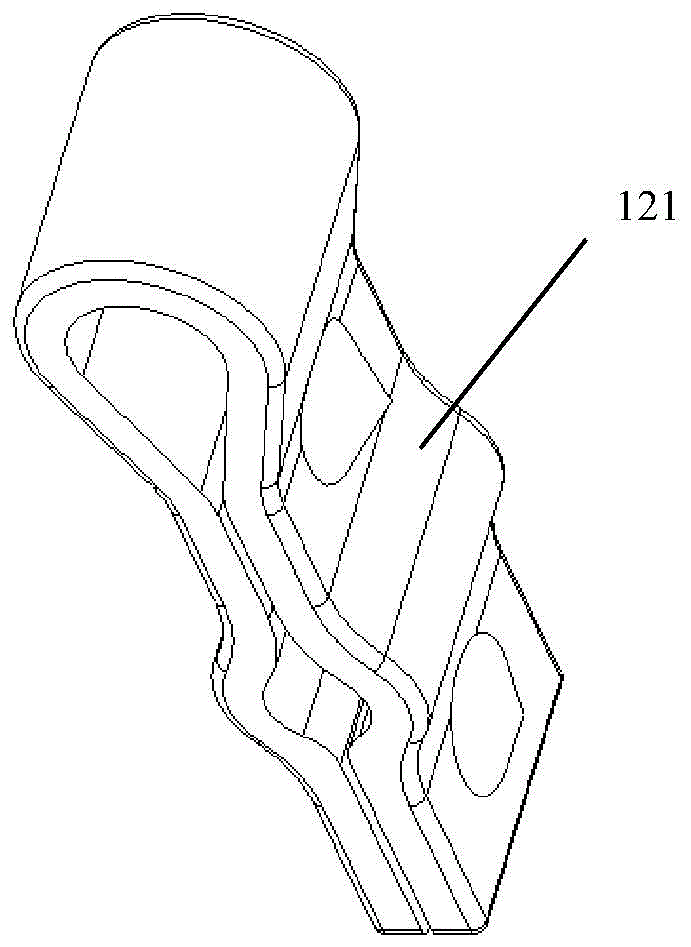

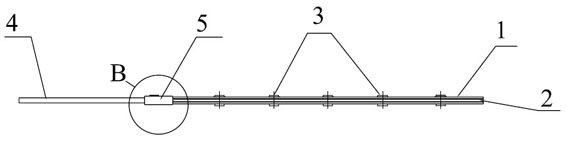

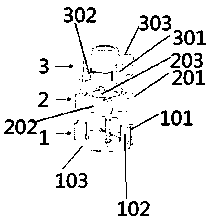

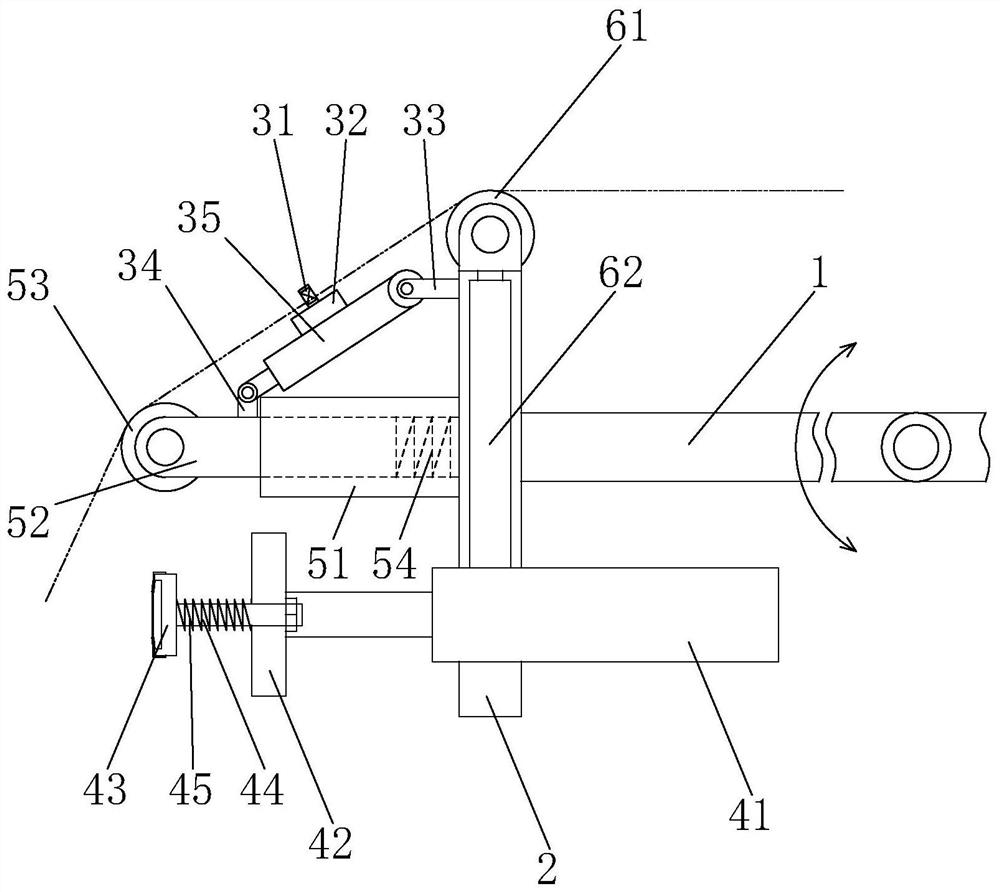

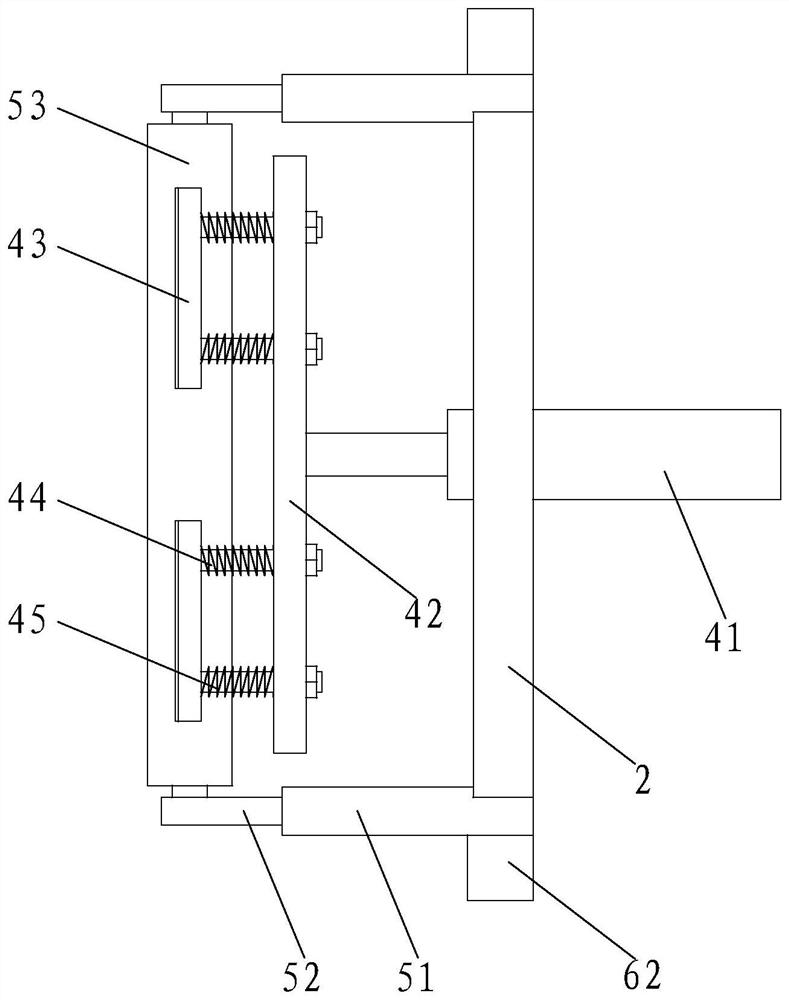

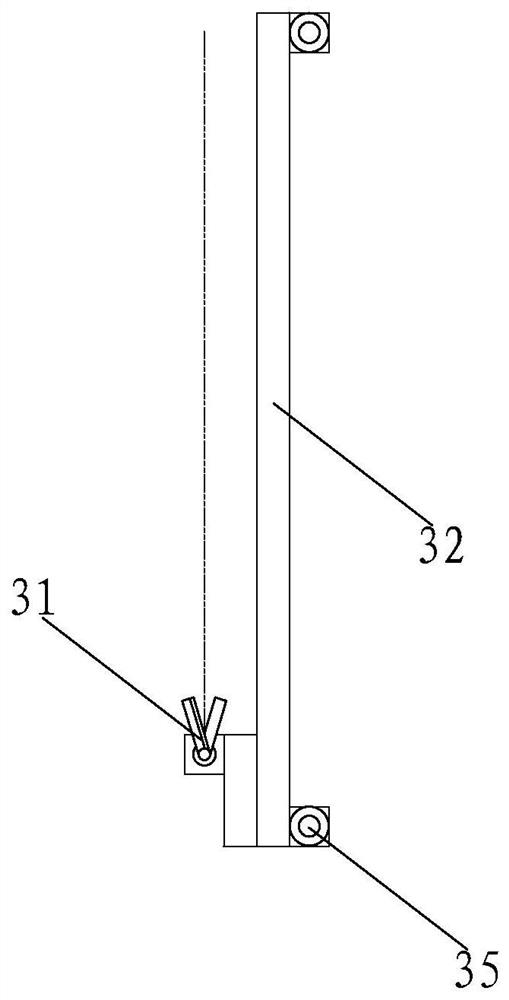

Yarn cutting apparatus

ActiveCN102560711AEasy to cutWon't relaxArtificial thread manufacturing machinesFilament manufactureYarnEngineering

A yarn cutting apparatus is provided that improves the workability of the yarn threading operation while securely cutting a plurality of yarns. A yarn cutting apparatus (50) is configured to cut a plurality of yarns (Y) and includes a yarn path regulating guide (51) configured to guide the plurality of yarns (Y), a yarn shift guide (52) disposed further upstream than the yarn path regulating guide (51) so as to shift the yarns (Y) fed onto the yarn path regulating guide (51) to one direction, an aspirator (53) disposed further upstream than the yarn shift guide (52) so as to suck the yarns Y shifted by the yarn shift guide, and a cutter (54) disposed between the yarn shift guide (52) and the aspirator (53) so as to cut the yarns Y sucked by the aspirator (53).

Owner:TMT MACHINERY INC

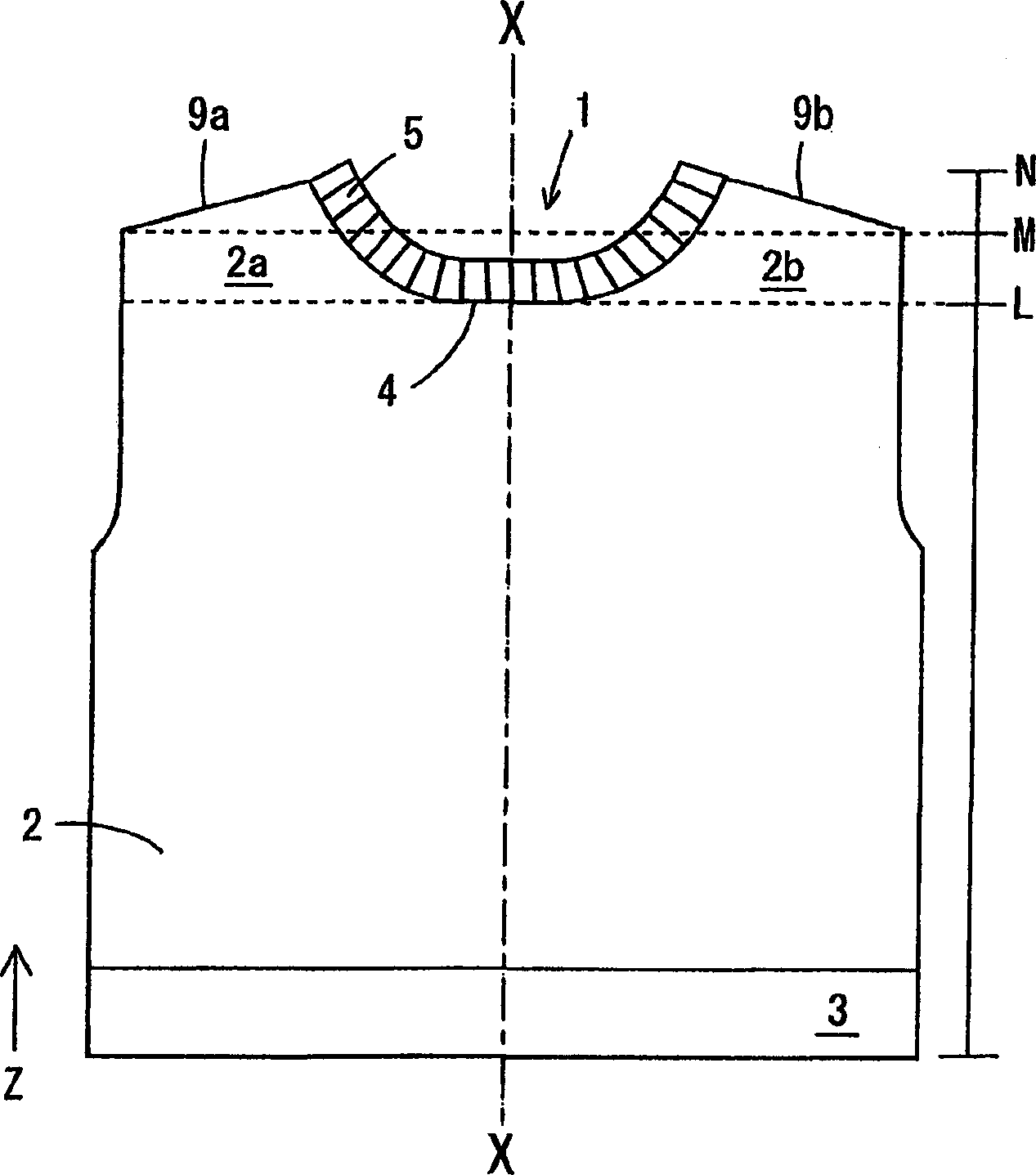

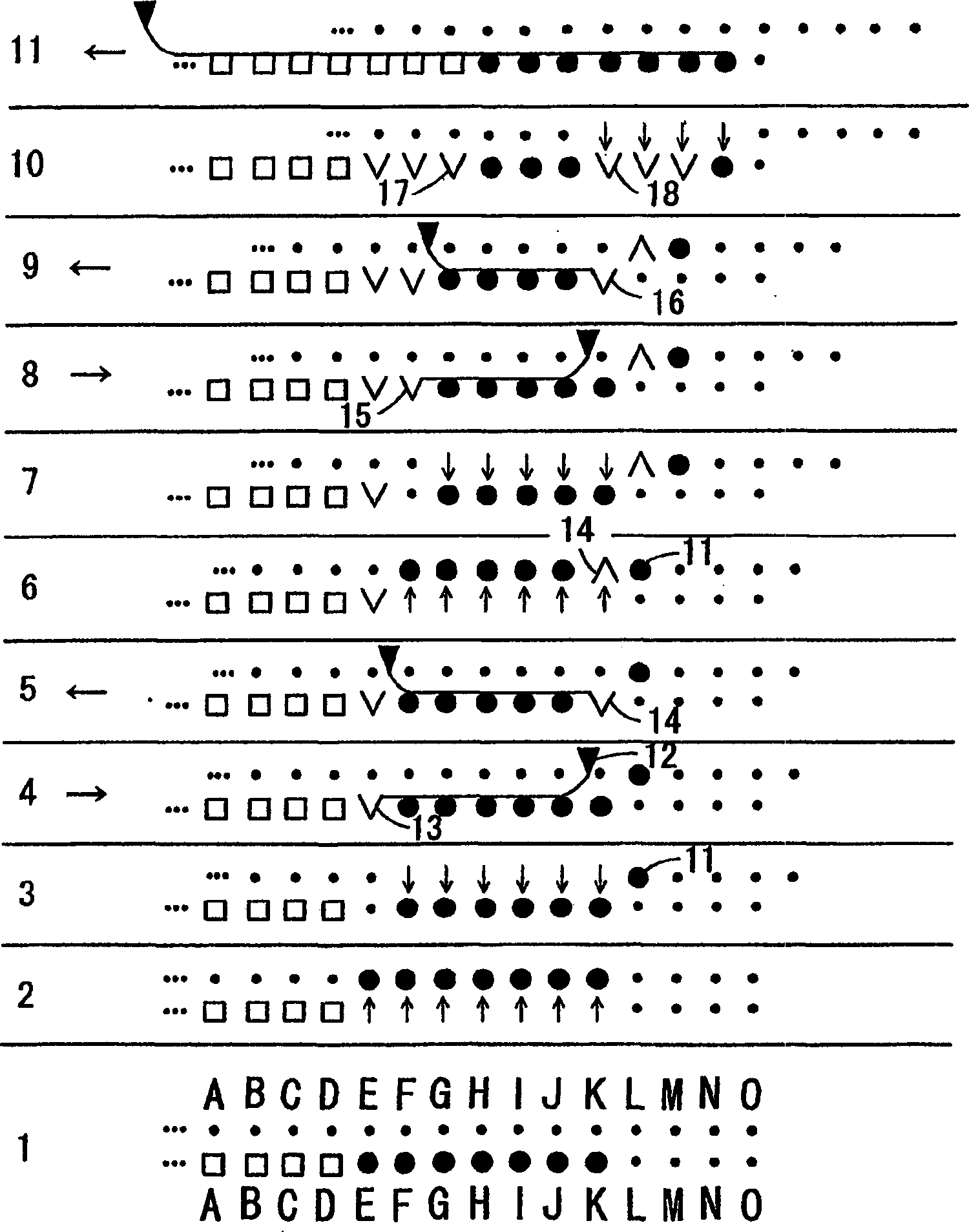

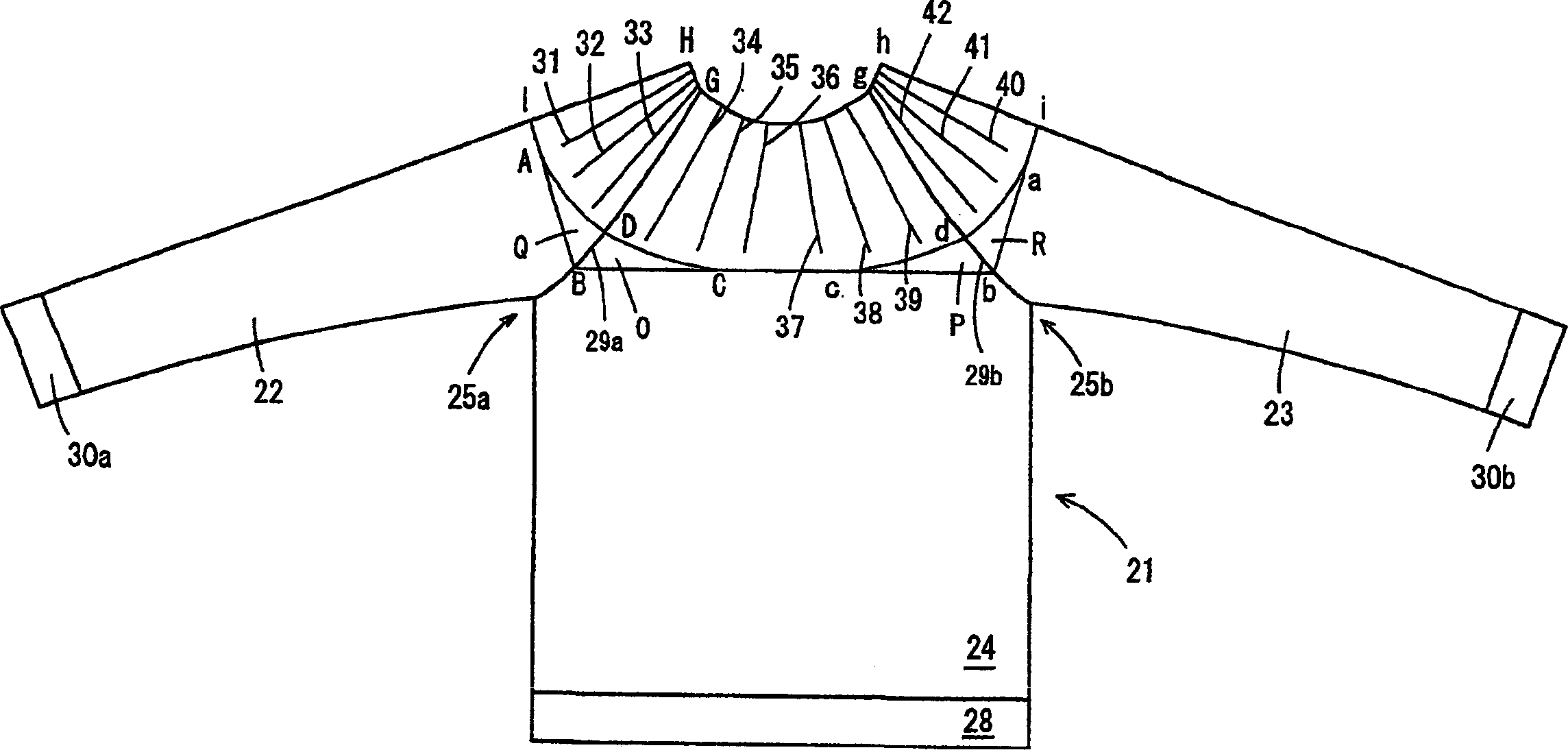

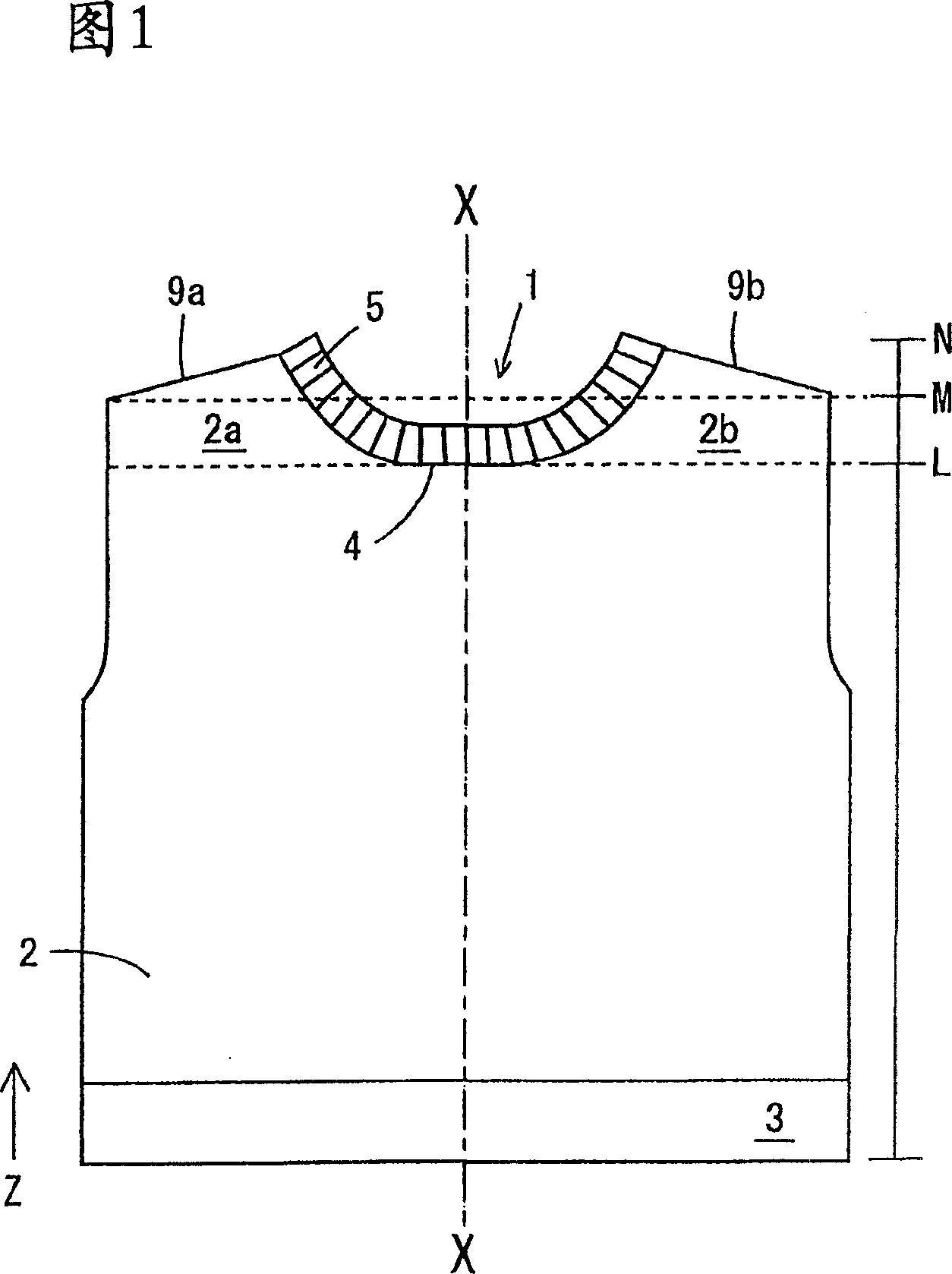

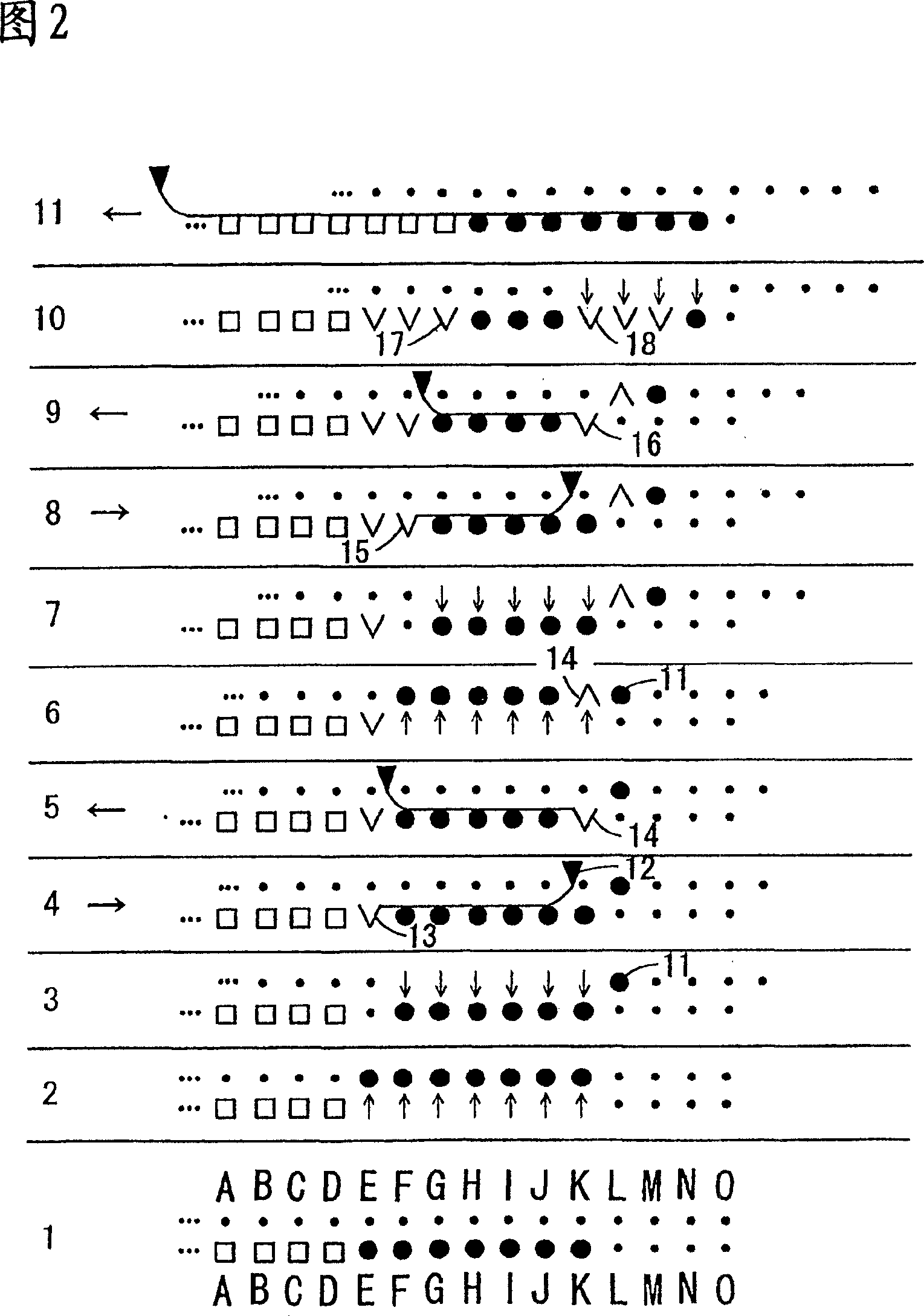

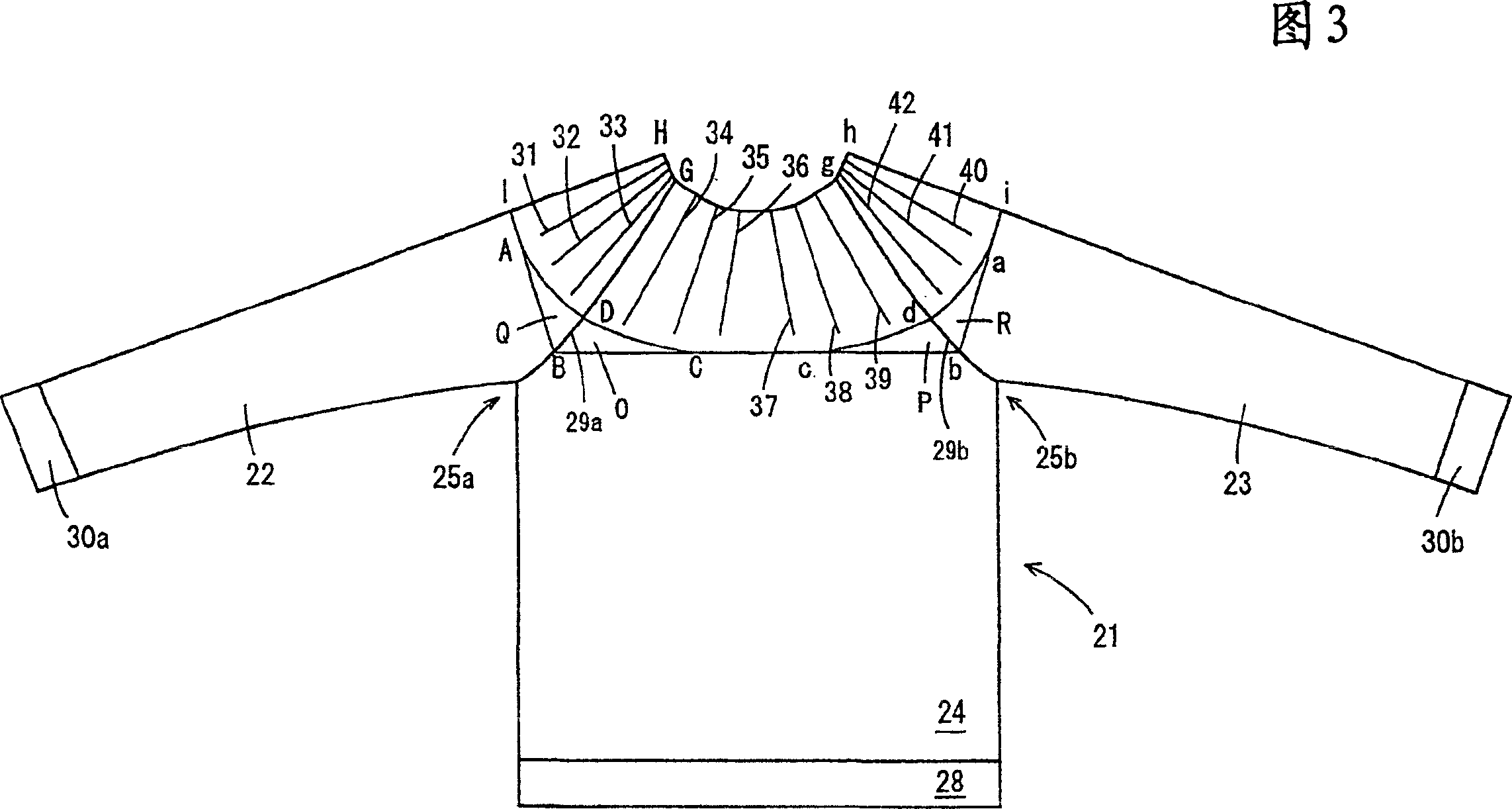

Method of knitting fabric

In a process of knitting a fabric during which at least a part of loops in the flechage knitting region are transferred between the front and back needle beds to move the loops laterally, loops in a stitch move region which are moved laterally whenever an adequate number of courses of the flechage knitting region are knitted are transferred to an opposite needle bed and then the front and back needle beds are moved relative to each other. Then, loops of wale which are put in the rest state in a process of the flechage knitting are held on the needle bed opposite to the needle bed on which loops of a next course are formed in a sequent flechage knitting until the stitch move is completed. Only the loops of the wale in which the loops of the next course are formed in the sequent knitting are transferred back to their originally retained needle bed prior to the forming of the loops of the next course. This knitting is repeatedly performed. This can allow the knitting of the region where the flechage knitting and the stitch move are performed concurrently without incurring problems such as stitch drop, yarn breakage, and the like.

Owner:SHIMA SEIKI MFG LTD

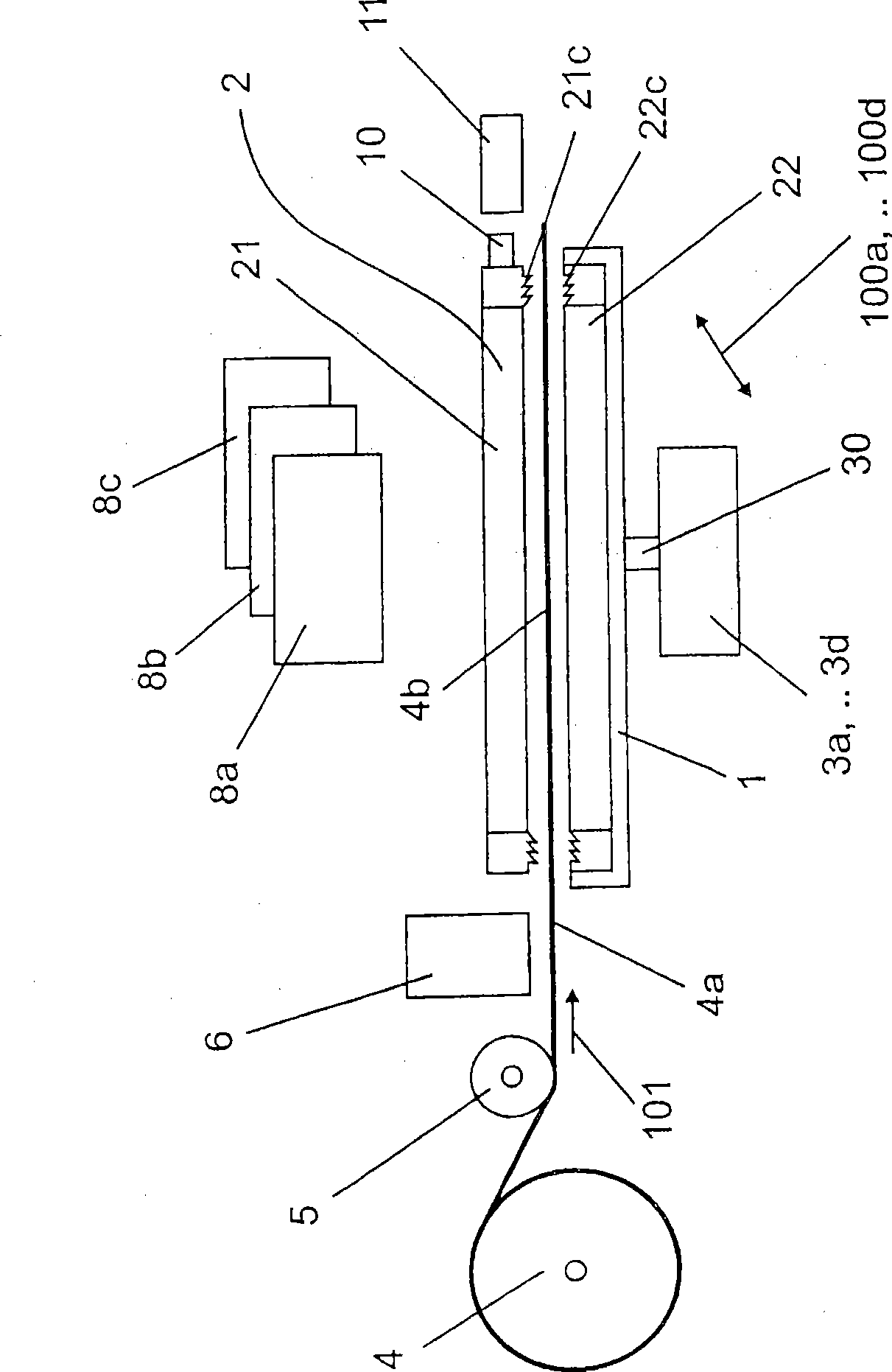

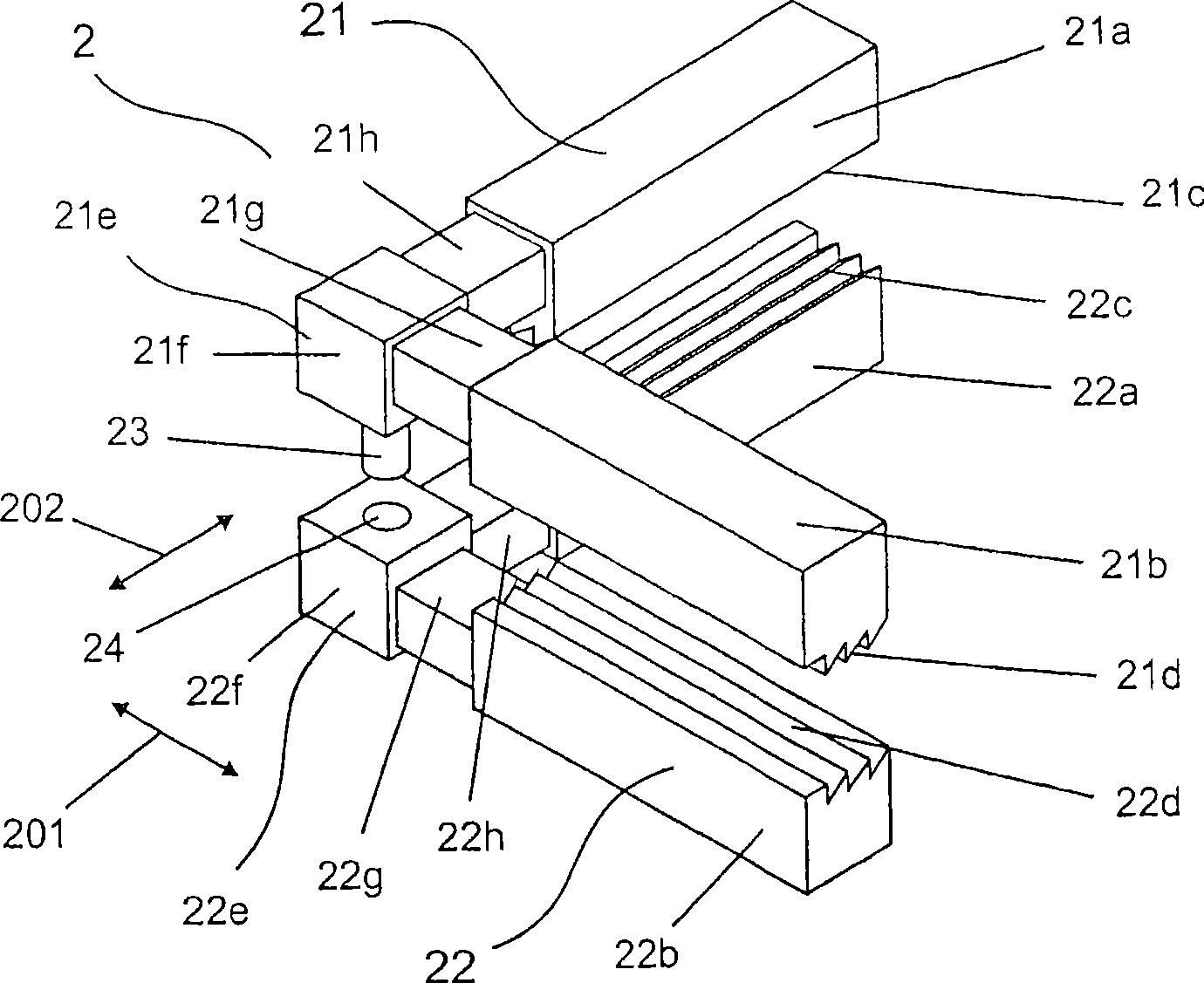

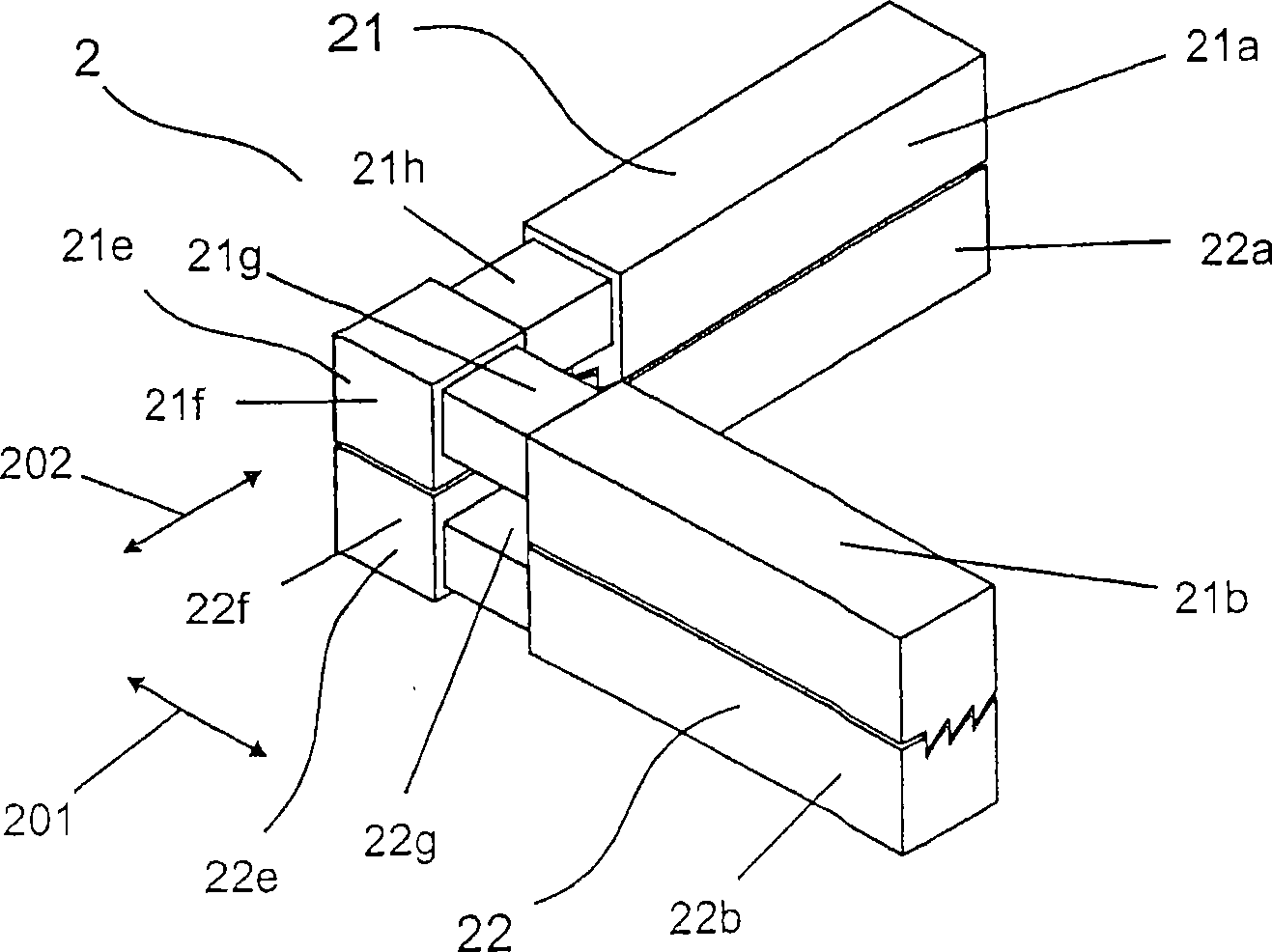

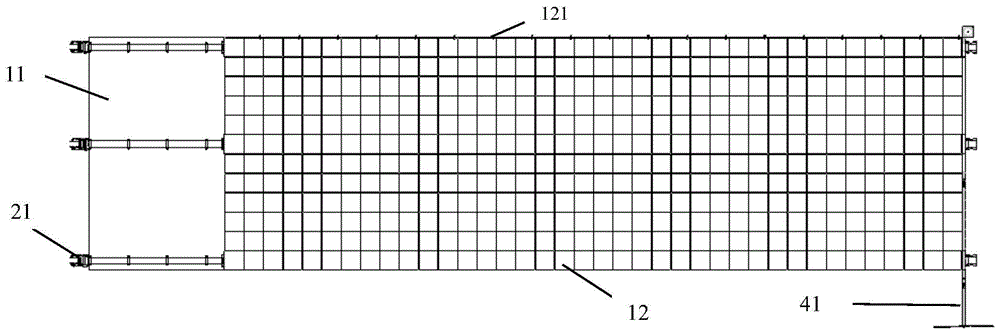

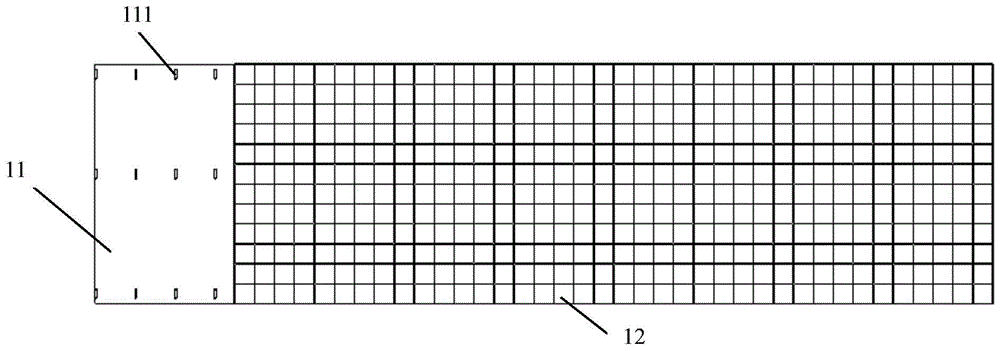

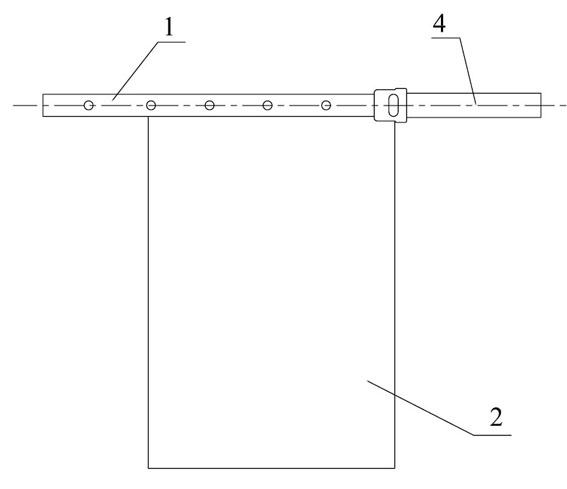

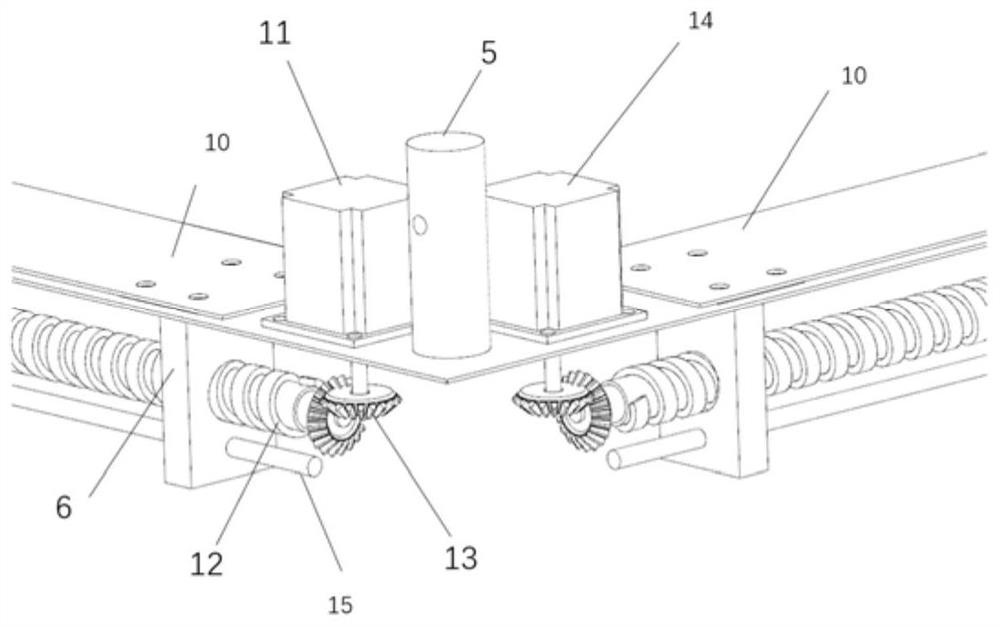

Device and method for tensioning screens and their use in printing presses as well as screen frame and silk screen printing press

InactiveCN101497256AClear positioningSuitable positioningScreen printersForme preparationEngineeringPrinting press

The invention relates to a method for manufacturing printed screens used in screen printing machine, including: fixing and positioning a screen frame (2) provided with filter screen (4a) or screen frame (2) which will be provided with filter screen (4a) in the next step, where position and state of the frame are detected. The filter screen (4a) of the frame is mechanically tensioned, and forces exerted on the screen are detected. The detected forces are stored as force data in a memory device (10), which is attached to the frame. The frame is removed from the accommodating device. The invention also relates to a method of using the printed screens used in screen printing machine, a device for manufacturing or using the printed screen, a screen frame and a screen printing machine.

Owner:KBA METRONIC AG

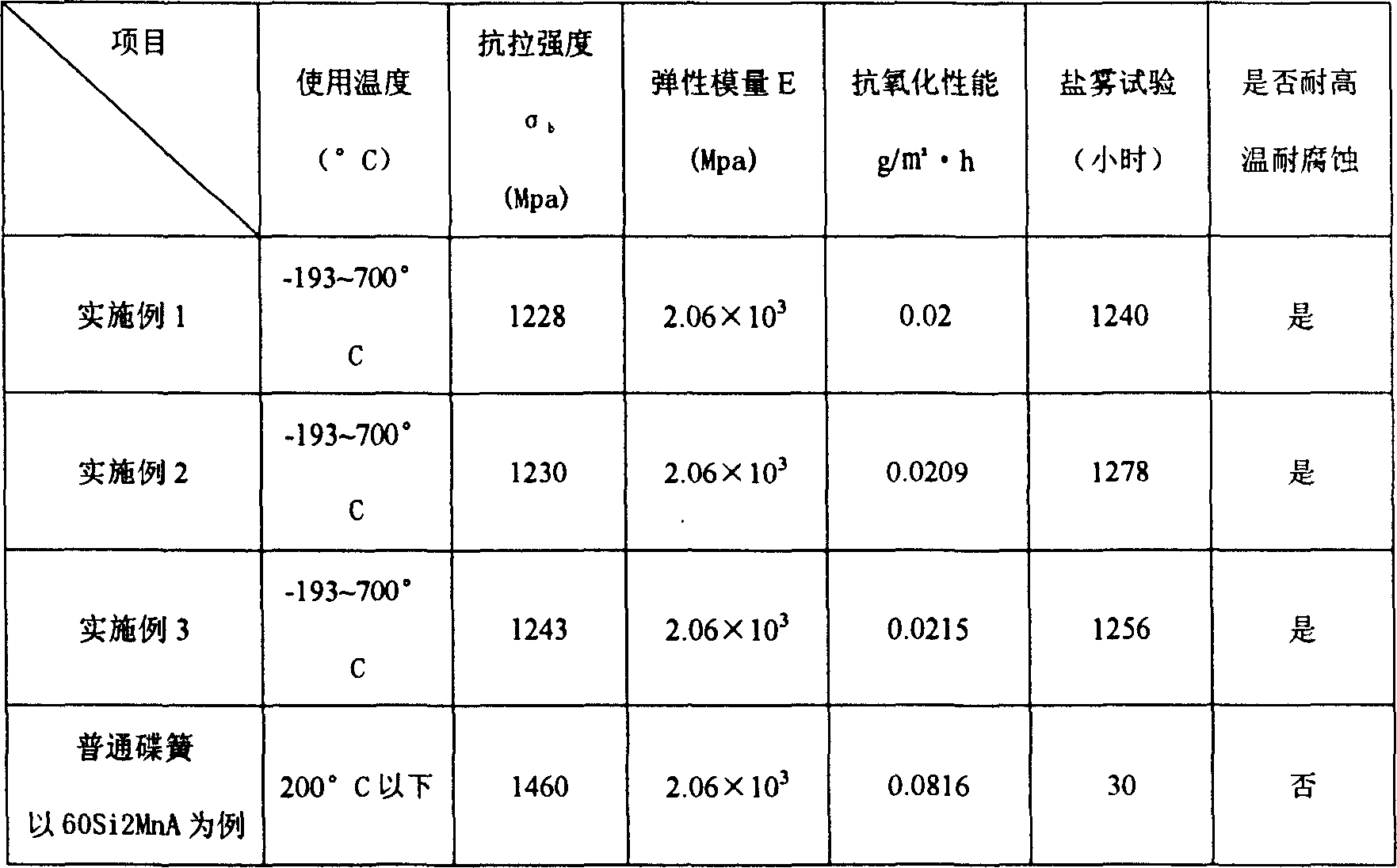

High temperature resistant anti-corrosion disc-shaped spring

The present invention relates to a kind of high temperature resistant anticorrosive disc spring, which is made with material comprising C, Si, Mn, Cr, Ni, Ti, Al, W, Mo, Nb, Fe and Cu. The making process includes the steps of: compounding material, smelting in vacuum high temperature furnace, ageing to form nickel base alloy material; punching, grinding, turning to form, heat treatment, shot blasting, pressing, and final surface treatment to obtain the high temperature resistant anticorrosive disc spring. The disc spring is used in avoiding loosing of screw to prevent leakage.

Owner:上海核工碟形弹簧制造有限公司

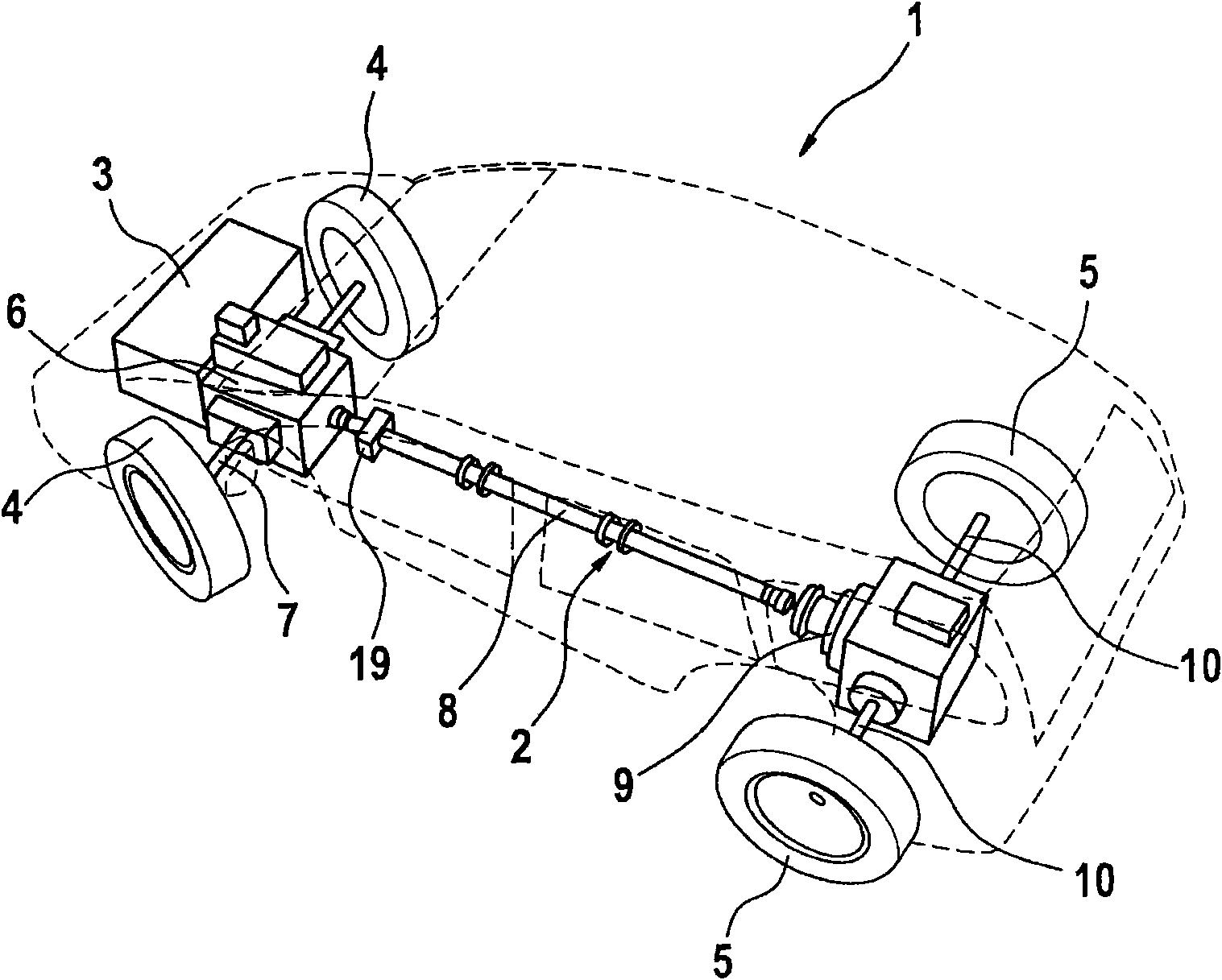

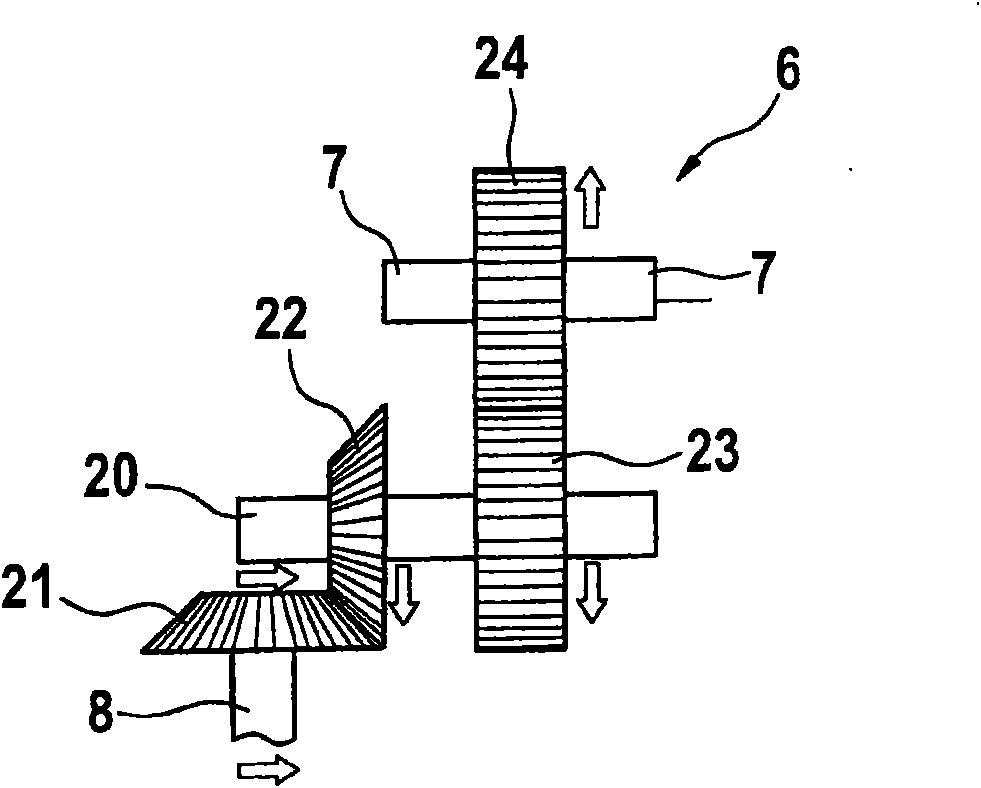

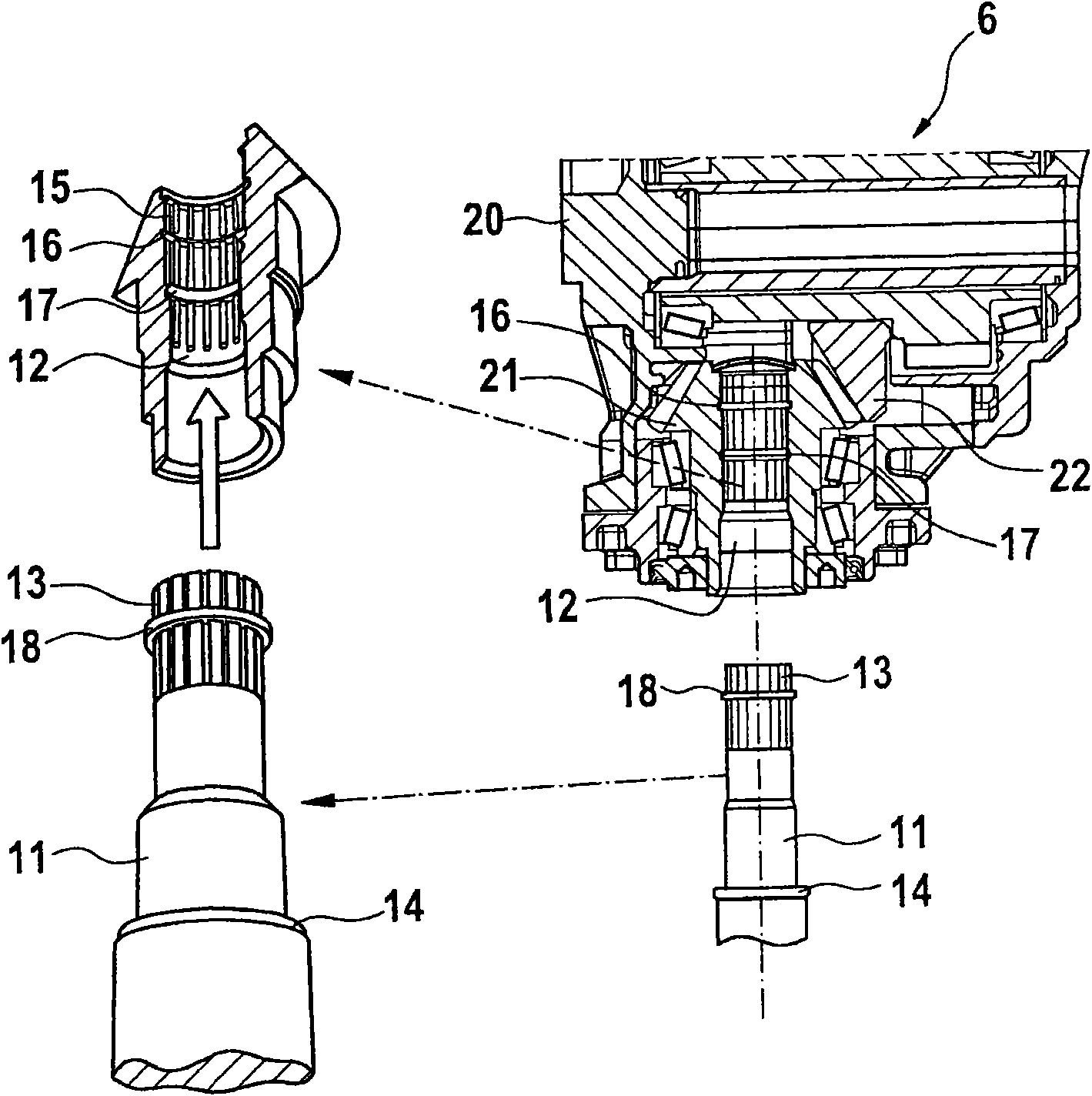

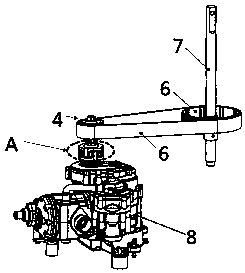

All wheel drive system

ActiveCN101595006AImprove space efficiencyReduce the risk of conflictCouplings for rigid shaftsConnectionsDrive shaftInterconnection

The present invention relates to a drive system and an interconnection unit for an all wheel drive vehicle (1), said drive system comprising a power take-off unit, a propshaft (8) and a rear drive module (9), said power take-off unit (6) being adapted to be attached to a vehicle's powertrain, and said propshaft (8) being adapted to transmit drive to the rear drive module (9), wherein the propshaft (8) and the power take-off unit (6) are connected by a joint for transmitting drive force from the power take-off unit (6) to the propshaft, wherein said joint between said power take-off unit (6) and said propshaft (8) comprises a female-male engagement, wherein the female (12) and male (11) engagement portions are non-rotatable in relation to each other when said joint is engaged.

Owner:GM GLOBAL TECH OPERATIONS LLC

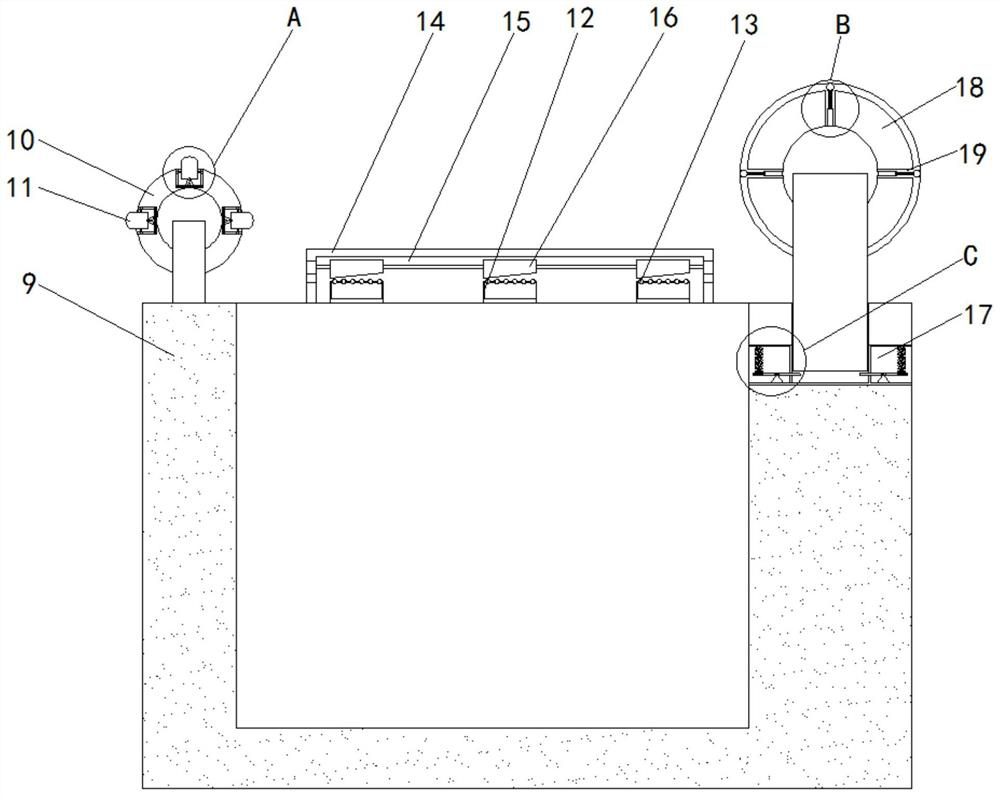

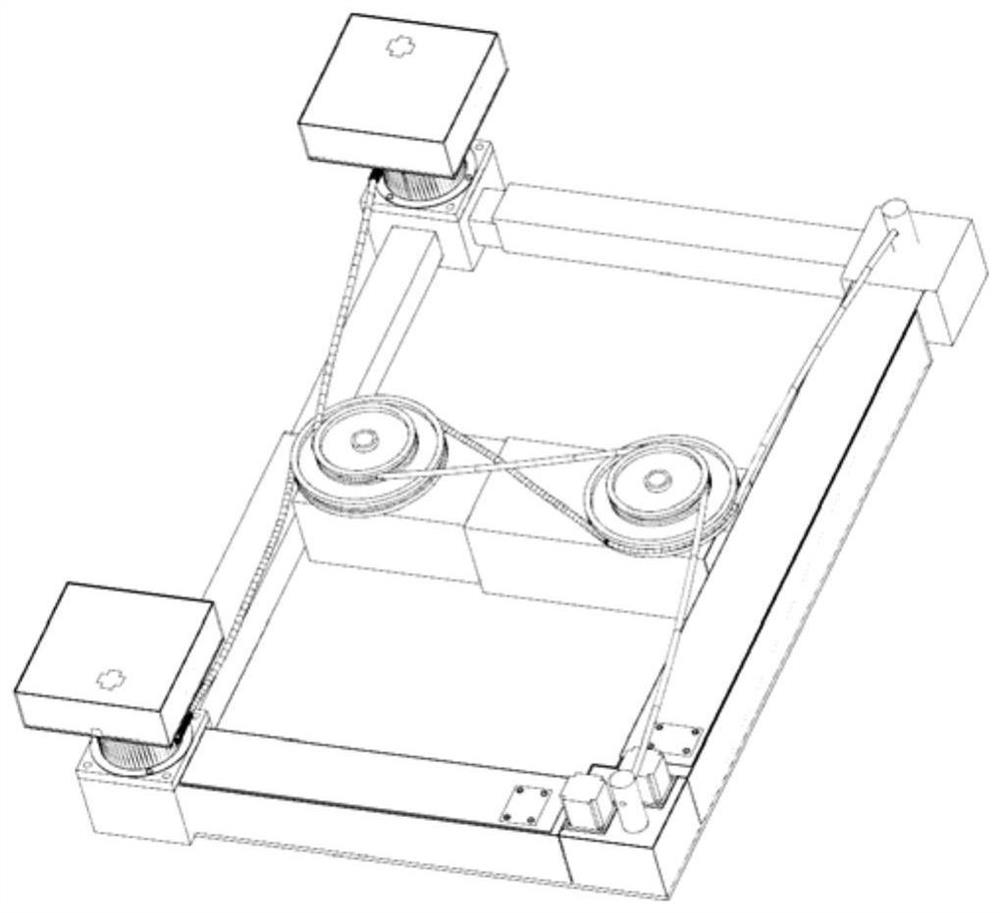

Pipe winding machine for condenser coil pipe

The invention discloses a pipe winding machine for a condenser coil pipe. The pipe winding machine for the condenser coil pipe comprises a bottom plate, wherein two supporting plates are welded to thetop of the bottom plate; a winding roller is rotatably installed between the two supporting plates; limiting plates sleeve two ends of the winding roller; the limiting plates are fixedly connected with the winding roller; a first bidirectional motor and a second bidirectional motor are fixedly installed on the bottom plate; an output shaft of the first bidirectional motor is fixedly connected with the winding roller; and two horizontally arranged guide rods are fixedly installed between the two supporting plates. A screw rod is rotatably installed between the two supporting plates, a moving plate is slidably installed on the guide rod, the moving plate is in threaded connection with the screw rod, an output shaft of the second bidirectional motor is fixedly connected with the screw rod, and the top of the moving plate is separately welded to a first side plate and a second side plate. According to the pipe winding machine for the condenser coil pipe, the uniform winding of a pipe is ensured, and meanwhile, the pipe is in a tight state in the winding process through a clamping mechanism, so that relaxation cannot occur, the pipe winding effect is good, the use is convenient, and the popularization is easy.

Owner:滁州雨博机电科技有限公司

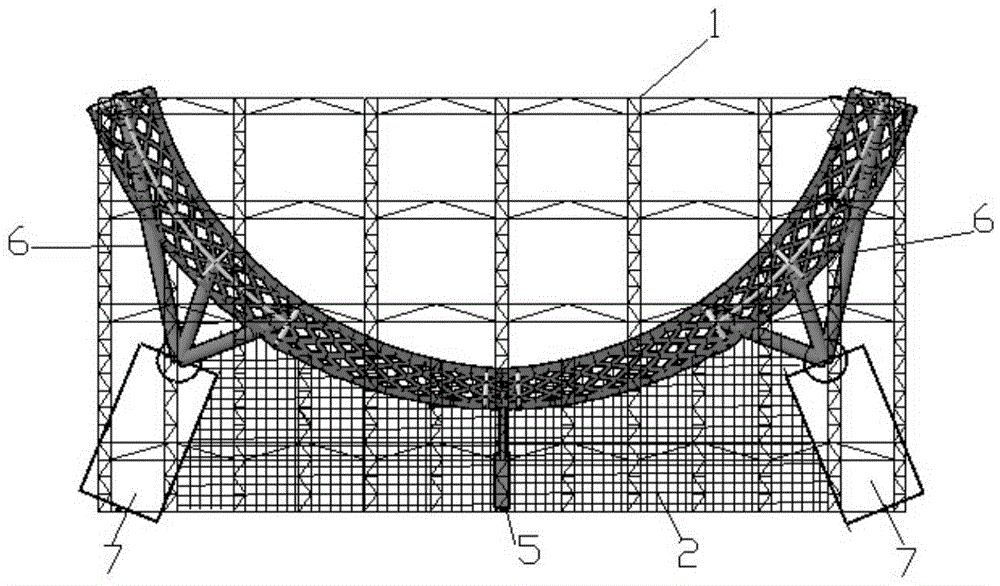

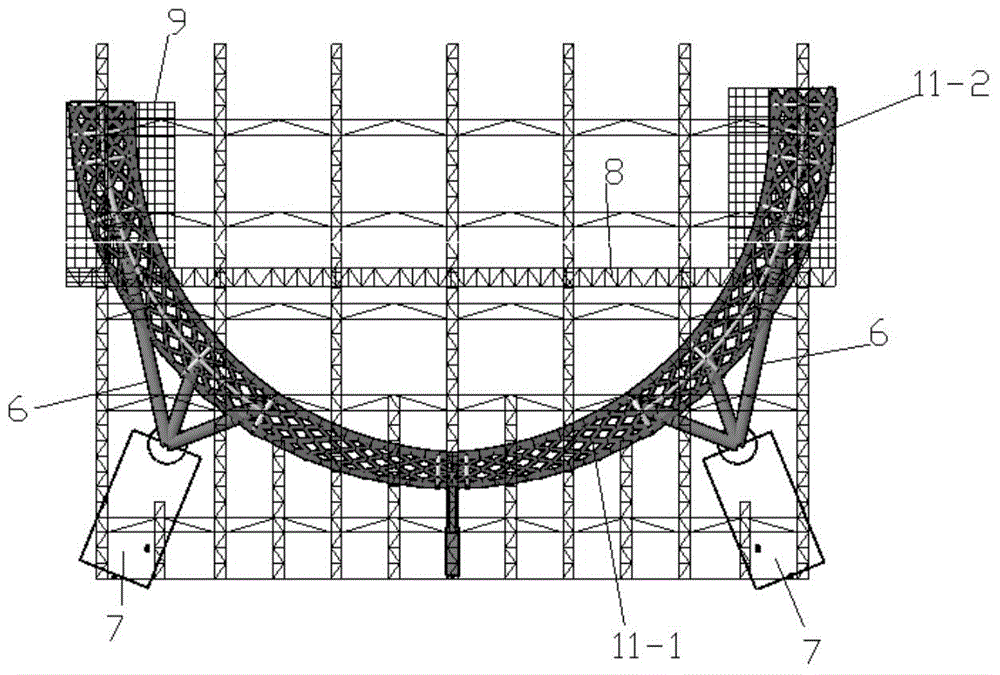

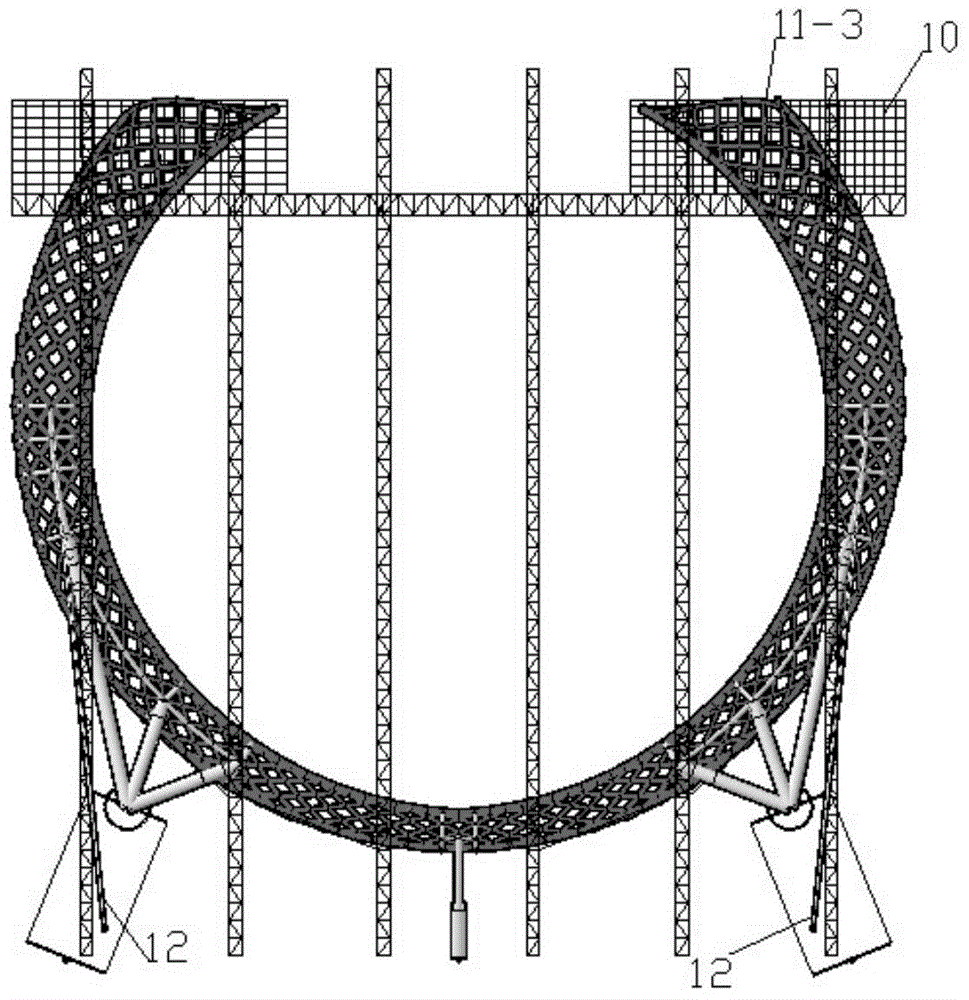

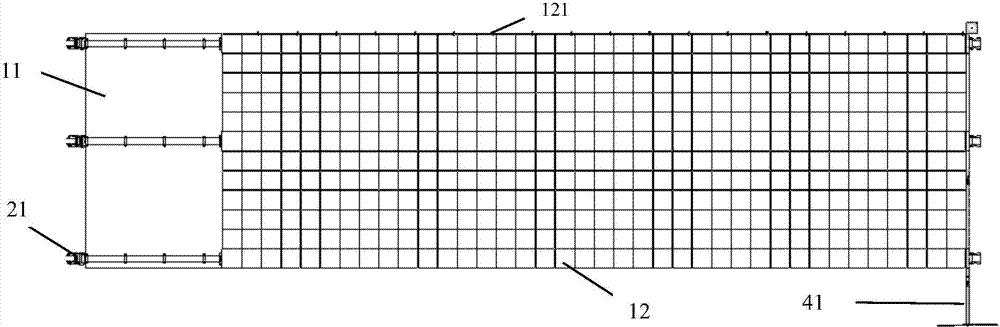

Assembling and support constructing method for wheel discs of sky wheels without axles

ActiveCN105298097AReduce distortionStable structureBuilding material handlingBuilding scaffoldsPre stressEngineering

The invention discloses an assembling and support constructing method for wheel discs of sky wheels without axles. The assembling and support constructing method includes steps of (1), respectively mounting two rows of lattice column bearing supports on the left side and the right side of each location where the corresponding sky wheel is about to be mounted; (2), mounting bottom constraint frames; (3), starting to mount the lower half portions of the wheel discs of the sky wheels on first all-round scaffold operation platforms, to be more specific, starting to mount the lower half portions of the wheel discs of the sky wheels from the bottom constraint frames, then symmetrically gradually extensively mounting the lower half portions of the wheel discs of the sky wheels until the lower half portions of the wheel discs reach positions for main leg of the lower portions of the wheel discs of the sky wheels, and mounting the main legs of the lower portions of the wheel discs of the sky wheels; (4), mounting lifting platforms on each two corresponding rows of lattice column bearing supports, continuously lifting the operation platforms to assemble the wheel discs of the sky wheels until more than halves of the wheel discs of the sky wheels are assembled, and symmetrically mounting six prestressed tension cables at two ends of each wheel disc of the sky wheel to carry out tension construction. The assembling and support constructing method has the advantage that structural stress and deformation requirements can be met by prestress distribution.

Owner:CHINA CONSTR SIXTH ENG BUREAU CIVILENG +1

Traditional Chinese medicine fat-reduction oral administration composition

InactiveCN104644821AImprove indigestionRestore energy metabolismMetabolism disorderPlant ingredientsLicorice rootsSenna

The invention relates to a traditional Chinese medicine fat-reduction oral administration composition and belongs to the technical field of traditional Chinese medicine preparations with indeterminate structures. The traditional Chinese medicine fat-reduction oral administration composition can obviously and fast reduce fat and has no side effects. The traditional Chinese medicine fat-reduction oral administration composition comprises 10-15g of cassia seed, 15-20g of haw, 10-15g of plantain seed, 5-10g of dried orange peel, 10-15g of fleece-flower root, 10-15g of licorice root, 6-8g of bitter orange, 4-6g of senna leaf and 5-10g of rose.

Owner:赵政

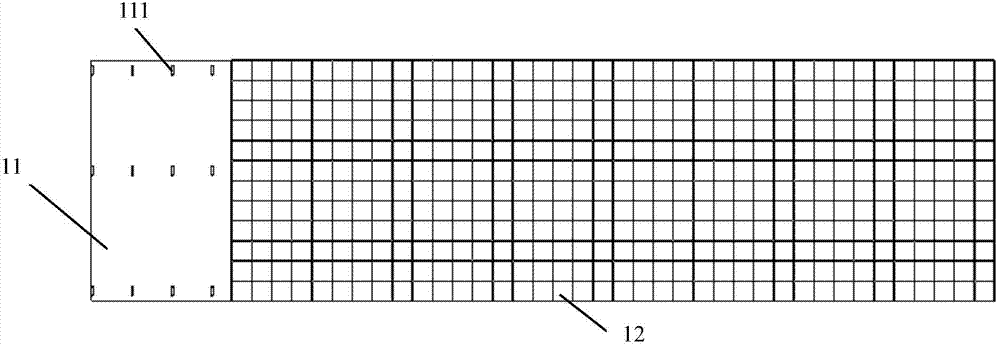

Pallet cargo packaging device

ActiveCN104760760ASave human effortLow costRigid containersContainers with multiple articlesEngineeringTorsion spring

The invention discloses a pallet cargo packaging device. The pallet cargo packaging device comprises a screen cloth component, an insert buckle component, a mounting component and a catch device and further comprises a storage device, the screen cloth component comprises a cloth piece and a screen piece connected with the right side of the cloth piece, the insert buckle component comprises an insert buckle, an insert box, a movable shaft, an insert buckle torsion spring, a button, a steel wire rope of the insert buckle and a steel wire rope chuck, the mounting component comprises a mounting rod and a connecting handle, the catch device comprises a plastic pipe with teeth, a switch component, a rubber band, a metal transverse plate, a round pin, a plastic standing leg gasket and a corrugated plastic piece, and the storage device comprises a wire storage box and a steel wire rope of the storage device. The pallet cargo packaging device can restrain all the cargoes in a package, the packaging, package unloading and package storage and arrangement are easy to perform and capable of being finished by one person, the person only needs to go around the pallet, the manpower investment and operation workload are reduced, and the packaging is stable.

Owner:金冠宏(泰安)生物科技有限公司

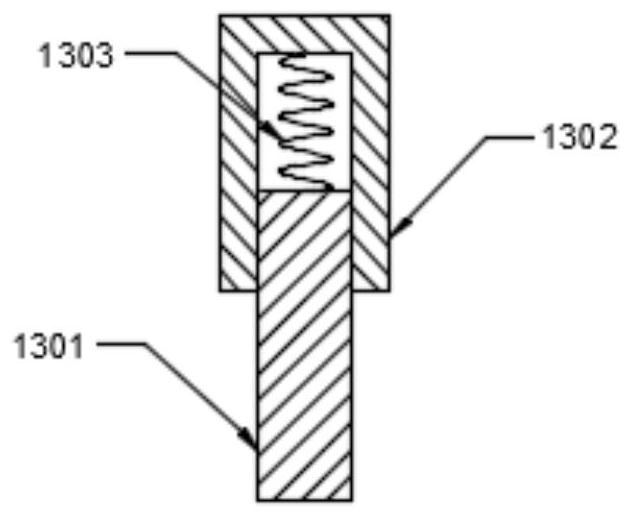

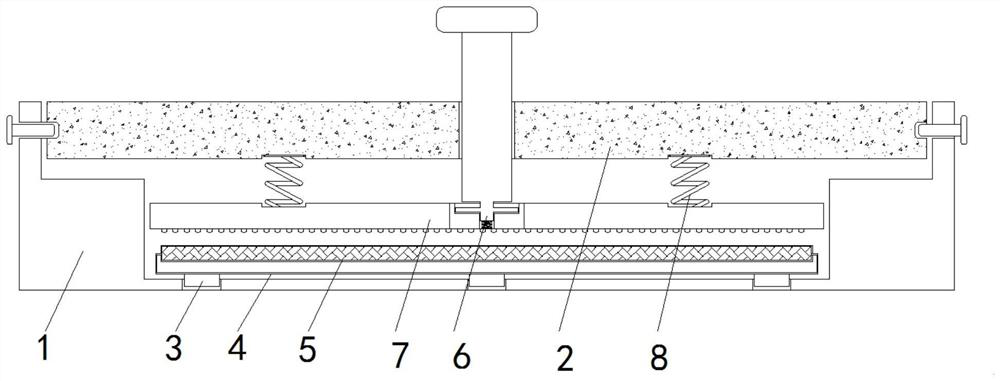

Take-up device for electric power

InactiveCN111847104AWon't relaxAvoid knotsFilament handlingApparatus for overhead lines/cablesElectric powerElectric wire

The invention discloses a take-up device for electric power. The take-up device comprises a base, wherein supporting frames are fixedly mounted on two sides of the base; a wire roller assembly is arranged between the two supporting frames; a take-up adjusting assembly is arranged on the base; the take-up adjusting assembly comprises slide blocks, a mounting plate, a roller and fixed plates; the two slide blocks are arranged on the base, and each of the two slide blocks is provided with a wire hole; the mounting plate is fixedly mounted above the slide blocks; the two fixed plates are symmetrically arranged at the lower end of the mounting plate; each fixed plate comprises a sleeve rod, a sleeve and a connecting spring; the sleeves are fixedly mounted on the mounting plate; each sleeve rodis movably arranged in the corresponding sleeve in a sleeving manner, and each connecting spring is arranged between the corresponding sleeve rod and the corresponding sleeve; the roller is rotatablymounted between the two sleeve rods; through arrangement of the take-up adjusting assembly, an electric wire on the wire roller assembly penetrates through the wire holes of the two slide blocks in atake-up process; and under the action of the connecting springs, the roller abuts against the electric wire all the time, so that the electric wire released from the wire holes is not loosened all thetime and is prevented from being knotted.

Owner:宋允华

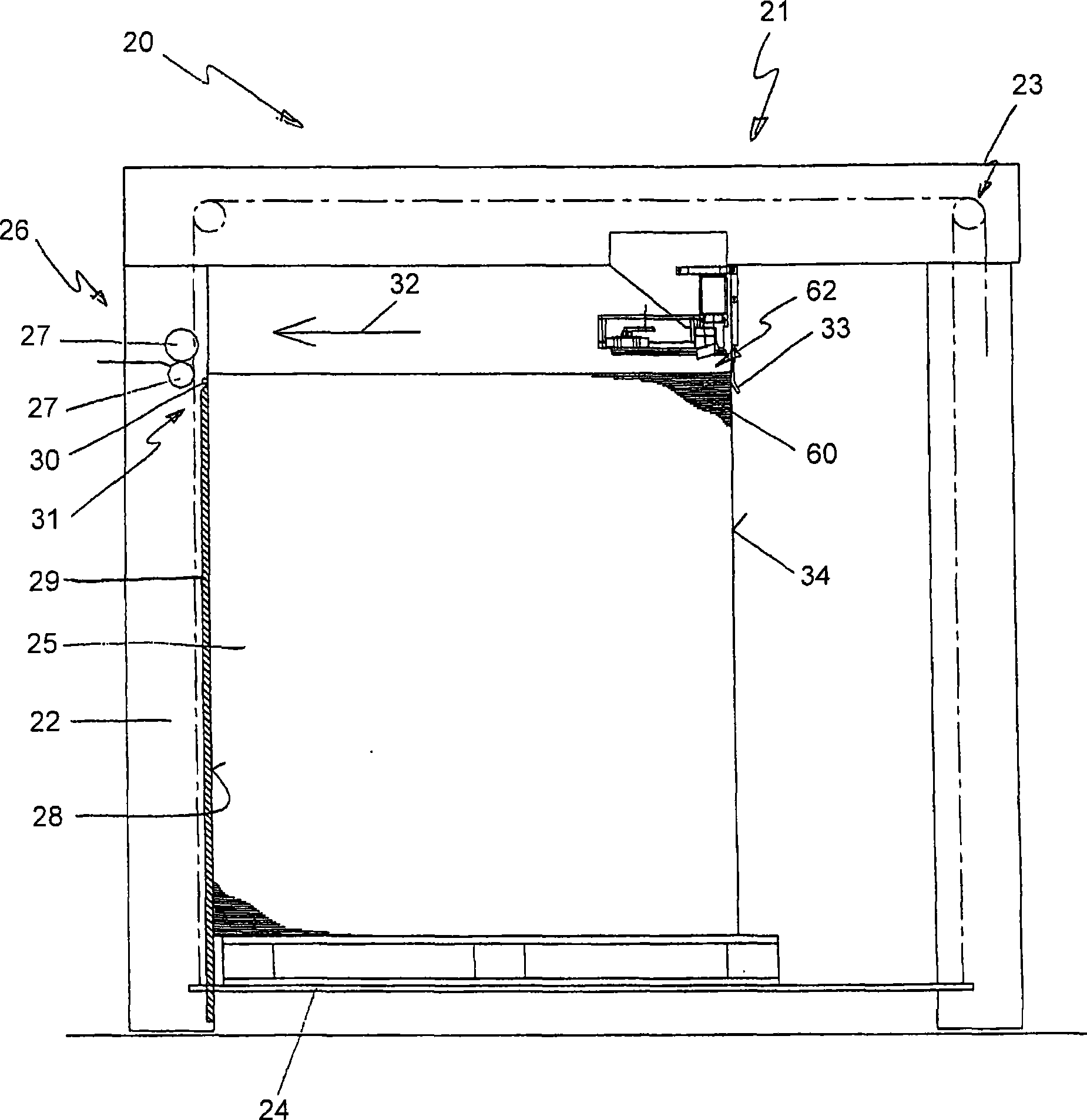

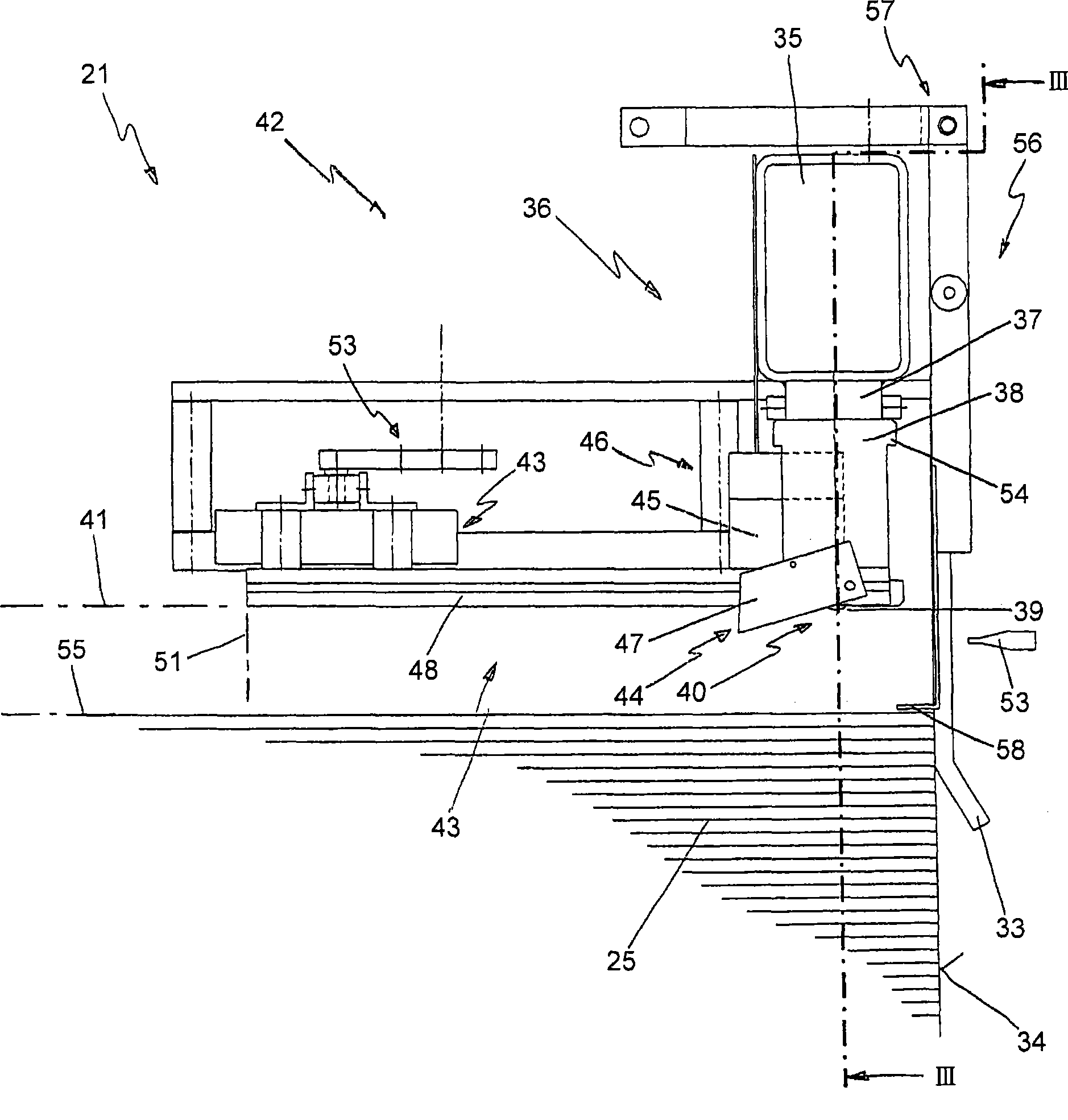

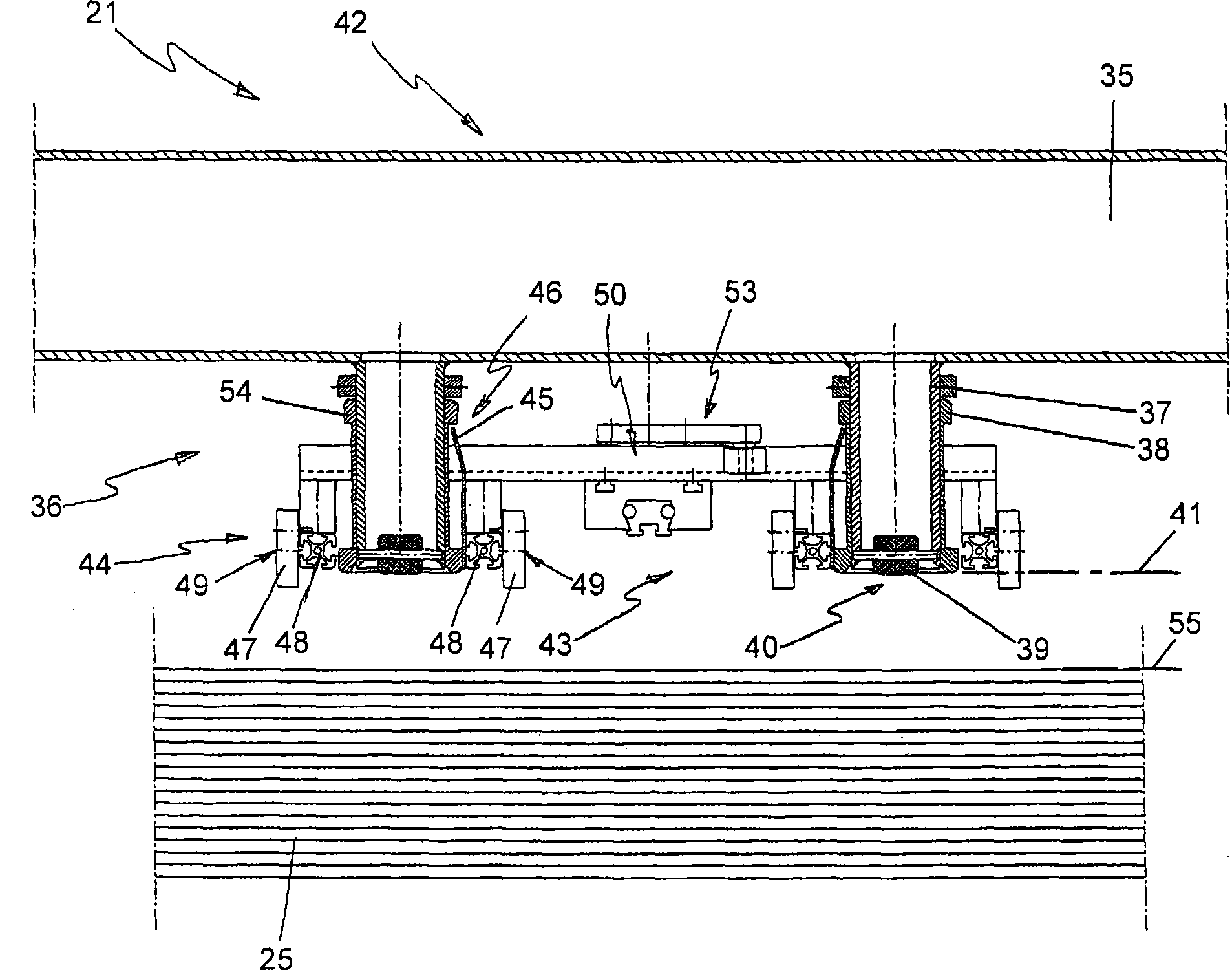

Handling apparatus and method for separating and feeding sheet blanks

InactiveCN101506072AFast working frequencyRapid positioningArticle separationSuction forcePaperboard

The invention relates to a handling apparatus (21) and to a method for separating and feeding sheet blanks (60) of a stack (25) to a transfer device, wherein the handling apparatus has a conveying apparatus (42) for feeding a sheet blank, having at least one lifting device (36) with a suction element (38) which can be moved vertically on the lifting device, and a separating apparatus (56) for separating the sheet blanks of the stack. A sheet blank can be picked up by the lifting device at a sheet rear edge region which faces away from the transfer device, the suction element is loaded with a constant vacuum and the conveying apparatus has a guide device (43) for guiding a stripping device (44) horizontally, in such a way that the sheet blank can be separated from the suction element by the stripping device and can be fed to the transfer device.

Owner:STOCK MASCHENBAU

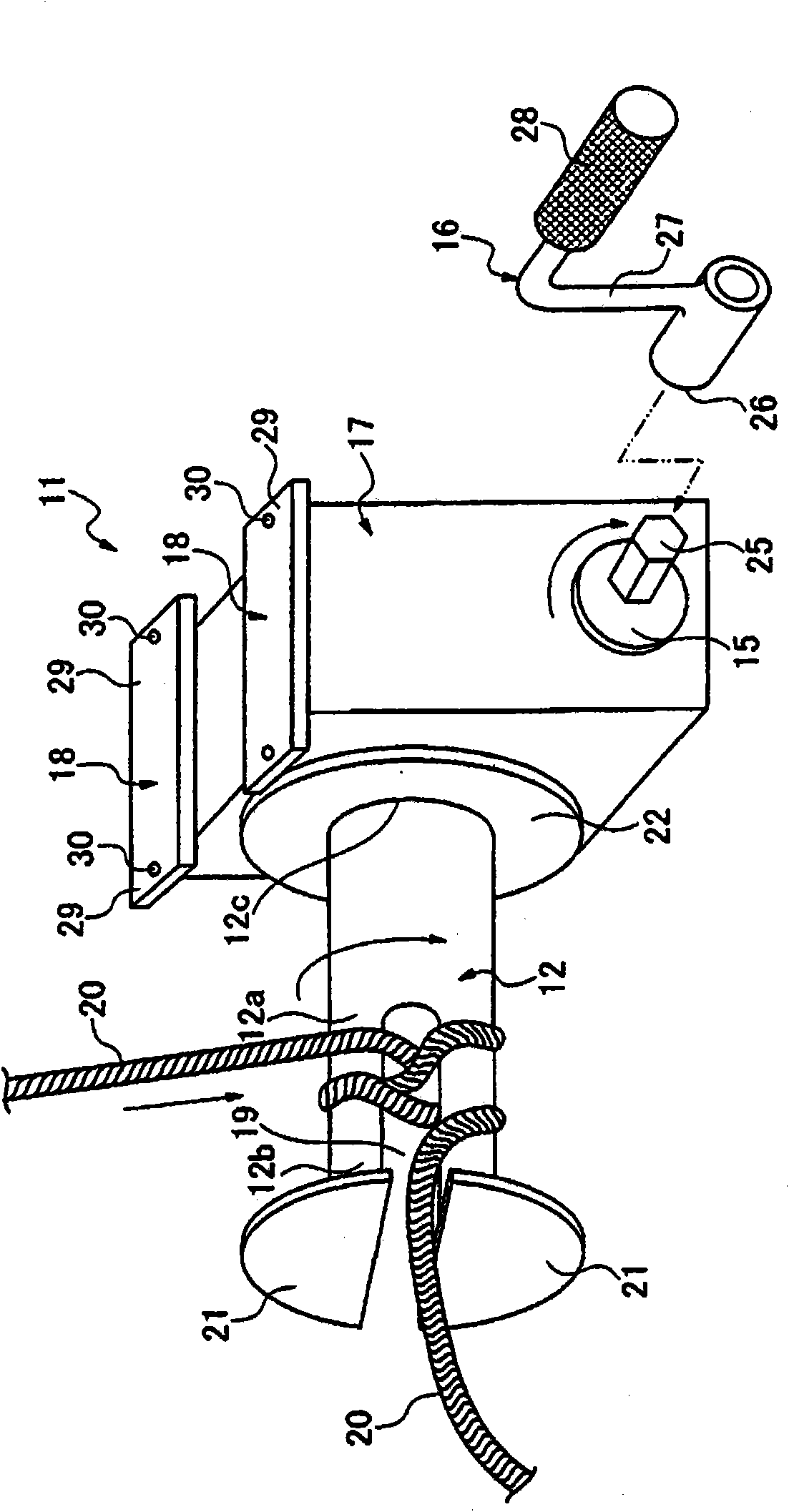

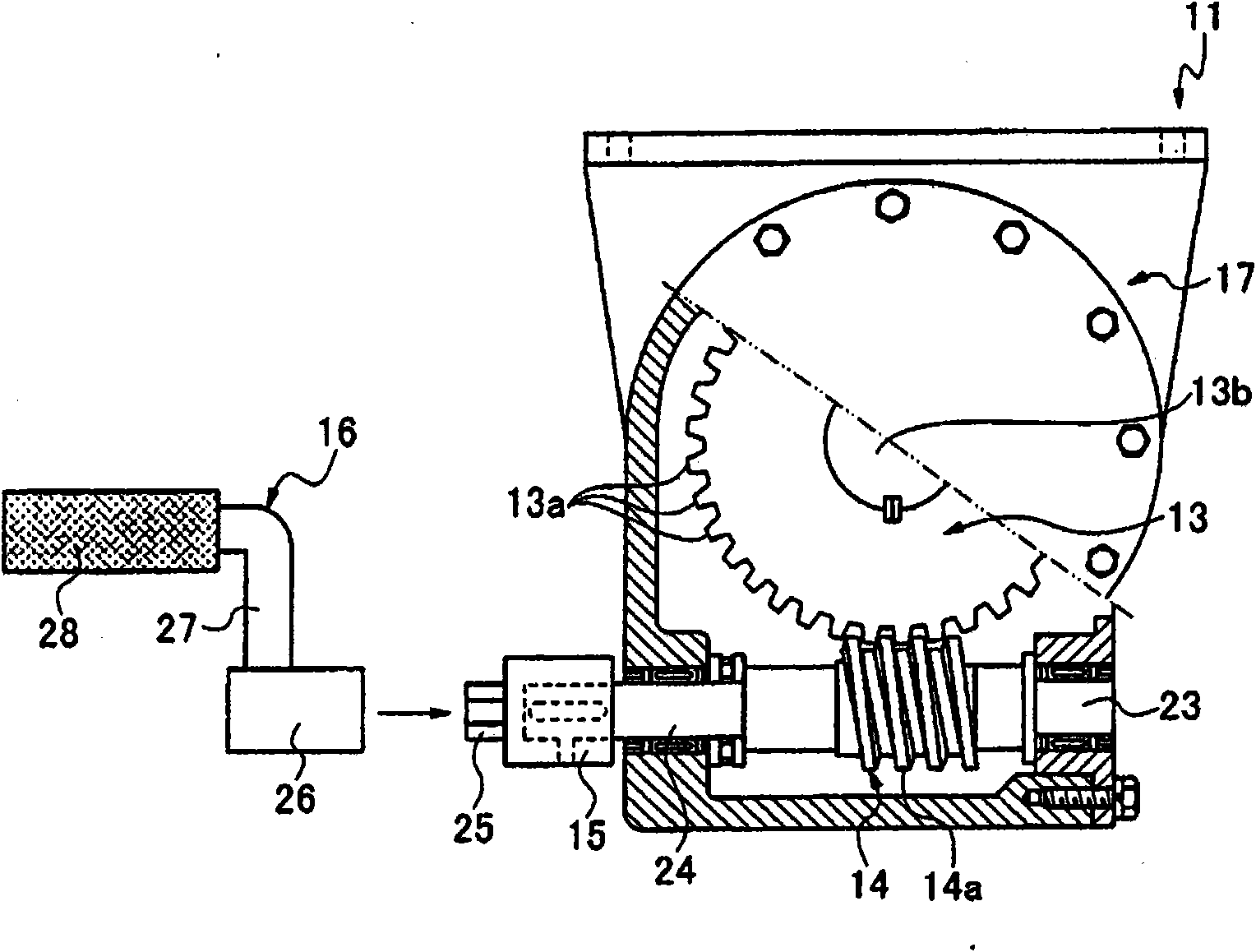

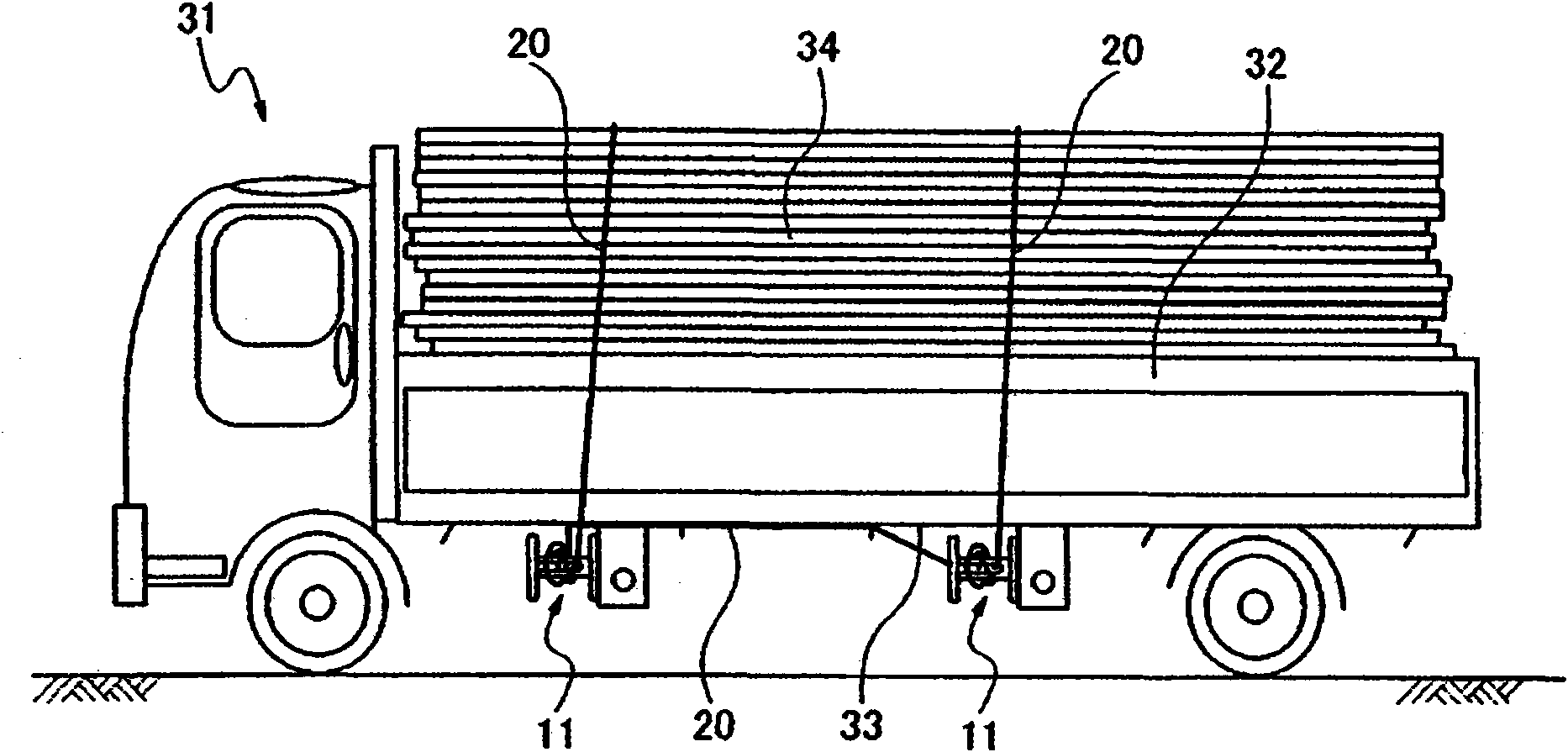

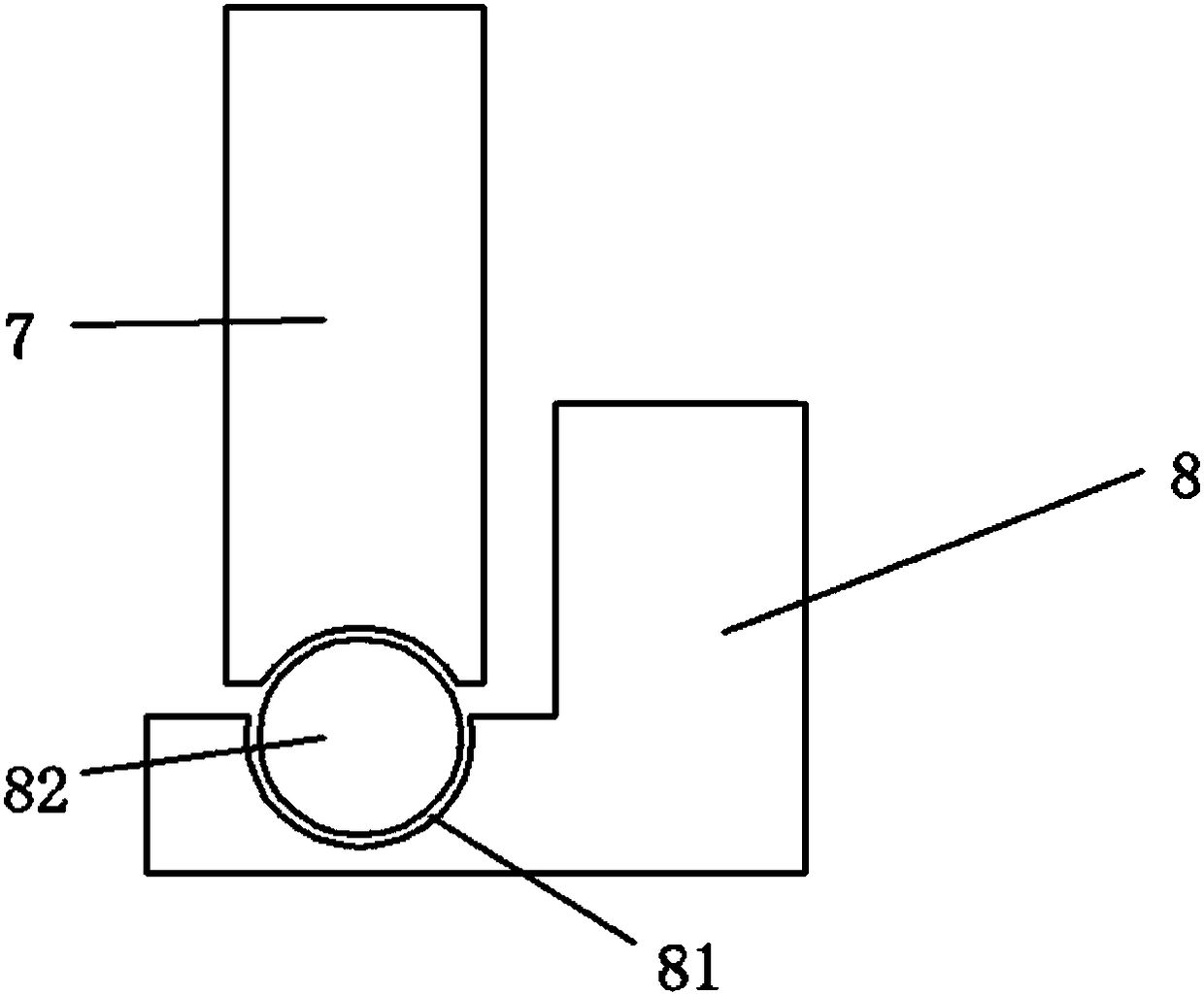

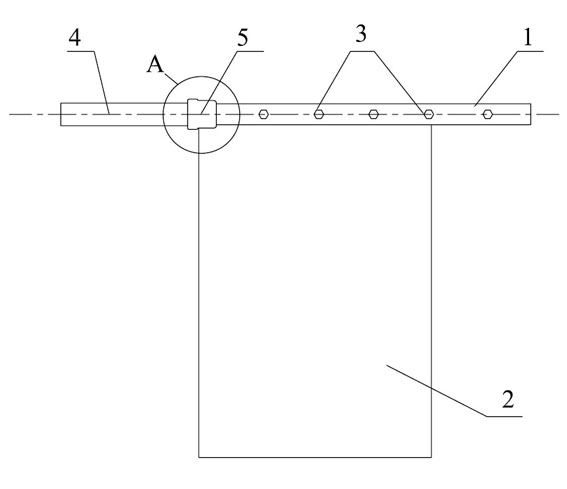

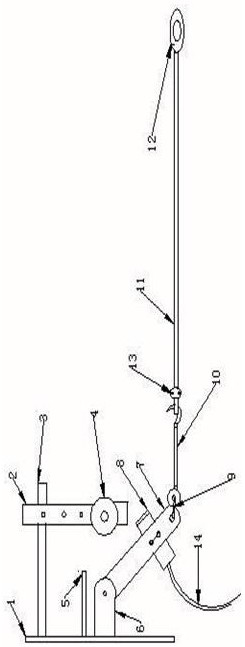

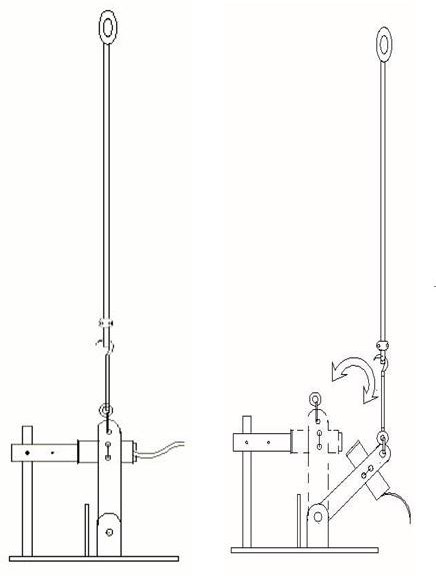

Rope fastening device

InactiveCN101896374AImprove fastnessWon't relaxLoad securingTransportation itemsEngineeringConductor Coil

A rope fastening device (11) provided at a predetermined position of a vehicle and fastening a rope (20) placed over a load on the vehicle. The rope fastening device (11) has a rope winding drum (12) having a rope hitch opening (19), a worm wheel (13) with which the drum (12) is operatively associated, a worm (14) meshing with the worm wheel (13), a rotation shaft (15) connected to the worm (14),rotation means (16) provided at an end of the rotation shaft (15), a gear box (17) in which the worm wheel (13) and the worm (14) are received, and an installation section (18) fitted to the gear box(17). The rope fastening device (11) can prevent a collapse of loads on a vehicle etc. by reliably fastening with simple operation a rope or other fastening materials placed over the loads.

Owner:沼田幸男

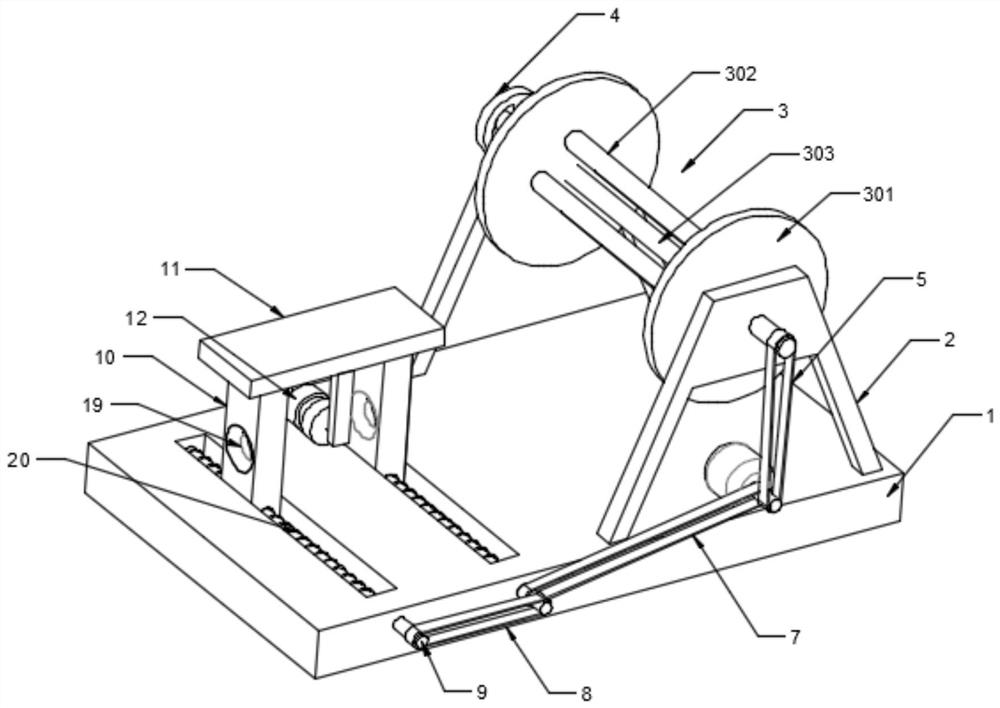

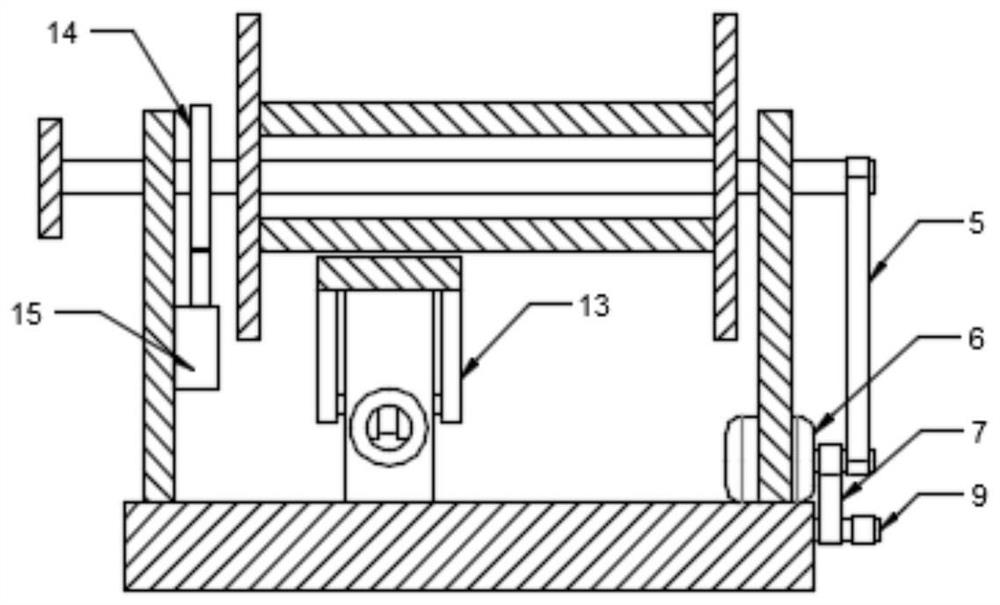

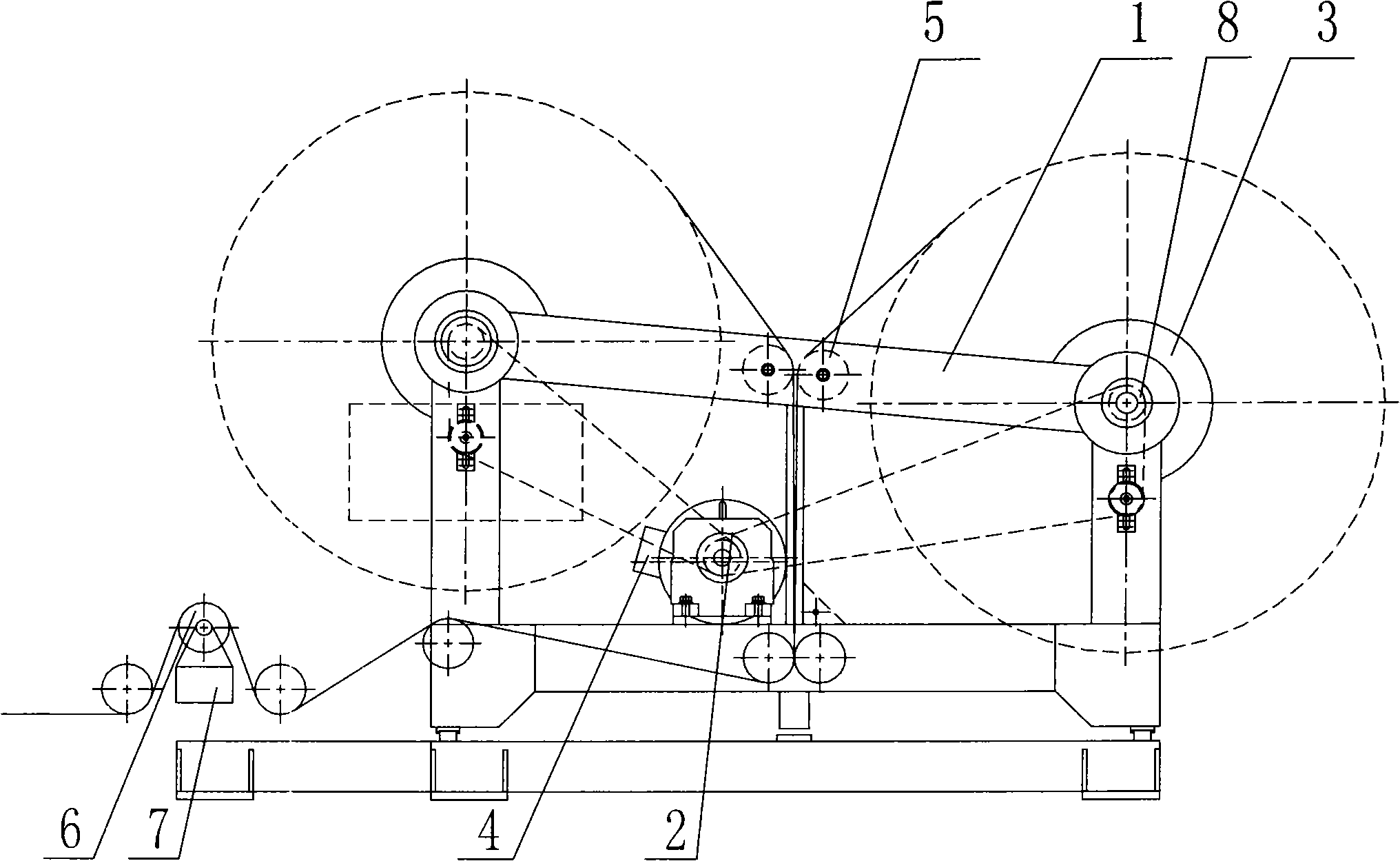

Constant-tension unreeling machine

The invention relates to an unreeling machine, in particular to a constant-tension unreeling machine. The constant-tension unreeling machine comprises a rack and a motor reducing gear; unreeling shafts are arranged at the two ends of the rack; chain wheels are arranged on the unreeling shafts; a clamping roller is arranged between the unreeling shafts; the unreeling shafts is connected with the motor reducing gear in a transmission way through chains; a transfer roller group is arranged at the position of a base of the rack; a vector frequency converter is arranged on the motor reducing gear; and a pressure sensor is arranged on one transfer roller in the transfer roller group. The unreeling machine solves the technical problem that the conventional unreeling machine cannot conveniently and effectively maintain a constant tension in an unreeling process, controls the linear velocity of materials when unreeling by arranging the vector frequency converter on the motor reducing gear to make the material unreeling linear velocity constant, and ensures the constant tension of the unreeling machine when unreeling.

Owner:CHANGZHOU HUASHENG PLASTIC MACHINERY

Calendering device and calendering method for producing table cloth

ActiveCN108215042AThe rotating structure is flexible and ingeniousAvoid damageFlat articlesMotor shaftEngineering

The invention discloses a calendering device for producing table cloth in the technical field of table cloth calendering. The device comprises a calendering base; an oil pump is arranged on the innerwall of the bottom of the calendering base; two oil guide pipes are respectively arranged at the left end and the right end of the oil pump; the oil guide pipes pass through the calendering base and are connected with hydraulic cylinders; the two sets of hydraulic cylinders are respectively positioned on the outer walls of the left side and the right side of the calendering base; two sets of piston rods are respectively arranged on the tops of the hydraulic cylinders; push blocks are respectively arranged on the tops of the piston rods; support plates are respectively arranged on the tops of the push blocks; a press roller I is arranged on the outer wall of a rotating shaft; the top of each support plate is provided with a running axis by means of a bearing; a press roller II is arranged on the outer walls of the running axes; a driving V-belt wheel is positioned on the outer wall of a motor shaft, the motor shaft is positioned at the right end of a rotating motor, and the motor shaftis connected with the left end of the rotating shaft by means of a coupling. The device is simple to operate, and can adjust the gap between the press rollers by operating the oil pump; a V belt and the V-belt wheel are matched with a locking swivel plate, so that the motion is enabled to be stable.

Owner:山东豪威日用品有限公司

Method for sticking connection joint of graphite electrode for making steel

InactiveCN101282602AWon't relaxReduce consumptionElectric discharge heatingAdhesive processes with surface pretreatmentGraphite electrodeGraphite

A method of preventing the graphite electrode connection part joints used in electric furnace steelmaking from relaxing. The method infuses asphalt in the graphite joints blank before processing into products. The best way of infusing is to process the graphite joints blank into the double-cone approximate to the shape of the joints in advance, then infuses. But if infusing the blank which is not processed in advance is also able to achieve the effect. The method directly processes the blank into electrode joints after infusing. The joints and the electrode are given to the users in matching. Adopting the invention is able to lead the electrode to not relax when used by the users, and the electrode consumption is reduced by 3-5%.

Owner:NANTONG RIVER EAST CARBON

Palletized goods packing device

ActiveCN104760760BSave human effortLow costRigid containersContainers with multiple articlesTorsion springPallet

The invention discloses a pallet cargo packaging device. The pallet cargo packaging device comprises a screen cloth component, an insert buckle component, a mounting component and a catch device and further comprises a storage device, the screen cloth component comprises a cloth piece and a screen piece connected with the right side of the cloth piece, the insert buckle component comprises an insert buckle, an insert box, a movable shaft, an insert buckle torsion spring, a button, a steel wire rope of the insert buckle and a steel wire rope chuck, the mounting component comprises a mounting rod and a connecting handle, the catch device comprises a plastic pipe with teeth, a switch component, a rubber band, a metal transverse plate, a round pin, a plastic standing leg gasket and a corrugated plastic piece, and the storage device comprises a wire storage box and a steel wire rope of the storage device. The pallet cargo packaging device can restrain all the cargoes in a package, the packaging, package unloading and package storage and arrangement are easy to perform and capable of being finished by one person, the person only needs to go around the pallet, the manpower investment and operation workload are reduced, and the packaging is stable.

Owner:金冠宏(泰安)生物科技有限公司

Transition method and transition joint between polar plate and copper conducting beam

The invention provides a transition method between a polar plate and a copper conducting beam. A conducting cross beam is provided and is fixed to the upper end of the polar plate, and a mold is also provided in the method. The copper conducting beam is adjacent to one section of the conducting cross beam, the conducting cross beam is adjacent to one section of copper conducting beam, one part of the polar plate connected with the conducting cross beam adjacent to the section of the copper conducting beam and an area of the polar plate adjacent to the part are horizontally placed in a reaction chamber of the mold and are welded together by using an exothermic welding method. A welding flux of exothermic welding contains copper oxide. Because the technical scheme of the invention is adopted, the copper conducting beam, the conducting cross beam and the polar plate are fused and welded at a time, so that the connecting molecular structure of the transition joint is reconstructed, and the integrity of the transition joint is reached.

Owner:石佐

Equal-distance molding press

Owner:叶纪友

Method of knitting fabric

Owner:SHIMA SEIKI MFG LTD

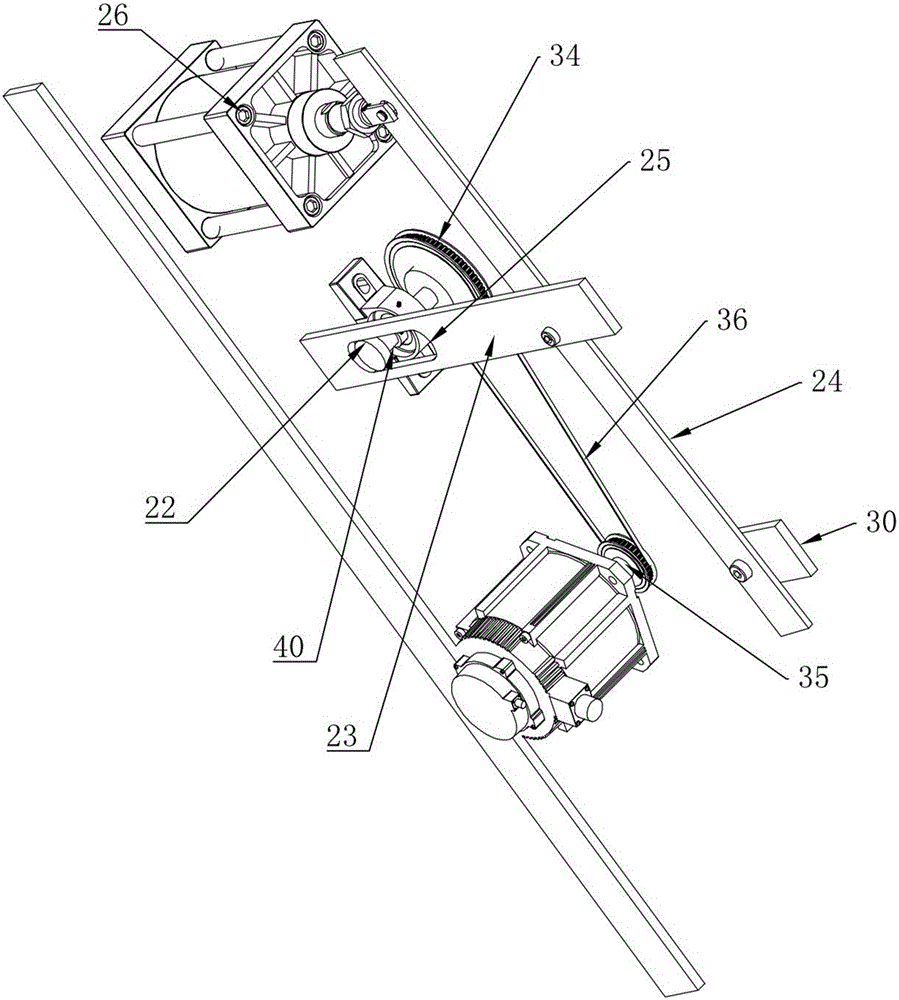

Synchronous belt transmission vibration reduction system of unmanned helicopter

PendingCN110979654AReduce secondary vibrationCache rotation vibrationRotocraftControl theoryLeather belt

The invention discloses a synchronous belt transmission vibration reduction system of an unmanned helicopter. The system is arranged between an output shaft of an engine and a rotor shaft and comprises an input connecting seat and an output connecting seat, wherein the input connecting seat is fixedly connected with the output shaft of the engine and connected with the output connecting seat through a flexible body, the output connecting seat is fixedly connected with an output wheel, and the output wheel is connected with an input wheel on the rotor shaft through a belt. The vibration reduction system can overcome vibration caused by belt tension in the acceleration and deceleration process, is not limited by the direct transmission layout form, and is suitable for various transmission modes and good in using effect.

Owner:河北春玖智能科技有限公司

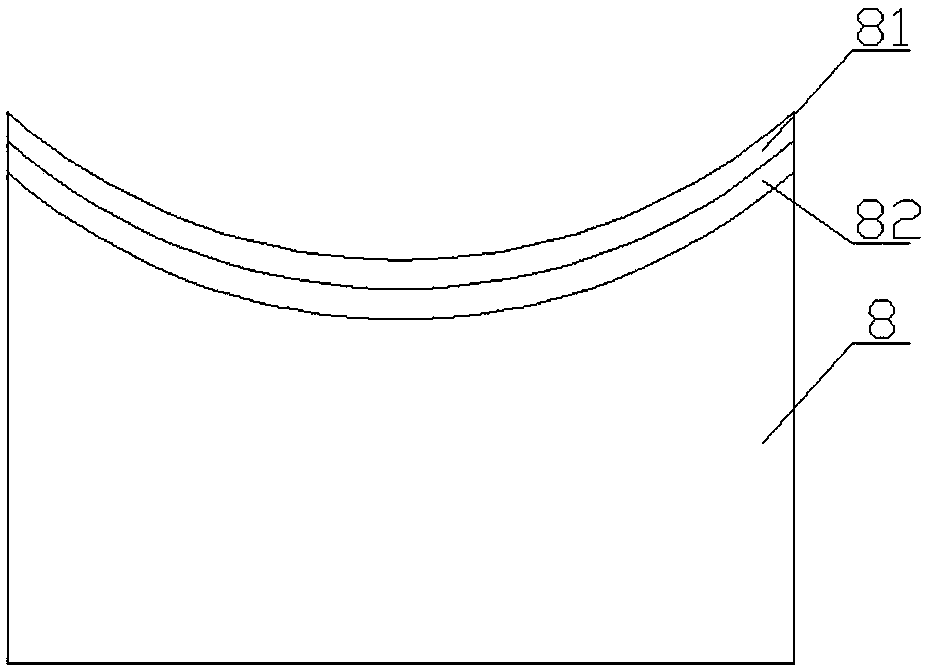

Cable self-adaptive buffering device for sudden load

The invention relates to a winch, in particular to a self-adaptive buffering device for a mooring rope, which is used for buffering and compensating the mooring rope of the traction winch and is particularly suitable for a universal winch. The winch is characterized by comprising a supporting holder, a sliding frame is arranged on one side of the supporting holder, and a horizontally arranged supporting cylinder is arranged between the wheel sliding frame and the supporting holder. Pulleys which are horizontally arranged are arranged on the wheel sliding frame, and the pulleys and the wheel sliding frames are matched in a rotating mode. According to the buffer device, the working efficiency of the winch using the buffering device is high, and the cable breaking phenomenon does not occur.

Owner:WUXI DELIN DEFENSE EQUIP CO LTD

Automatic feeding textile machine

The invention relates to the technical field of textile machines, and discloses an automatic feeding textile machine which comprises a feeding table and an auxiliary table. A pressing rod is movably connected to the top end of the feeding table, a clamping nail is fixedly installed at the bottom end of the feeding table, a clamping rod is fixedly installed at the top end of the clamping nail, anda dehairing rod is fixedly installed on the inner wall of the clamping rod; and a buckling nail is fixedly mounted on the inner wall of the pressing rod. According to the automatic feeding textile machine, cloth is wound on the outer wall of a second roller, then forwards penetrates through a gap between a bottom-layer check block and an upper-layer check block and then is wound around a first roller; and when the cloth is wound around the first roller, the cloth extrudes a movable head, the movable head moves downwards, and sliding blocks at the left side and the right side of the movable head can slide, so that a first sliding rod and a second sliding rod can move leftwards and rightwards correspondingly, and the effects that the cloth cannot be loosened, the winding condition cannot happen, the flatness of the cloth is achieved, and smooth automatic feeding is guaranteed are achieved.

Owner:嘉兴旺盛纺织股份有限公司

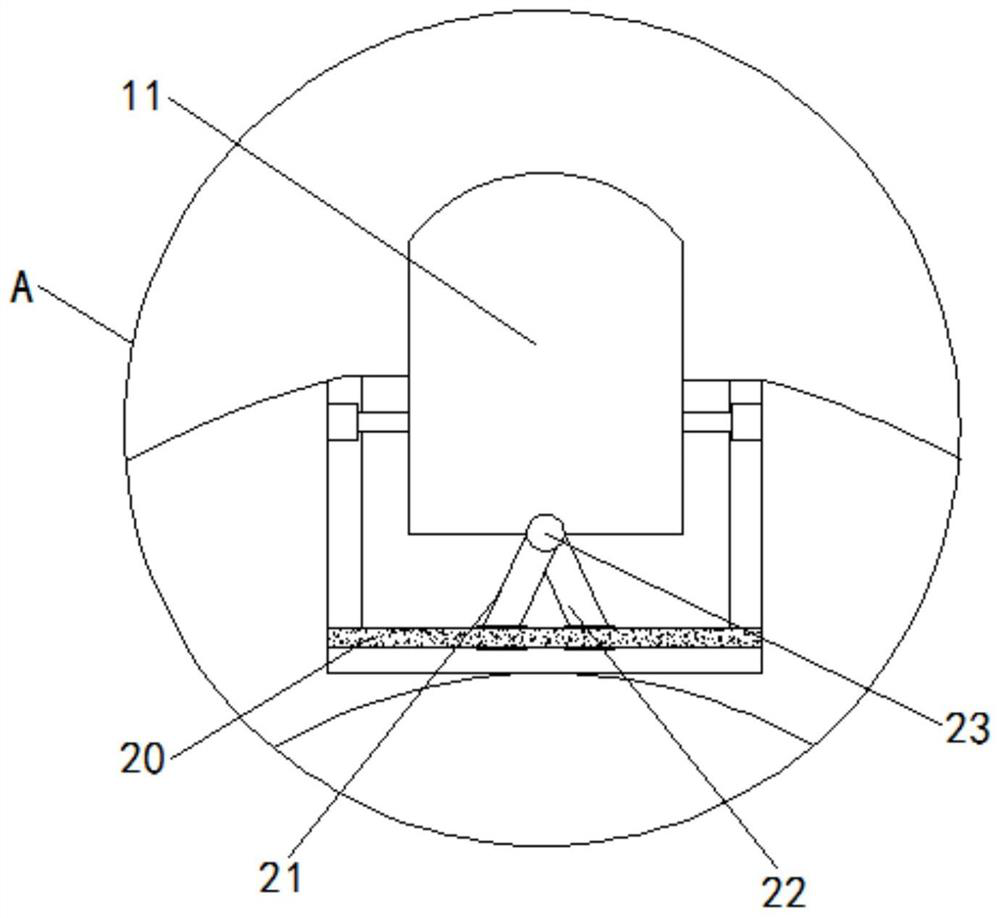

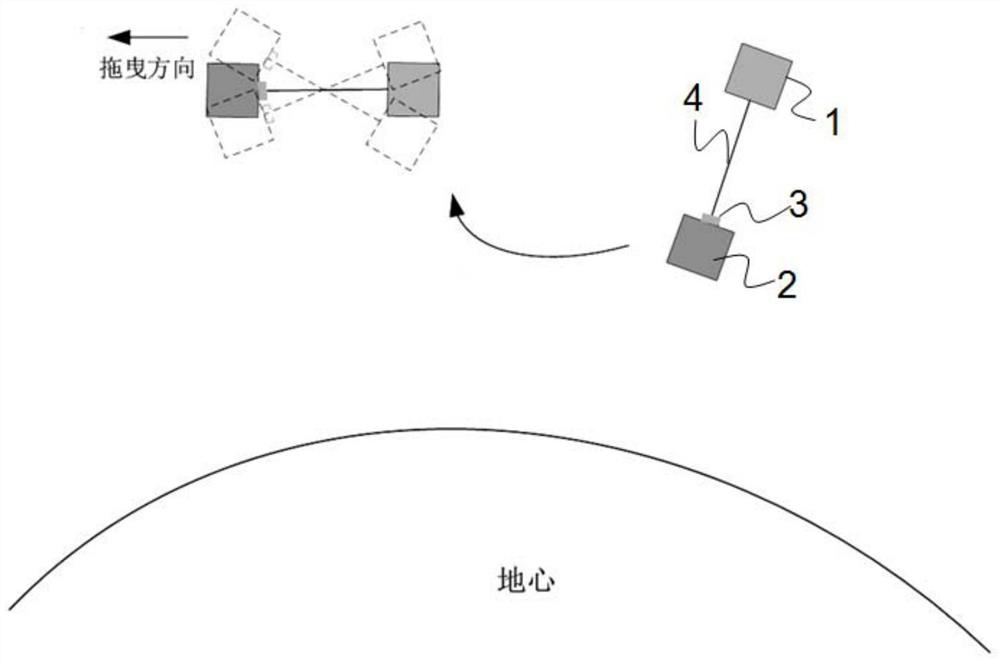

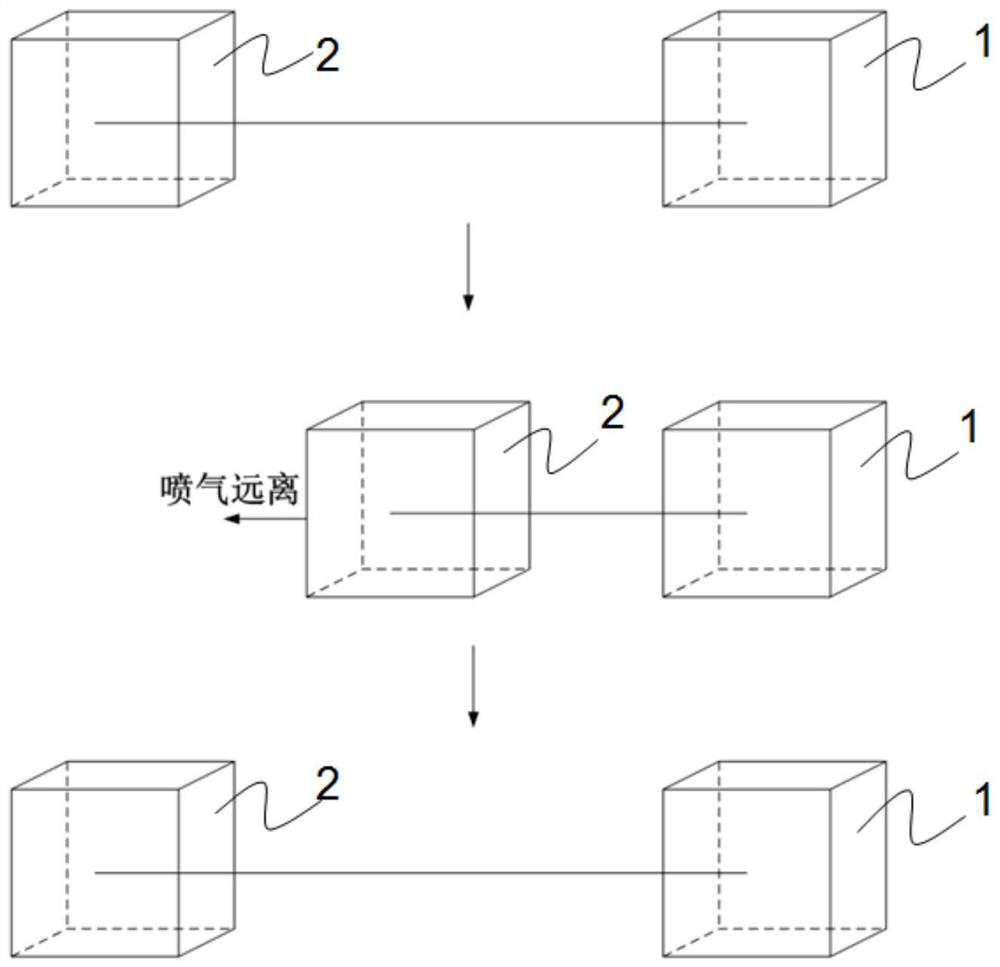

A dragging derailment method based on a tether retractable device

The invention discloses a dragging off-orbit method based on a rope retractable device. During the entire dragging process to the target star, the rope retractable device on the mission star is used to output a constant small tension to keep connected to the mission star. The tether tension between the target star and the target star; specifically includes the following steps: Step 1: Establish the center-of-mass dynamic equation and attitude dynamic equation of the mission star and the target star, as well as the dynamic model of the tether; Step 2: Take the dragging direction Perform assembly attitude maneuver for the target; Step 3: The mission star drags the target star out of orbit through the tether, and controls the attitude of the assembly during the period to make it face the dragging direction. The invention is based on the dragging off-track method of the rope retractable device, and uses the rope retractable device to generate a constant small tension, which not only ensures that the tether is tensioned without the risk of winding, but also ensures that the tension of the tether will not be too large without the risk of breakage, and the grasping The target is dragged stably and safely to the grave track.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

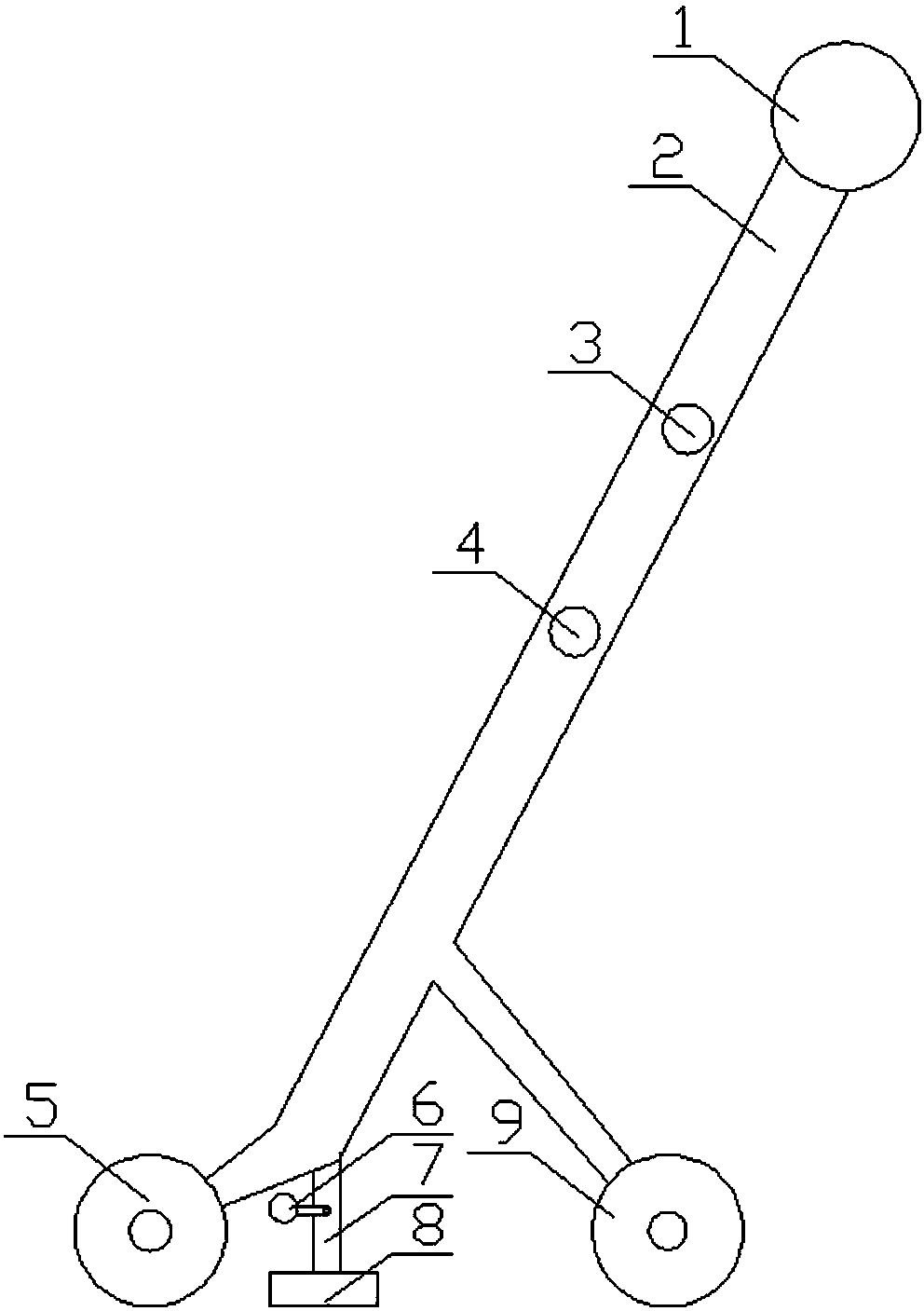

Ground surface network cable laying trolley

InactiveCN107845981AReduce the burden onRelieve pressureApparatus for laying cablesVertical planeEngineering

The invention discloses a trolley for laying surface network cables, which includes a handle, a connecting rod, a first winding stake, a front wheel, and a rear wheel. The connecting rod includes a main rod and an auxiliary rod, and a handle is arranged on the top of the main rod. The bottom of the main rod is provided with a front wheel, one end of the auxiliary rod is connected to the main rod, the other end is connected to the rear wheel, and the first winding pile is arranged on the main rod, the first winding pile is parallel to the horizontal plane, and the front wheel and the The rear wheel connection line is perpendicular to the first winding pile, and a vertical extension rod is arranged on the connecting rod between the front wheel and the rear wheel, the vertical extension rod is vertical to the horizontal plane, and a line pressing plate is arranged at the bottom of the vertical extension rod; The bottom of the front wheel, the bottom of the rear wheel and the bottom of the line pressing plate are on the same horizontal plane. The invention hangs the network cable to be embedded on the first winding pile, which is labor-saving and convenient; the cable pressing plate is manually driven to embed the network cable in the pipeline, which is convenient and simple, not only improves the efficiency but also reduces the burden on workers.

Owner:成都领域弱电工程有限公司

Wire cutting device

ActiveCN102560711BEasy to cutWon't relaxArtificial thread manufacturing machinesFilament manufactureYarnEngineering

Owner:TMT MACHINERY INC

A mine hoist tail rope monitoring device

ActiveCN111847190BAvoid damageAccurate detection and monitoringElectric switchesElevatorsFailure rateEngineering

The invention relates to a mine hoist tail rope monitoring device, which is characterized in that the monitoring device includes a detection switch bracket, a magnetic control switch, a steel wire rope assembly and a double switch series switchable control circuit, the magnetic control switch, the steel wire rope assembly and The double-switch series switchable control circuits are all set on the detection switch bracket; this technical solution solves many defects in the above-mentioned traditional technology, reduces the failure rate, improves work efficiency, and reduces the difficulty of maintenance.

Owner:NANJING MEISHAN METALLURGY DEV

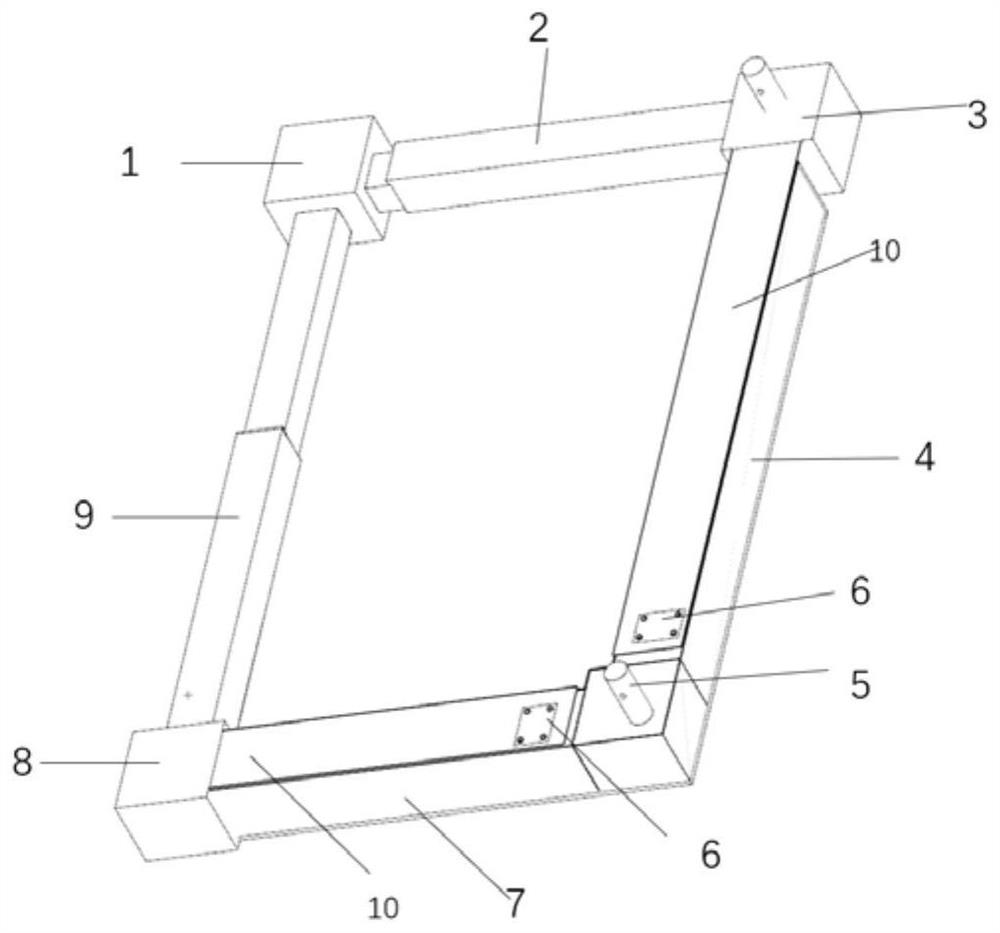

Full-automatic window cleaner suitable for multiple sizes

The invention discloses a full-automatic window cleaner suitable for multiple sizes and belongs to the field of window cleaners. According to the full-automatic window cleaner suitable for the multiple sizes, a telescopic mechanism stretches out and draws back till an edge of the telescopic mechanism abuts against an edge of a window, so the full-automatic window cleaner is suitable for cleaning windows of various sizes, and adaptability is wide; on the other hand, up-down scrubbing of a scrubbing plate is achieved through cooperation of a locking mechanism and a steel wire; and the locking mechanism can prevent the steel wire from extending when the telescopic mechanism reaches a preset position, so the steel wire cannot be loosened in the running process. The device is small in size, small in occupied space and capable of being unfolded only in use. When in use, the automatic window cleaning device is fixed on glass to realize automatic window cleaning, is suitable for windows with different sizes in families, can directly and efficiently clean outdoor glass surfaces, and has small potential safety hazards.

Owner:SHAANXI UNIV OF SCI & TECH

Safe film interrupting mechanism and film interrupting method thereof

The invention relates to the field of automatic film winding, in particular to a safe film interrupting mechanism. The safe film interrupting mechanism is rotatably arranged on a winding machine and comprises a support, a mounting base arranged on the support, a first guide roller mechanism arranged in the middle of the mounting base, an ironing mechanism arranged on the mounting base and located on one side of the first guide roller mechanism, and a cutting mechanism arranged on the side, away from the ironing mechanism, of the mounting base. The cutting mechanism comprises a cutting knife and a cutting driving device which is arranged on the mounting base and is used for driving the cutting knife to move up and down. The ironing mechanism comprises an ironing cylinder arranged on the mounting base, a supporting plate arranged on a piston rod of the ironing cylinder and an ironing plate arranged on the supporting plate. The technical problem that when an existing winding film machine adopts an electric heating component to achieve winding film breaking, fire potential safety hazards are prone to being generated is solved. The invention also provides a film interrupting method.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com