Device and method for tensioning screens and their use in printing presses as well as screen frame and silk screen printing press

A technology of screen printing machine and printing screen, which is applied in the field of screen frame and screen printing machine, manufacturing or using printing screen, and can solve the problem of mechanical tension change of printing screen, mechanical tension change, printing screen storage Change etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

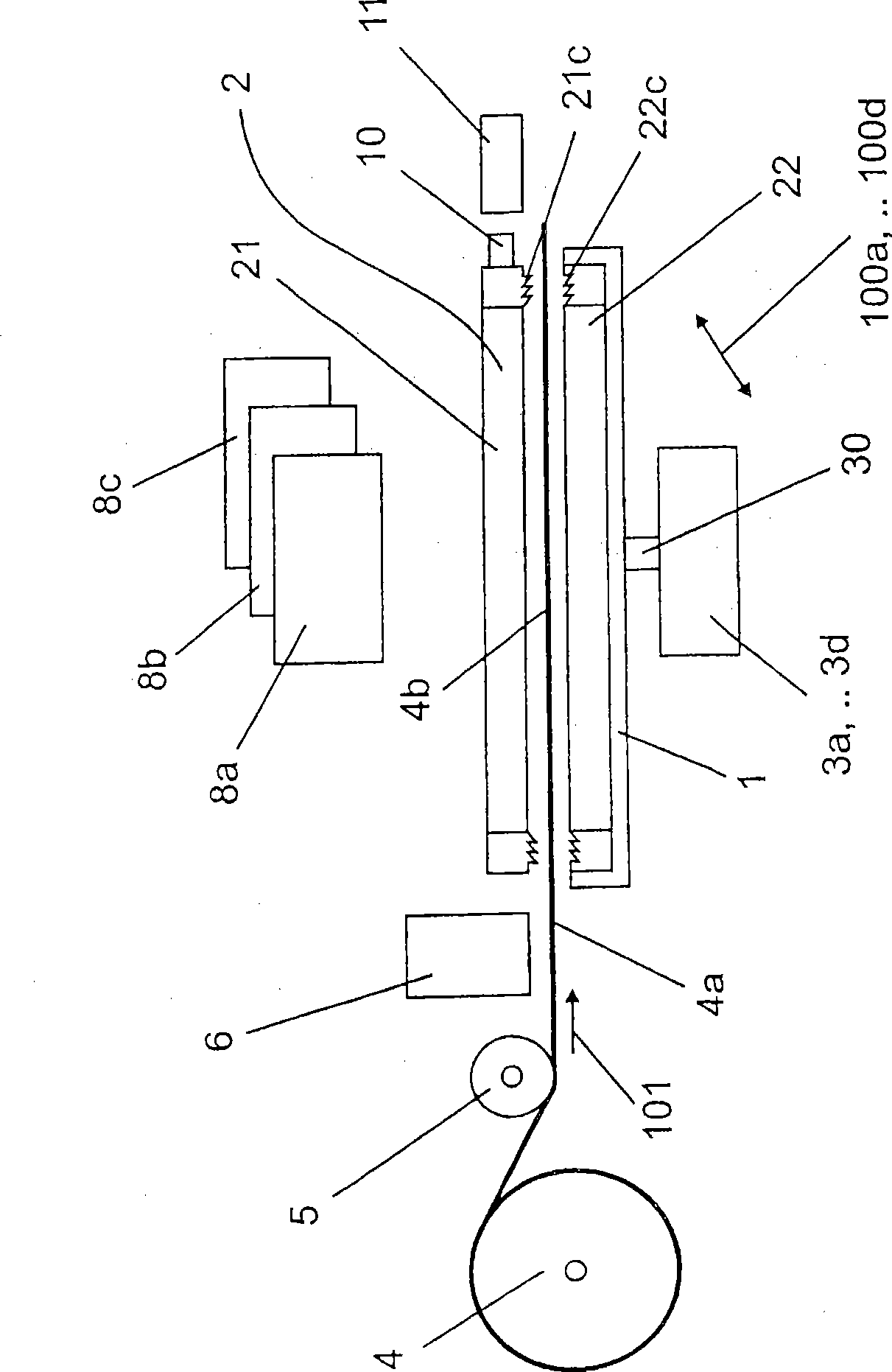

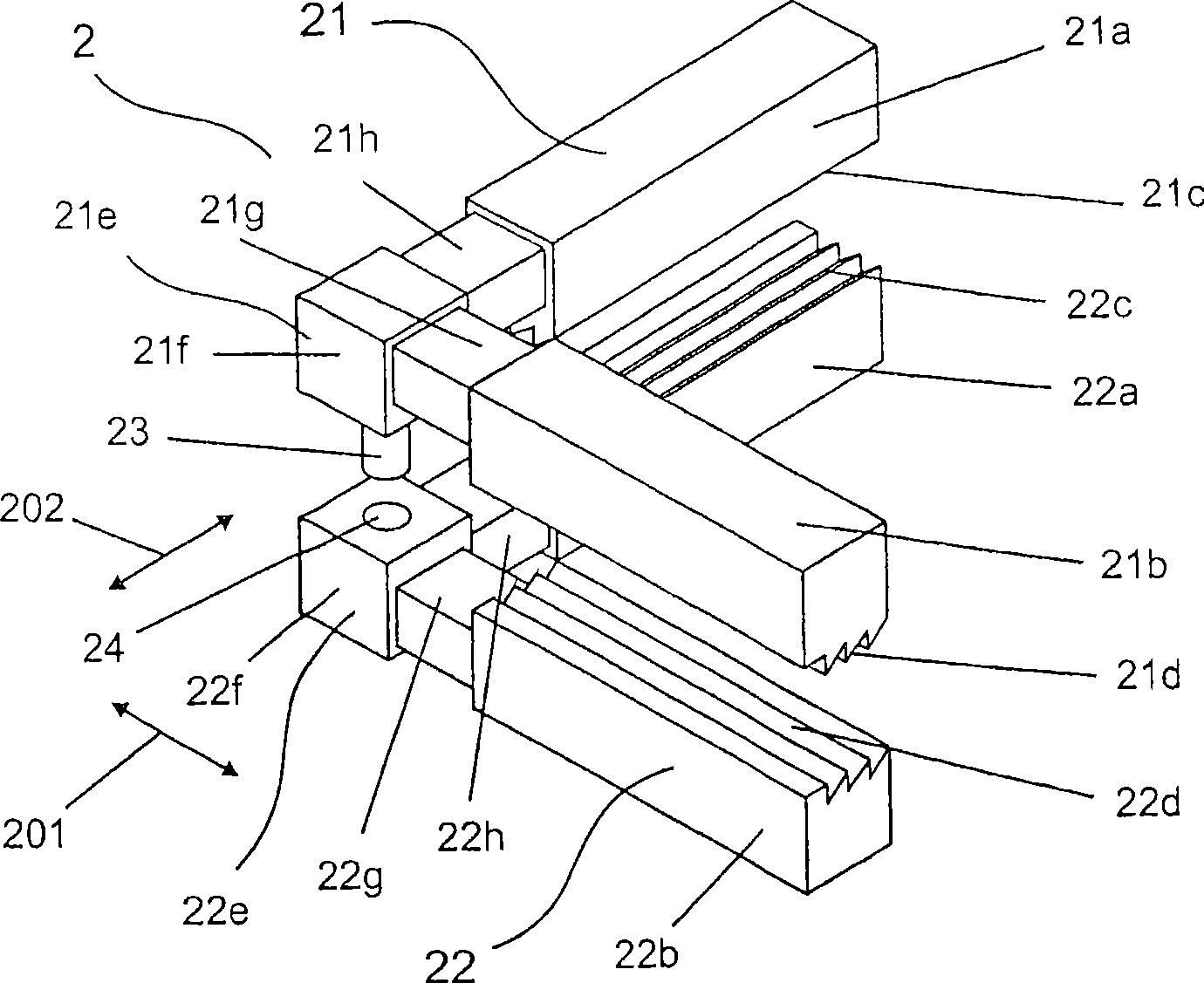

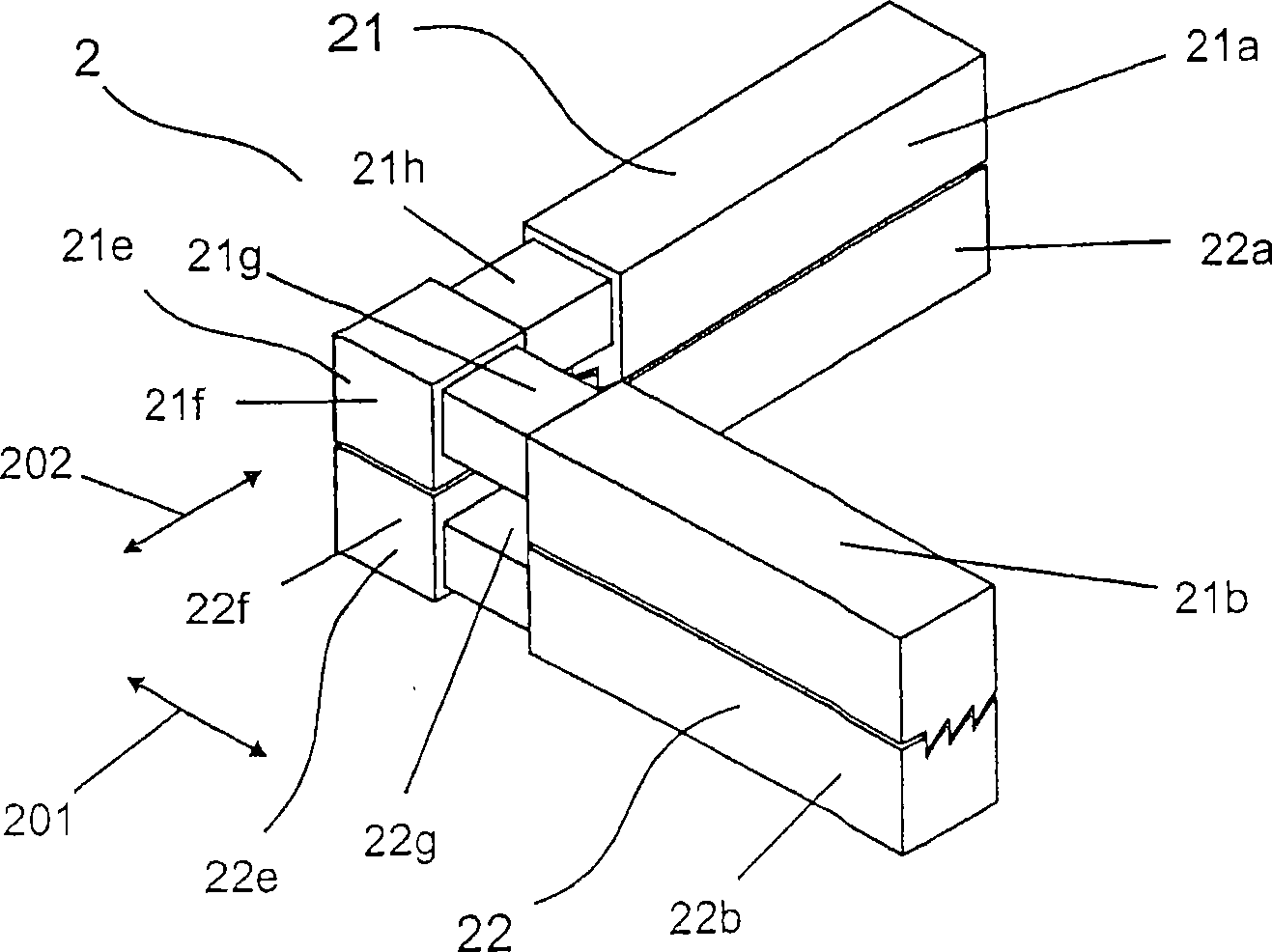

[0042] attached figure 1 Shown is a schematic diagram of the screen printing screen frame manufacturing and imaging device of the present invention. The device has an accommodating device 1 for accommodating a screen frame 2, for example, the screen frame 2 is composed of an upper component 21 and a lower component 22, and these components can be engaged with each other through matching pins 23 and matching holes 24.

[0043] In order to produce a printing screen, for example, a section 4b of the screen fabric 4a can be passed from the screen fabric roll 4 through the guide device 5 along the Put it in the direction 101 between the upper member 21 and the lower member 22 of the screen frame 2, and then put the two members 21 and 22 together in the second step, and fix and clamp the screen fabric along the edge of the screen frame.

[0044] For example, a clamping device or a screwing device not shown in the figure may also be used to fix the screen frame members 21, 22 to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com