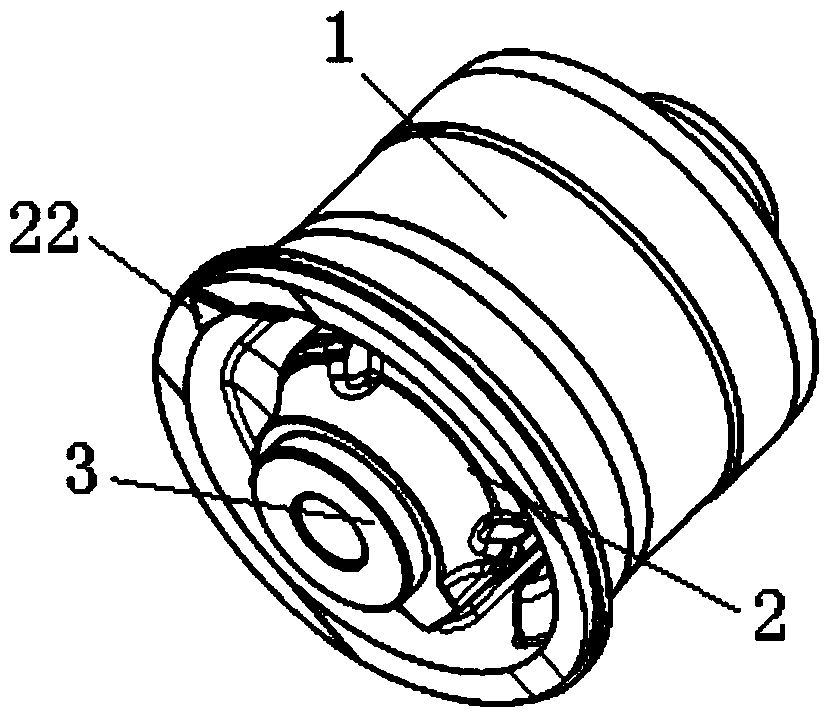

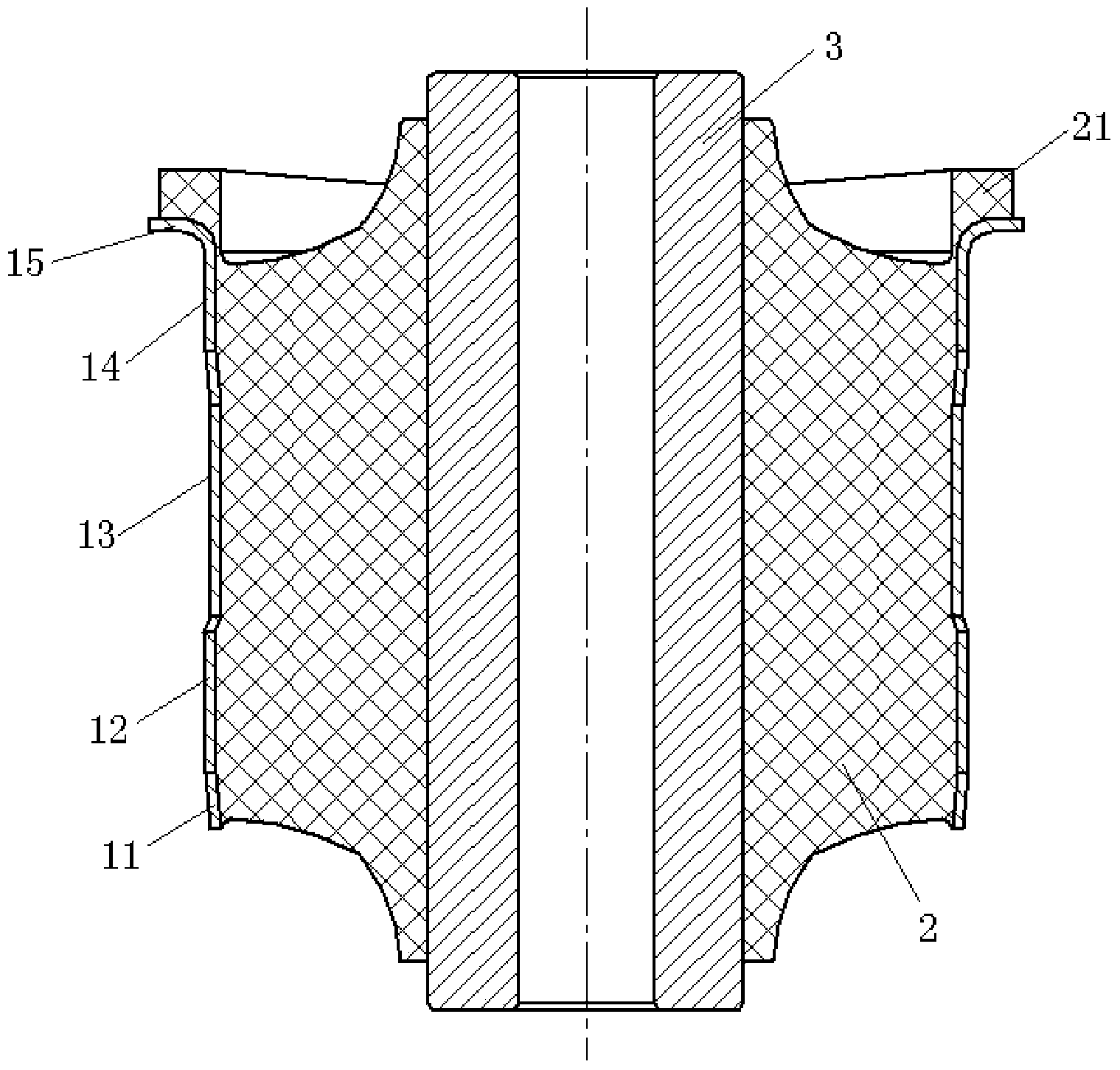

Rubber bushing

A rubber bushing and rubber technology, which is applied in the field of automotive bushings, can solve the problems of torsion beam bushing, bushing, sheet metal interference noise, etc., and achieve the effect of solving the interference noise, expanding the press-fitting bearing surface, and optimizing the interference fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention are described below through specific examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, and cannot be construed as limitations on the technical solutions of the present invention.

[0031] The introduction of rubber bushings in the suspension system can alleviate the vibration and impact from the road and ensure the stability of the handling. wear and tear. Compared with other parts, the rubber bushing also has the following advantages: the shape of the rubber is not limited, and the spring stiffness ratio in three directions can be properly selected; it can be easily combined with the metal parts firmly, so that the rubber bushing can withstand many The load in the direction not only simplifies the structure, but also reduces the mass of the vehicle; the internal friction of vulcanized rubber is larger than that of metal, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com