Hybrid vehicle driving motor stator core structure

A hybrid electric vehicle and drive motor technology, applied in the magnetic circuit shape/pattern/structure, magnetic circuit static parts, etc., can solve the problems of complex assembly, waste of materials, and increased cost, so as to improve assembly efficiency and reduce production costs. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

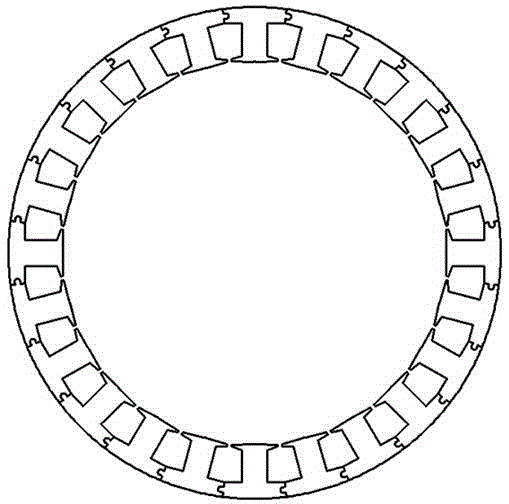

[0026] See Figure 3-Figure 5 , hybrid vehicle drive motor stator core structure, including a ring-shaped stator yoke 1 and twenty-four stator teeth 2 connected to the inner ring of the stator yoke 1, formed between adjacent stator teeth 2 For filling the tooth slots 3 of the coil, the inner ring of the stator yoke 1 is provided with twenty-four protruding buckles 4, and the inner ends of the twenty-four stator teeth 2 are provided with corresponding buckles 4 Connected card slot 5.

Embodiment 2

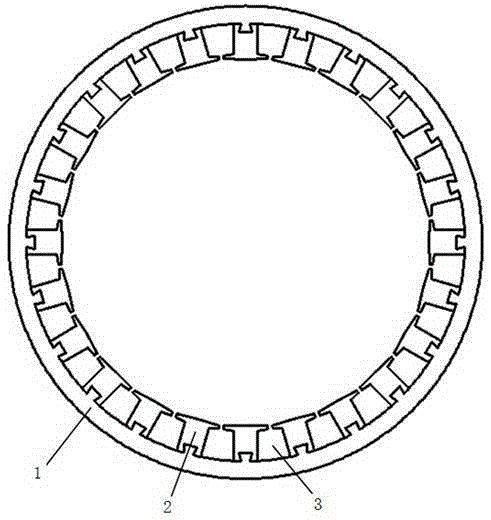

[0028] See Figure 6-Figure 8 , the hybrid vehicle drive motor stator core structure, including a ring-shaped stator yoke 6 and twenty-four stator teeth 7 connected to the inner ring of the stator yoke 6, forming a gap between adjacent stator teeth 7 For filling the tooth slot 3 of the coil, the inner ring of the stator yoke 6 is provided with twenty-four card slots 8, and the inner ends of the twenty-four stator teeth 7 are all provided with cards that are engaged with the corresponding card slots 8 Buckle 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com