Motor train unit checker

A technology of inspectors and car groups, applied in the direction of instruments, mechanical counters/curvature measurement, measuring devices, etc., can solve the problems of not being able to measure QR values, and achieve the effects of direct reading, good repeatability, and clear positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

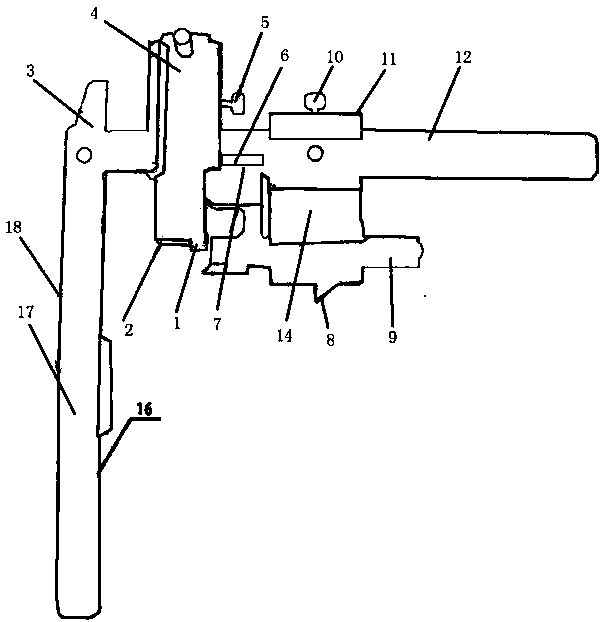

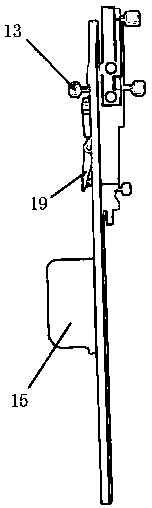

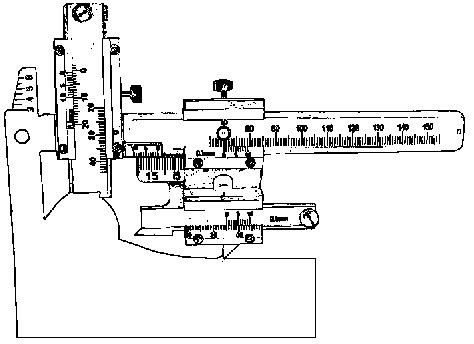

[0015] Below in conjunction with embodiment and accompanying drawing, the present invention is explained and illustrated in detail, figure 1 It is a front view of an EMU checker according to the present invention. figure 2 is a side view. image 3 It is a schematic diagram of an embodiment for detecting tires. As can be seen from the accompanying drawings, a checker for a train set includes a ruler body 12, a ruler frame 4 for measuring rim height and tread wear, a ruler surface 2 for measuring rim height and tread wear, a QR value main ruler 7, and a QR value Vernier 6, tire width measuring ruler 8, rim thickness measuring ruler 9, tire width measuring ruler ruler frame 11, positioning angle iron 15, positioning pin handle 19; The two rulers are integrated into one; the rim width measuring ruler frame 11 is slidably sleeved on the level ruler of the ruler body 2, and can be locked by the wheel rim width measuring ruler locking screw 10; the rim height and tread wear measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com