Battery internal resistance prediction and fault early warning method based on LSTM

A battery internal resistance and fault early warning technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of unsuitable batteries, time-consuming and labor-intensive problems, save time and cost, simplify cumbersome procedures, and save troubleshooting. The effect of time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

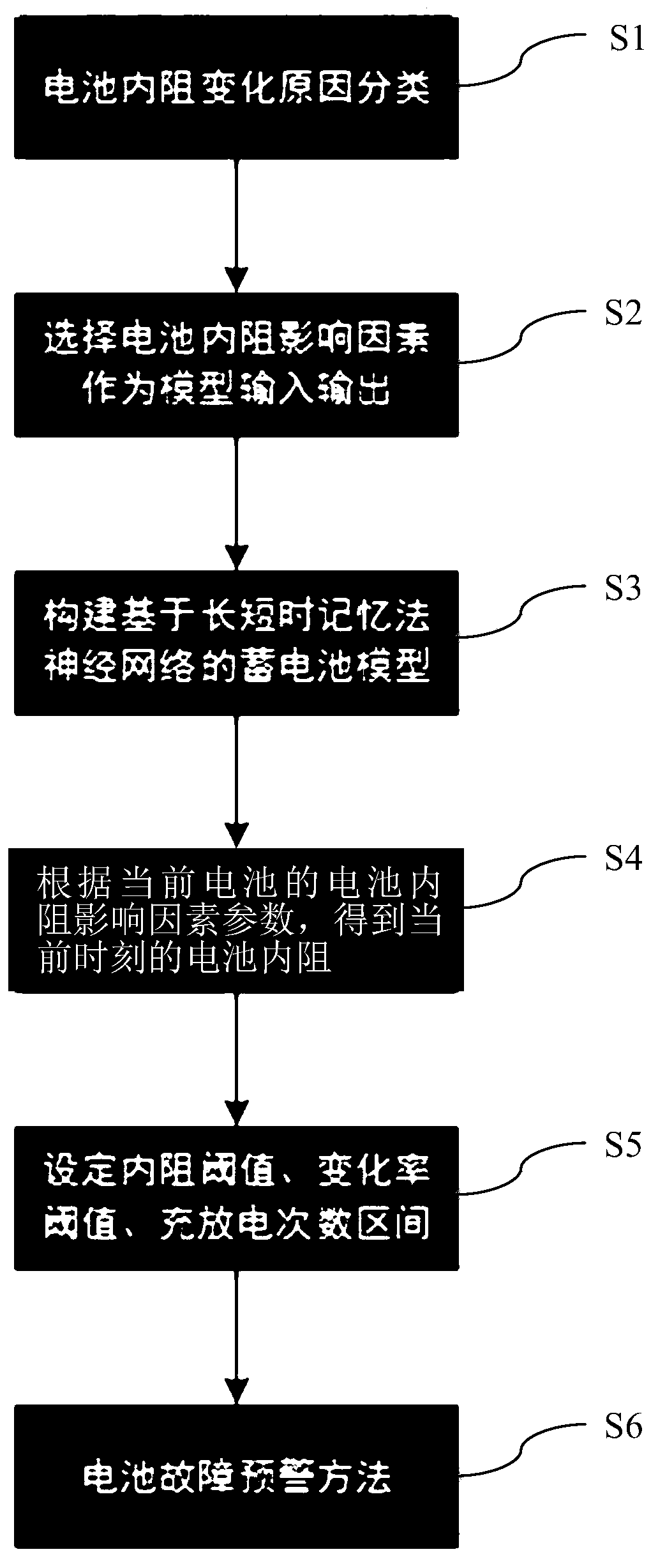

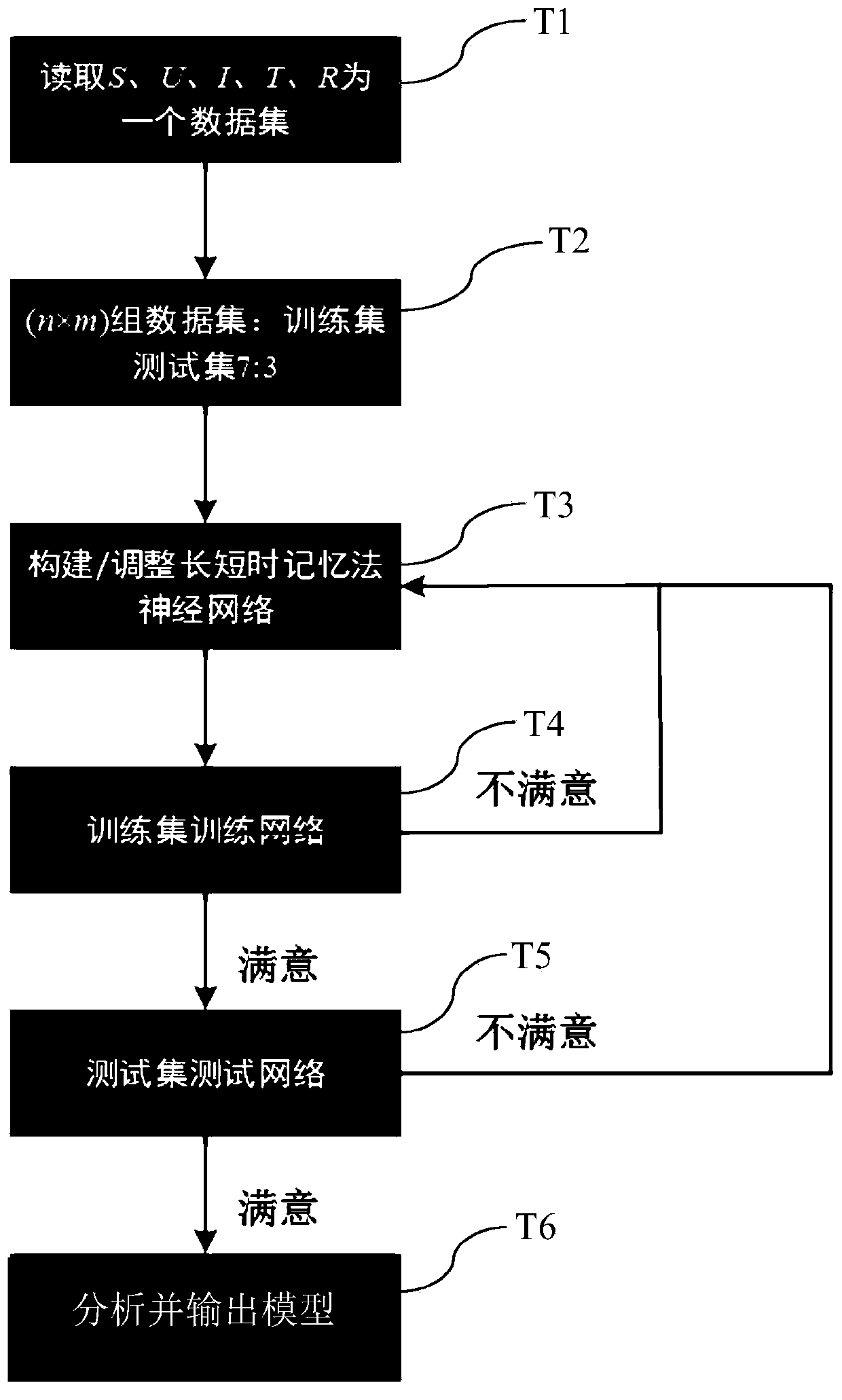

[0043] Such as figure 1 As shown, it is an LSTM-based battery internal resistance prediction and fault early warning method of the present invention, the method includes:

[0044] S1. Classification of reasons for changes in battery internal resistance R.

[0045] In this embodiment, the battery equipment consisting of n valve-regulated lead-acid batteries is selected as the research object. The reasons for the change of the battery internal resistance R include: battery aging, battery failure, and manual troubleshooting.

[0046] Among them, the aging of the battery is due to the continuous increase of the internal resistance R of the battery due to the long-term use of the battery. min ,m max ], the battery internal resistance R will exceed the battery internal resistance threshold R th . A battery fault ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com