High temperature resistant anti-corrosion disc-shaped spring

A disc spring, anti-corrosion technology, applied in the direction of low internal friction spring, spring/shock absorber, mechanical equipment, etc., can solve the problem of non-rust, anti-corrosion, anti-magnetic, heat-resistant, surrounding areas and people's hazards , early failure and other issues, to achieve the effect of eliminating leakage events, maintaining strength, and lasting and effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

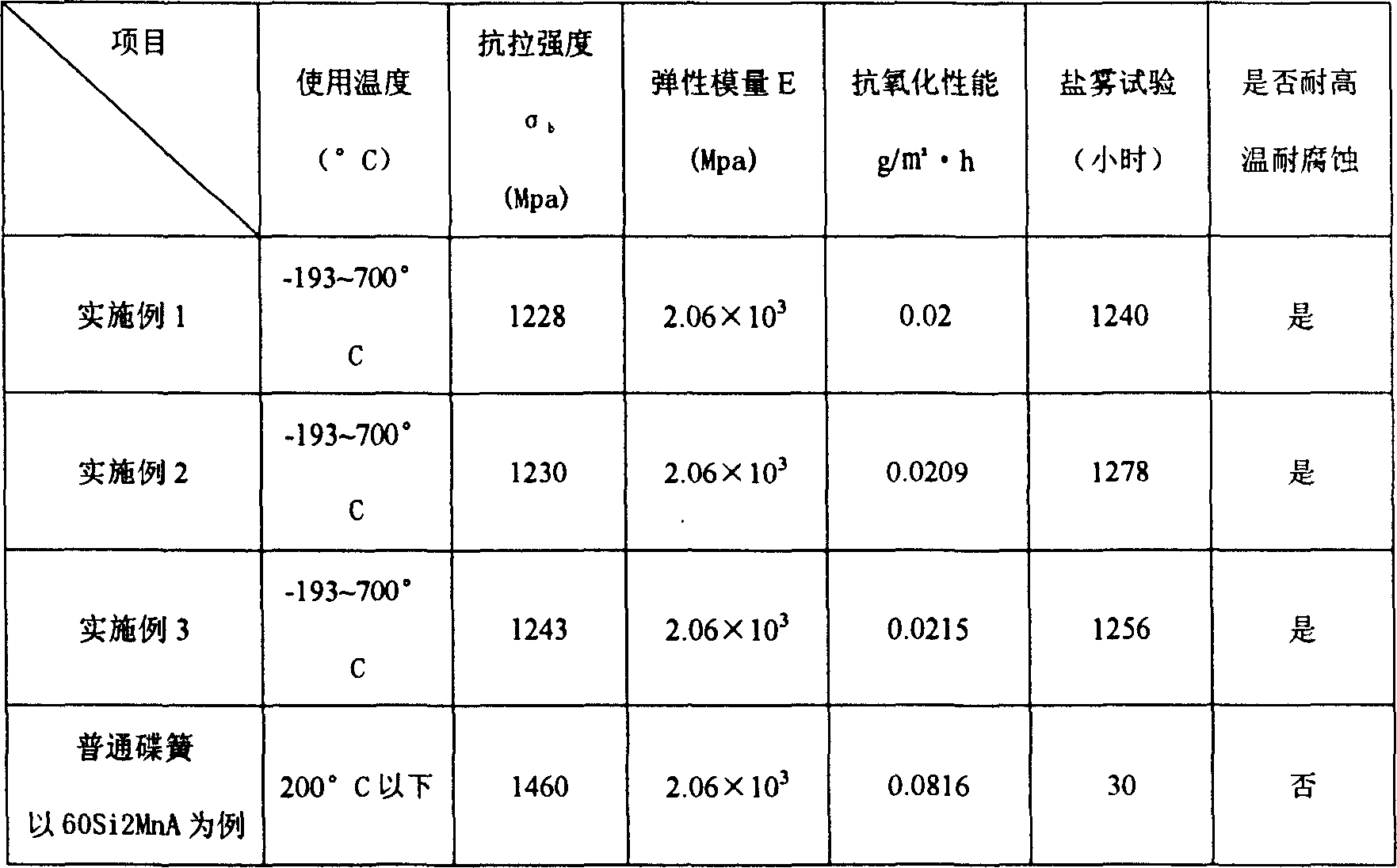

Examples

Embodiment 1、2 and 3

[0038] Its manufacturing process is:

[0039] 1. First manufacture high temperature and corrosion resistant disc spring material:

[0040] Step 1. Prepare raw materials and melt them in a melting furnace to make billets. Melting temperature: 1800°C;

[0041] The second step. Put the raw materials into a solid solution in a vacuum high-temperature furnace, and the solid solution temperature is 1220°C;

[0042] The third step. Aging treatment: the temperature is 650°C, the time is 2 hours, and nickel-based alloy is made as the material;

[0043] 2. Then make a high temperature and corrosion resistant disc spring:

[0044] The first step. Stamping: using a compound die to punch a disc spring blank;

[0045] Step 2. Grinding: The disc spring blank surface tolerance, oxidation decarburization and roughness cannot meet the technical requirements of the disc spring, so it must be ground, and the machining allowance is 0.2-0.5mm on one side;

[0046] The third step. Turning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com