All wheel drive system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

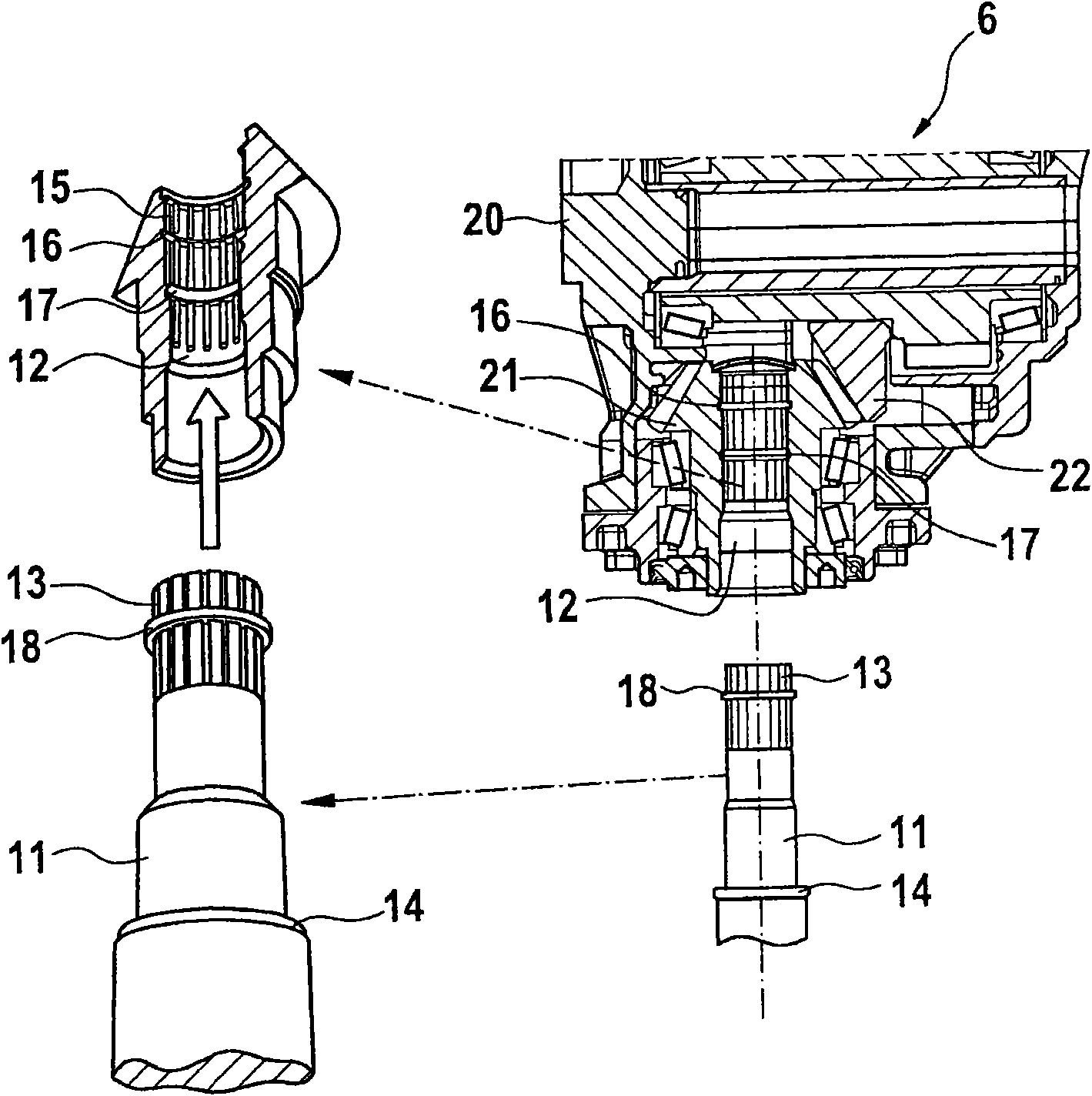

[0036] The invention will now be described in further detail for illustrative purposes by way of example and with reference to the accompanying drawings.

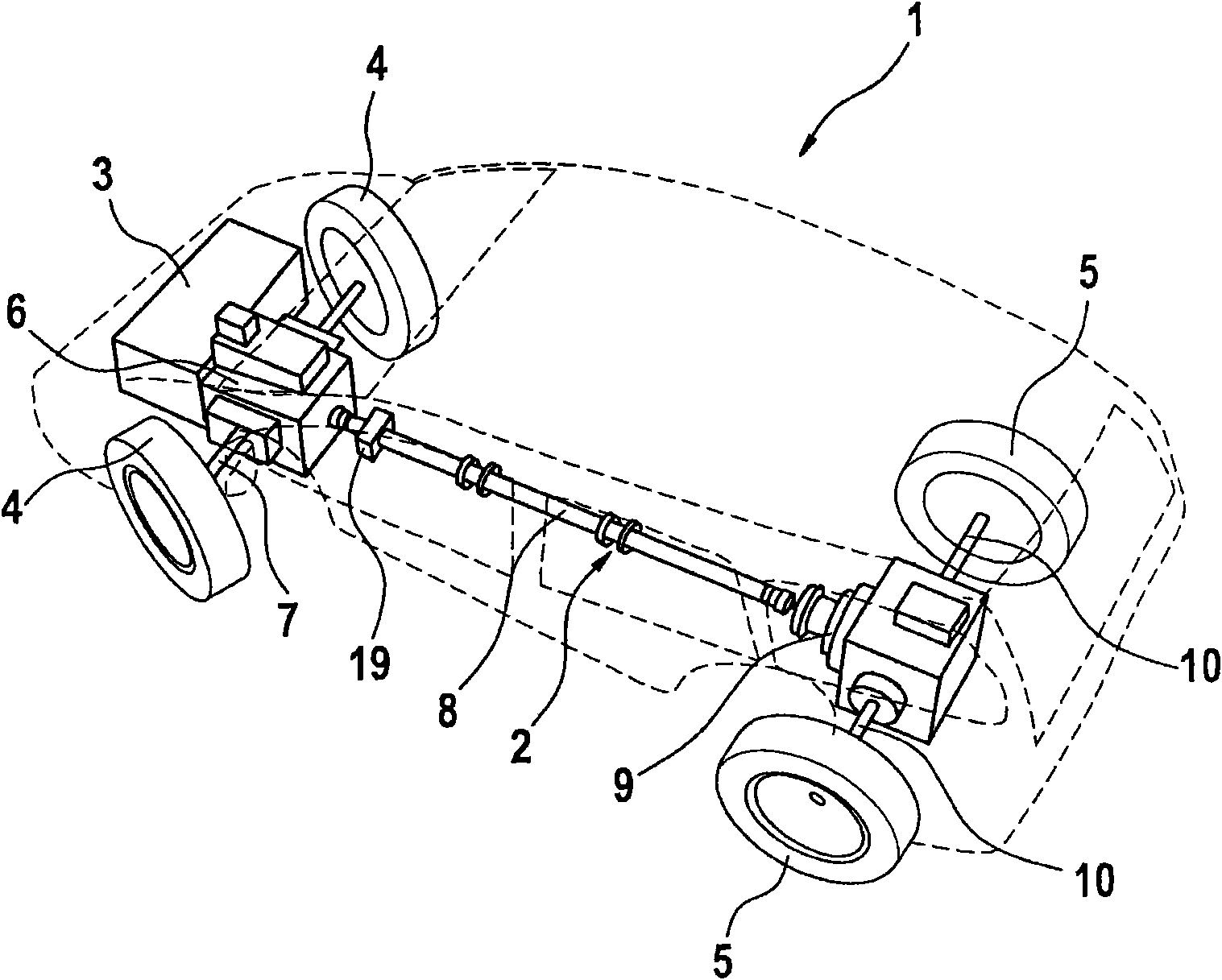

[0037] figure 1An exemplary vehicle 1 is shown in . Vehicle 1 is equipped with an all-wheel drive system 2 , an engine 3 , front wheels 4 and rear wheels 5 . The all-wheel drive system comprises a power acquisition unit 6 at its front, half shafts 7 extending to the front wheels 4 respectively, and a prop shaft 8 extending from the power acquisition unit 6 to a rear drive module 9 substantially in the longitudinal direction of the vehicle.

[0038] The drive shaft also includes a constant velocity joint 19 . The rear drive module 9 is connected to the rear wheels 5 via half shafts 10 via a torque converter and a differential (not shown), respectively.

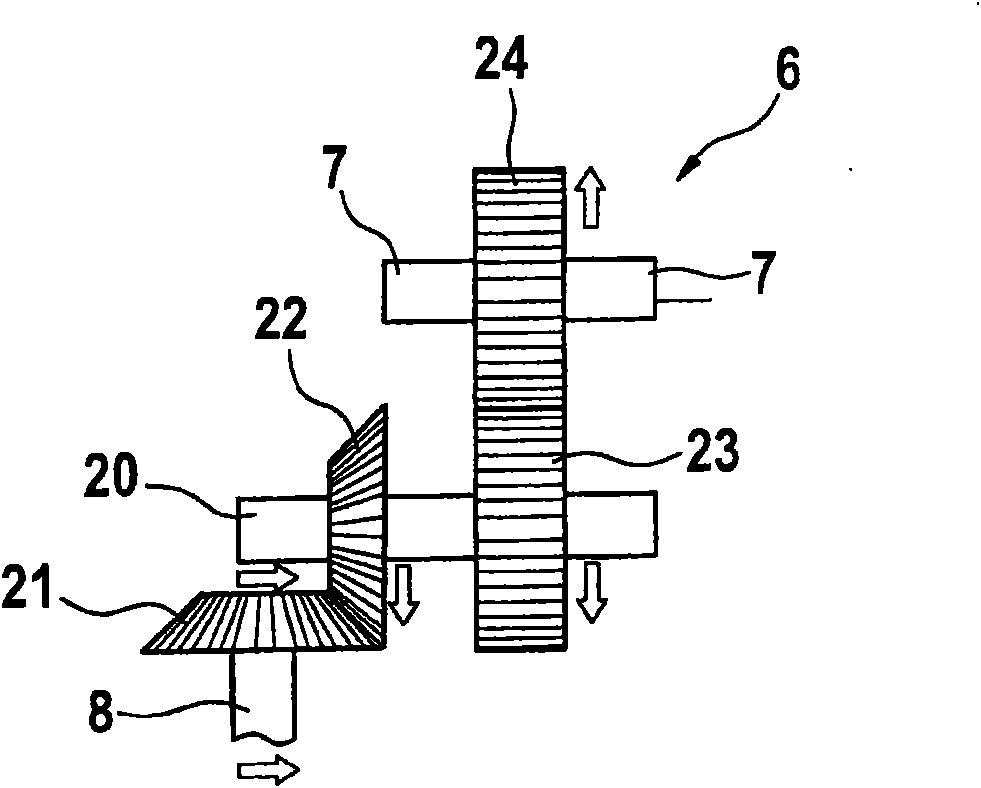

[0039] In use, such as from figure 2 It can be seen schematically that the engine 3 generates driving force, which is transmitted to the power acquisition unit through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com