Yarn cutting apparatus

A cutting device and thread technology, applied in the direction of filament generation, transportation and packaging, artificial filament support, etc., can solve problems such as wire guides hindering operations, difficulties, etc., achieve miniaturization and cost reduction, realize cost reduction, Achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

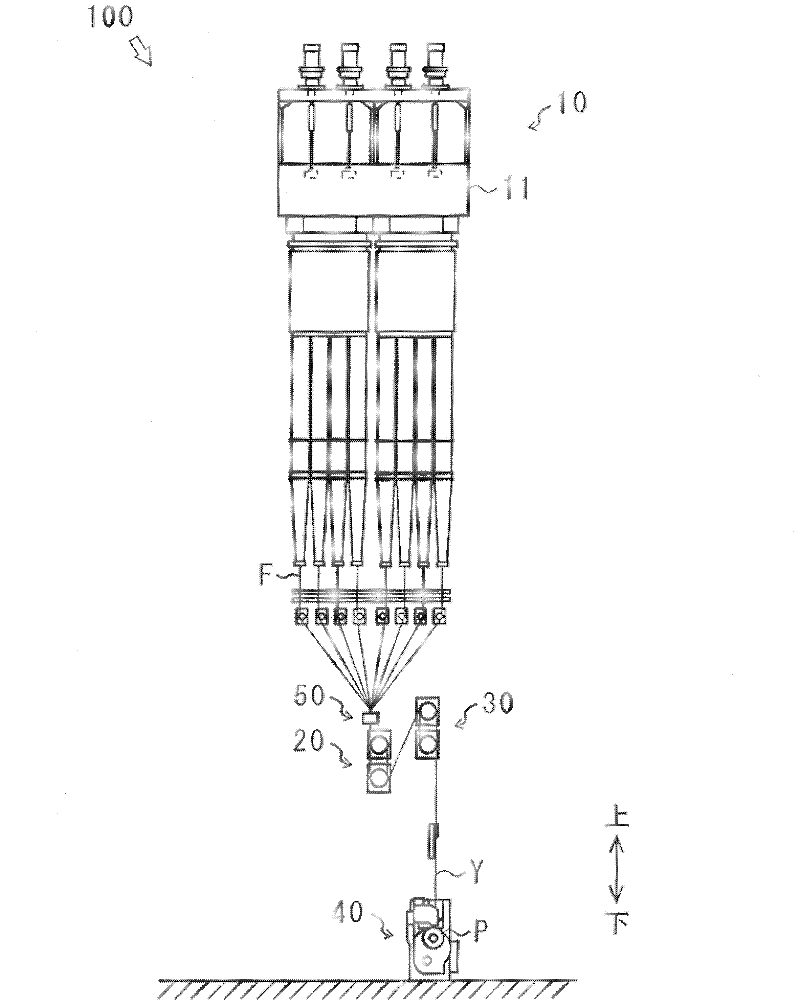

[0033] First, the spinning winding device 100 will be described.

[0034] figure 1 It is a figure which shows the structure of the spinning winding equipment 100. In addition, the acting direction of gravity is shown in the figure as an up-down direction.

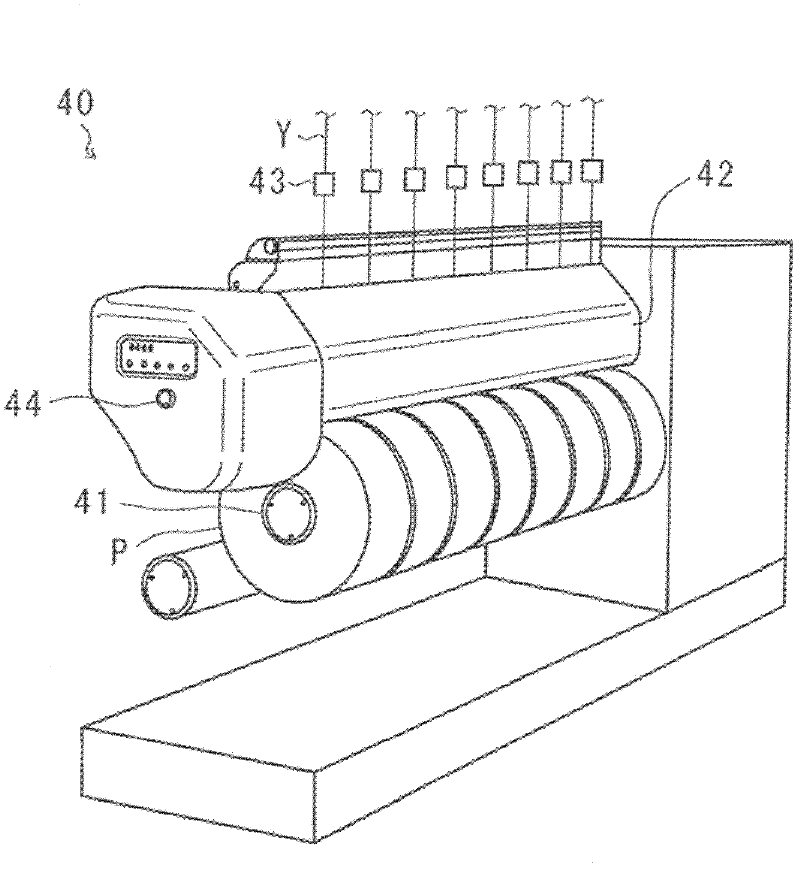

[0035] The spinning and winding facility 100 bundles a plurality of filaments F spun from the spinning device 10 to form a yarn Y, and processes the yarn Y such as stretching, and then winds it up to produce a package P. The spinning winding device 100 of this embodiment mainly includes a spinning device 10 , a first pair of godet rollers 20 , a second pair of godet rollers 30 , and a winding device 40 .

[0036] The spinning device 10 spins a plurality of filaments F. The spinning device 10 press-feeds the input synthetic fiber raw material (filament raw material) in a molten state, and spins it out from a spinning port provided on the spinning head 11 . In addition, the spinning device 10 is arranged at the uppermost ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com