Patents

Literature

156results about How to "Reliable cut off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

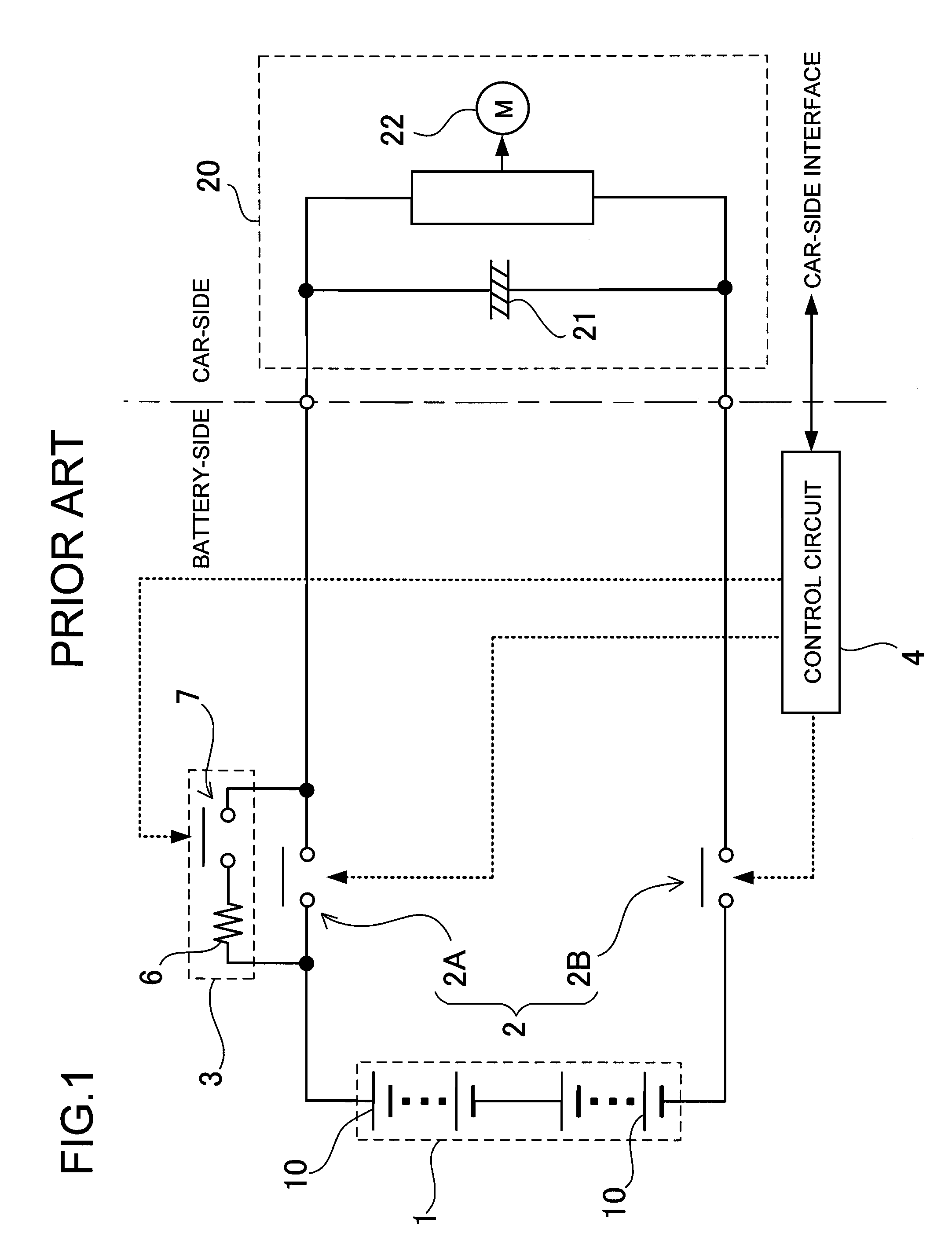

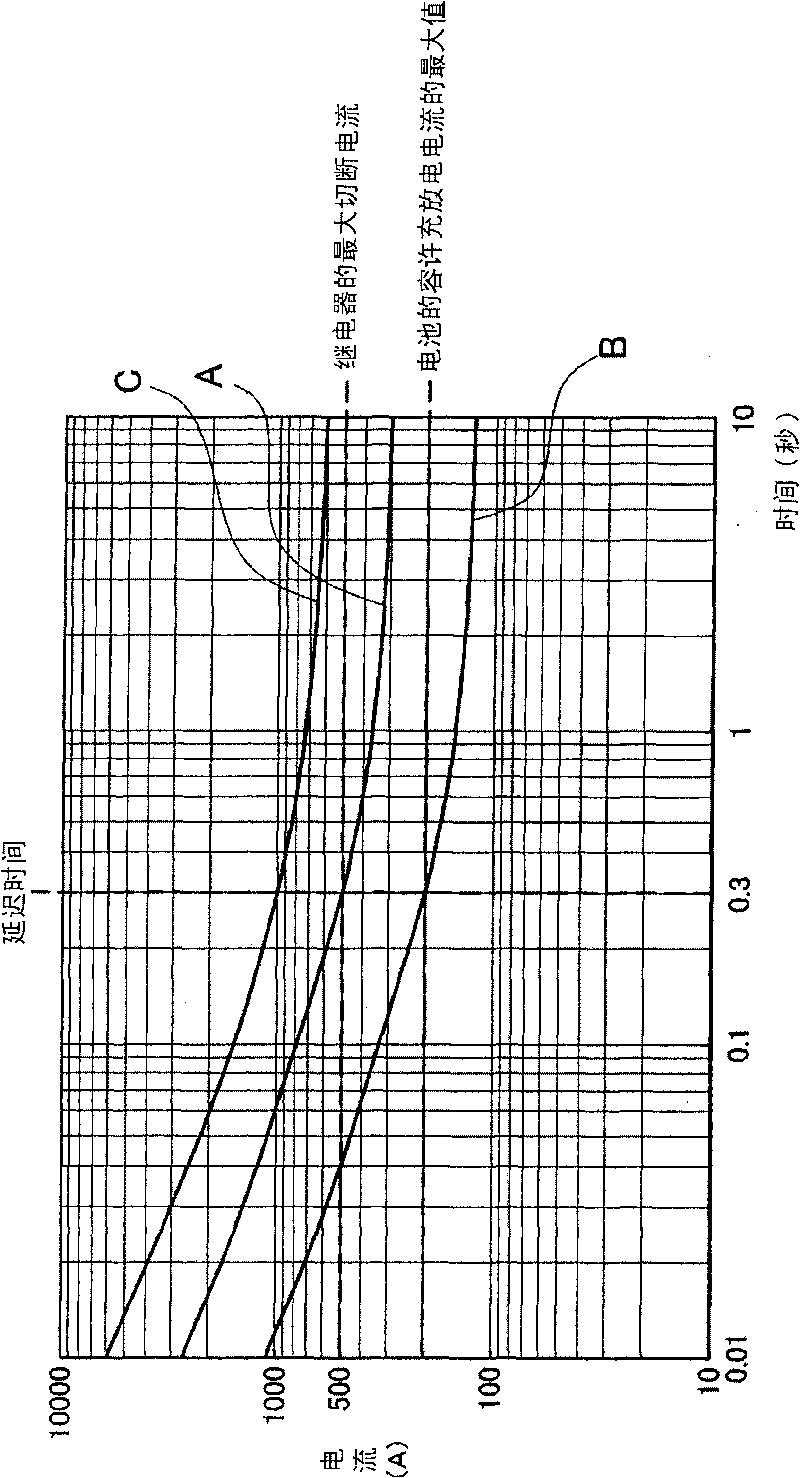

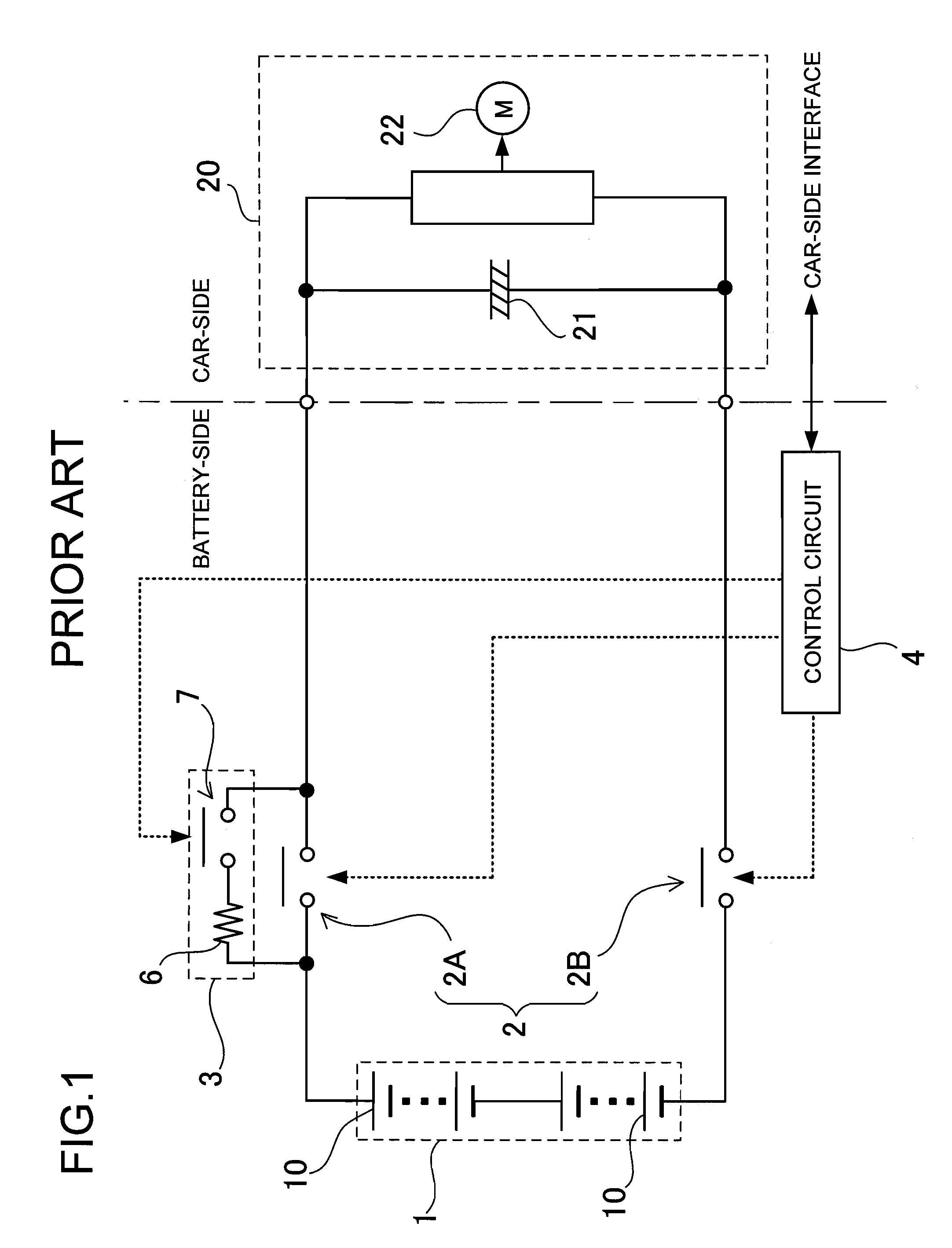

Battery system with relays

ActiveUS20100127663A1Reliable cut-offMore currentCharge equalisation circuitSafety/protection battery circuitsDelayed timeBattery system

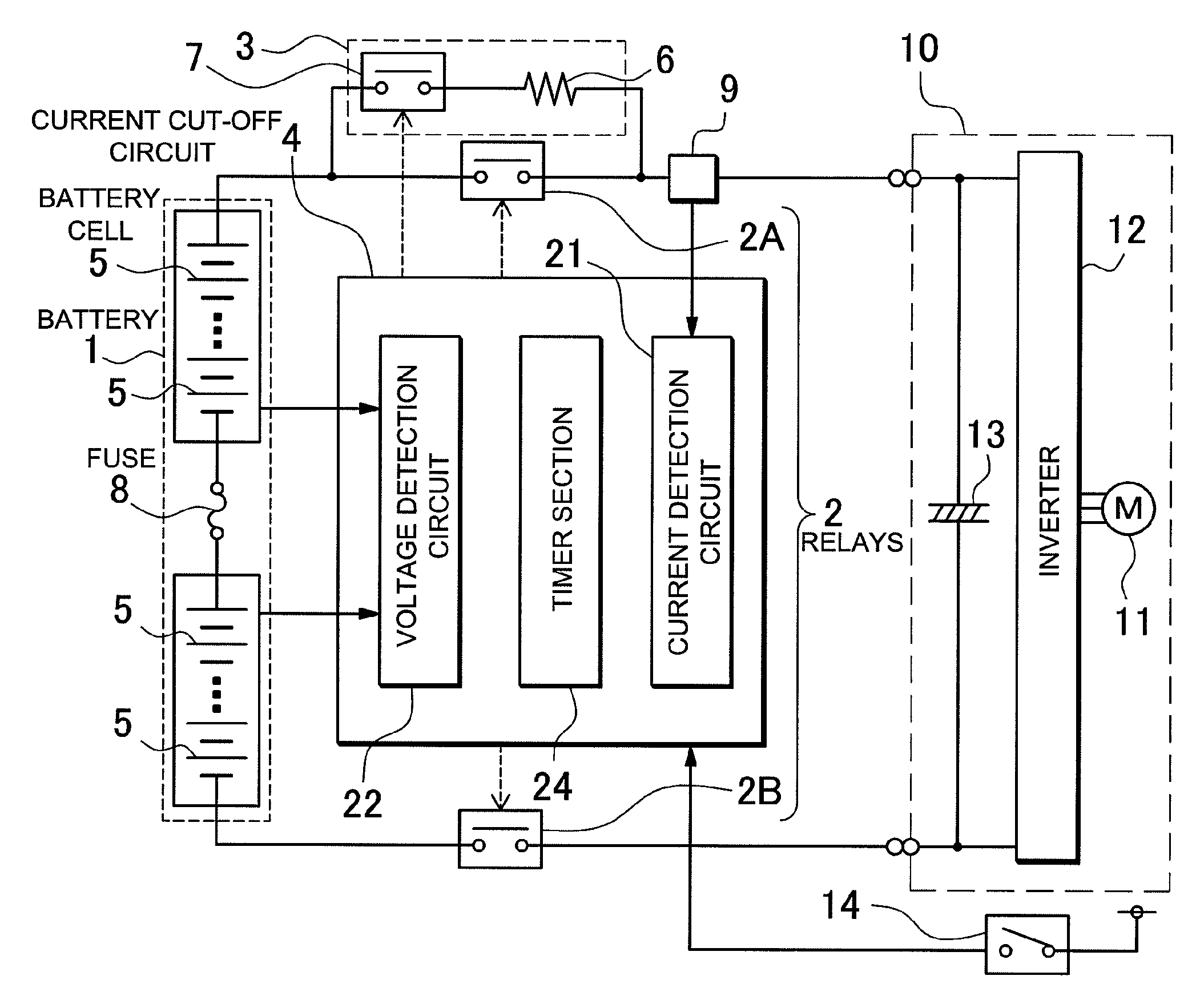

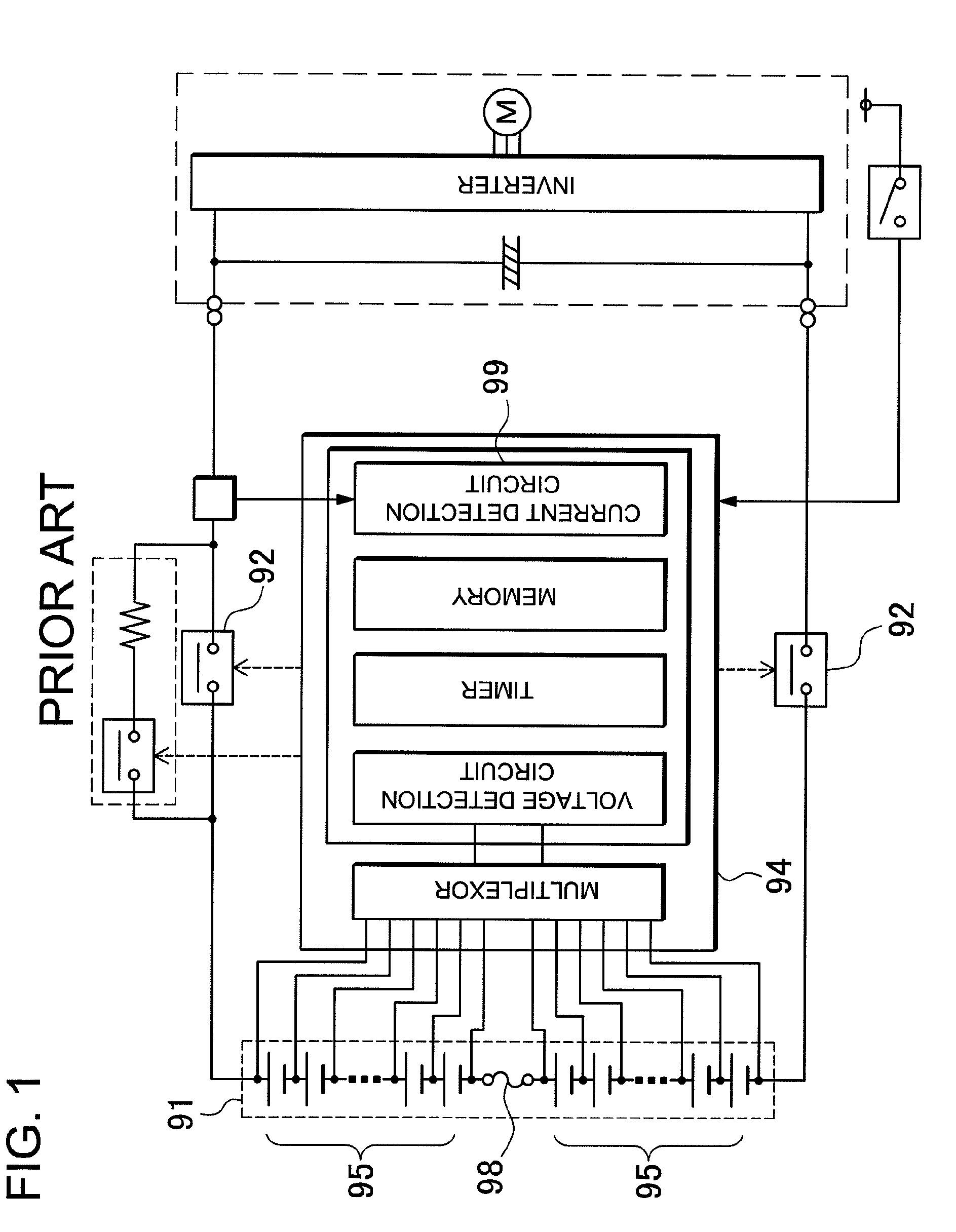

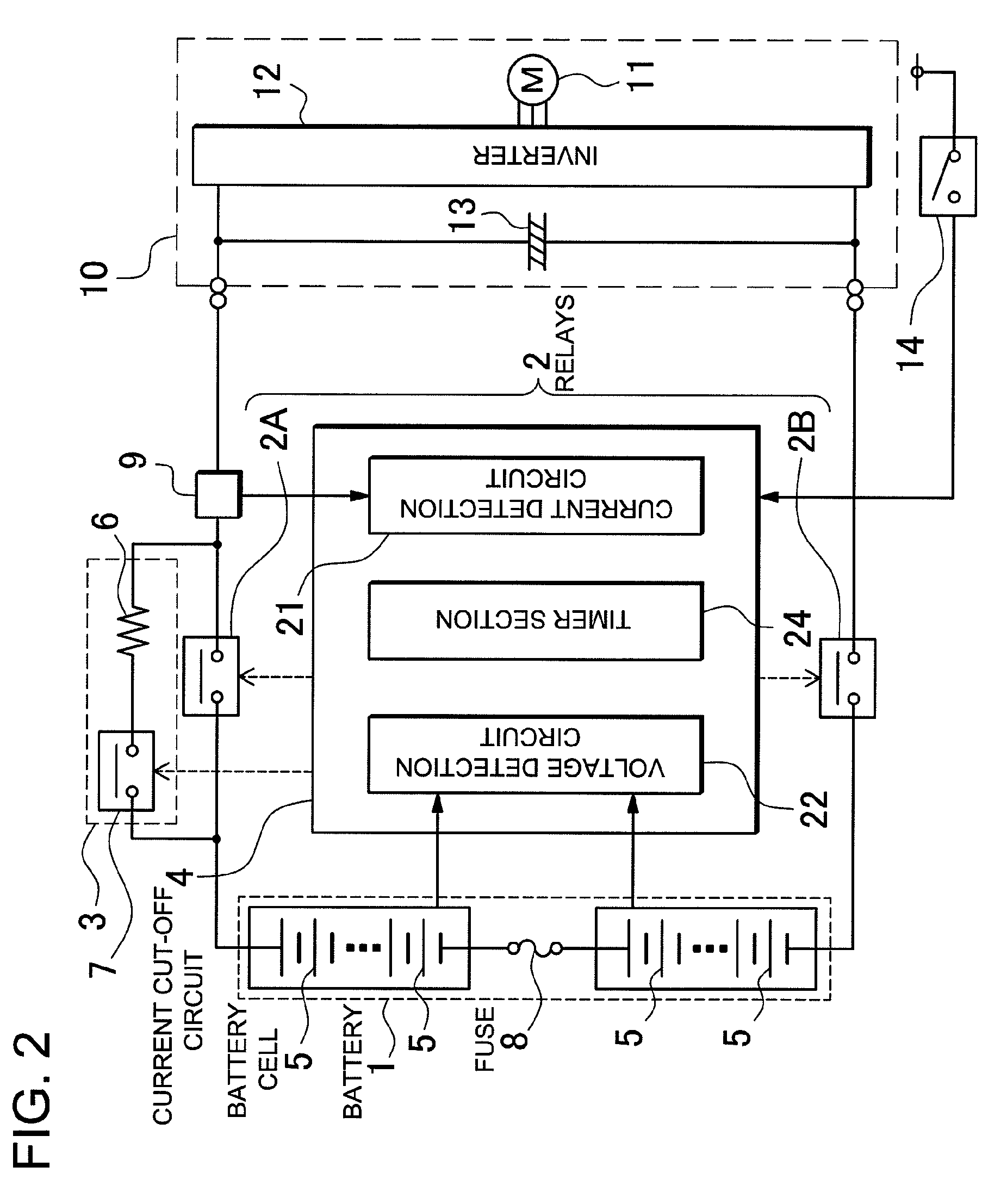

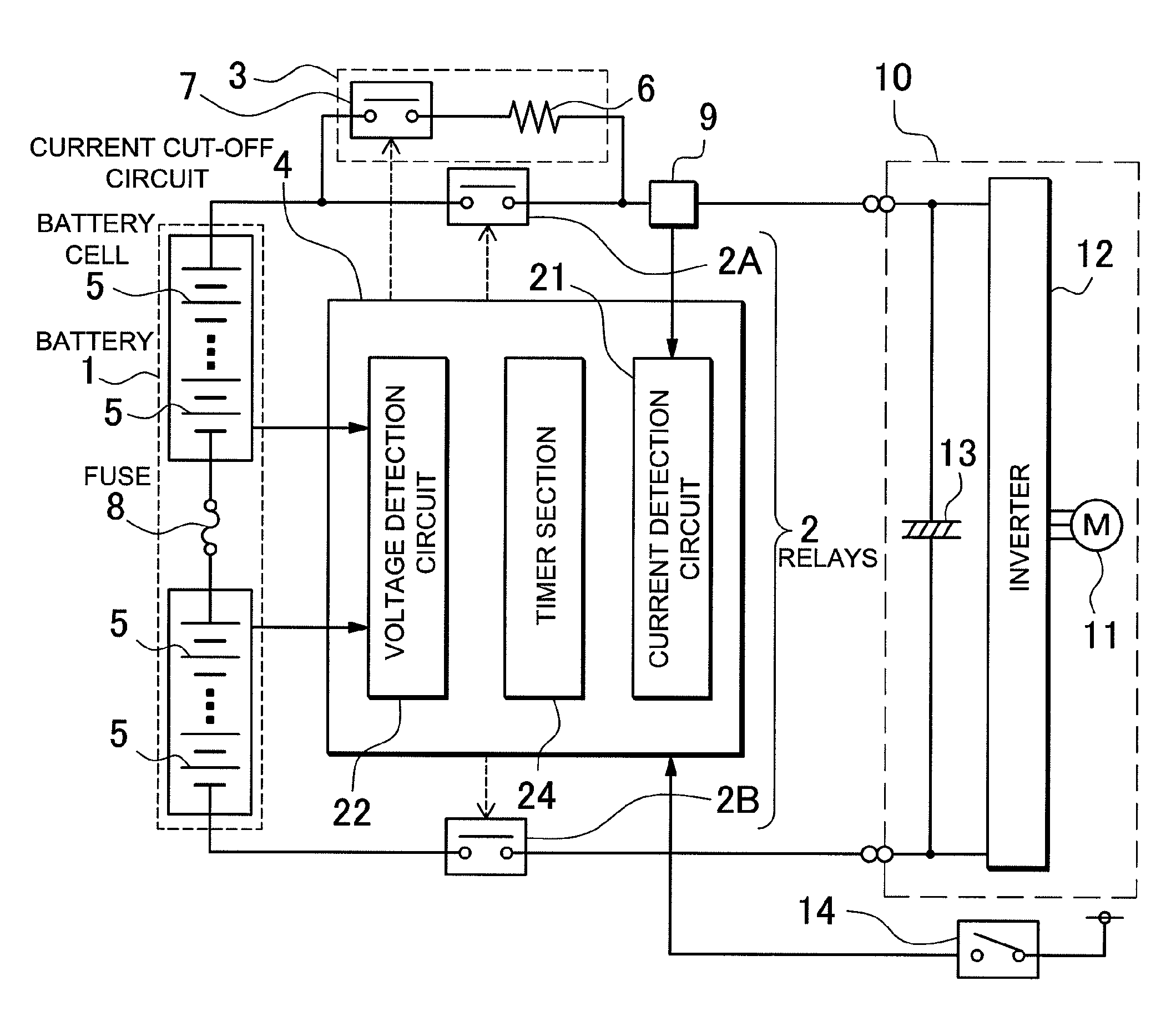

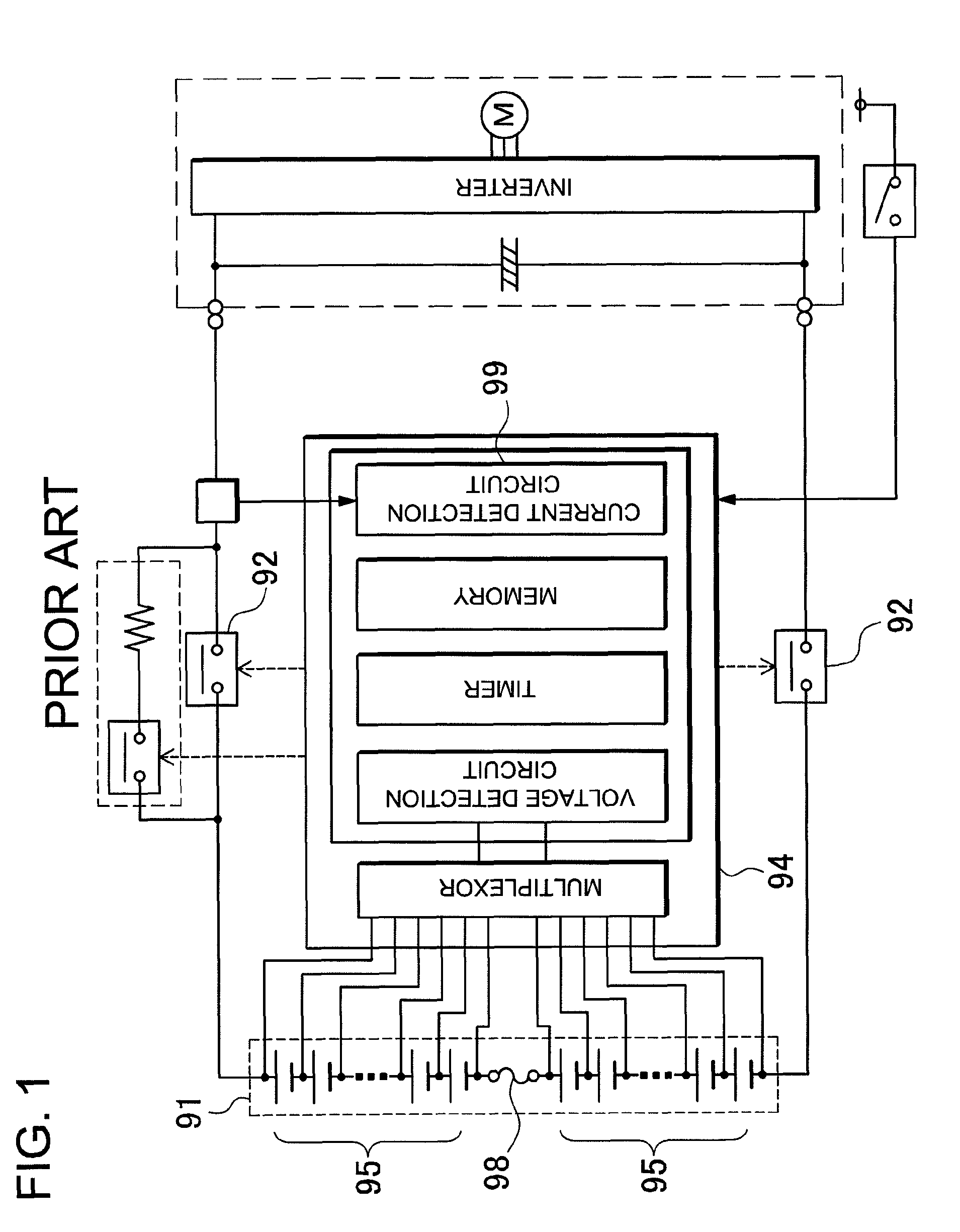

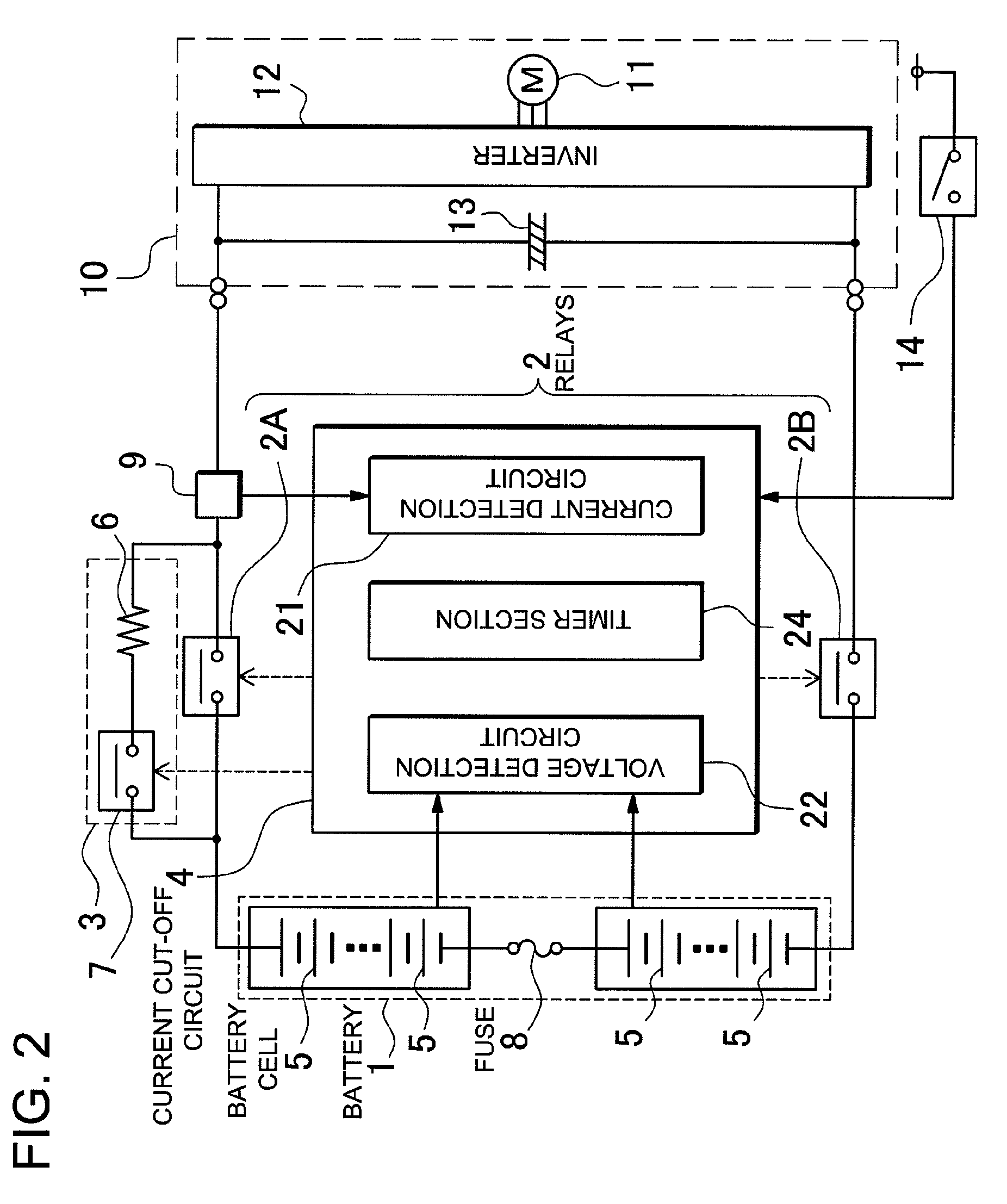

The battery system is provided with a battery 1 that can be recharged, a fuse 8 connected to the battery 1 that blows with excessive current flow, relays 2 connected to the output-side of the battery 1, and a current cut-off circuit 4 that detects excessive battery 1 current and controls the relays 2. The current cut-off circuit 4 detects excessive battery 1 current, and is provided with a timer section 24 that designates a time delay until the relays 2 are switched from ON to OFF. For the delay time of the timer section 24, the fusing current of the fuse 8 is set lower than the maximum cut-off current of the relays 2 and higher than the maximum allowable battery 1 charging and discharging current. In a situation where excessive current greater than the maximum cut-off current of the relays 2 flows through the battery 1, the fuse 8 is blown during the timer 24 delay time, and the current cut-off circuit 4 switches the relays 2 from ON to OFF when the delay time has elapsed.

Owner:SANYO ELECTRIC CO LTD

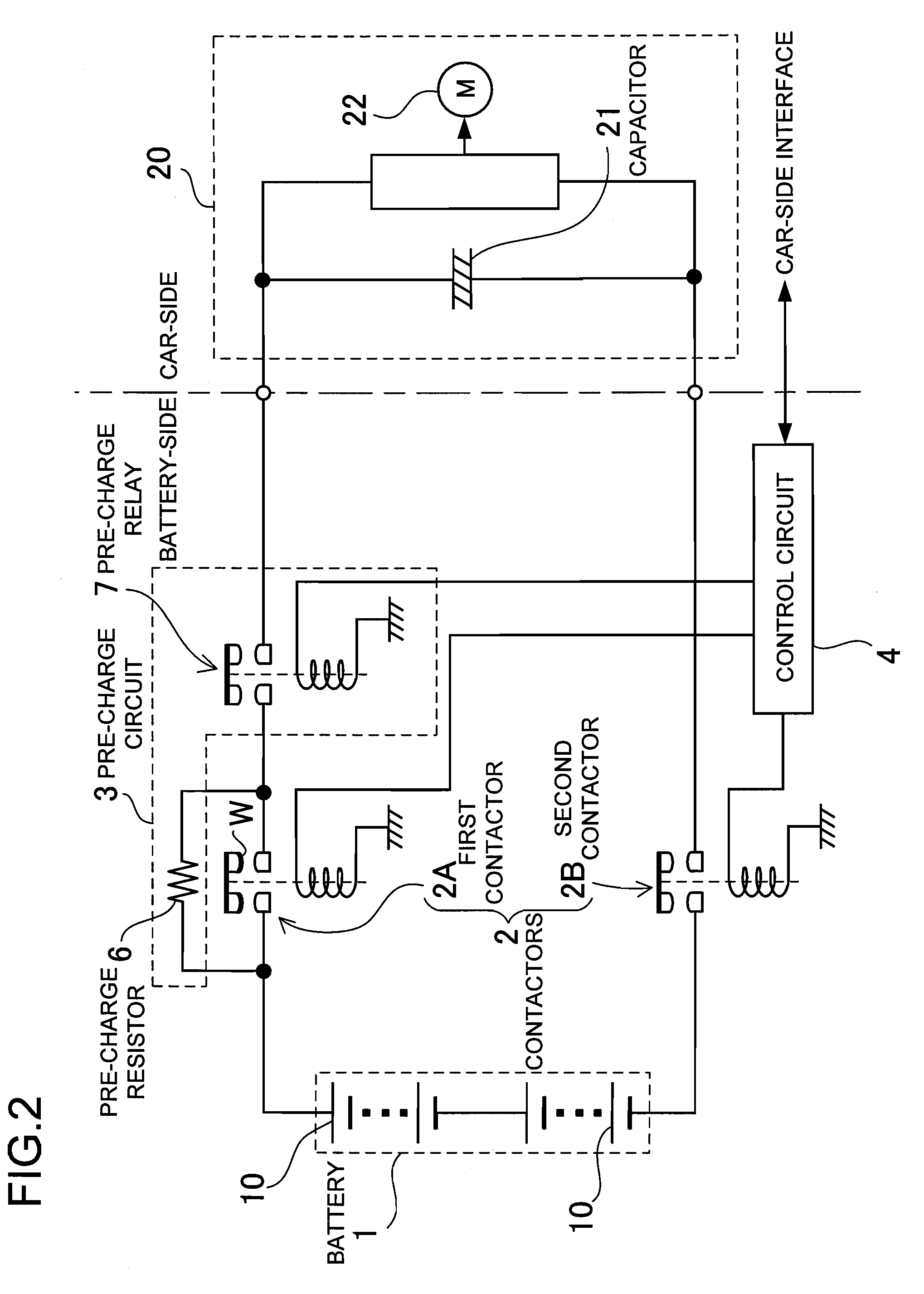

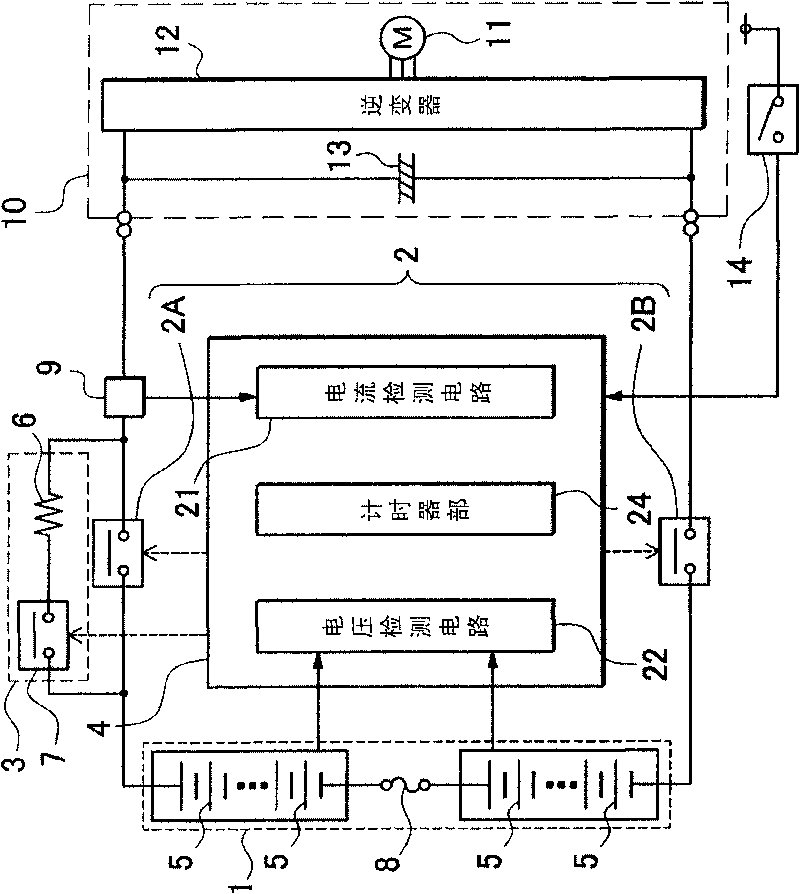

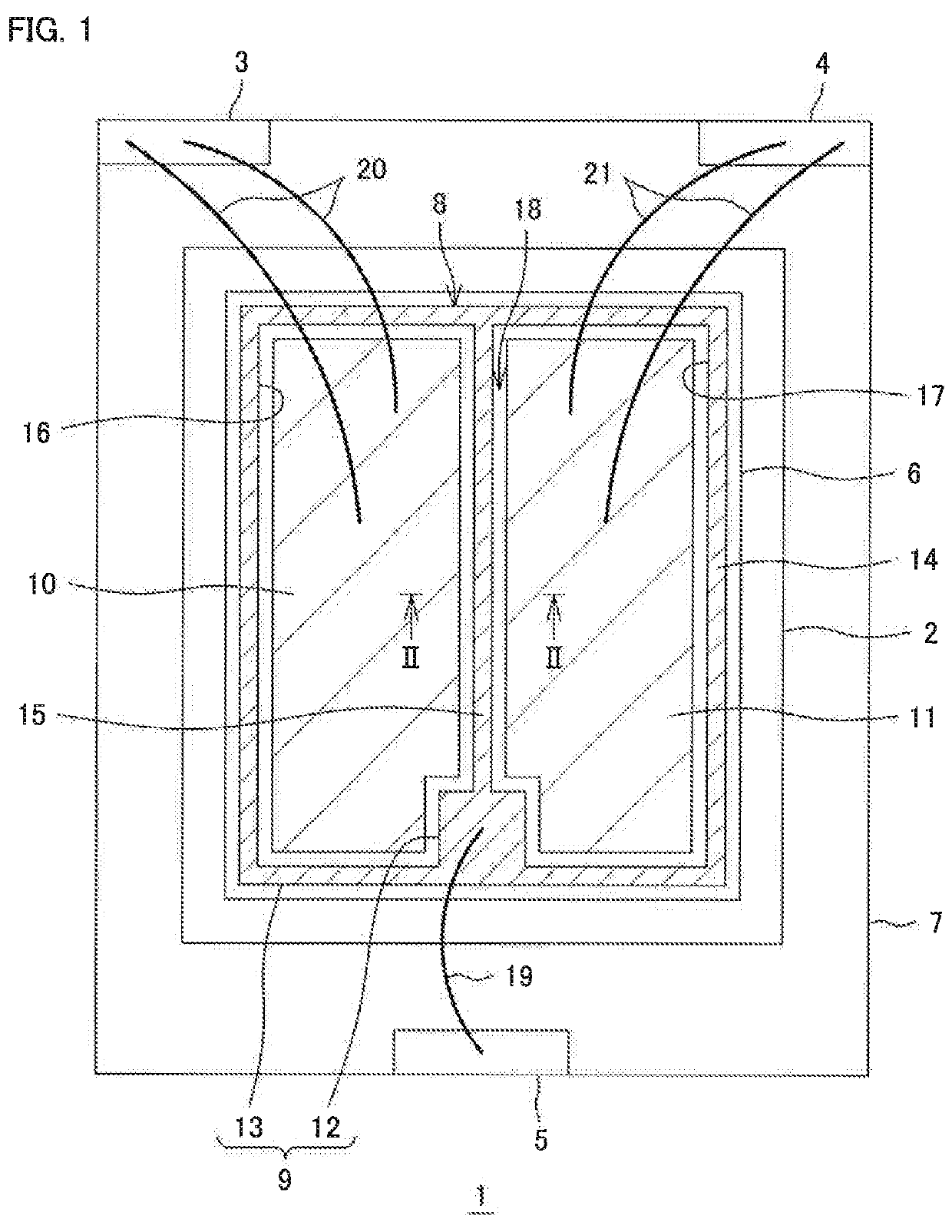

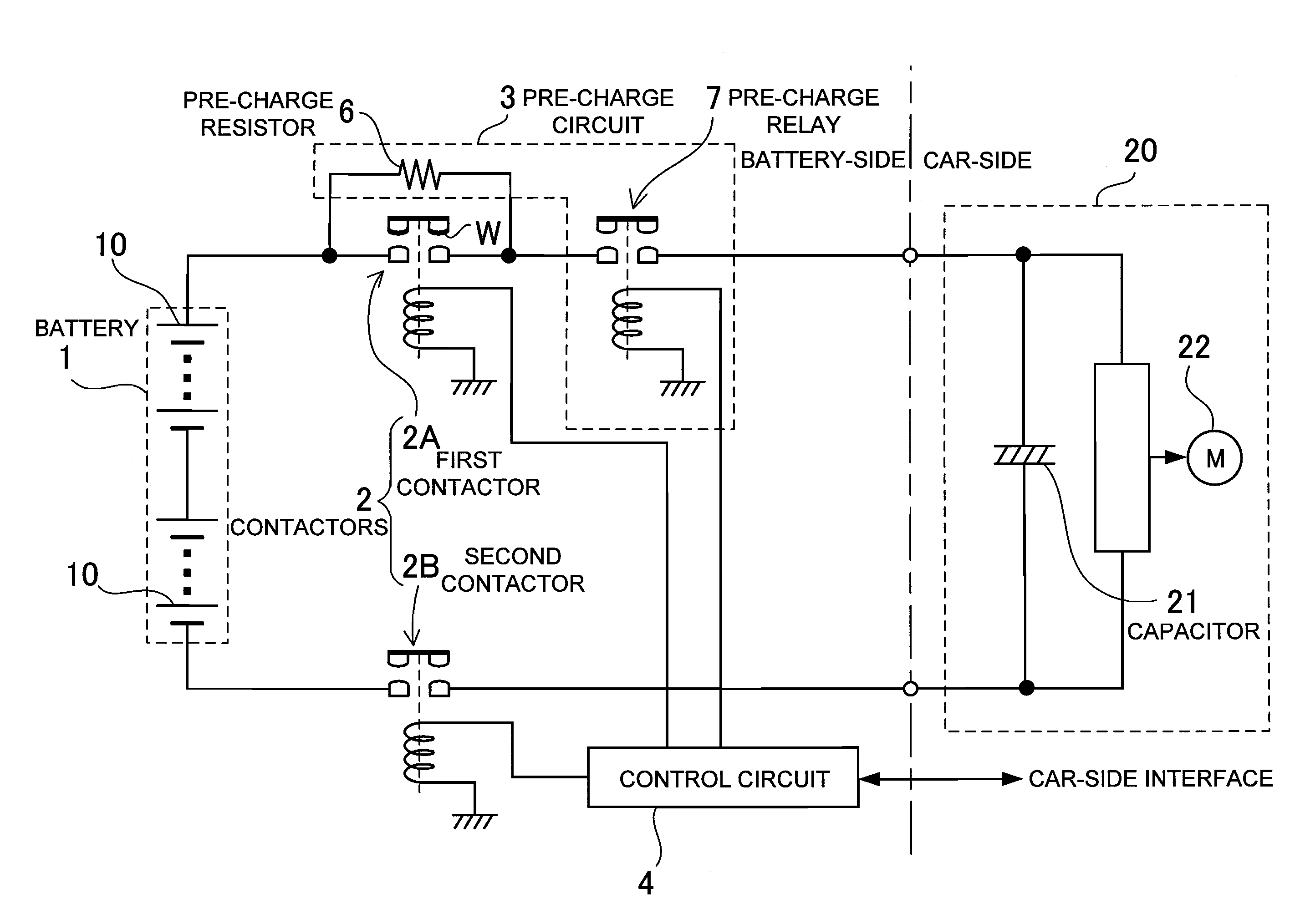

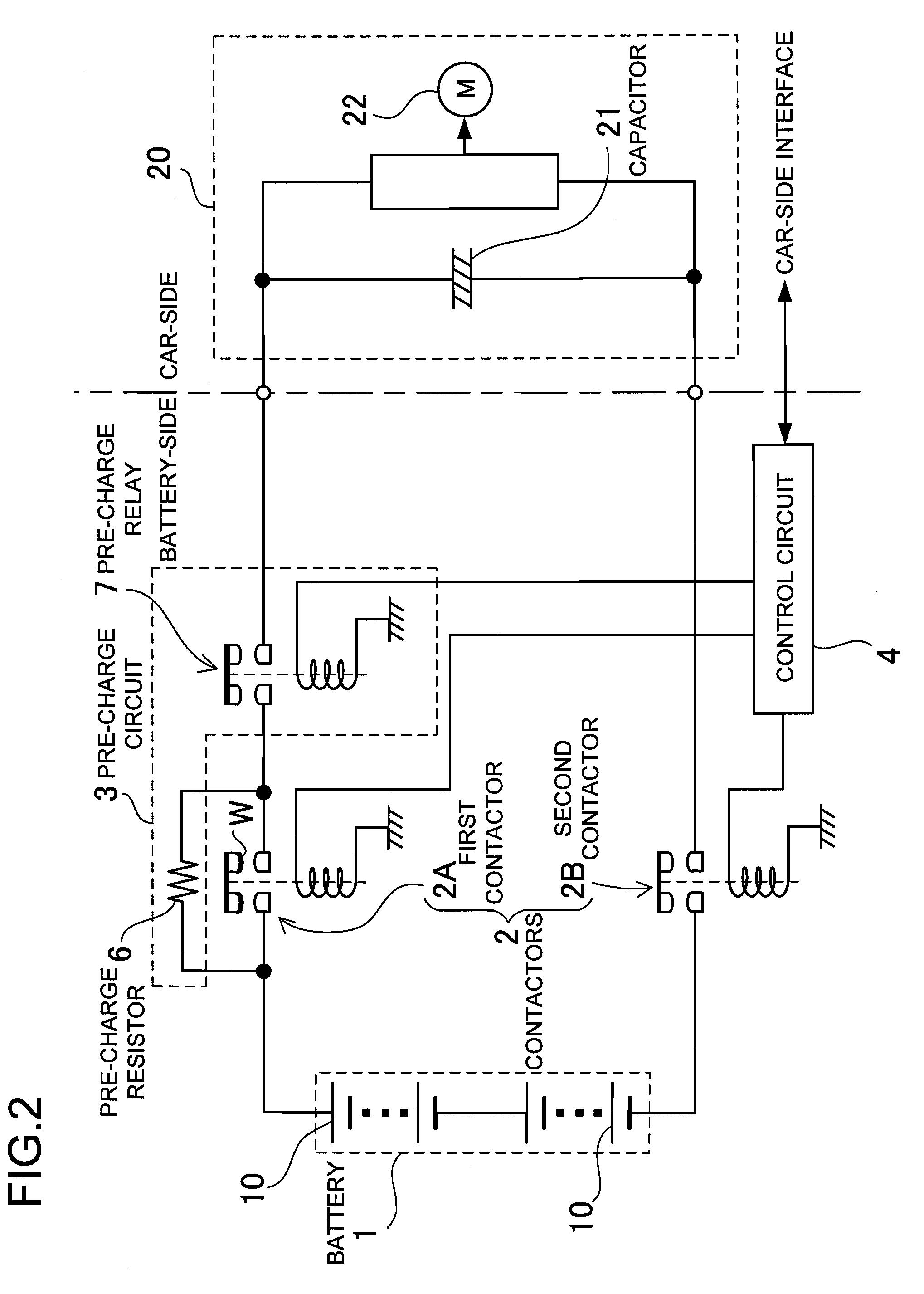

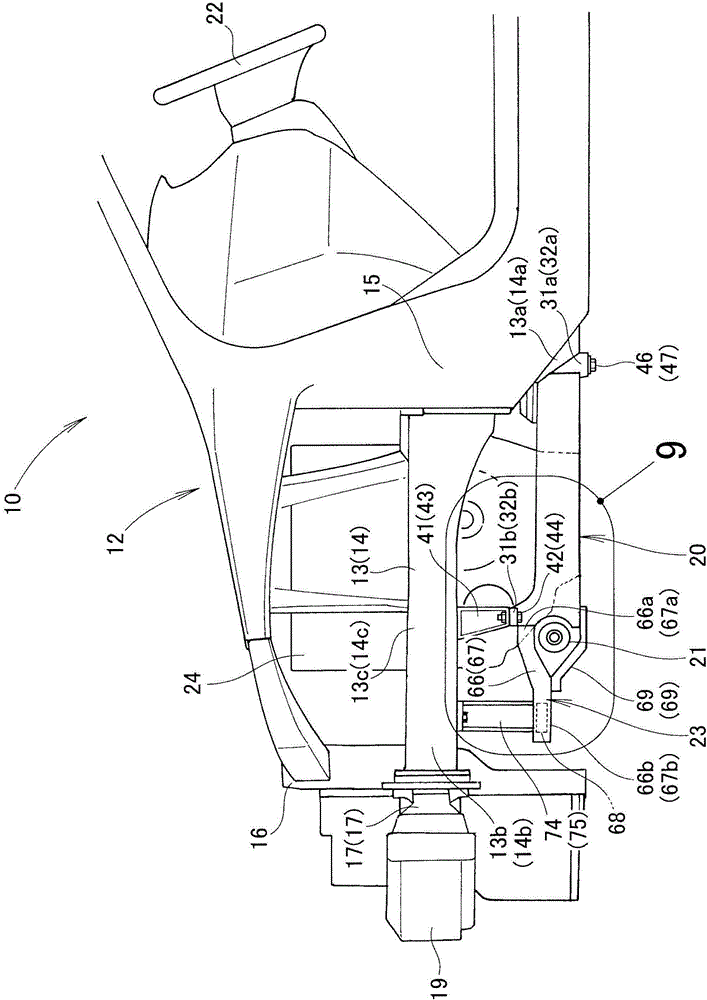

Car power source apparatus

InactiveUS20090212627A1Reliable cut-offLong lastingElectric devicesElectric powerPre-chargeControl circuit

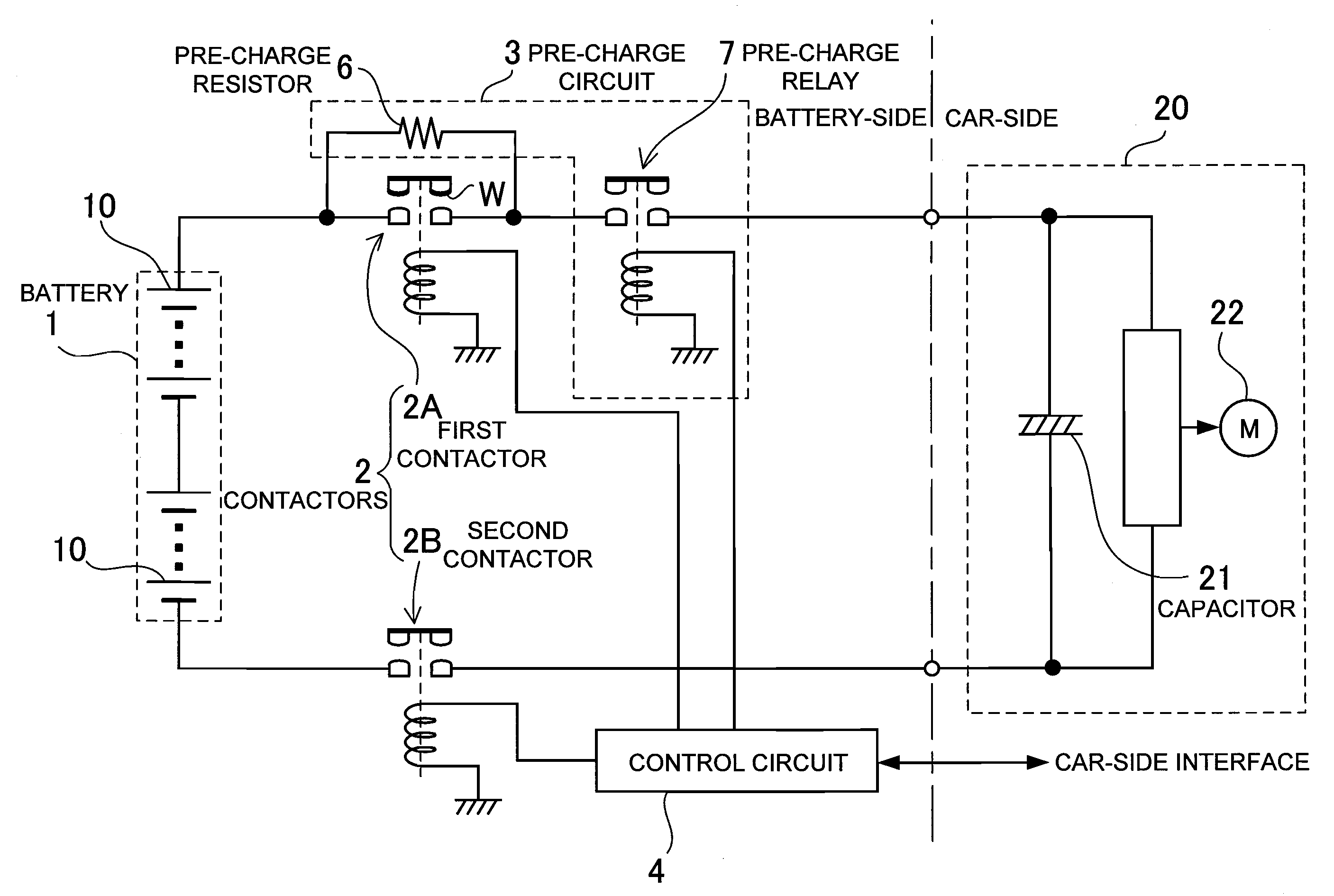

The car power source apparatus is provided with contactors 2 connected to the output-side of the battery 1; a pre-charge circuit 3 made up of a series connected pre-charge resistor 6 and a pre-charge relay 7, which is connected with a contactor 2 to supply auxiliary charge to a capacitor 21 connected to the car-side of the battery 1; and a control circuit 4 to control the contactors 2 and pre-charge relay 7.The pre-charge resistor 6 is connected in parallel with a contactor 2, and the pre-charge relay 7 is connected in series with that contactor 2. The control circuit 4 switches the pre-charge relay 7 ON to pre-charge the car-side capacitor 21, and then switches the contactor 2 ON to connect the battery 1 to the car-side.

Owner:SANYO ELECTRIC CO LTD

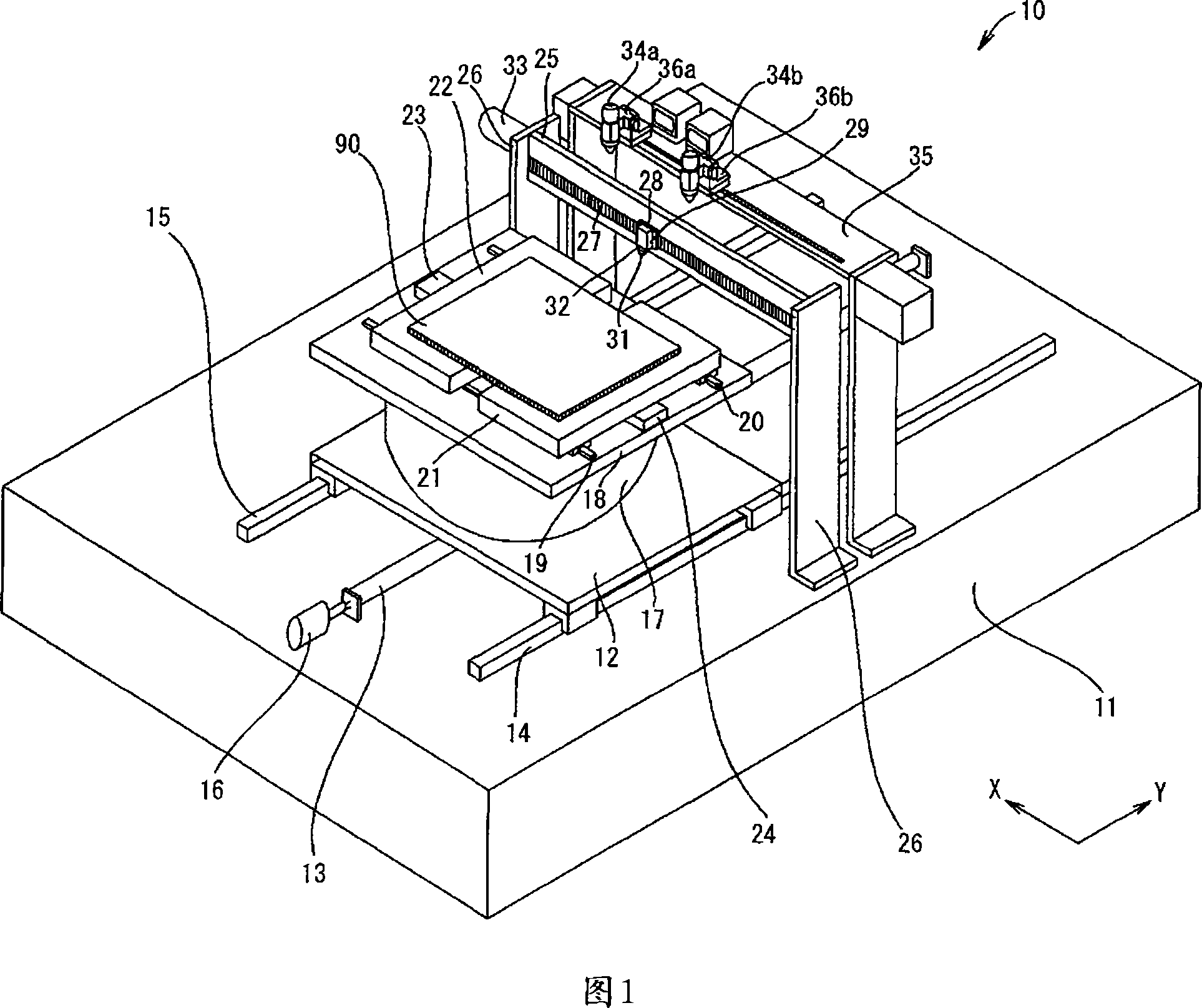

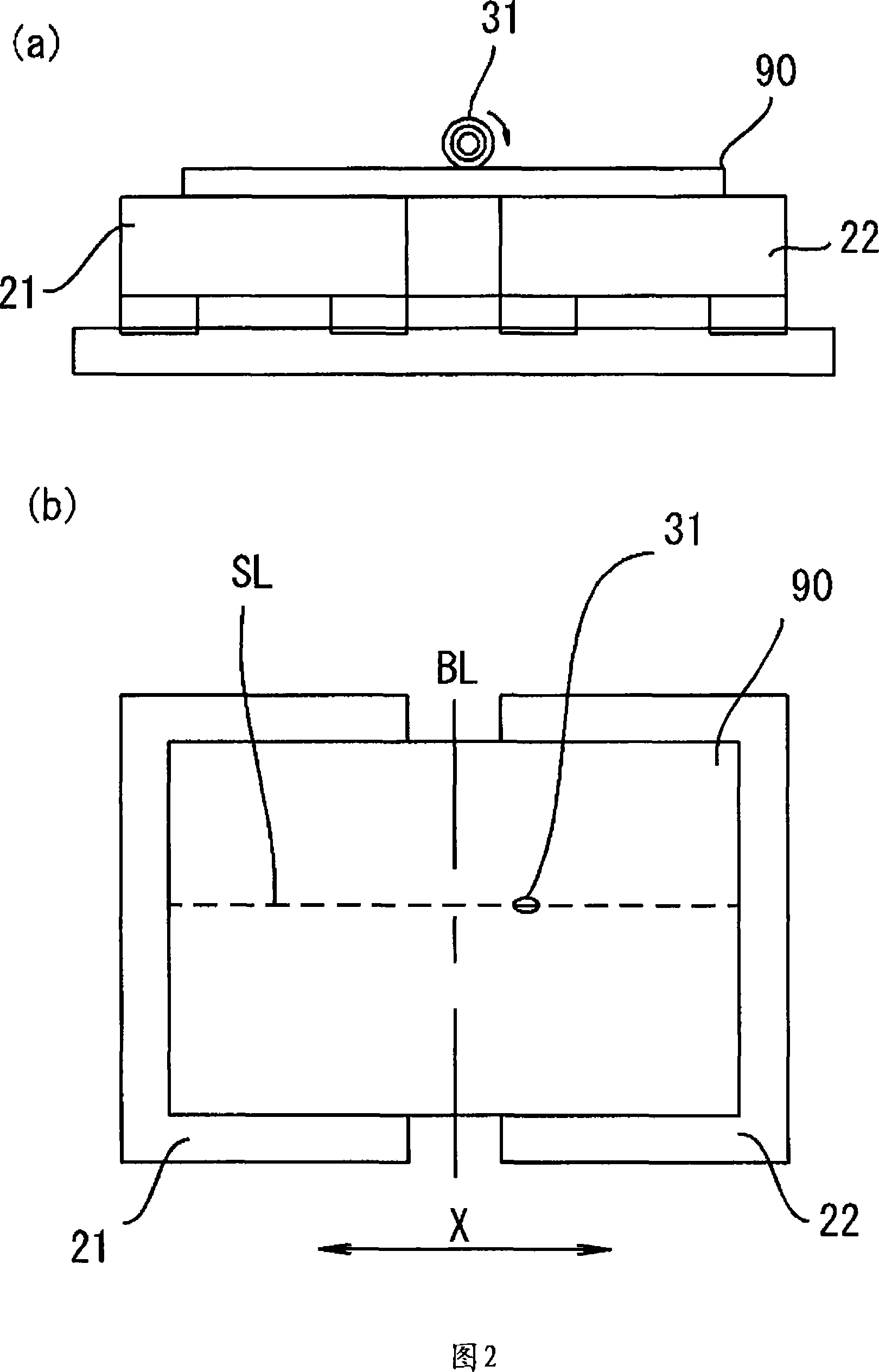

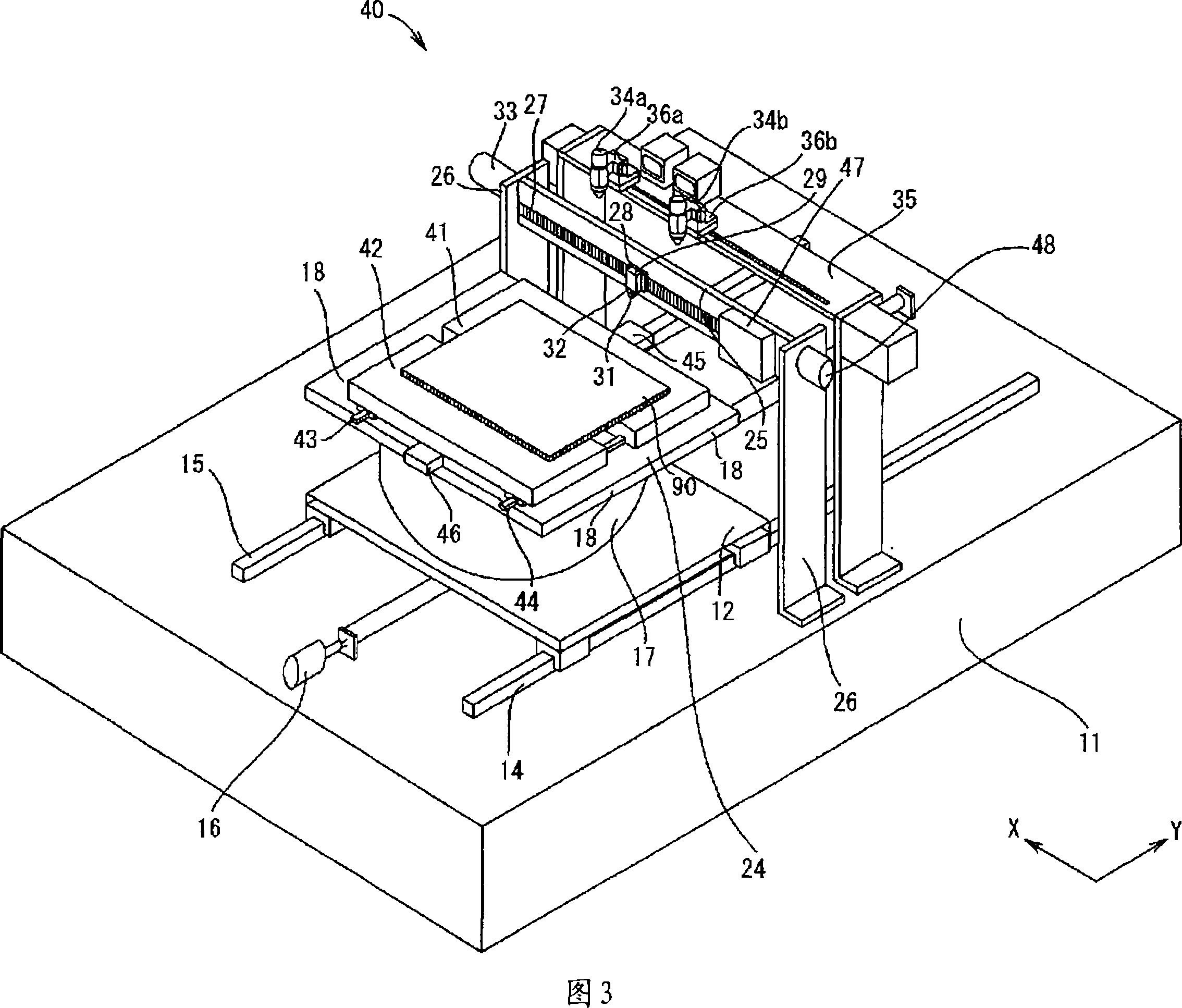

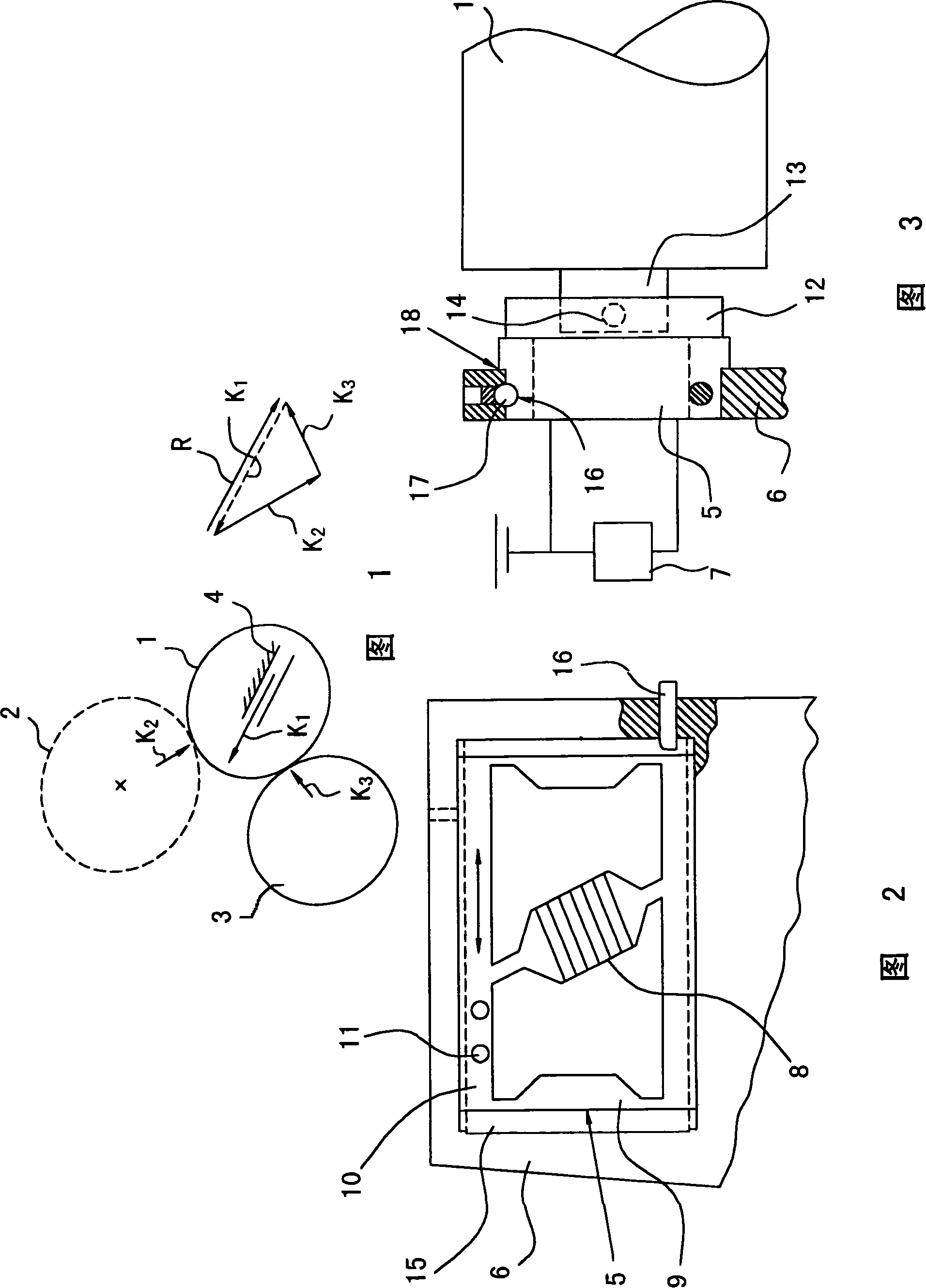

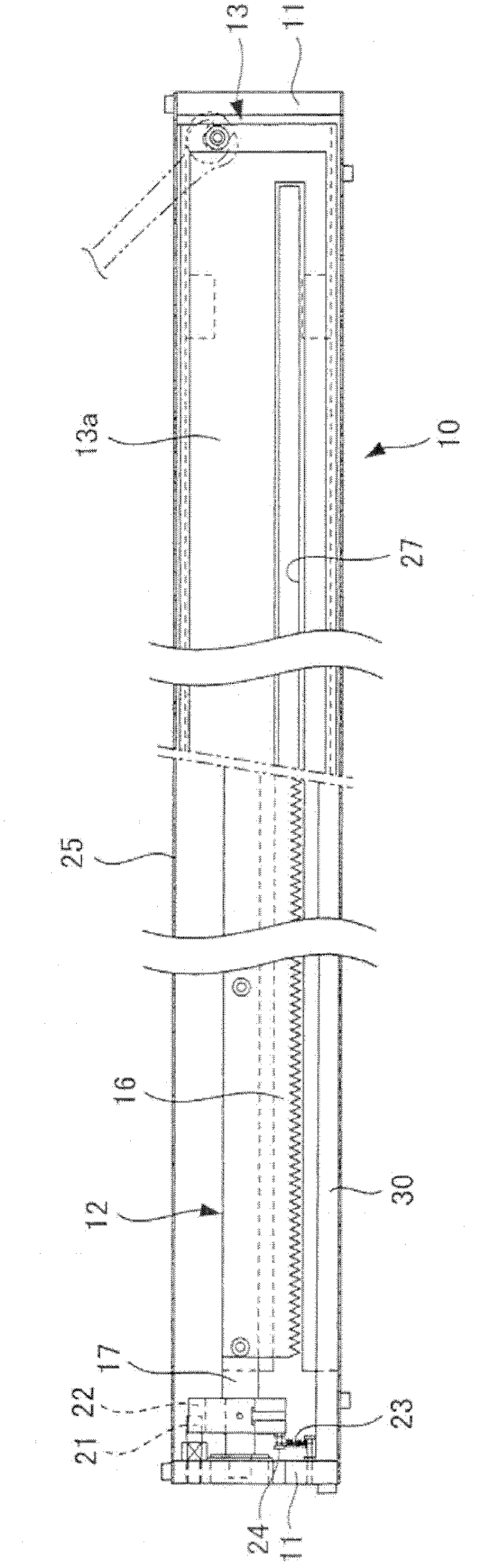

Method and apparatus for scribing brittle material board and system for breaking brittle material board

InactiveCN101068666AEasy to crimp and turnAvoid it happening againConveyorsWorking accessoriesEngineeringVacuum pump

According to the inventive method and apparatus for scribing brittle material board and system for breaking brittle material board, generation of uncontrollable unnecessary cracks in unspecified directions is prevented during scribing process of a brittle material board. A mother glass board (90) is provided on the surface of a first holding table (21) and a second holding table (22). When the mother glass board is fixed on the first holding table (21) and the second holding table (22) by being sucked from a suction hole by a vacuum pump and the like, nonuniform internal stress existing in the mother glass board (90) is adjusted in a specific direction for scribing, by moving the first holding table (21) and / or the second holding table (22) a minute distance along a prescribed direction.

Owner:MITSUBOSHI DIAMOND IND CO LTD

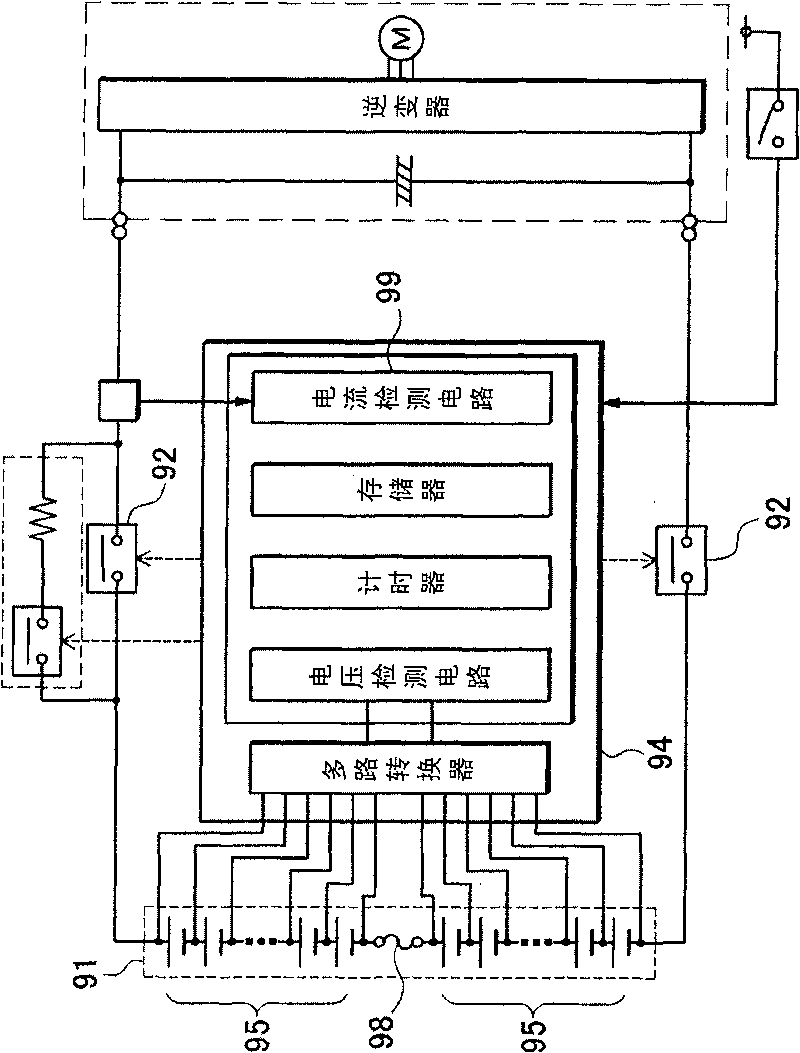

Battery system

ActiveCN101740839AReliable cut offCharge equalisation circuitSafety/protection battery circuitsTime delaysDelayed time

The battery system is provided with a battery (1) that can be recharged, a fuse (8) connected to the battery (1) that blows with excessive current flow, relays (2) connected to the output-side of the battery (1), and a current cut-off circuit (4) that detects excessive battery (1) current and controls the relays (2). The current cut-off circuit (4) detects excessive battery (1) current, and is provided with a timer section (24) that designates a time delay until the relays (2) are switched from ON to OFF. For the delay time of the timer section (24), the fusing current of the fuse (8) is set lower than the maximum cut-off current of the relays (2) and higher than the maximum allowable battery (1) charging and discharging current. In a situation where excessive current greater than the maximum cut-off current of the relays (2) flows through the battery (1), the fuse (8) is blown during the timer (24) delay time, and the current cut-off circuit (4) switches the relays (2) from ON to OFF when the delay time has elapsed.

Owner:SANYO ELECTRIC CO LTD

Battery system with relays

ActiveUS8228037B2Reliable cut-offMore currentCharge equalisation circuitSafety/protection battery circuitsEngineeringTimer

The battery system is provided with a battery 1 that can be recharged, a fuse 8 connected to the battery 1 that blows with excessive current flow, relays 2 connected to the output-side of the battery 1, and a current cut-off circuit 4 that detects excessive battery 1 current and controls the relays 2. The current cut-off circuit 4 detects excessive battery 1 current, and is provided with a timer section 24 that designates a time delay until the relays 2 are switched from ON to OFF. For the delay time of the timer section 24, the fusing current of the fuse 8 is set lower than the maximum cut-off current of the relays 2 and higher than the maximum allowable battery 1 charging and discharging current. In a situation where excessive current greater than the maximum cut-off current of the relays 2 flows through the battery 1, the fuse 8 is blown during the timer 24 delay time, and the current cut-off circuit 4 switches the relays 2 from ON to OFF when the delay time has elapsed.

Owner:SANYO ELECTRIC CO LTD

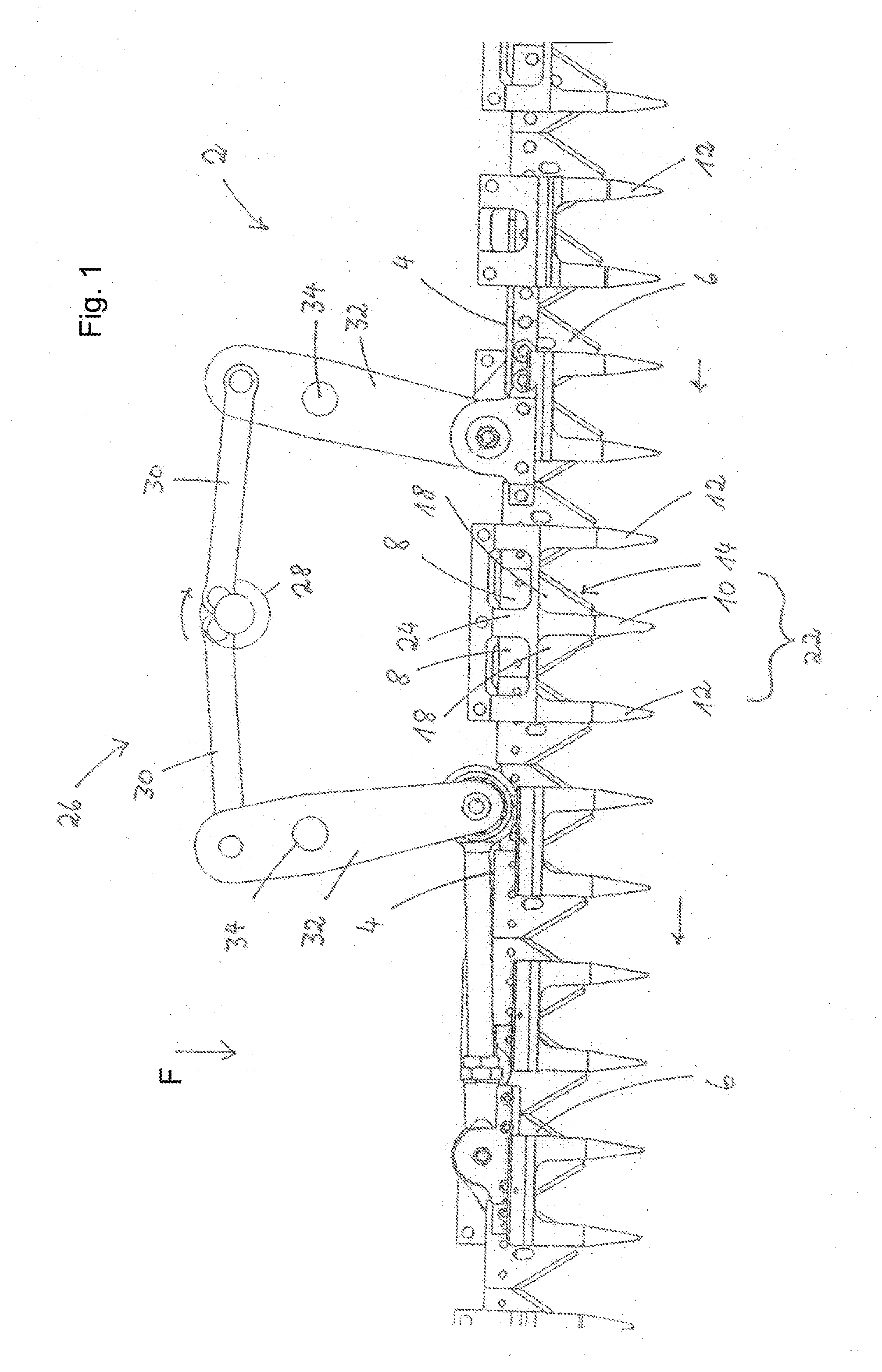

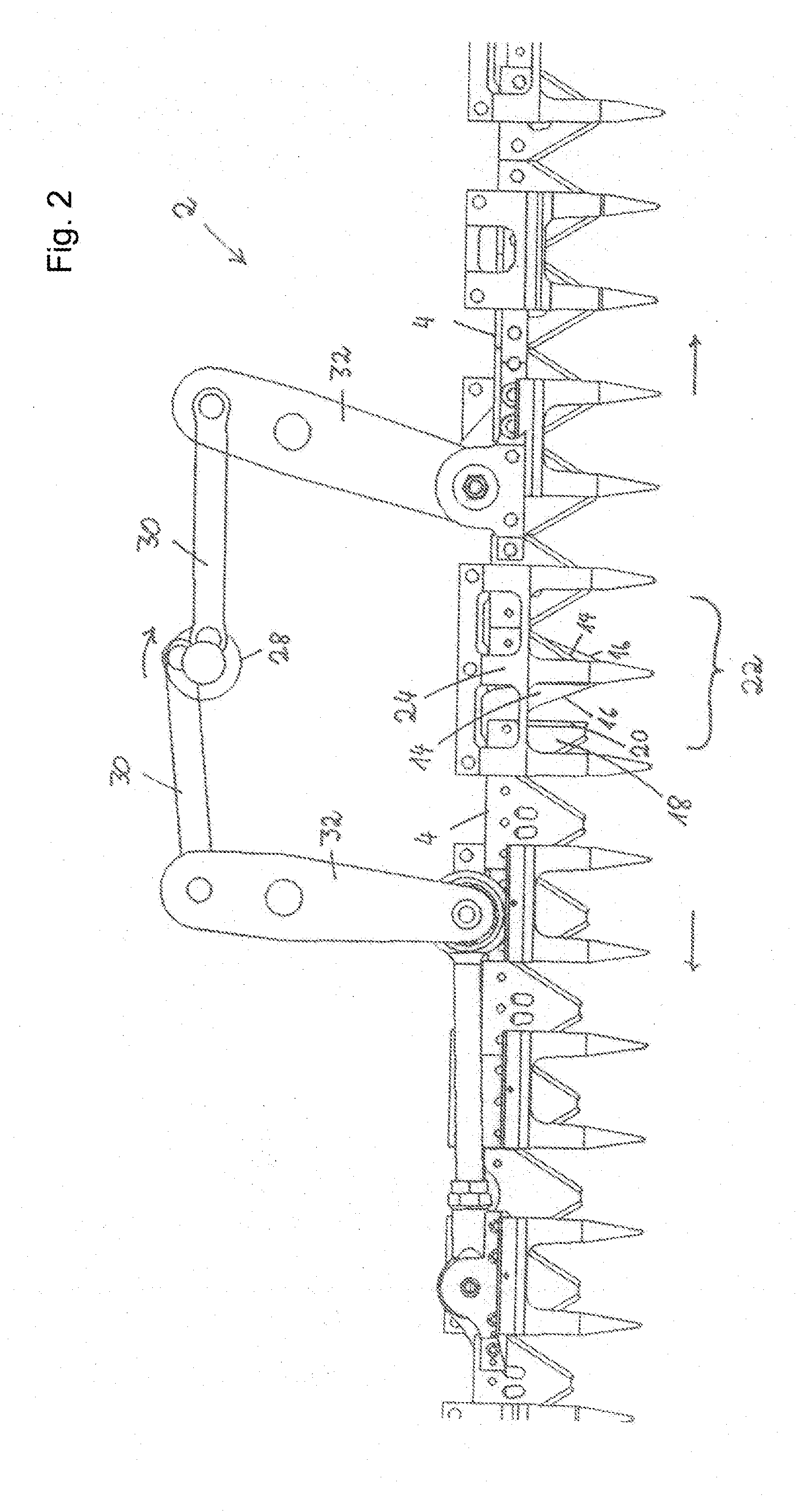

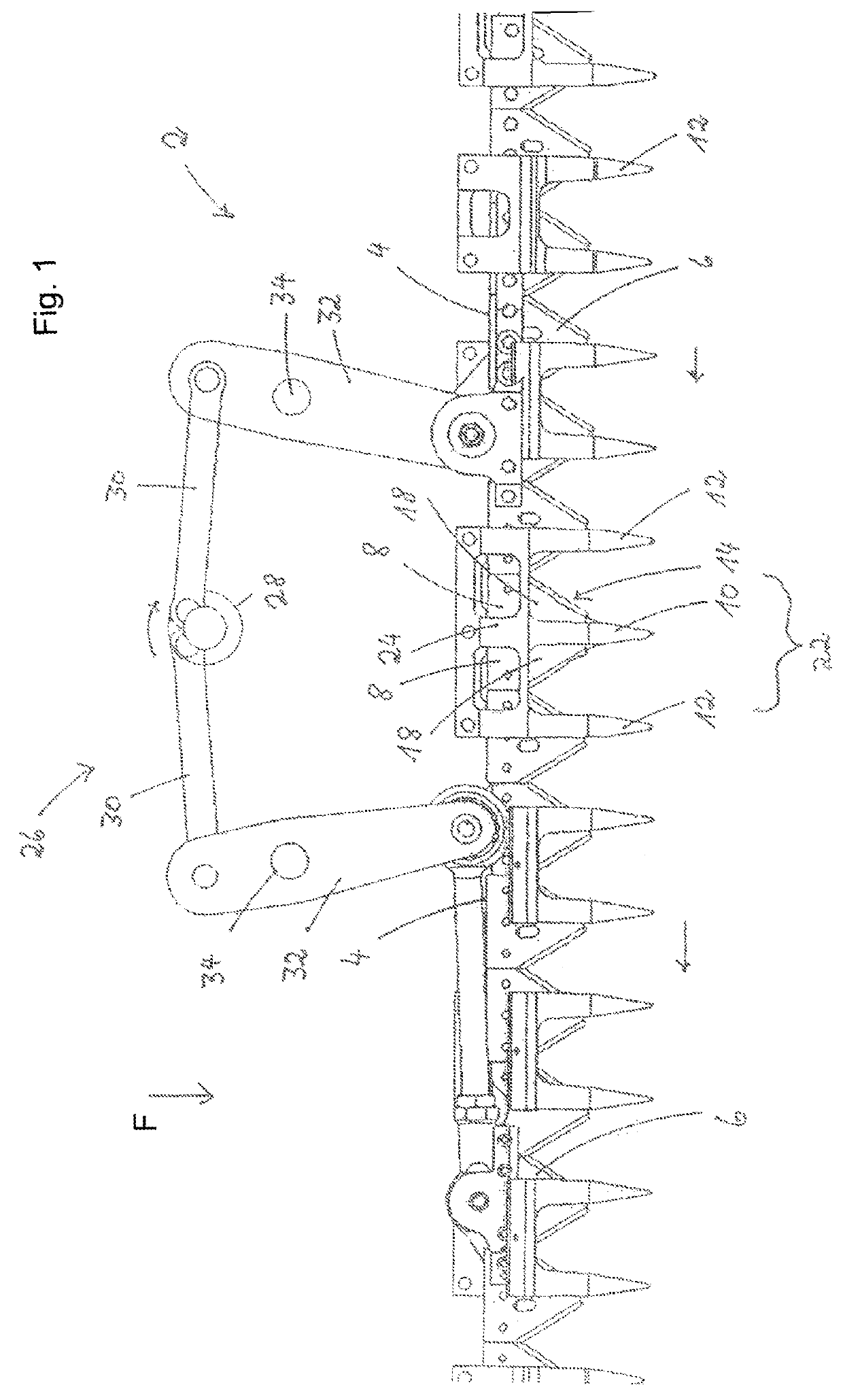

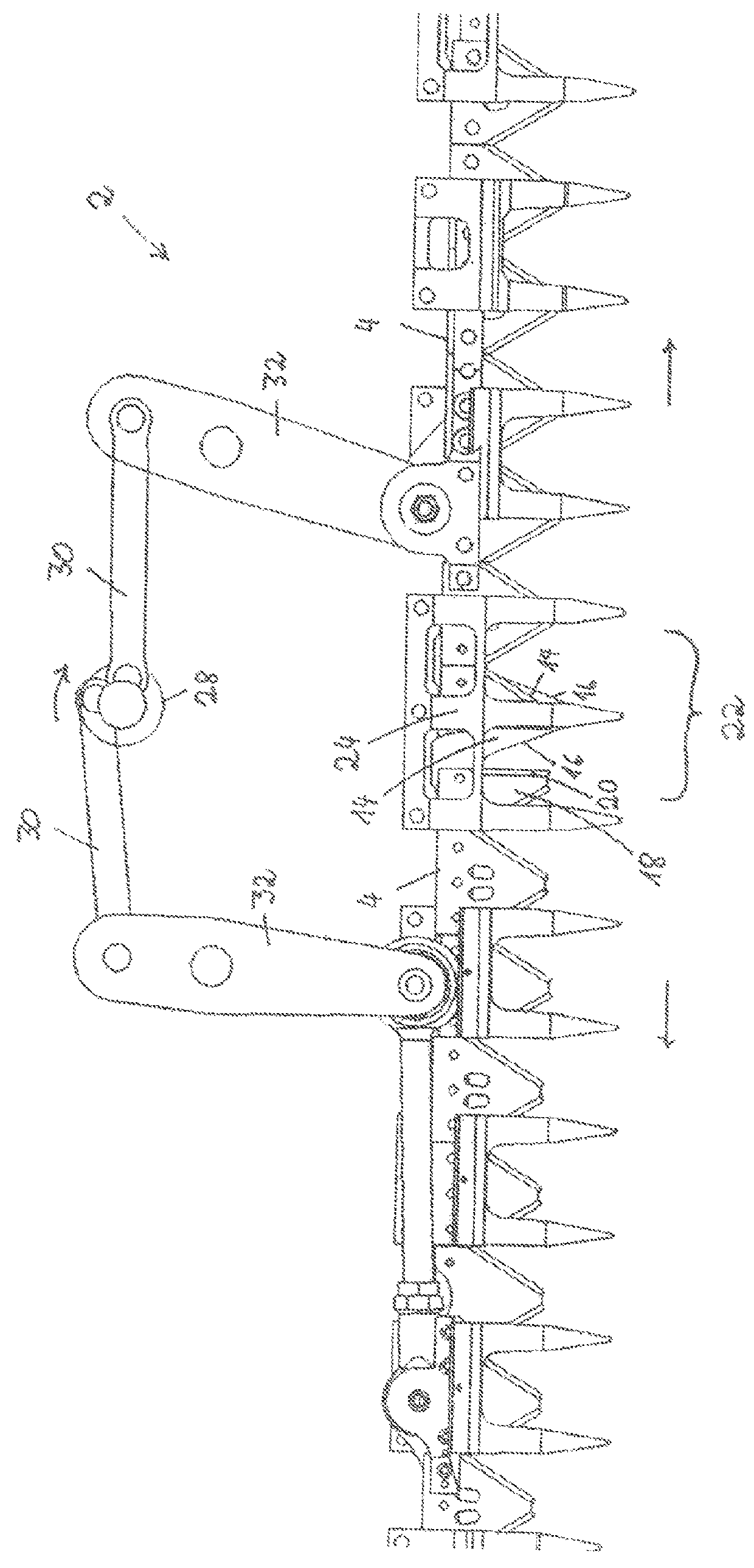

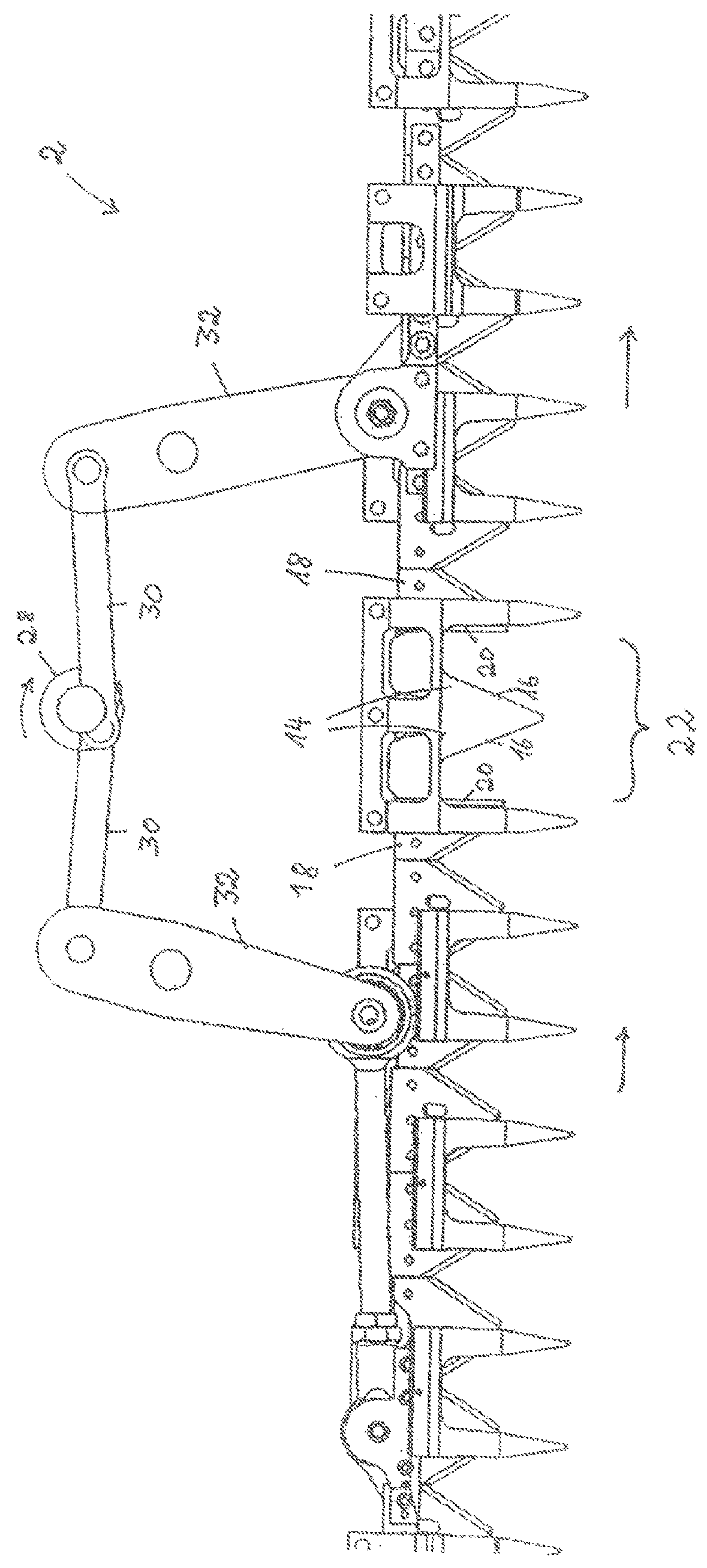

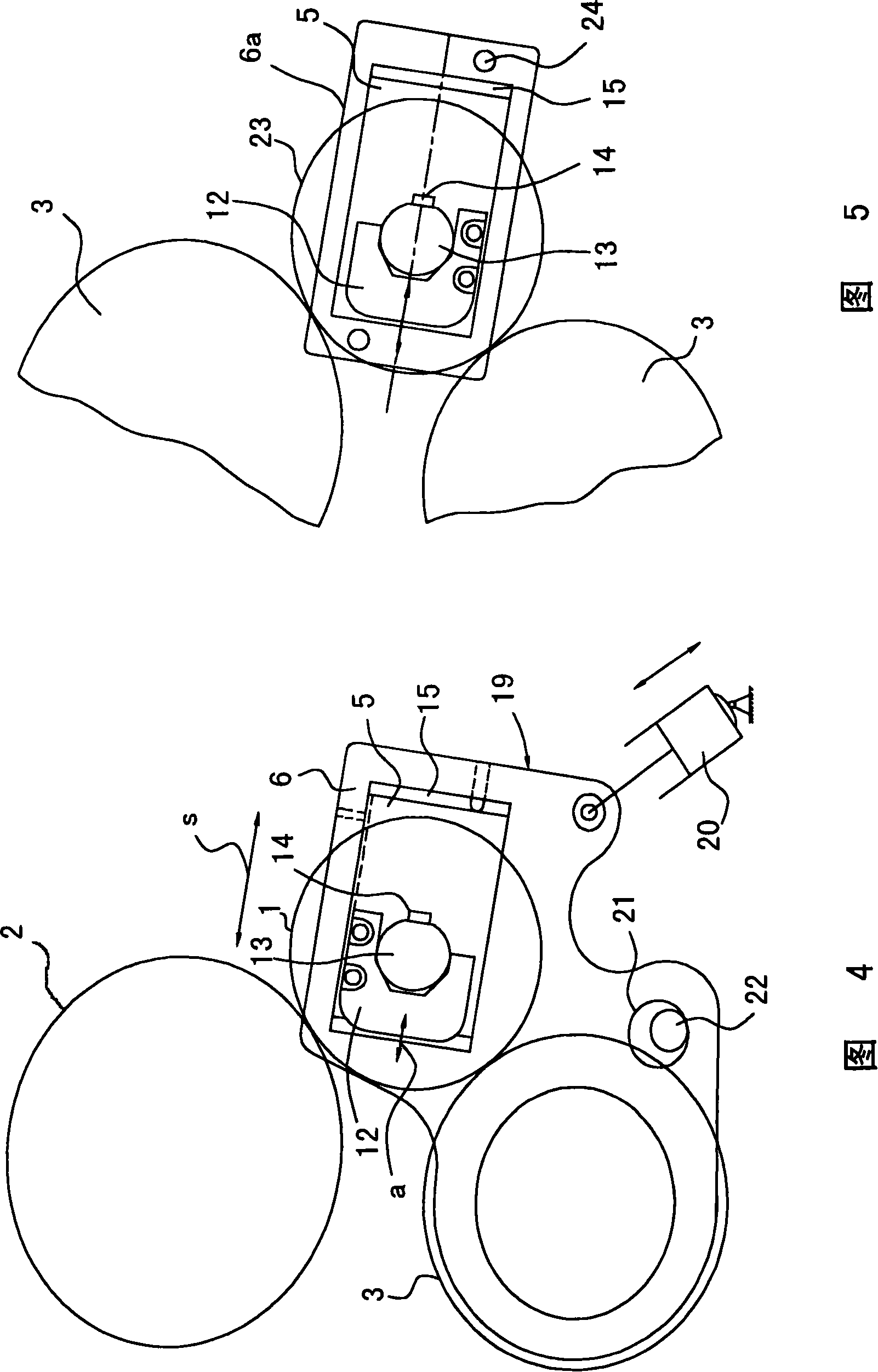

Cutting Device for Agricultural Machines

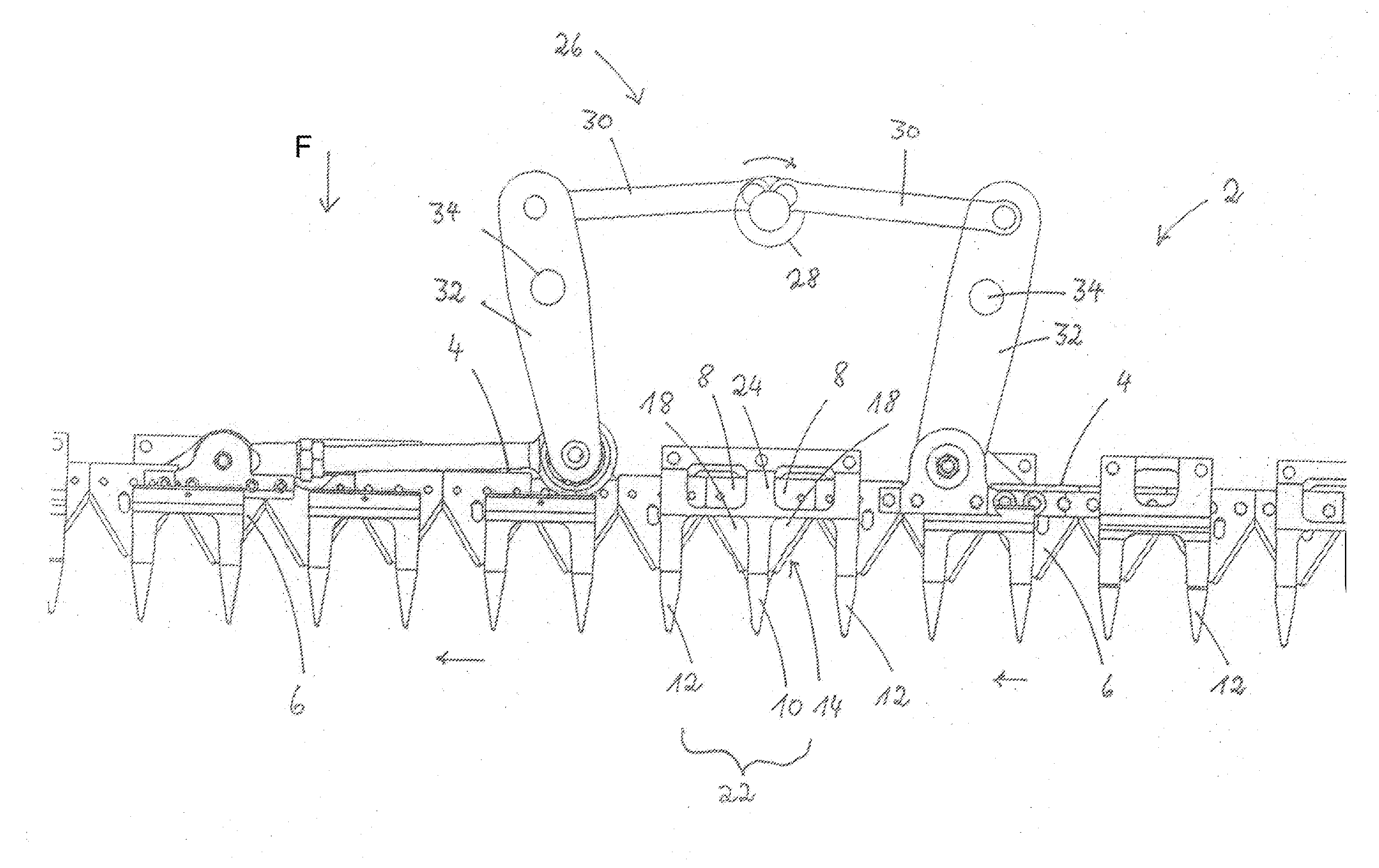

An agricultural cutting device has knife bar sections with section knife blades. A drive with phase offset drives the knife bar sections at least temporarily in opposite directions. The section knife blades interact scissor-like with counter knives. The knife bar sections have adjacently positioned bar ends. When the knife bar sections move, a gap of varying size is formed between the bar ends. A mowing finger is arranged at the gap. A stationary knife blade with first cutting edges is arranged at the mowing finger. The first cutting edges are arranged adjacent to the mowing finger and extend at a slant relative to a forward travel direction of the cutting device so that the cutting edges have a V-shaped arrangement broadening in travel direction. The knife bar sections have an outer knife blade attached to the bar ends whose cutting edges extend parallel to the travel direction.

Owner:CARL GERINGHOFF

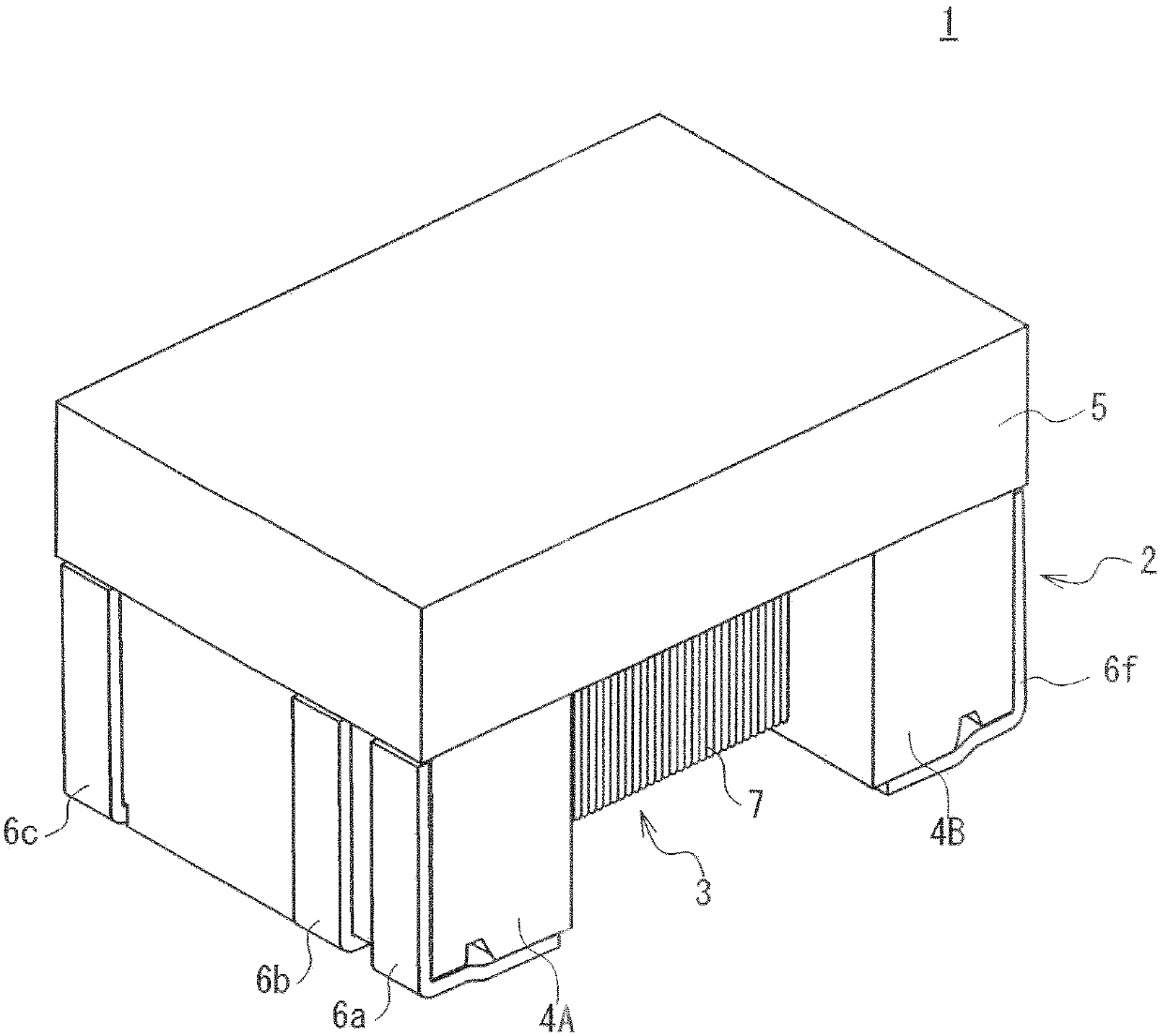

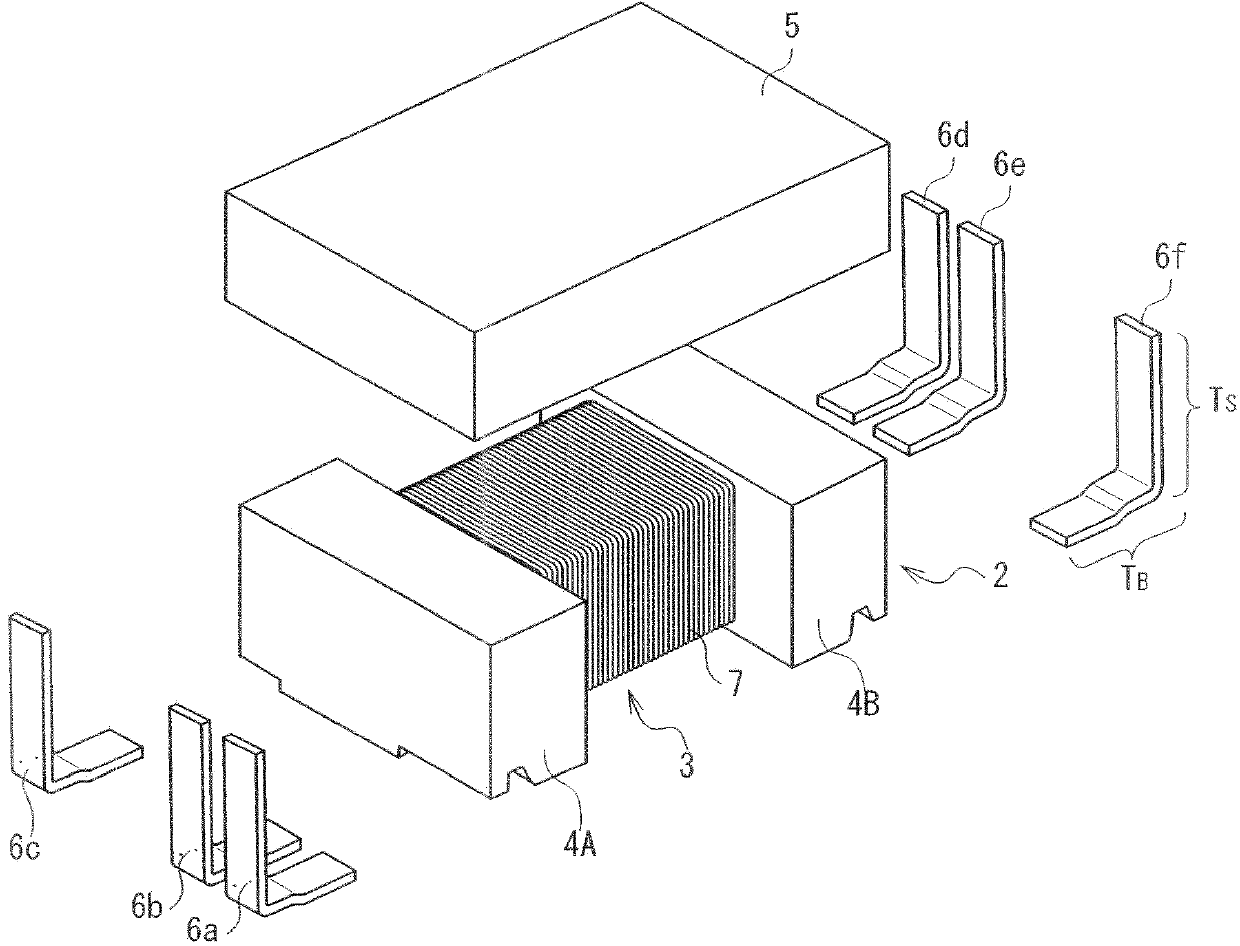

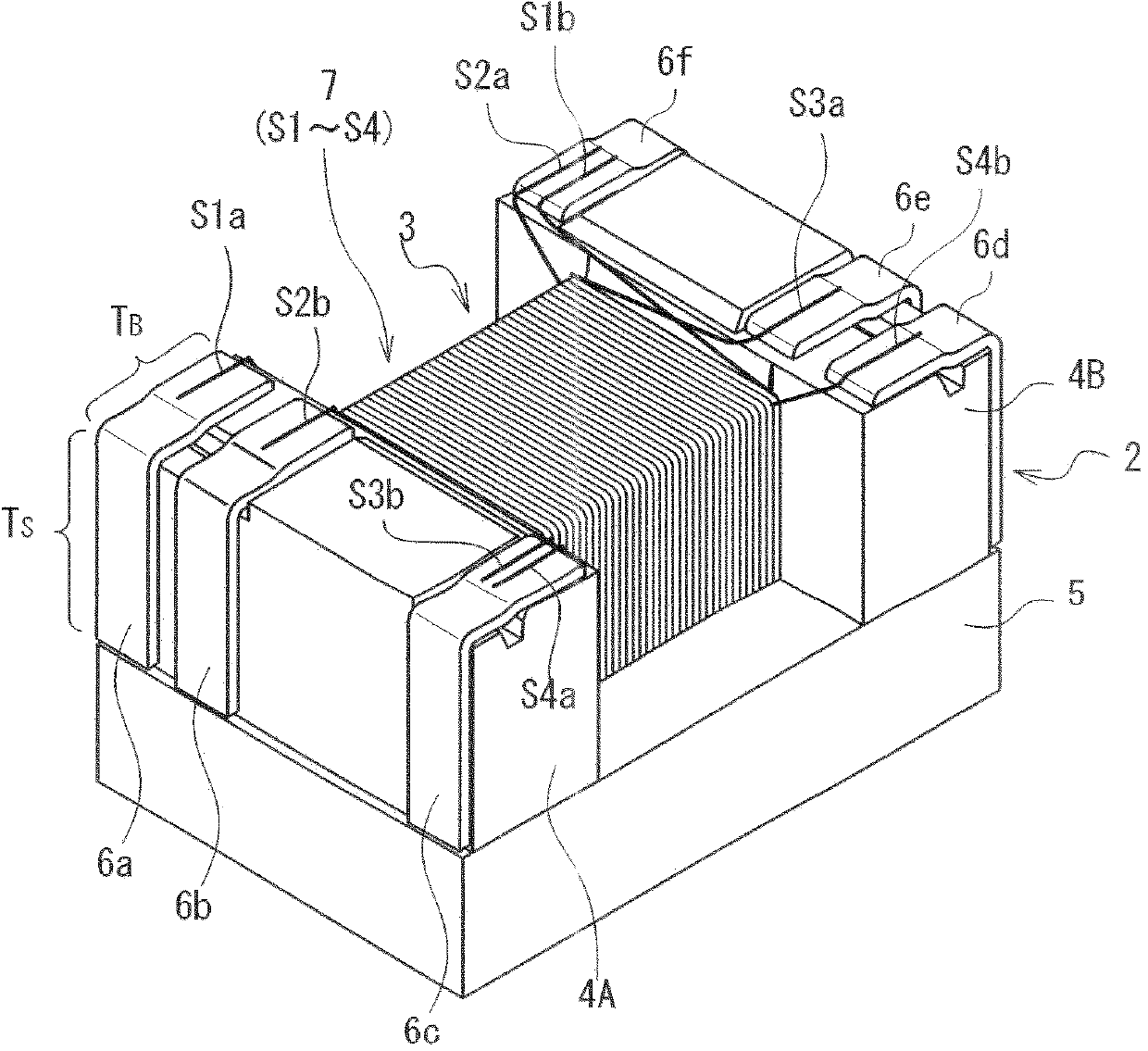

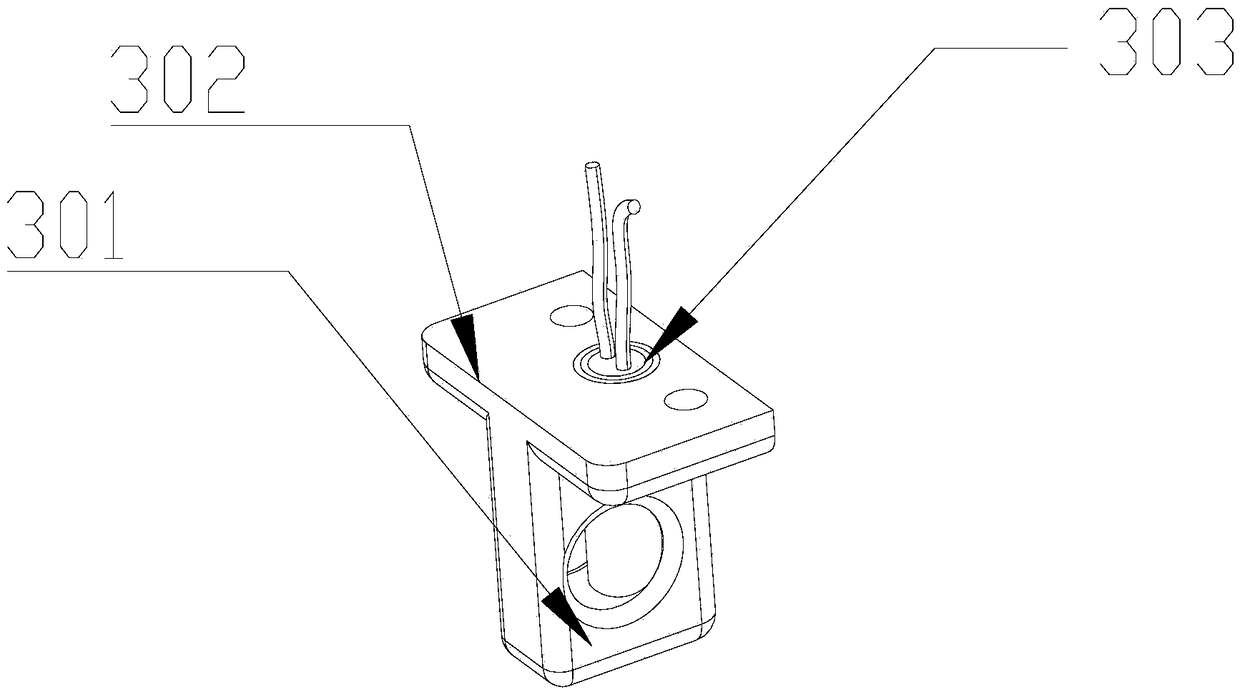

Coil component

ActiveCN103730229ASuppression of height deviationImprove flatnessTransformers/inductances coils/windings/connectionsInductance with magnetic coreHeight differenceEngineering

The invention provides a coil component which can remove height difference of the terminal surface of a terminal metal piece caused by thickness difference of a bonding agent, and has the characteristics of good installation and wiring and high reliability. The coil component (1) possesses a coil (7) coiled by wires; a drum type core (2) supporting the coil (7); terminal metal pieces (6a-6f) connecting to the terminals of the coil (7); and a binding agent (11B) used for bonding the terminal metal pieces to the flange parts (4A,4B) of the drum type core (2). The drum type core (2) possesses the bottom surface (SB) of a flange part becoming an installation surface; each metal piece possesses a bottom surface part (TB) located on the surface of the flange part of the drum type core (2). The bottom surface (SB) of each flange part is provided with a jump formed by an upper segment surface (SB2) and a lower segment surface (SB1). The bottom surface part (TB) of the terminal metal piece is in direct contact with the upper segment surface (SB2); the gap (d1) between the bottom surface part (TB) of the terminal metal piece and the lower segment surface (SB1) is filled with the first binding agent (11B). Part of the binding agent (11B) is filled in the groove (SB3) formed on the lower segment surface (SB1) just below the jump.

Owner:TDK CORPARATION

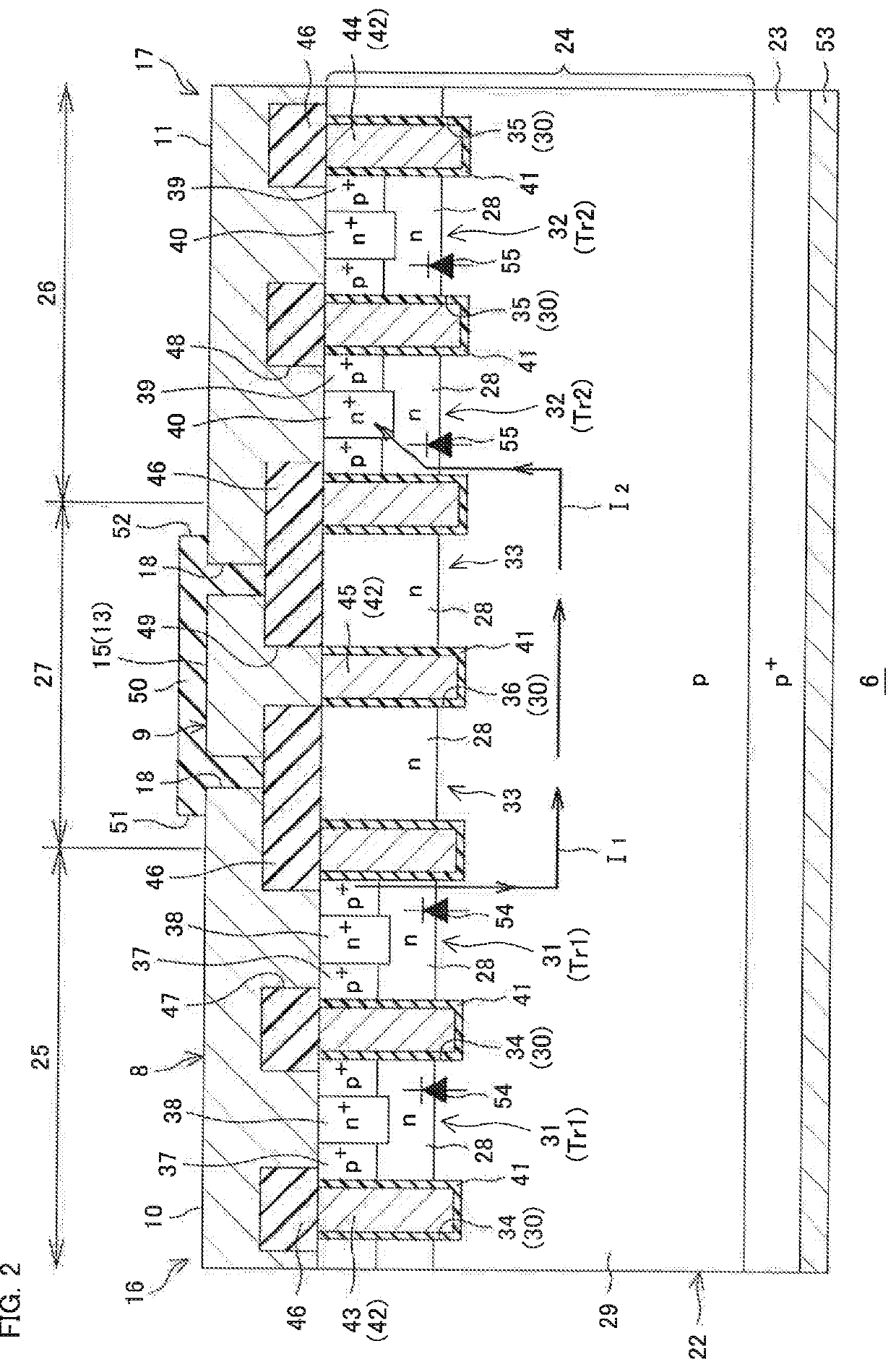

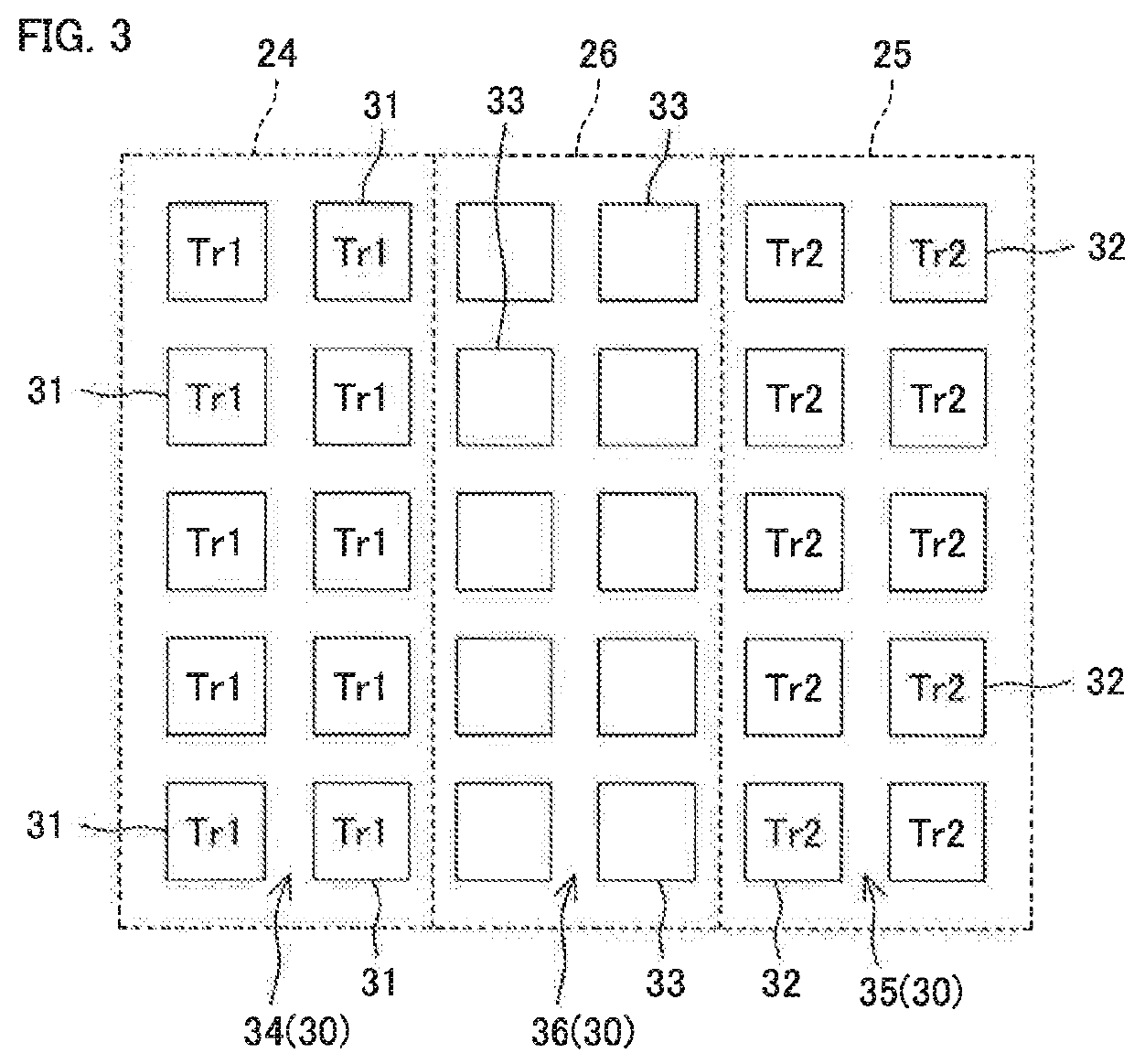

Semiconductor device and semiconductor package

ActiveUS20180096991A1Reliable cut-offResistance of layer is preventedTransistorSemiconductor/solid-state device detailsElectrical conductorSemiconductor package

A semiconductor device includes an enhancement-mode first p-channel MISFET, an enhancement-mode second p-channel MISFET, a drain conductor electrically and commonly connected to the first p-channel MISFET and the second p-channel MISFET, a first source conductor electrically connected to a source of the first p-channel MISFET, a second source conductor electrically connected to a source of the second p-channel MISFET, and a gate conductor electrically and commonly connected to a gate of the first p-channel MISFET and a gate of the second p-channel MISFET.

Owner:ROHM CO LTD

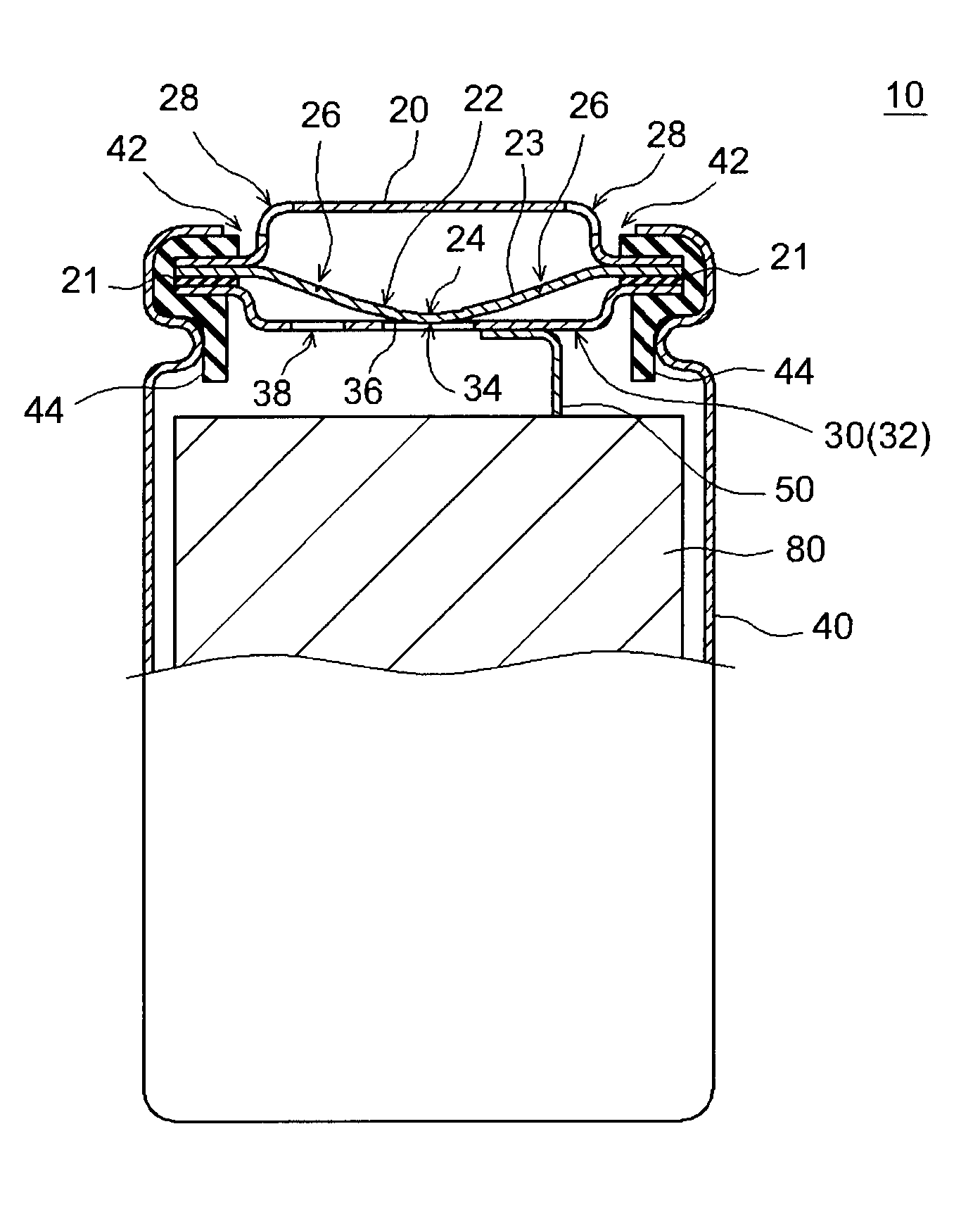

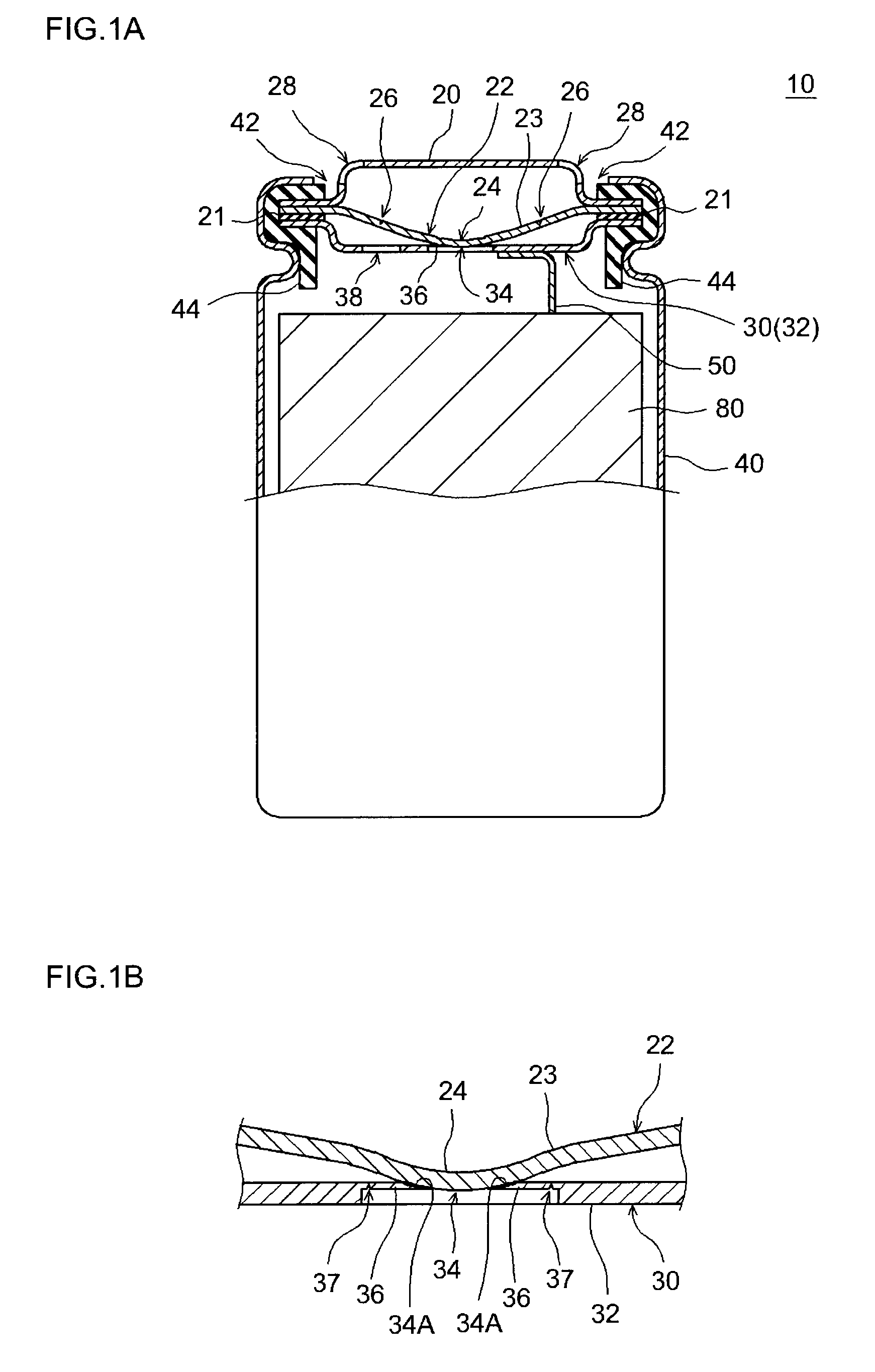

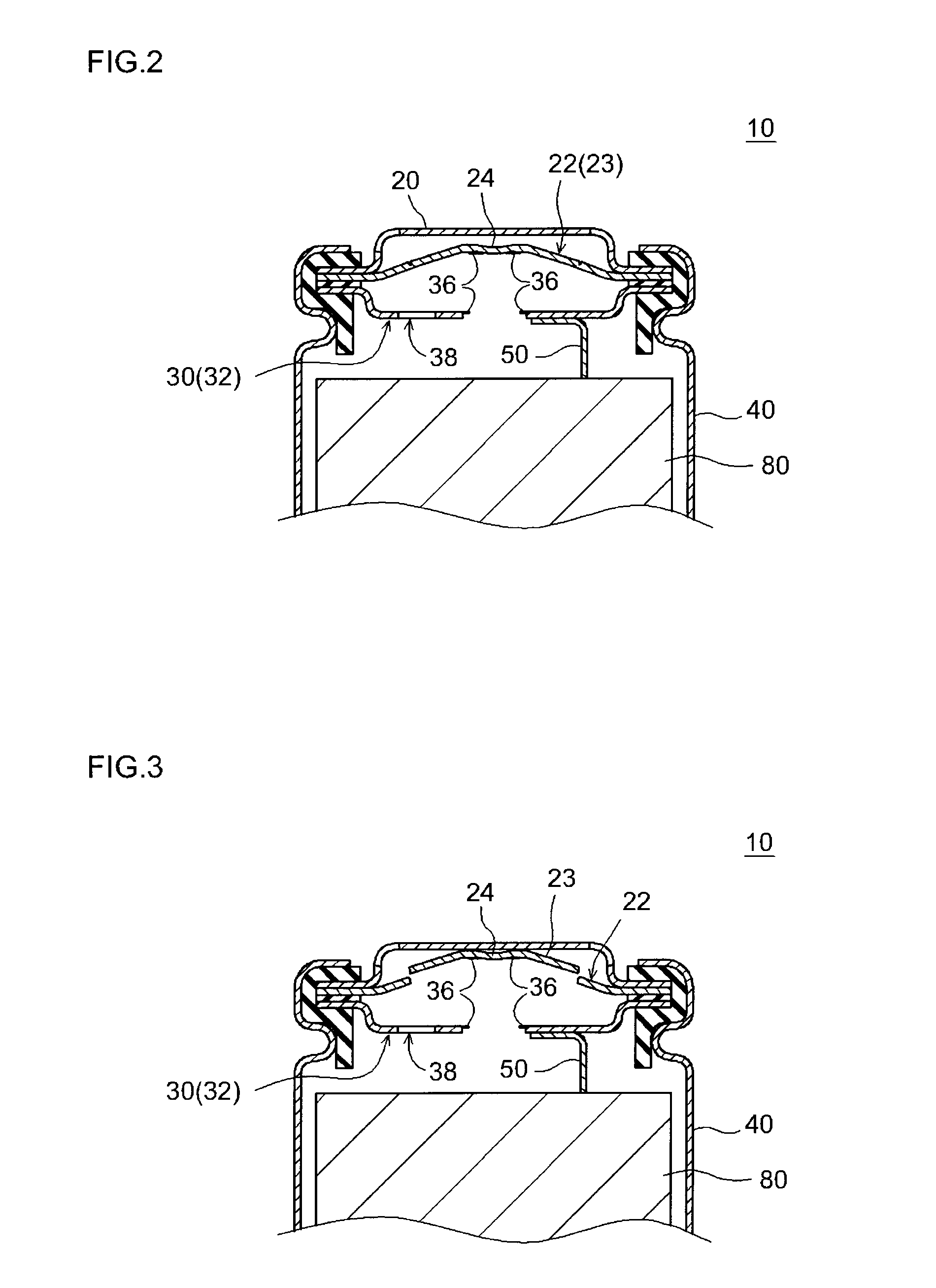

Sealed battery

ActiveUS20110206958A1Avoid environmentIncrease internal pressureVent arrangementsCell lids/coversInternal pressurePower flow

A sealed battery (10) provided by the present invention includes: a current cut-off valve (22); and a connecting member (30) having an engagement hole (34) formed in a location adjacent to the current cut-off valve. The current cut-off valve is conductively connected to the connecting member by joining linearly to a peripheral edge of the engagement hole and / or joining at a surface that is in contact with an inner wall of the engagement hole in a state in which part of the current cut-off valve is fitted into the engagement hole. When an internal pressure of a battery case (40) rises above a predetermined level, the current cut-off valve is deformed outward of the case by the internal pressure, the current cut-off valve is separated from the connecting member, and the electric connection between the connecting member and the current cut-off valve is broken.

Owner:TOYOTA JIDOSHA KK

Car power source apparatus

InactiveUS8063506B2Long lastingProbability of contacts fusing togetherElectric devicesElectric powerElectrical batteryEngineering

A power source apparatus of a car is provided with contactors (2) connected to an output-side of a battery (1); a pre-charge circuit (3) made up of a series connected pre-charge resistor (6) and a pre-charge relay (7), which is connected with a contactor (2) to supply auxiliary charge to a capacitor (21) connected to a car-side of the battery (1); and a control circuit (4) to control the contactors (2) and the pre-charge relay (7). The pre-charge resistor (6) is connected in parallel with a contactor (2), and the pre-charge relay (7) is connected in series with that contactor (2). The control circuit (4) switches the pre-charge relay (7) ON to pre-charge the car-side capacitor (21), and then switches the contactor (2) ON to connect the battery (1) to the car-side.

Owner:SANYO ELECTRIC CO LTD

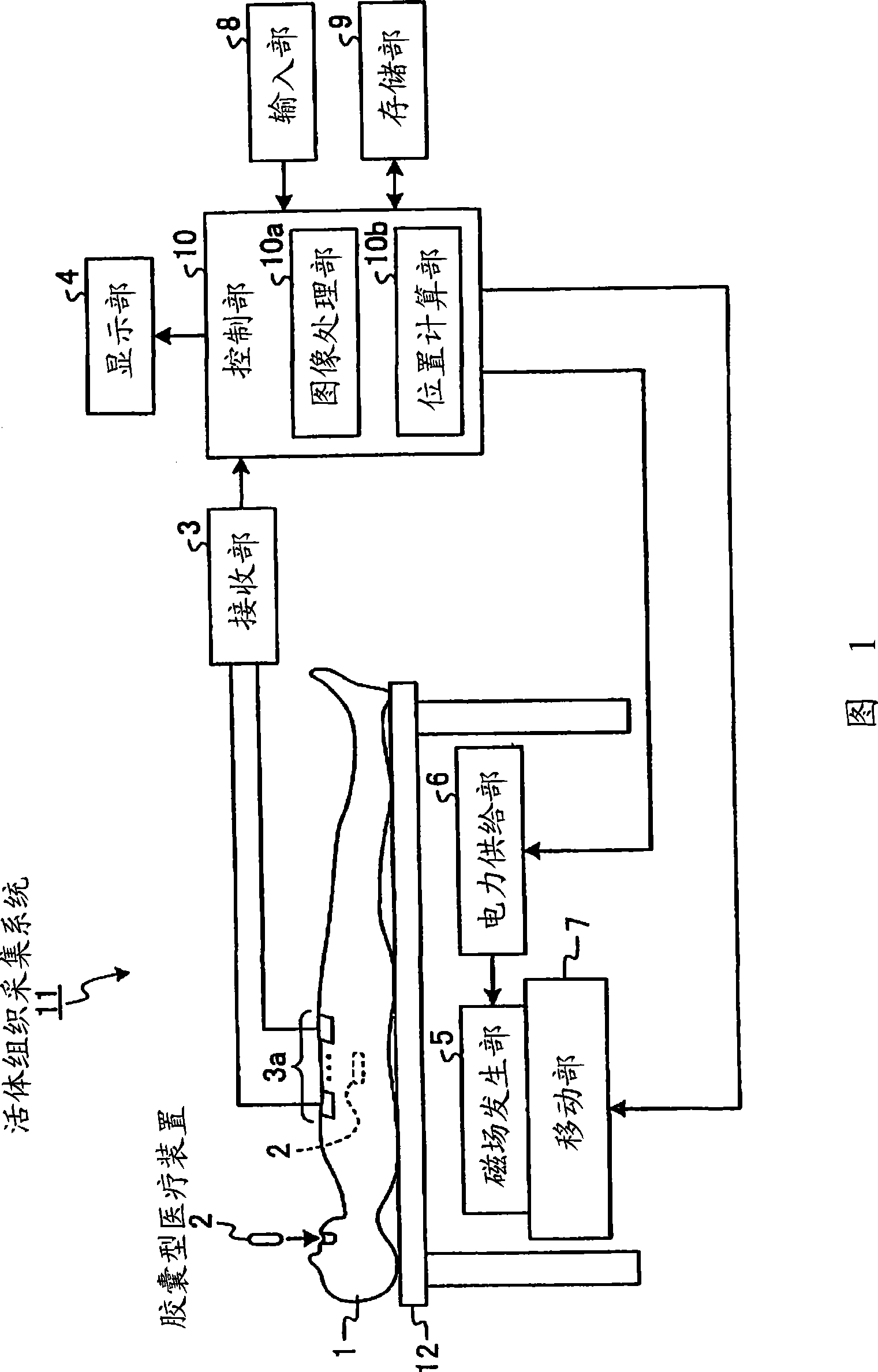

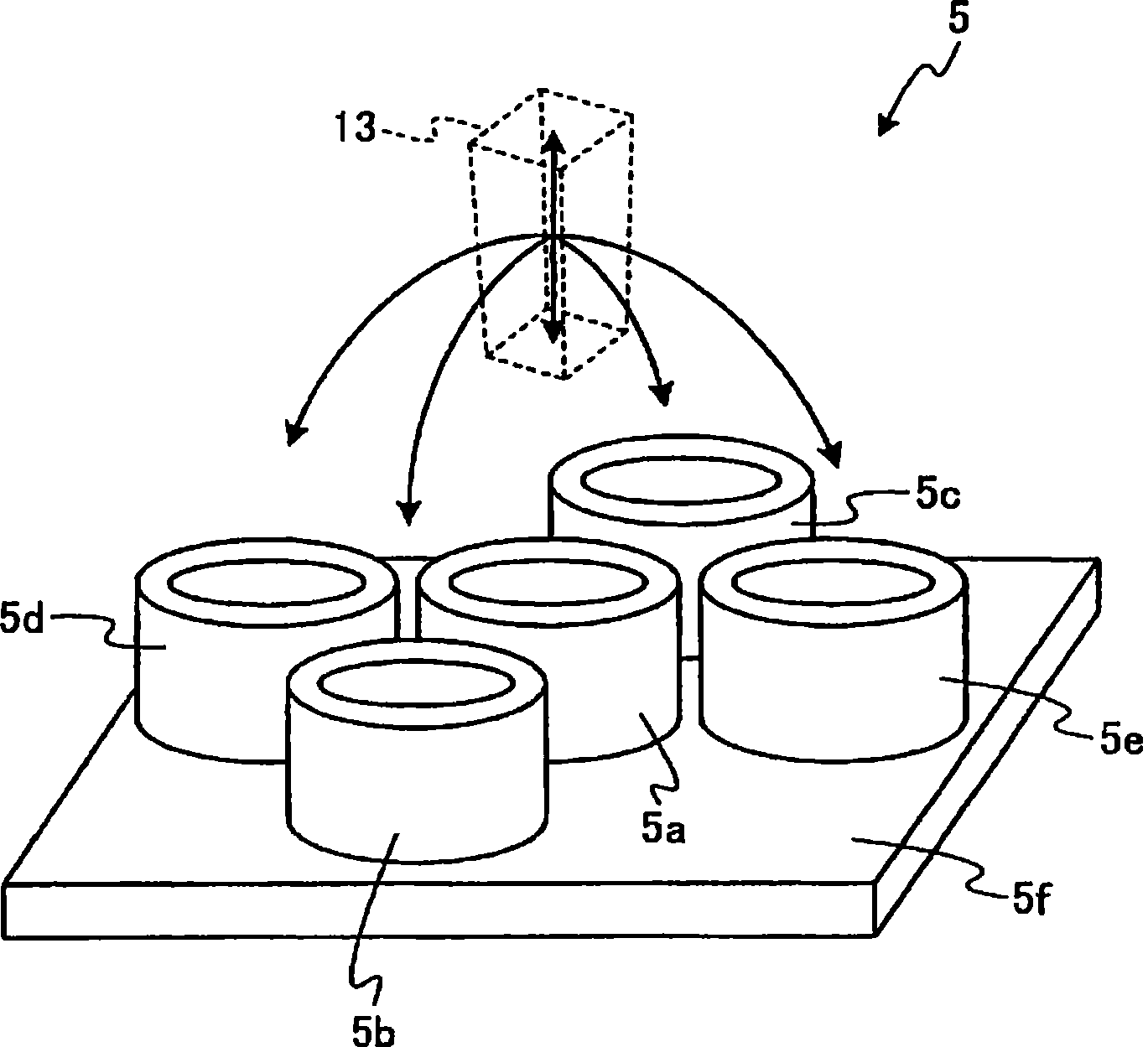

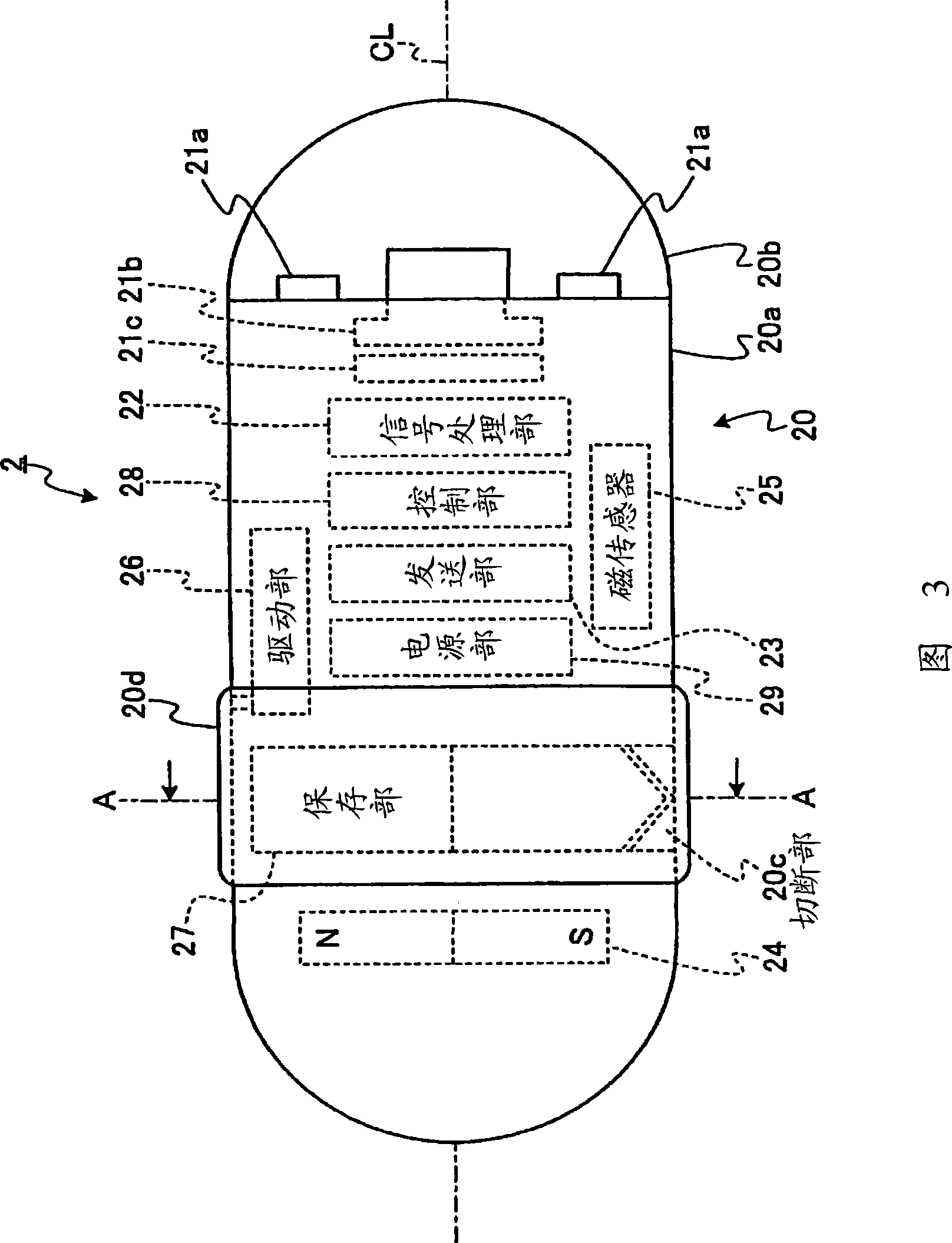

Capsule medical device and body-tissue obtaining method

InactiveCN101444425AMaintain rotational inertiaIncrease cutting forceEndoscopesVaccination/ovulation diagnosticsCapsule ShapeIn vivo

The present invention provides a capsule medical device and a body-tissue obtaining method, capable of collecting a mass of body tissue from the in-vivo region of a subject. The capsule medical device (2) includes a capsule-shaped casing (20) that can be introduced into an in-vivo region of a subject (1); and a rotation driving unit (24) that generates torque along a circumferential direction of the capsule-shaped casing (20). The capsule medical device (2) also includes a cutting-obtaining unit (20c) that rotates along the circumferential direction of the capsule-shaped casing (20) due to the torque to cut out and obtain a mass of body tissue from the in-vivo region of the subject (1).

Owner:OLYMPUS CORP

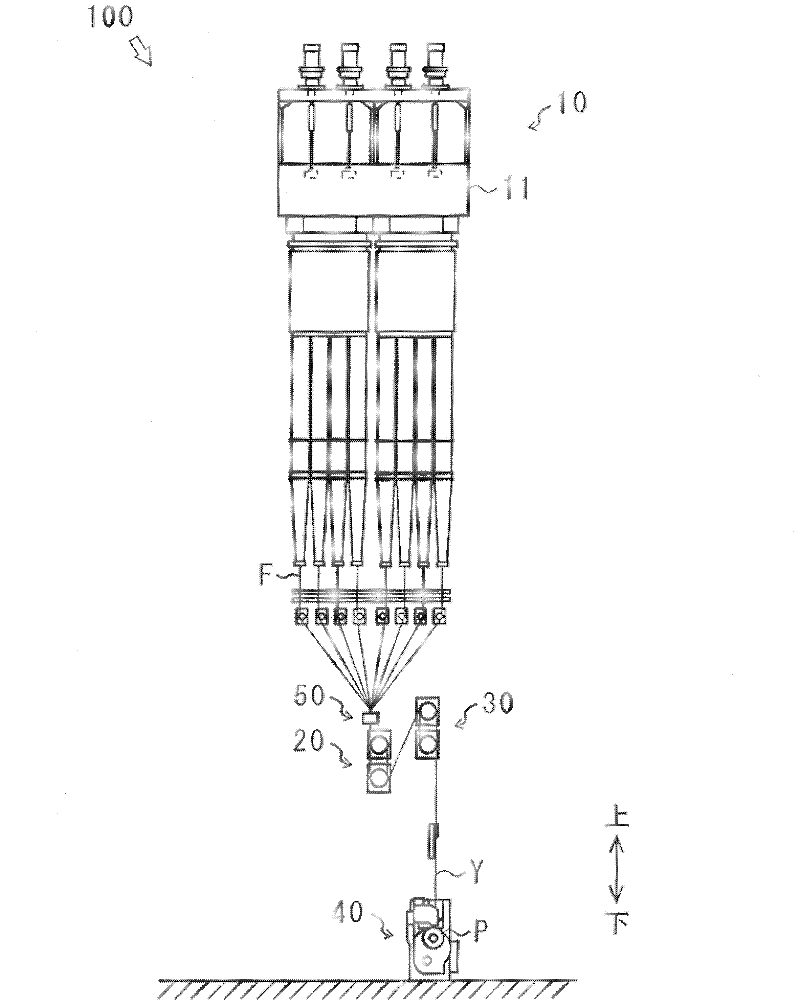

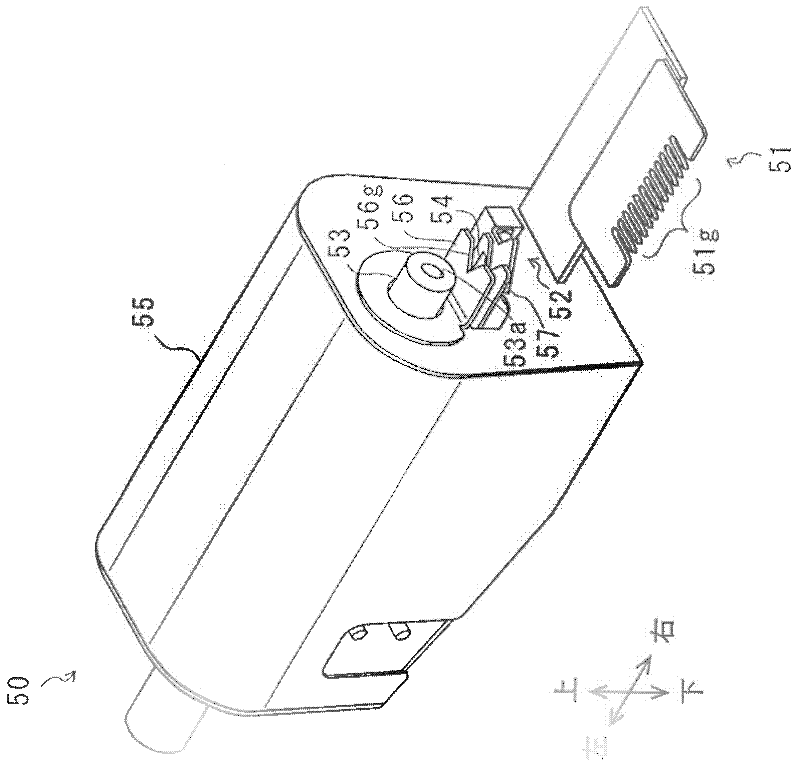

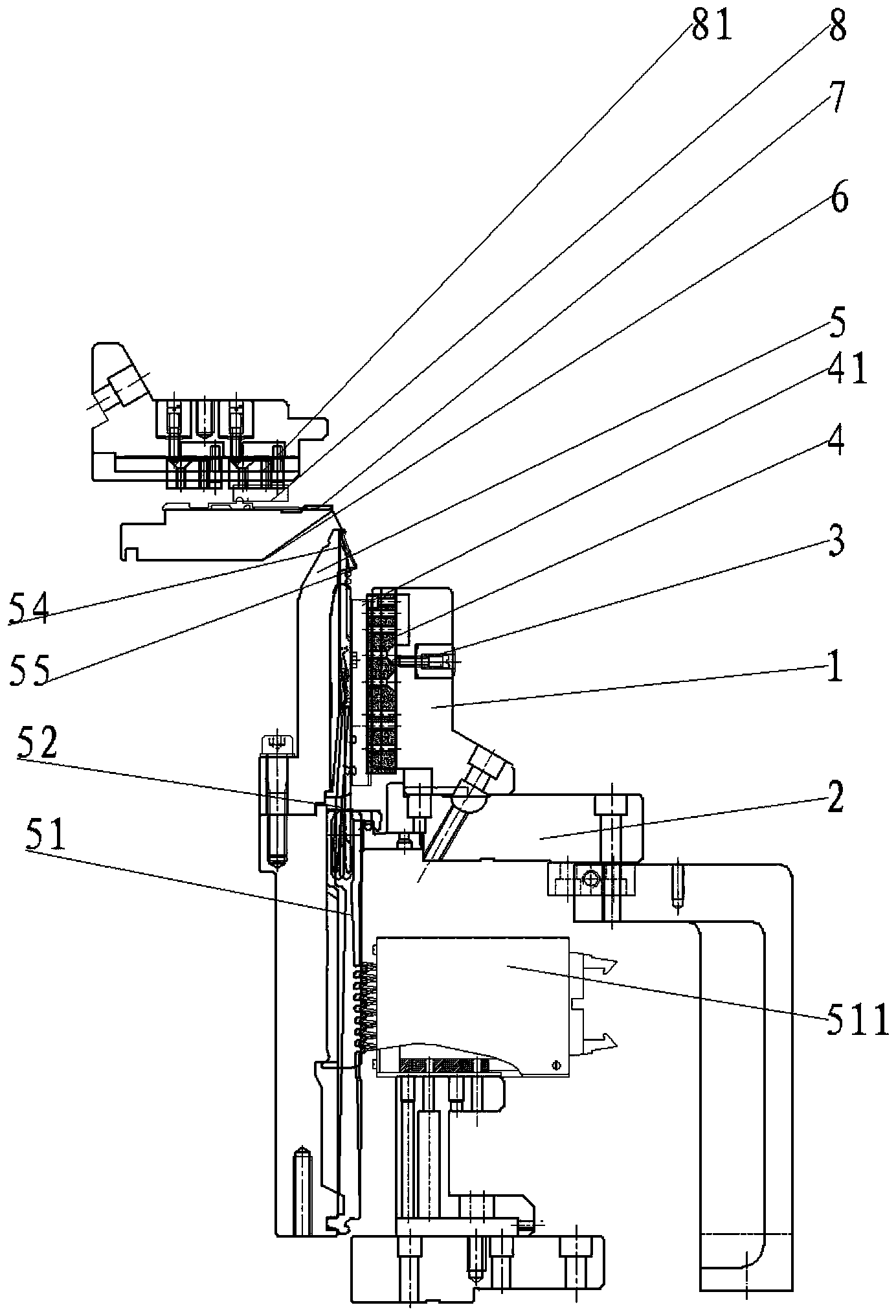

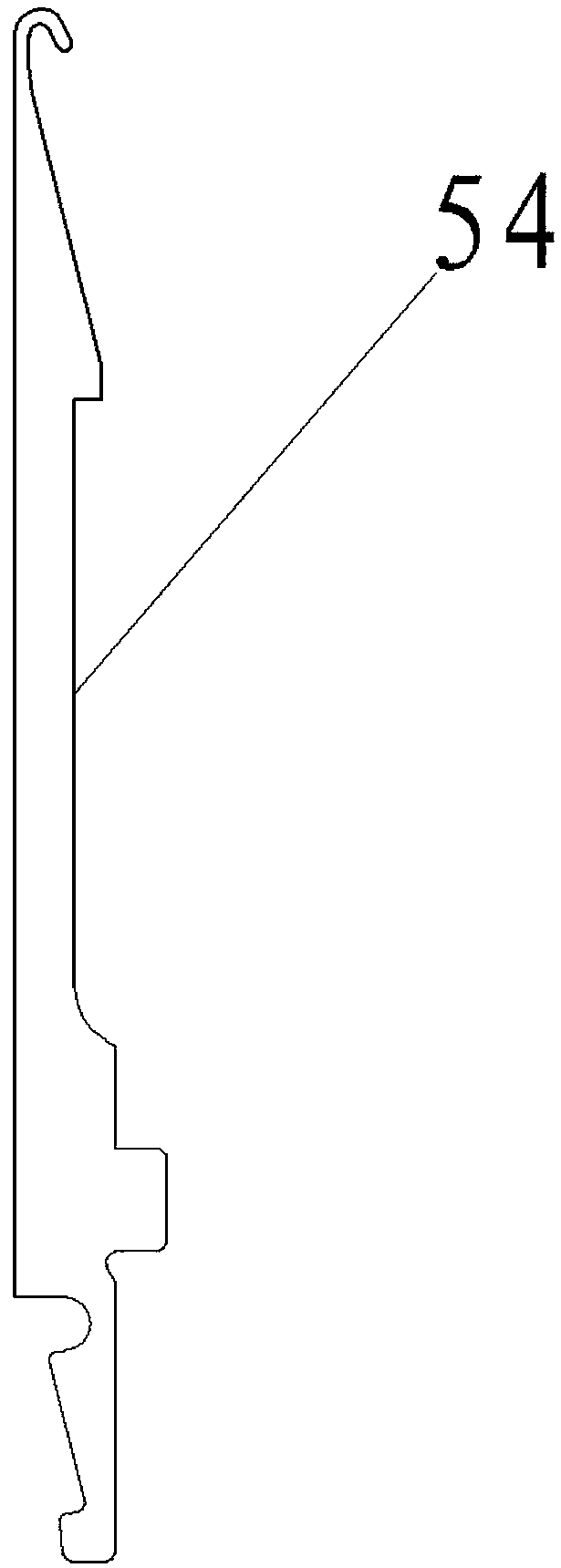

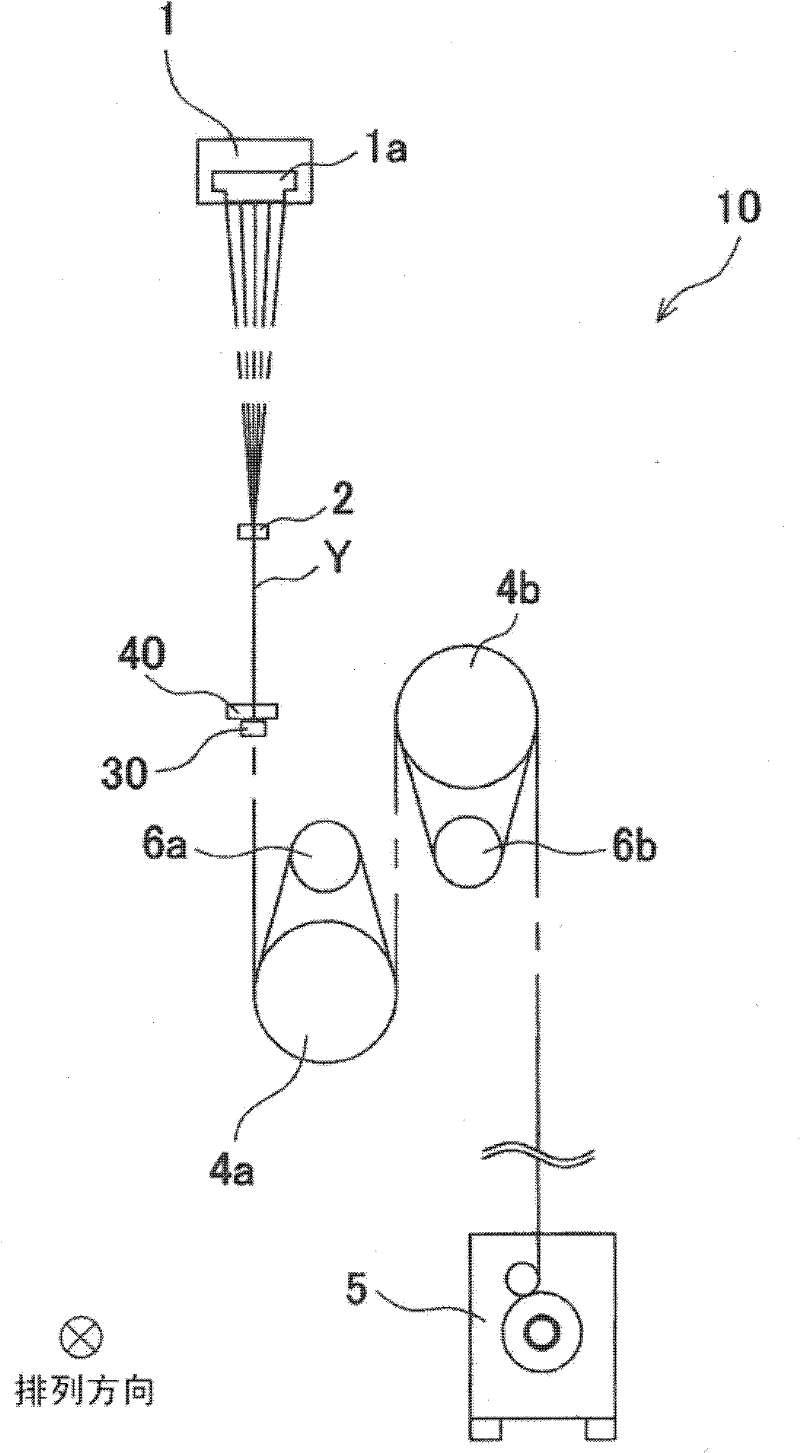

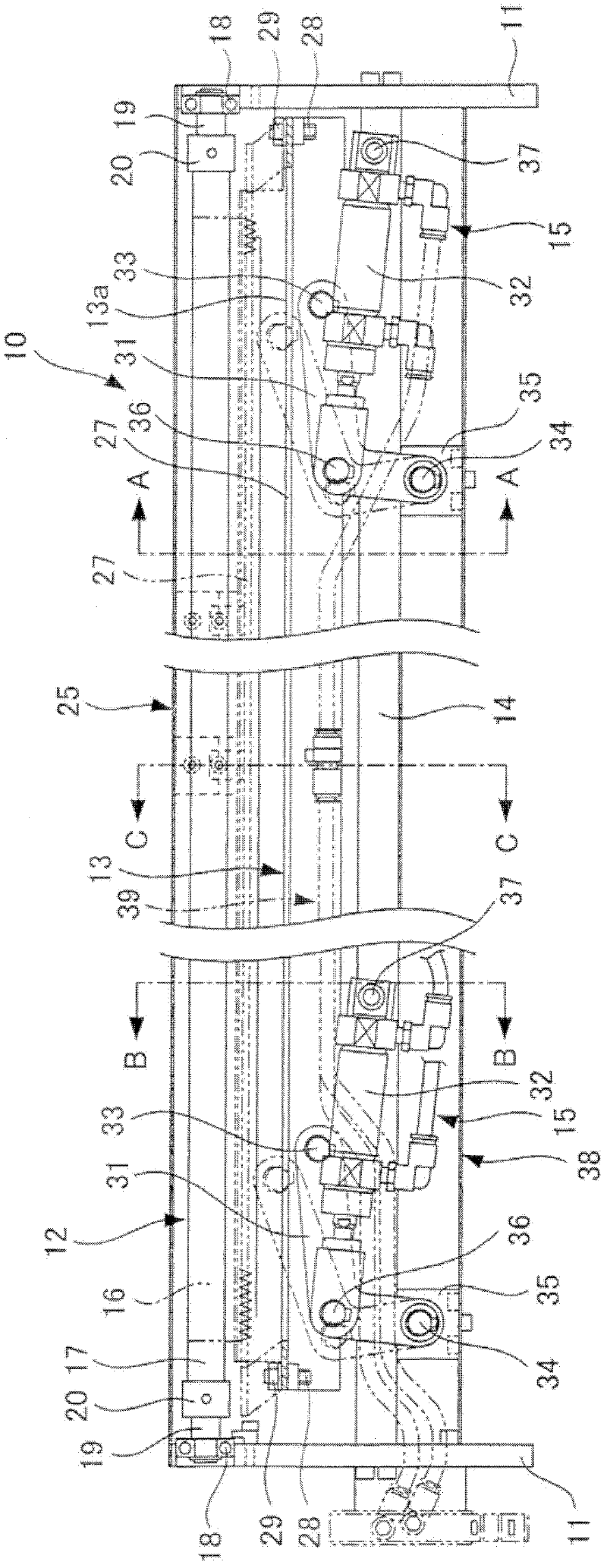

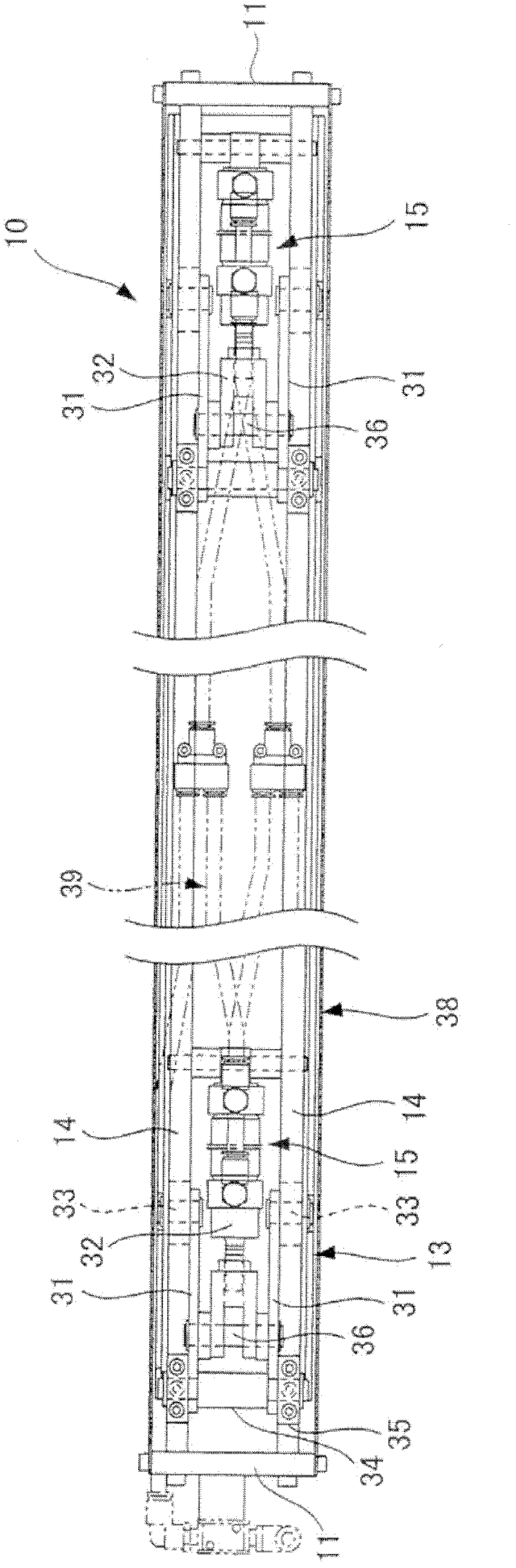

Yarn cutting apparatus

ActiveCN102560711AEasy to cutWon't relaxArtificial thread manufacturing machinesFilament manufactureYarnEngineering

A yarn cutting apparatus is provided that improves the workability of the yarn threading operation while securely cutting a plurality of yarns. A yarn cutting apparatus (50) is configured to cut a plurality of yarns (Y) and includes a yarn path regulating guide (51) configured to guide the plurality of yarns (Y), a yarn shift guide (52) disposed further upstream than the yarn path regulating guide (51) so as to shift the yarns (Y) fed onto the yarn path regulating guide (51) to one direction, an aspirator (53) disposed further upstream than the yarn shift guide (52) so as to suck the yarns Y shifted by the yarn shift guide, and a cutter (54) disposed between the yarn shift guide (52) and the aspirator (53) so as to cut the yarns Y sucked by the aspirator (53).

Owner:TMT MACHINERY INC

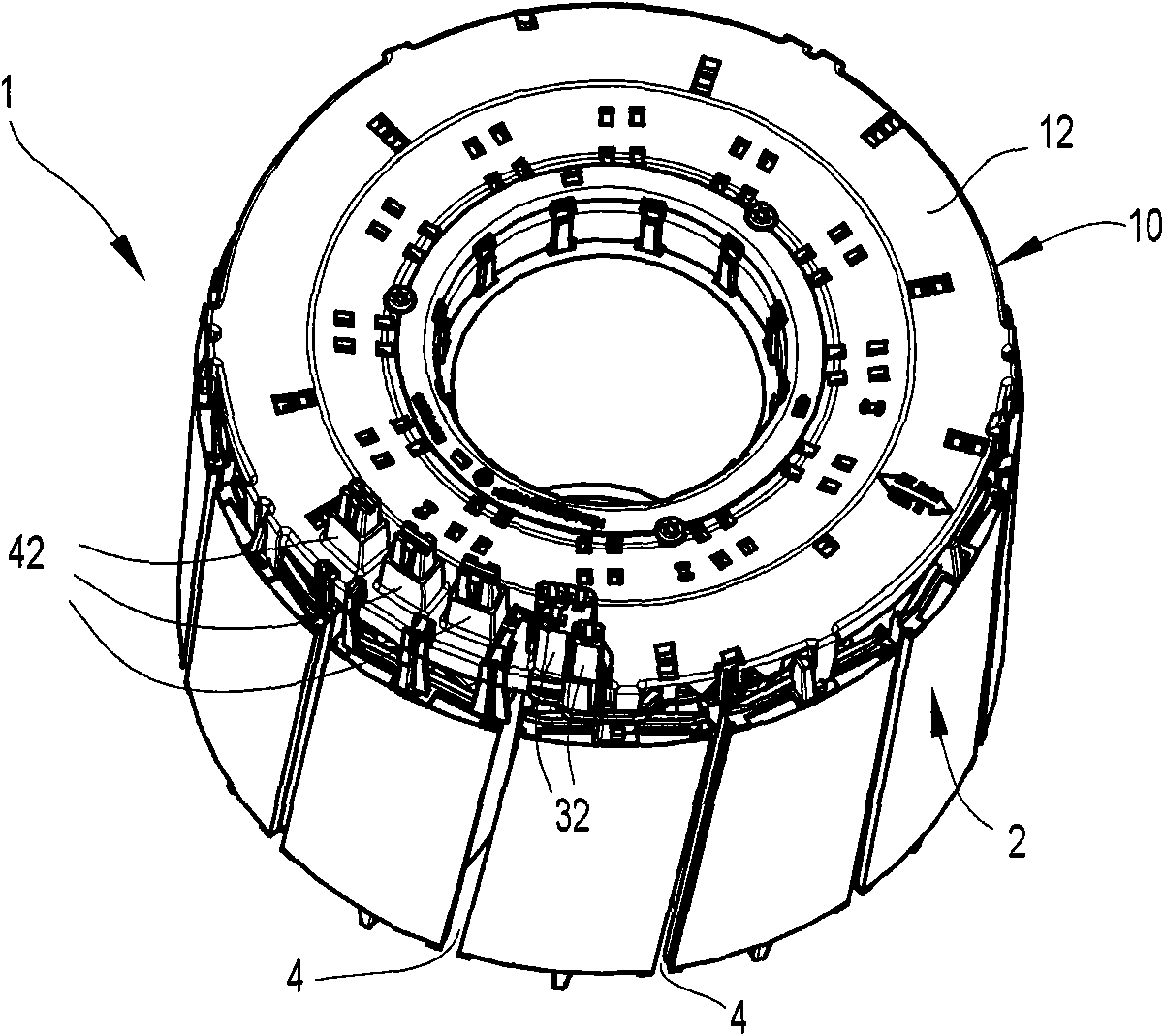

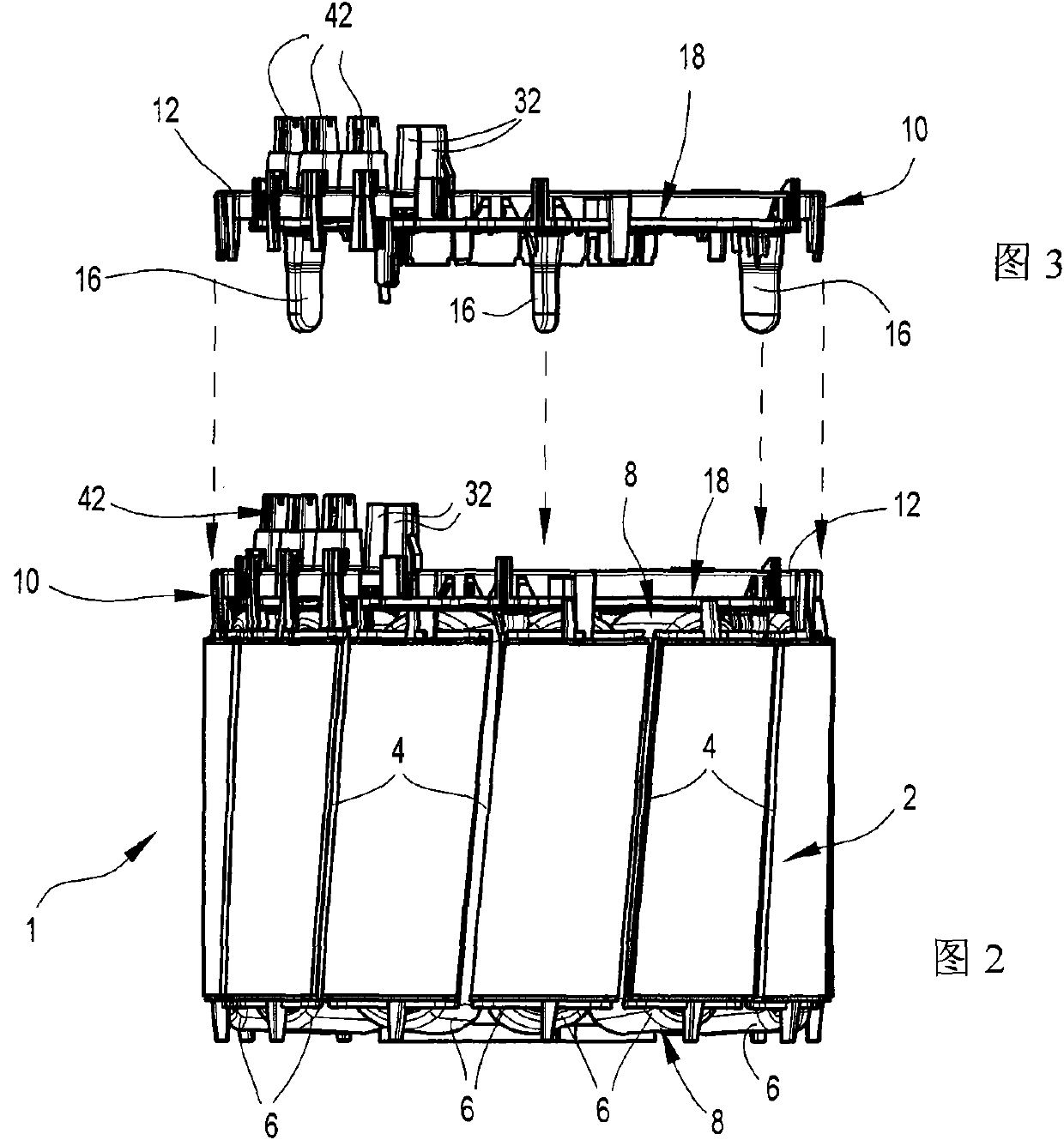

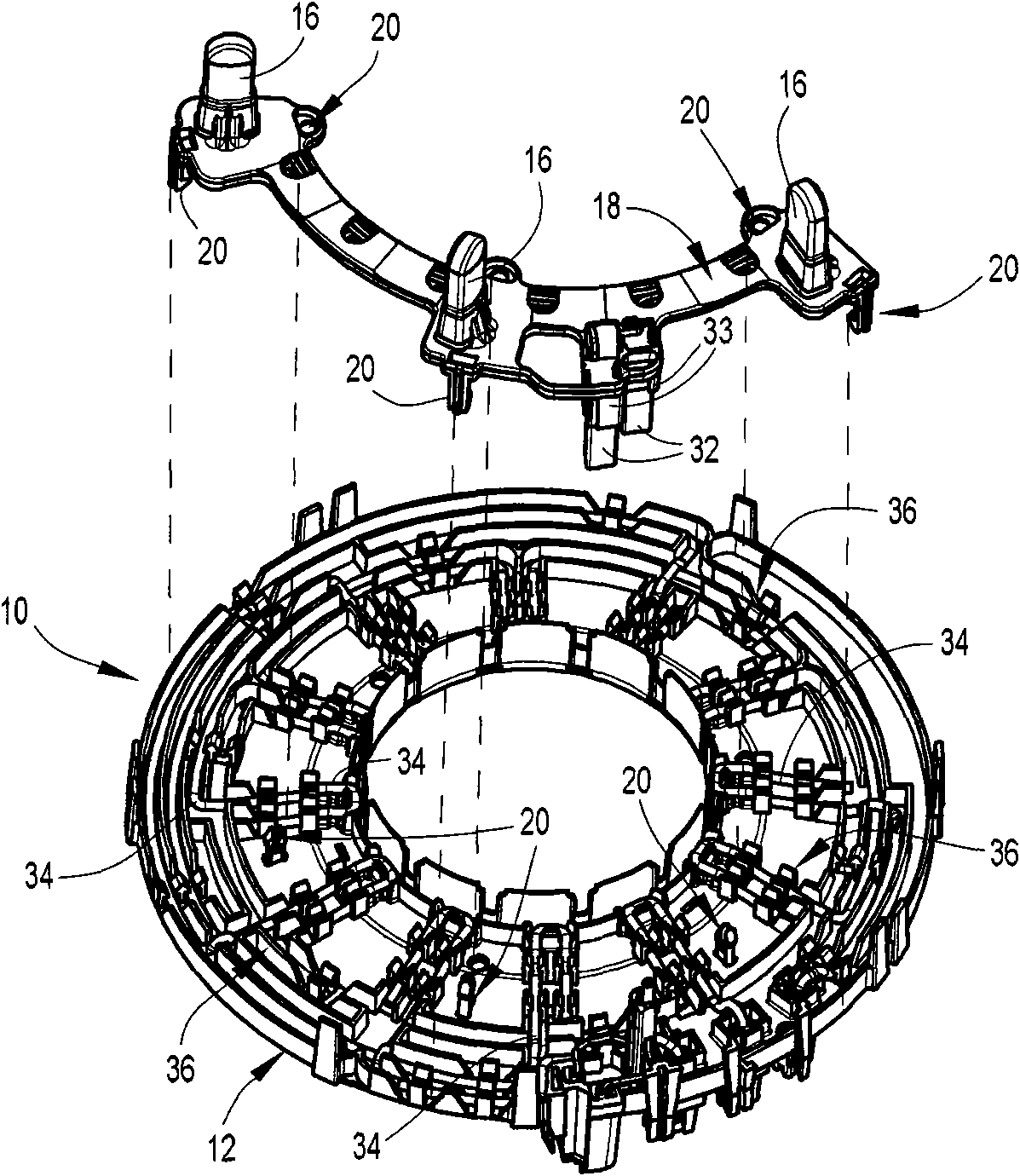

Stator assembly for an electric motor

ActiveCN102035308ASmall sticking forceFast heat conductionWindingsMagnetic circuit stationary partsElectric machineInterconnection

A stator arrangement for an electric motor. The stator arrangement including a laminated stator core with stator windings running through stator grooves and forming winding overhangs at each end face of the laminated stator core. The stator arrangement also includes an interconnection unit having a switching disk covering the winding overhangs on one end face of the stator. The switching disk further including at least one temperature monitor mounted thereon for monitoring the temperature of the stator windings. The temperature monitor being seated in a holding pocket that is resiliently connected to the switching disk in such a manner that, when positioned in one of the stator grooves, it is resiliently biased into engagement with a stator winding.

Owner:EBM PAPST MULFINGEN GMBH & CO KG

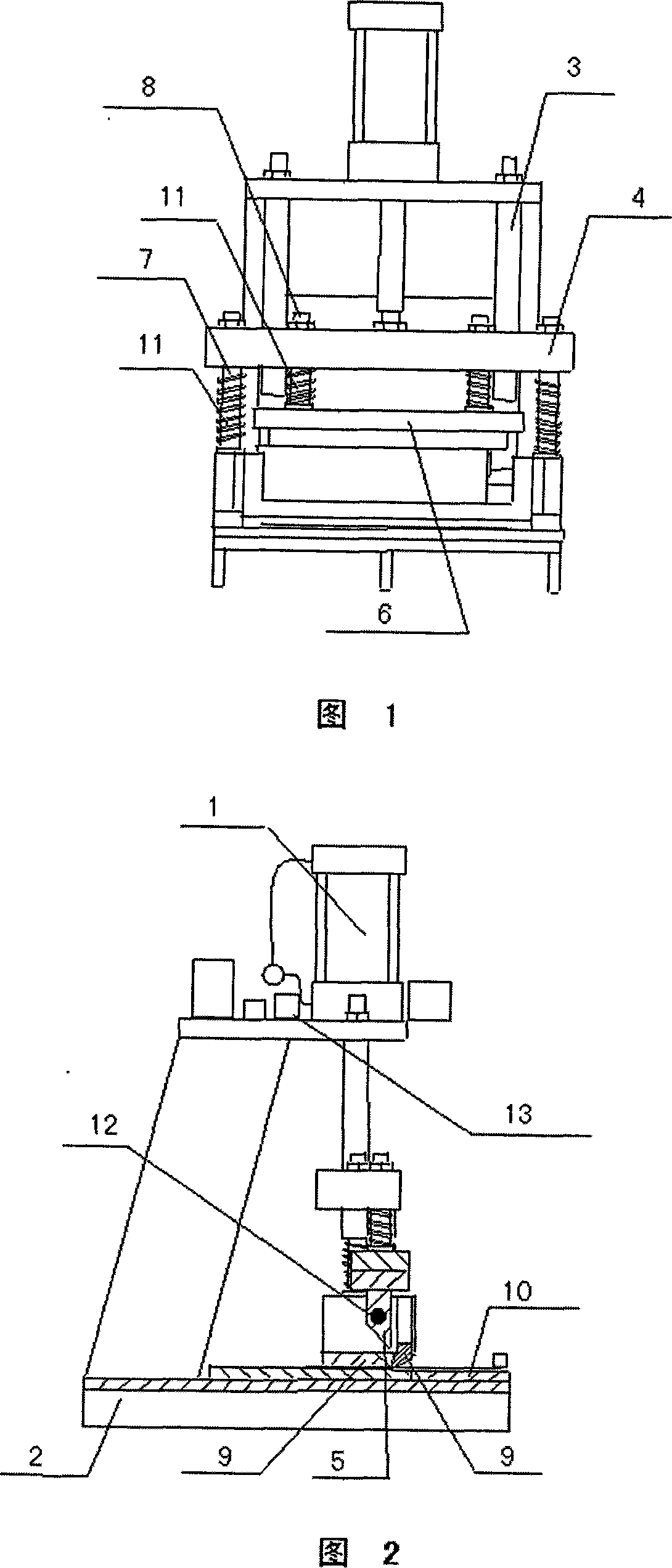

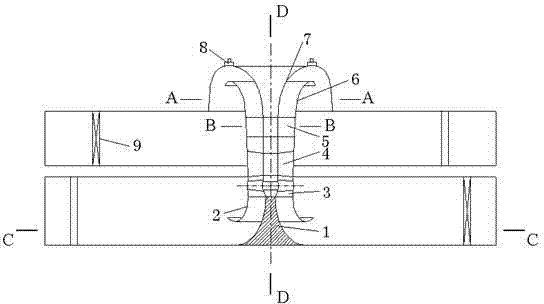

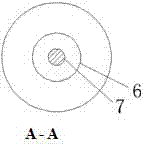

A sealing technology and device for separation film bag

The invention discloses the edge enveloping art of a septum bag and the device thereof. The device comprises a gas cylinder (1) and a base (2). A guide rod retaining plate (4), an electric knife (5), an electric knife retaining plate (6), a pressing plate guide rod (7), an electric knife guide rod (8), two pressing plates (9) and a backing plate (10) are arranged between the gas cylinder (1) and the base (2). The lower end of a cylinder pushing rod is connected with the guide rod retaining plate (4). A structure which is as simple as possible is adopted for the invention to achieve that the cutting and the combining of two layers of septum can be finished simultaneously. The edge enveloping width of the septum bag is small, and the stickability of the bag mouth is tight without breach.

Owner:BAILE ELECTROTHERMIC ELECTRIC APPLIANCE JIANGSU

Battery, vehicle and apparatus mounting battery

ActiveCN101983447AReliable cut offNo void spaceSmall-sized cells cases/jacketsSecondary cellsInternal pressureRivet

Disclosed is a battery provided with a current interruption mechanism (20). The current interruption mechanism (20) is provided with thick portions (48, 49) and a fragile portion (45) in an external terminal (21) connecting an electrode terminal with a terminal rivet (31) to be connected with a power generation element (16), wherein the thick portions (48, 49) are connected with each other only through the fragile portion (45). Furthermore, the current interruption mechanism (20) comprises: the terminal rivet (31) which penetrates a sealing plate (12), has a portion thereof on the outside of a battery case (11) arranged to be in close contact with the thick portion (48) of the external terminal (21) and cover the same, and is provided with a through hole (32), which is a part of the battery case (11); and a sealing cap (25) which covers the outlet of the through hole (32) on the outside of the battery case (11) and is bonded to the external terminal (21) over the entire circumference of the through hole (32) or bonded across the external terminal (21) and the terminal rivet (31). When the internal pressure of the battery case (11) rises, at least a portion of the sealing cap (25) moves to recede from the battery case (11), so that a portion of the external terminal (21) deforms to thereby destroy the fragile portion (45).

Owner:TOYOTA JIDOSHA KK

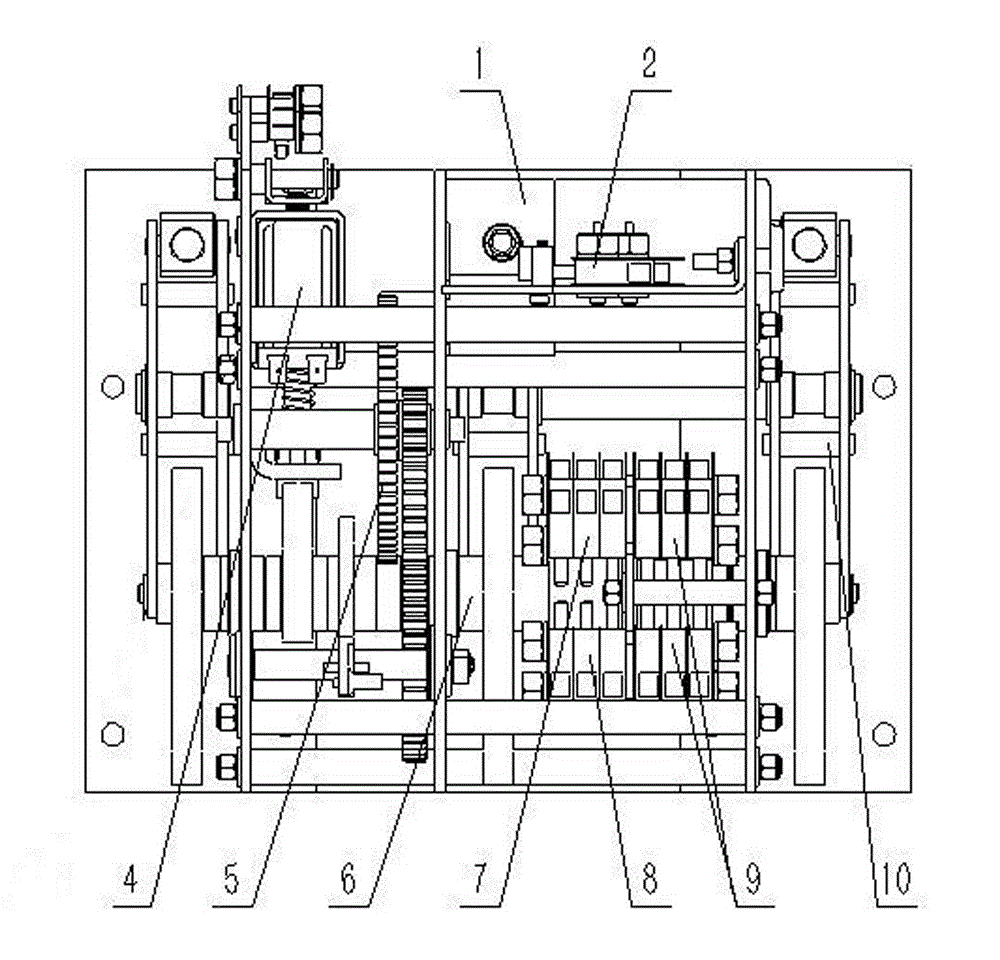

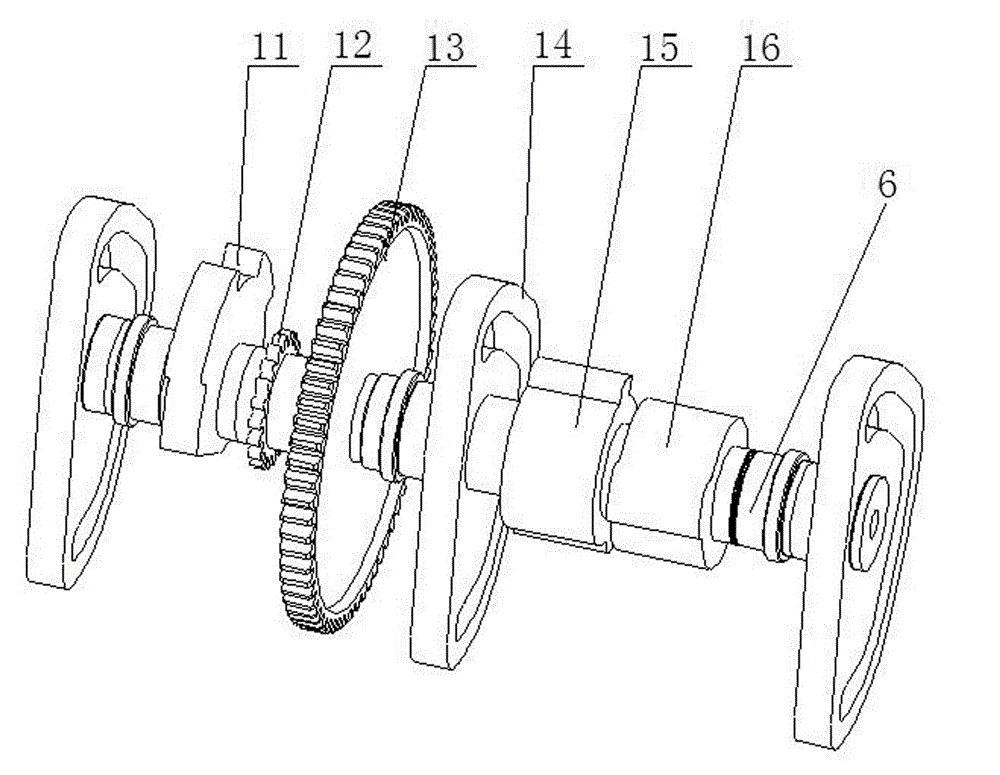

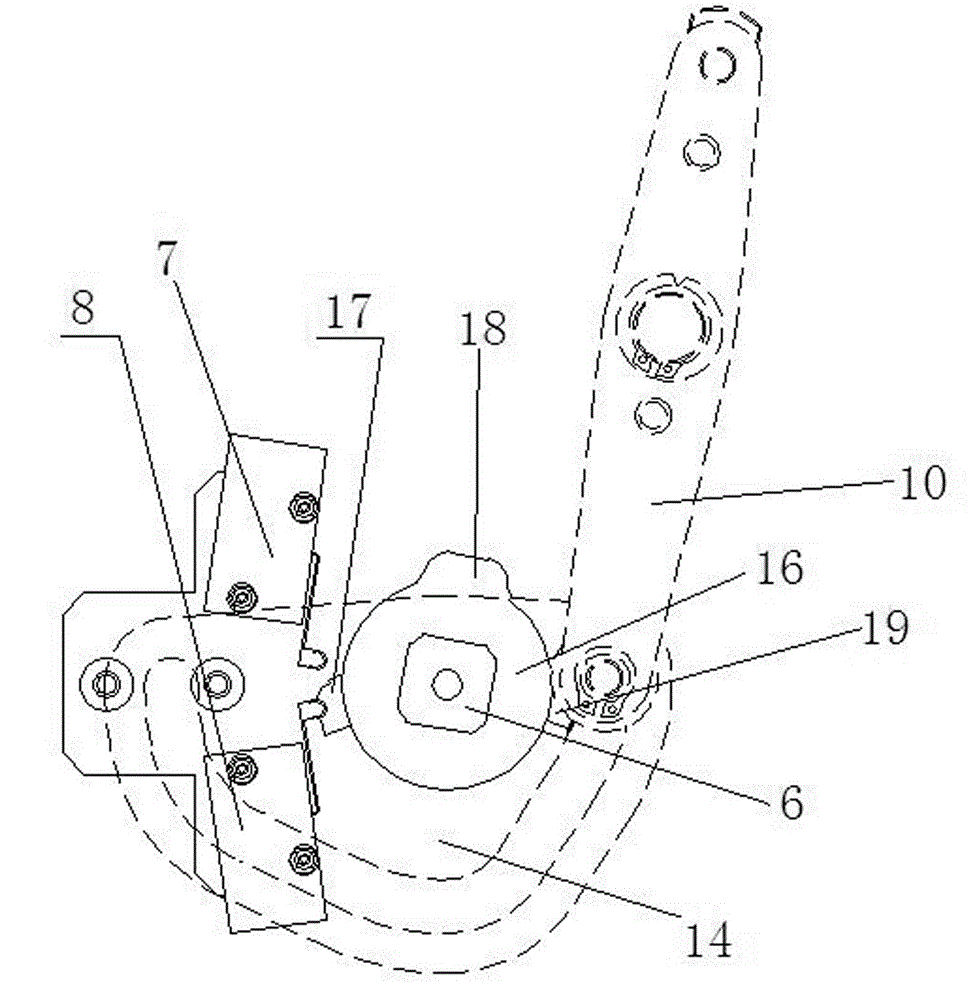

Three-position operating mechanism and transmission shaft thereof

ActiveCN104485250AReliable power offReliable cut offContact driving mechanismsAir-break switch detailsCamEngineering

The invention relates to a three-position operating mechanism and a transmission shaft thereof. The three-position operating mechanism comprises a motor and a transmission shaft in transmission connection with the motor, wherein the transmission shaft comprises a shaft body with an axis extending along a front-rear direction, a cutoff cam is fixedly arranged on the shaft body, the cutoff cam is provided with a grounding position bulge, an opening position bulge and a closing position bulge which are arranged at intervals around the circumferential direction, and the opening position bulge is arranged in a manner of being staggered relative to the grounding position bulge and the closing position bulge in the front-rear direction. The three-position operating mechanism further comprises a grounding travel switch, an opening travel switch and a closing travel switch which are respectively used for being in push fit with the grounding position bulge, the opening position bulge and the closing position bulge to respectively cut off the motor when the transmission shaft rotates to a grounding position, an opening position and a closing position. The invention provides the three-position operating mechanism which can cut off the motor when the transmission shaft rotates in place and the transmission shaft used in the three-position operating mechanism.

Owner:PINGGAO GRP +2

Non-initiating unlocking device and locking and unlocking method thereof

ActiveCN109229431AImprove utilization efficiencyImprove reliabilityCosmonautic vehiclesCosmonautic power supply systemsSpace environmentEngineering

The invention provides a non-initiating unlocking device and a locking and unlocking method thereof, which belongs to the field of unlocking devices. The device comprising a fastening cord, A hot knife assembly and at least two locking release members, the lock release member is used for fixing on the first member and the lock release member is used for fixing on the first member, the fastening cord is for providing a tightening force to the lock release member such that the lock release member locks the second member in a first state, the hot knife assembly comprises a hot knife and a hot knife mounting part, The hot knife mounting part is made of heat insulating material, the hot knife is arranged in the hot knife mounting part, the fastening rope is in close contact with the hot knife,and the hot knife is an electric heating element for generating heat to fuse the fastening rope, so that the locking releasing part returns to the second state and releases the second part. The invention avoids the carbonaceous fragments caused by the radial thrust, and the hot knife and the hot knife mounting part are structured under the space environment, and the performance is stable and the reliability is high.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

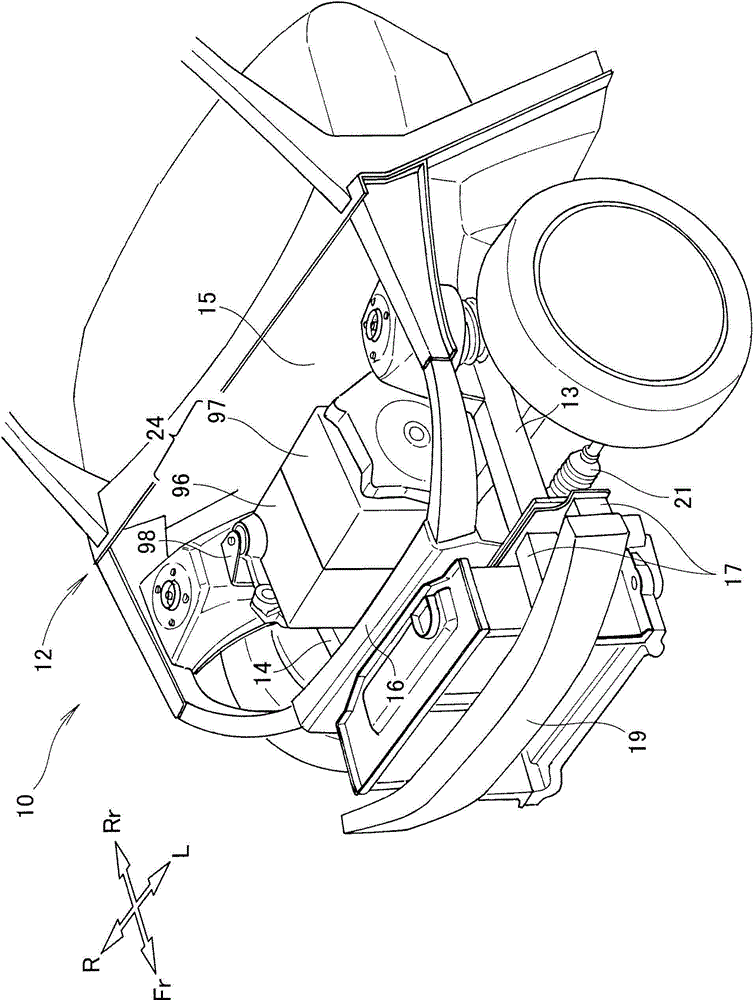

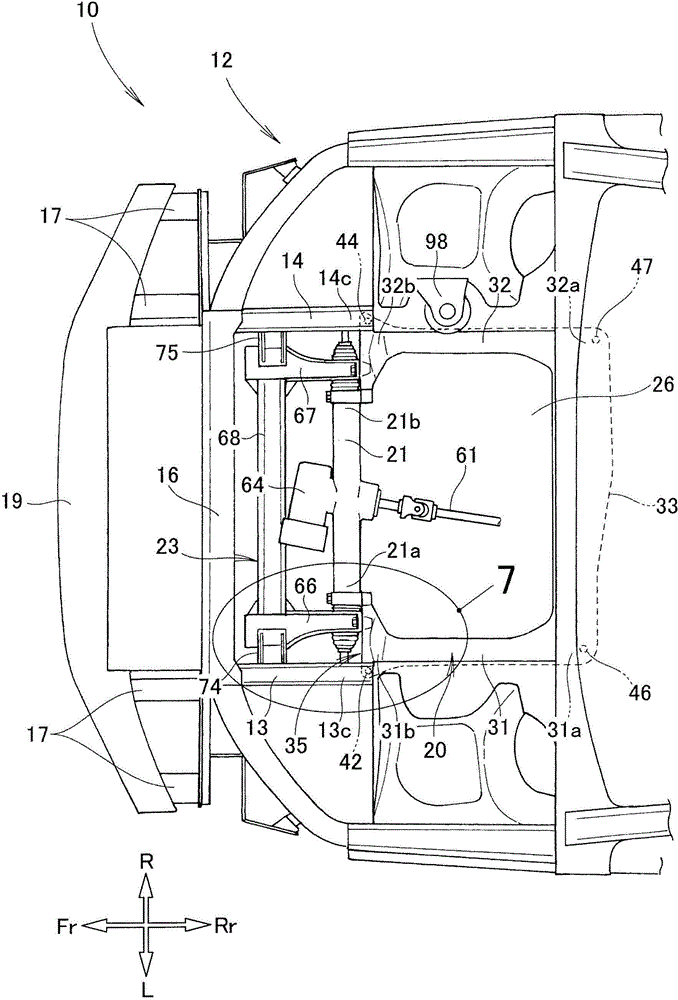

Vehicle front structure

InactiveCN104029734AImprove rigidityAchieve lightweightMechanical steering gearsUnderstructuresVehicle frameEngineering

A vehicle front structure includes left and right side frames and a sub-frame disposed below the left and right side frames. The sub-frame includes a cross member, which connects rear end portions of left and right side members, and a support unit, which supports a steering gear box at front end portions of the left and right side members. The steering gear box is supported by the support unit so as to be located in a vehicle-front-side region of the power plant. The support unit is capable of being broken by an impact load so that the steering gear box is dropped when the impact load is applied.

Owner:HONDA MOTOR CO LTD

Novel cut pile jacquard machine

The invention relates to the field of circular knitting machines, and in particular relates to a novel cut pile jacquard machine which comprises a saddle, a saddle foundation ring arranged at the bottom end of the saddle, a graduator mounted on the saddle, a sliding block arranged on the outer side of the saddle, a lower triangle arranged on the outer side of the sliding block, a needle barrel arranged on the outer side of the saddle foundation ring, a needle dial arranged above the needle barrel, an upper needle mounted on the needle dial, an upper triangle arranged above the upper needle, an upper triangle seat arranged on the upper triangle, a pattern bit arranged on the inner side of the needle barrel, a middle needle arranged at the upper end of the pattern bit, and an electronic needle selector arranged on one side of the pattern bit. The novel cut pile jacquard machine is characterized in that bearded needles and a cutter needle which are matched with the lower triangle are arranged at the upper end of the middle needle; the two bearded needles are adopted; the cutter needle is positioned in the middle of the two bearded needles; the needle selector is additionally arranged at the pile cutting triangle part of the low triangle. The novel cut pile jacquard machine is reliable in cutting without the assistance of a pile pressing wheel, incision is smooth and few soft flocks exist. The surface effect of the produced cut pile can reach a high level. In addition, the novel cut pile jacquard machine is simple in structure.

Owner:QUANZHOU HENGYI MACHINE

Cutting device for agricultural machines

An agricultural cutting device has knife bar sections with section knife blades. A drive with phase offset drives the knife bar sections at least temporarily in opposite directions. The section knife blades interact scissor-like with counter knives. The knife bar sections have adjacently positioned bar ends. When the knife bar sections move, a gap of varying size is formed between the bar ends. A mowing finger is arranged at the gap. A stationary knife blade with first cutting edges is arranged at the mowing finger. The first cutting edges are arranged adjacent to the mowing finger and extend at a slant relative to a forward travel direction of the cutting device so that the cutting edges have a V-shaped arrangement broadening in travel direction. The knife bar sections have an outer knife blade attached to the bar ends whose cutting edges extend parallel to the travel direction.

Owner:CARL GERINGHOFF GMBH & CO KG

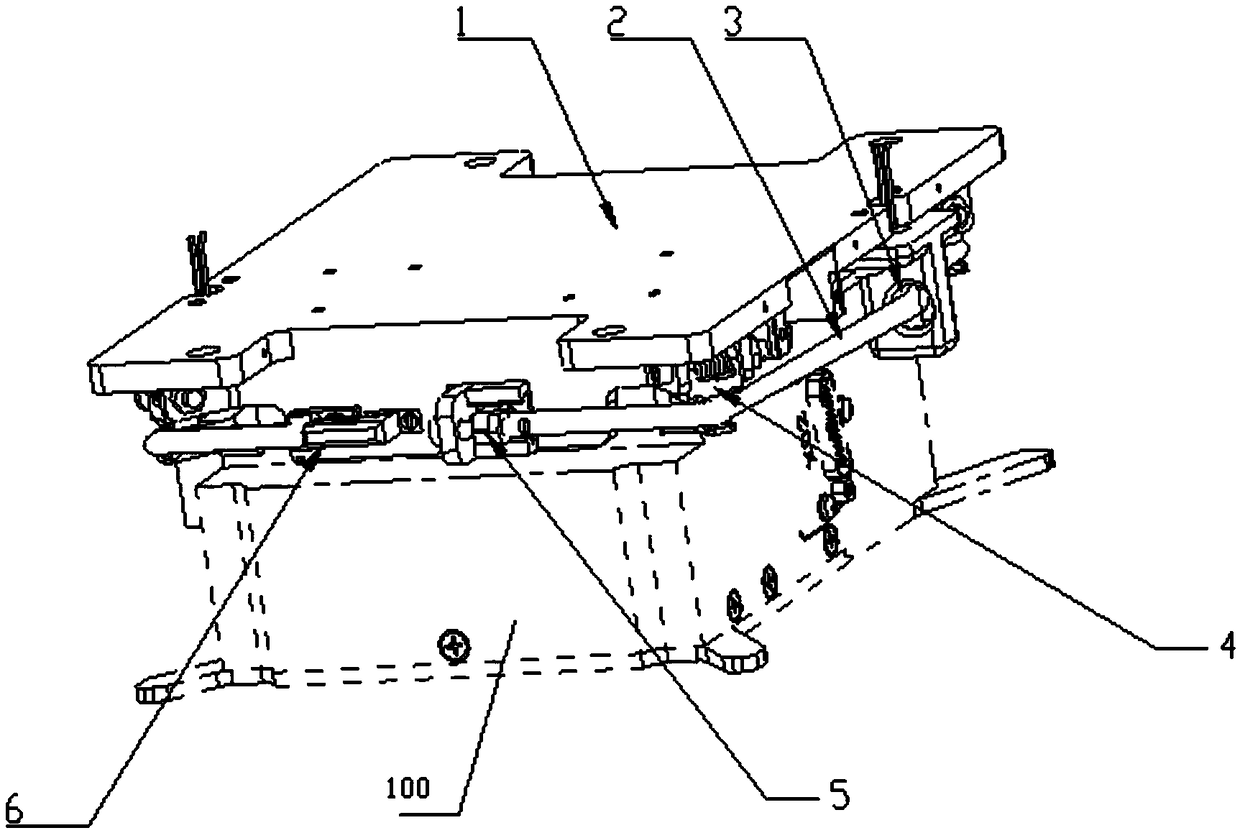

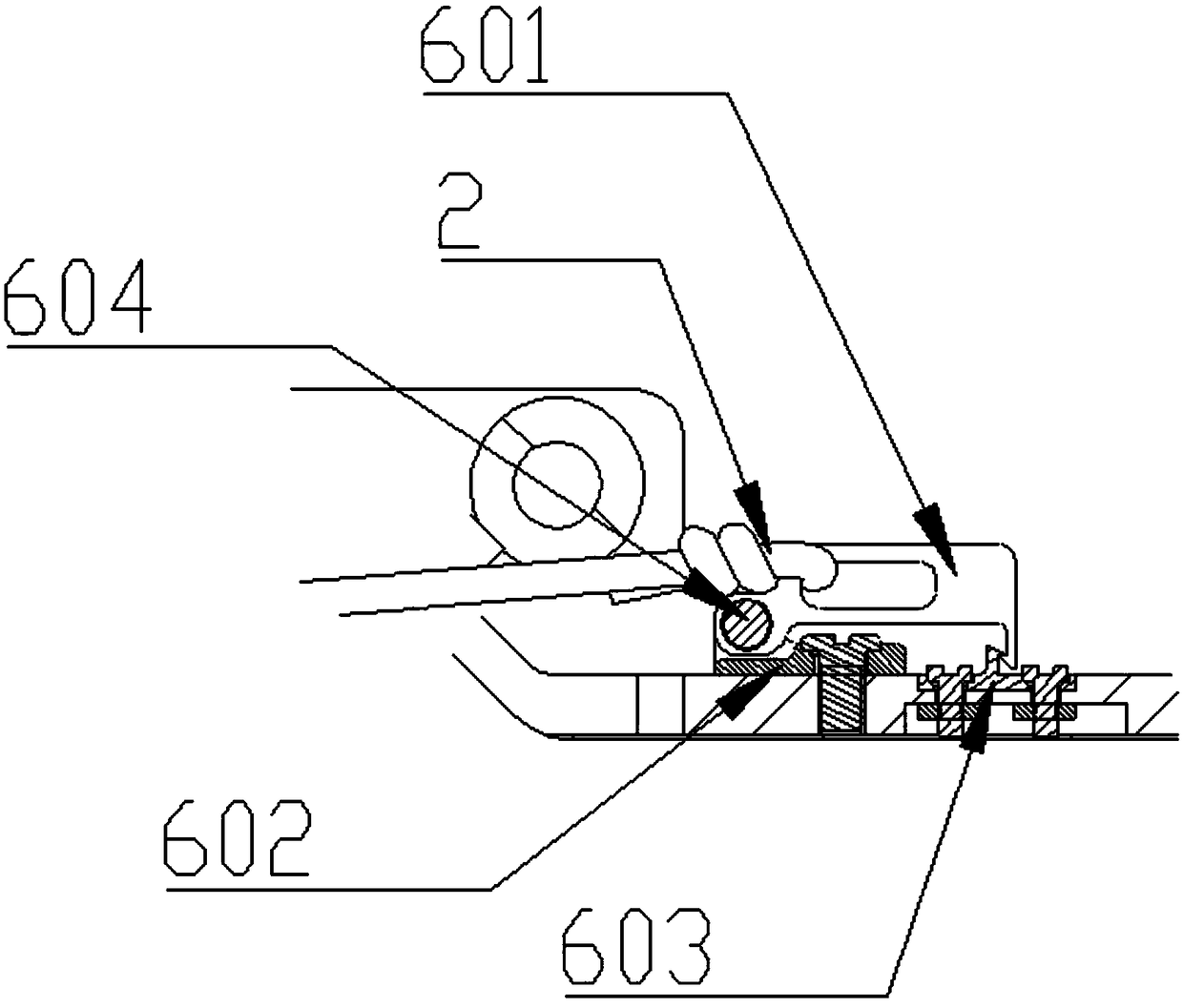

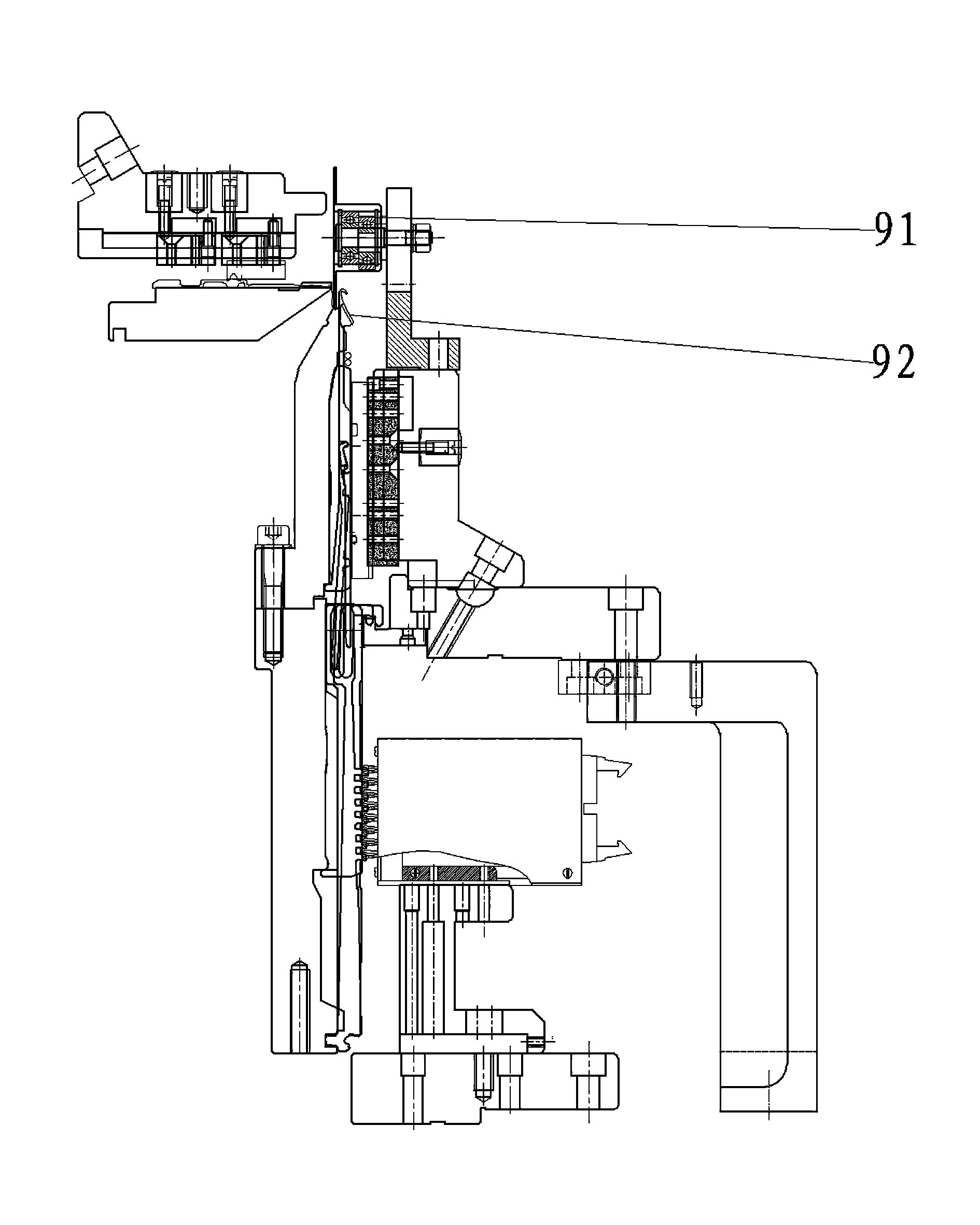

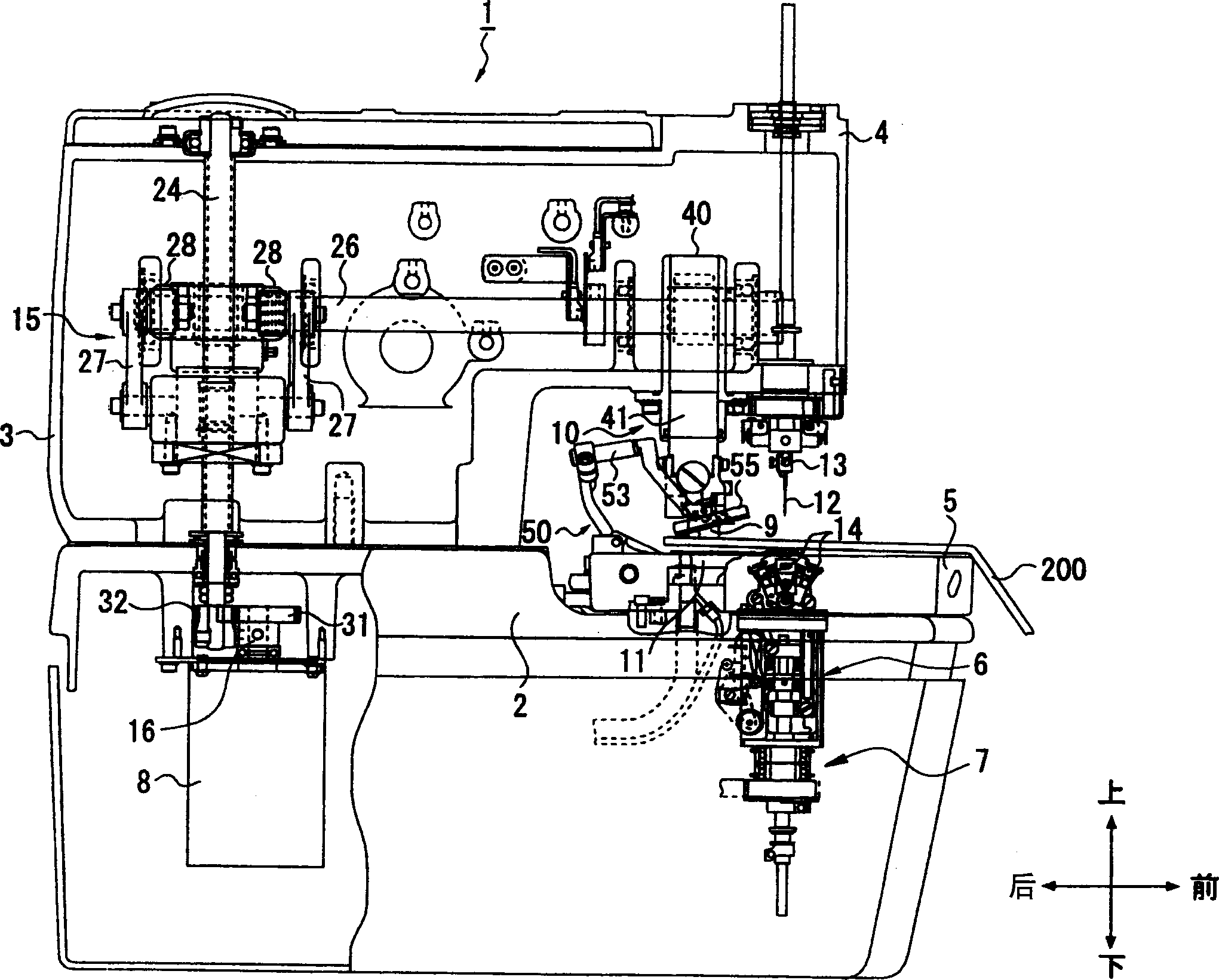

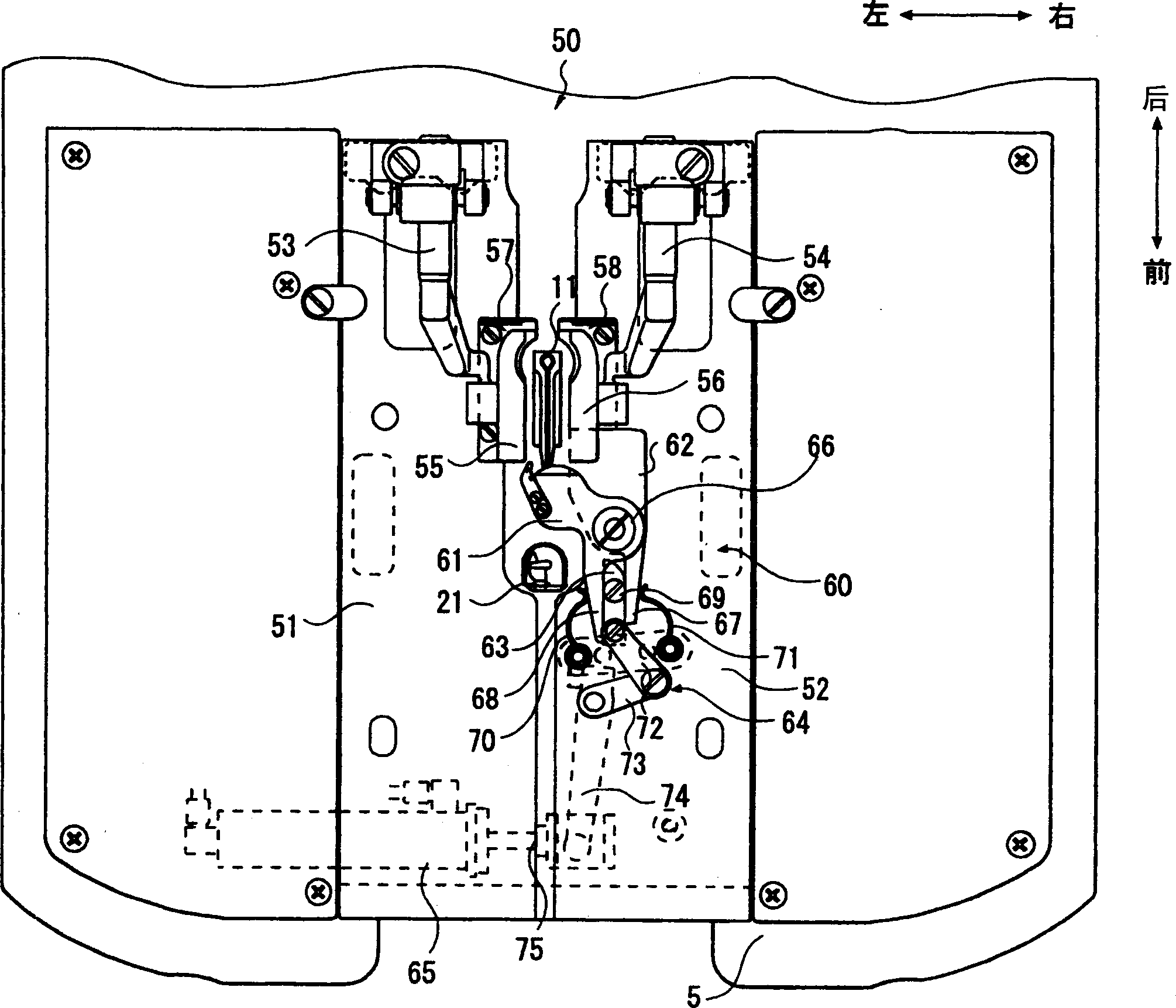

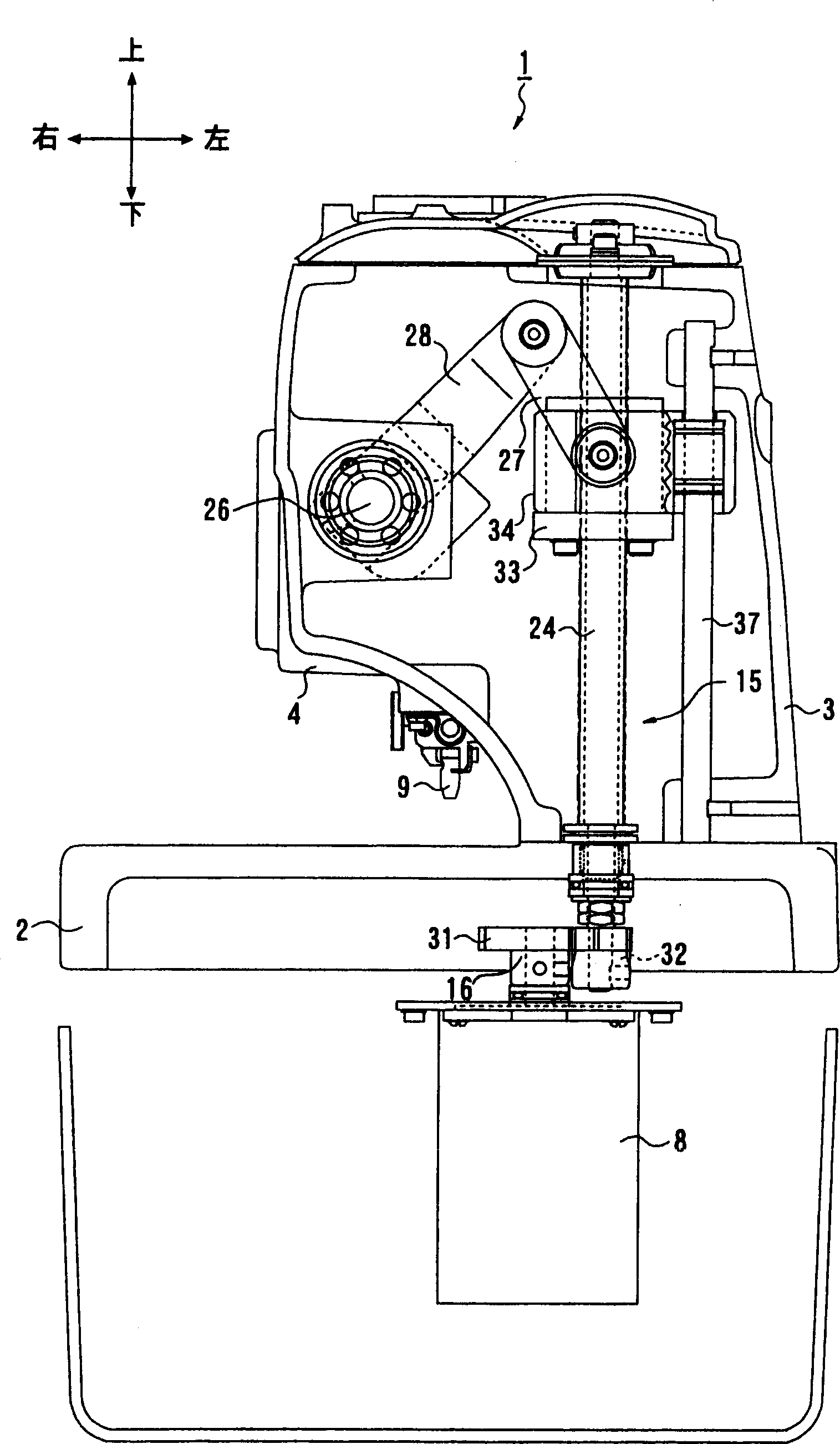

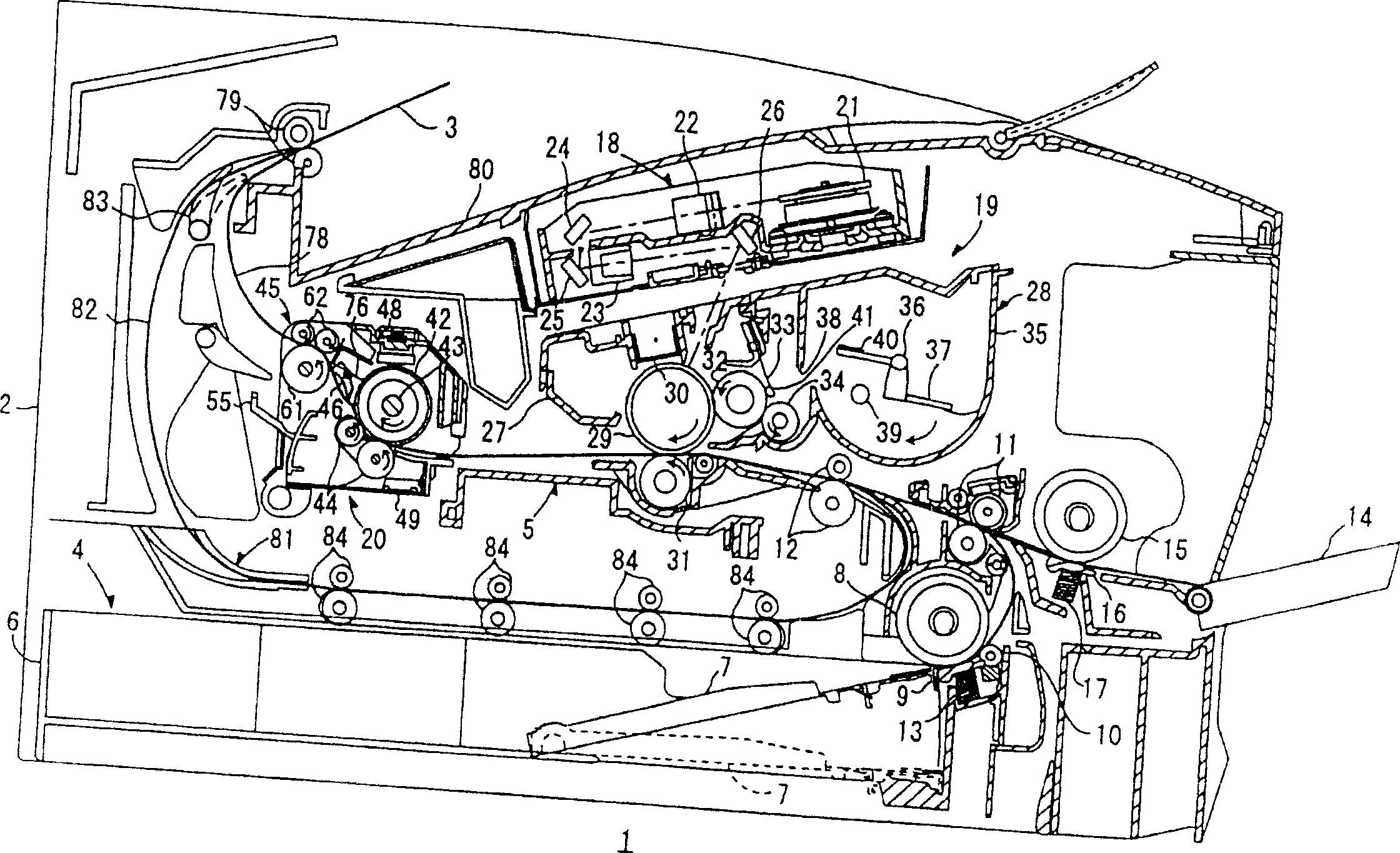

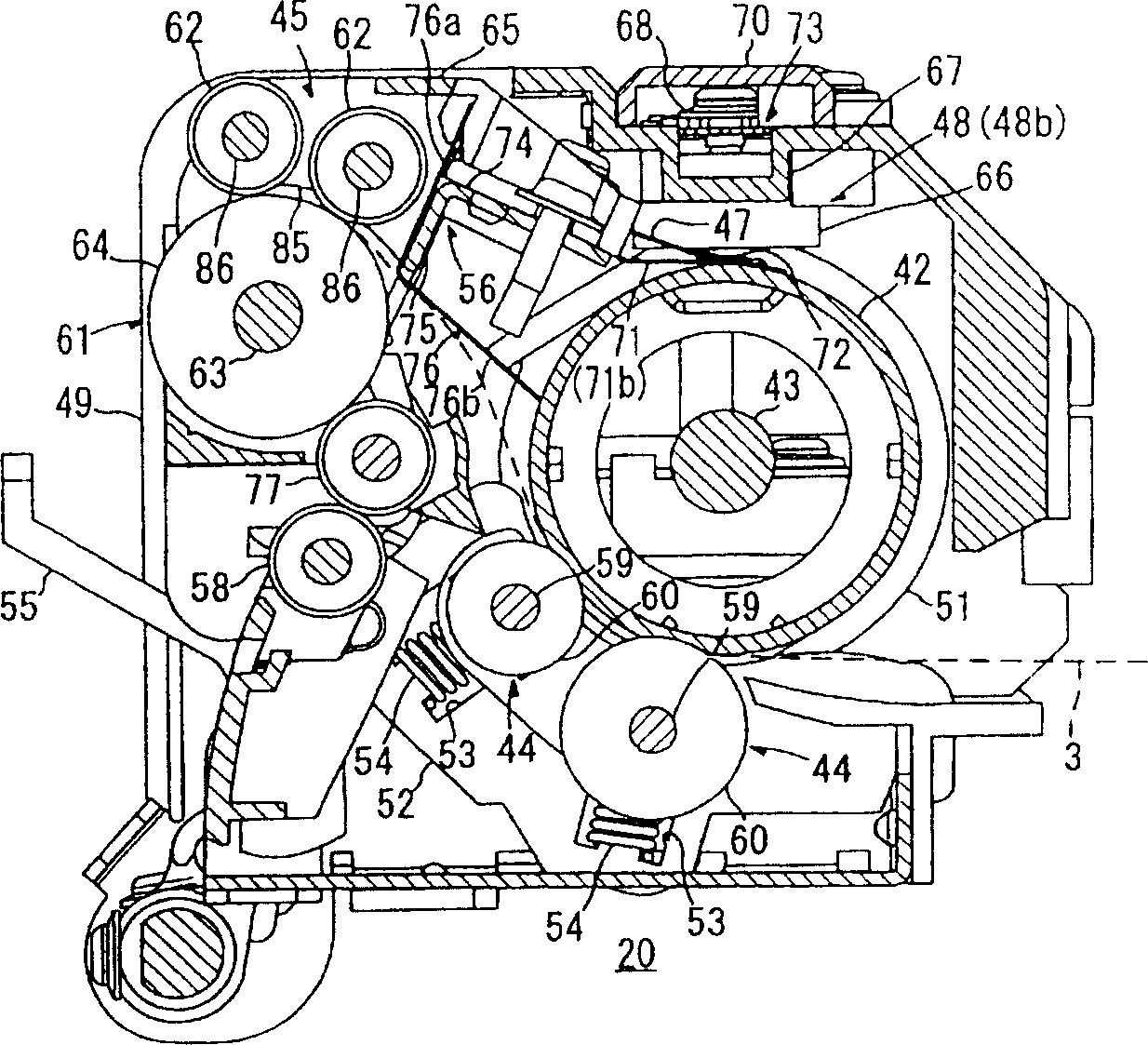

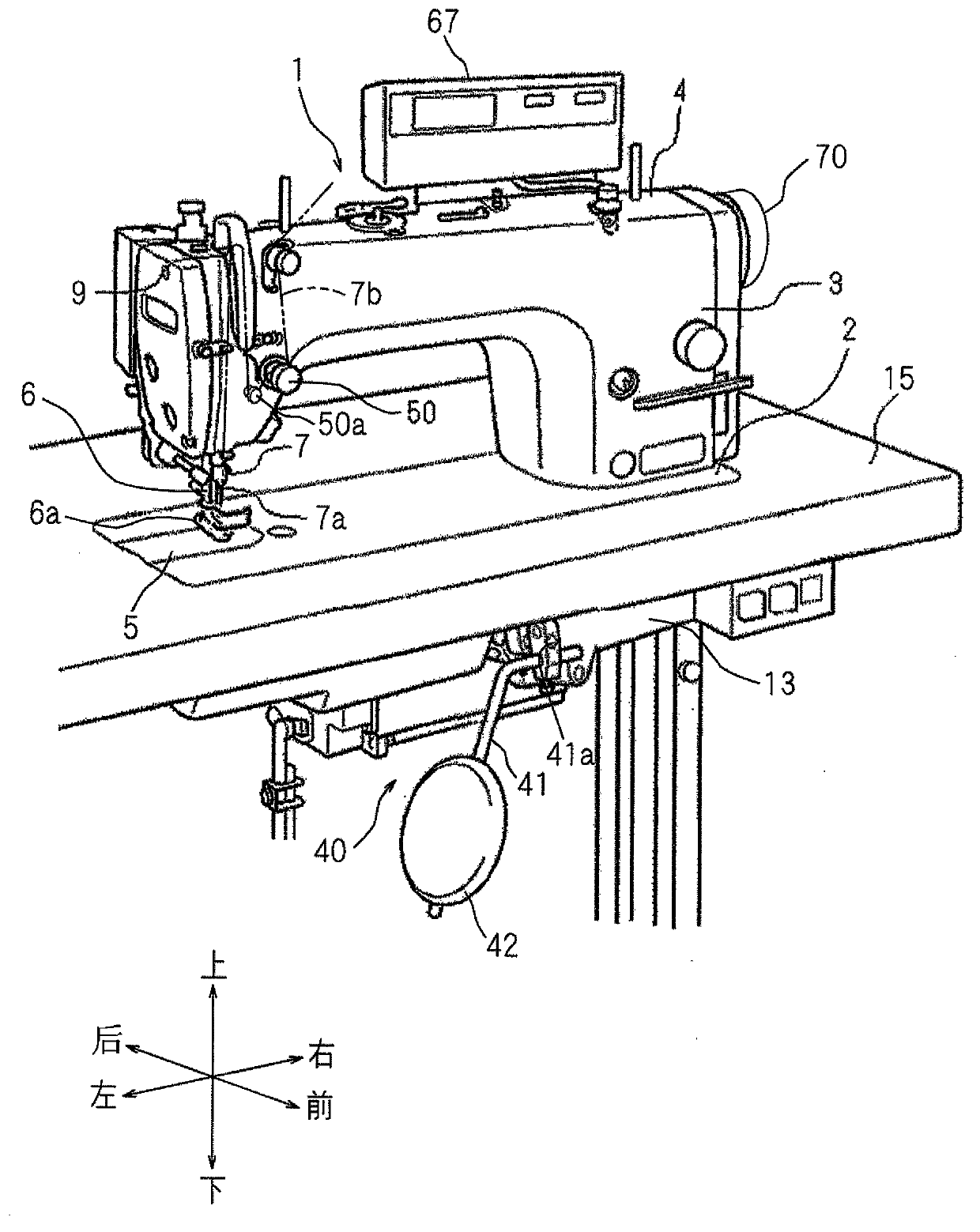

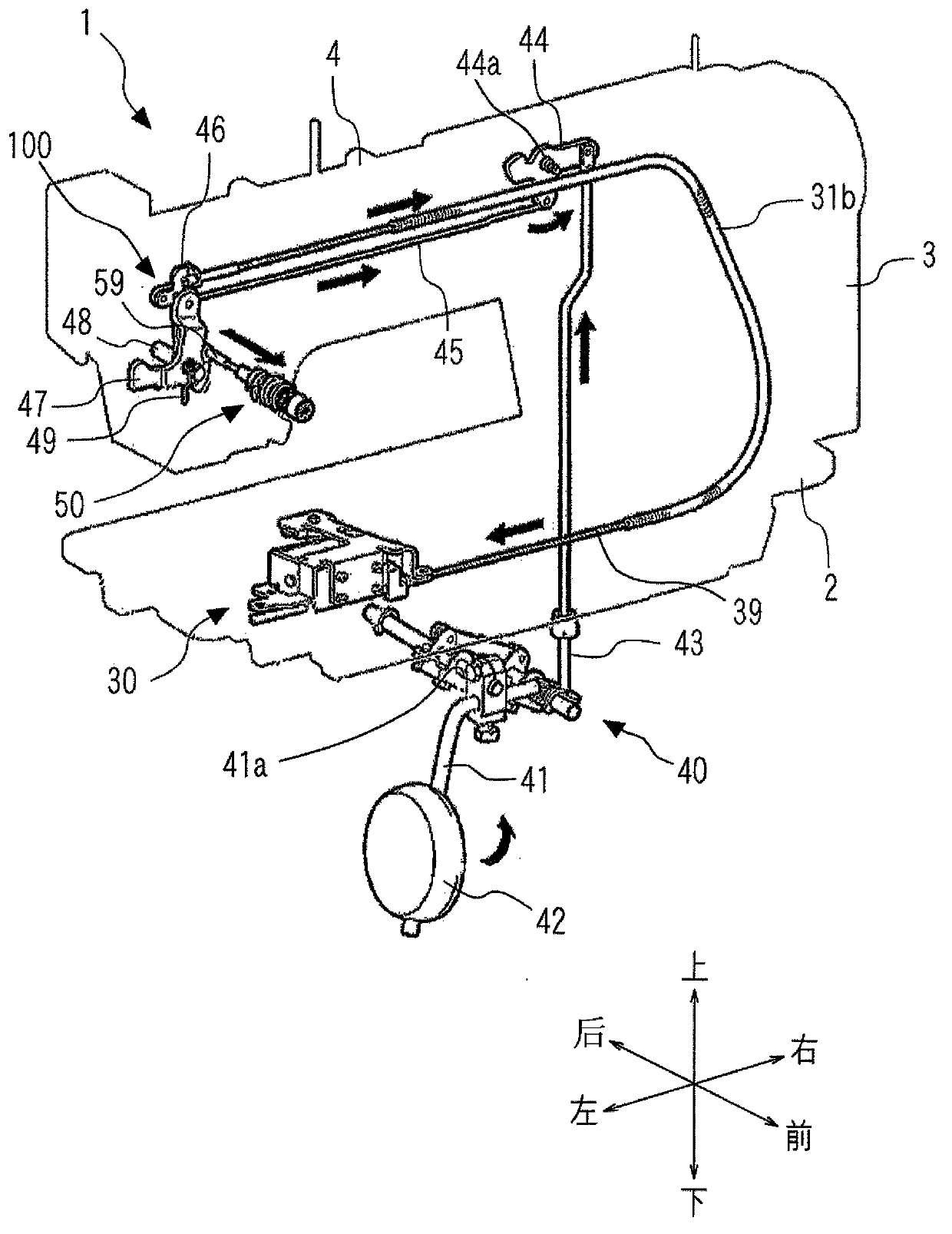

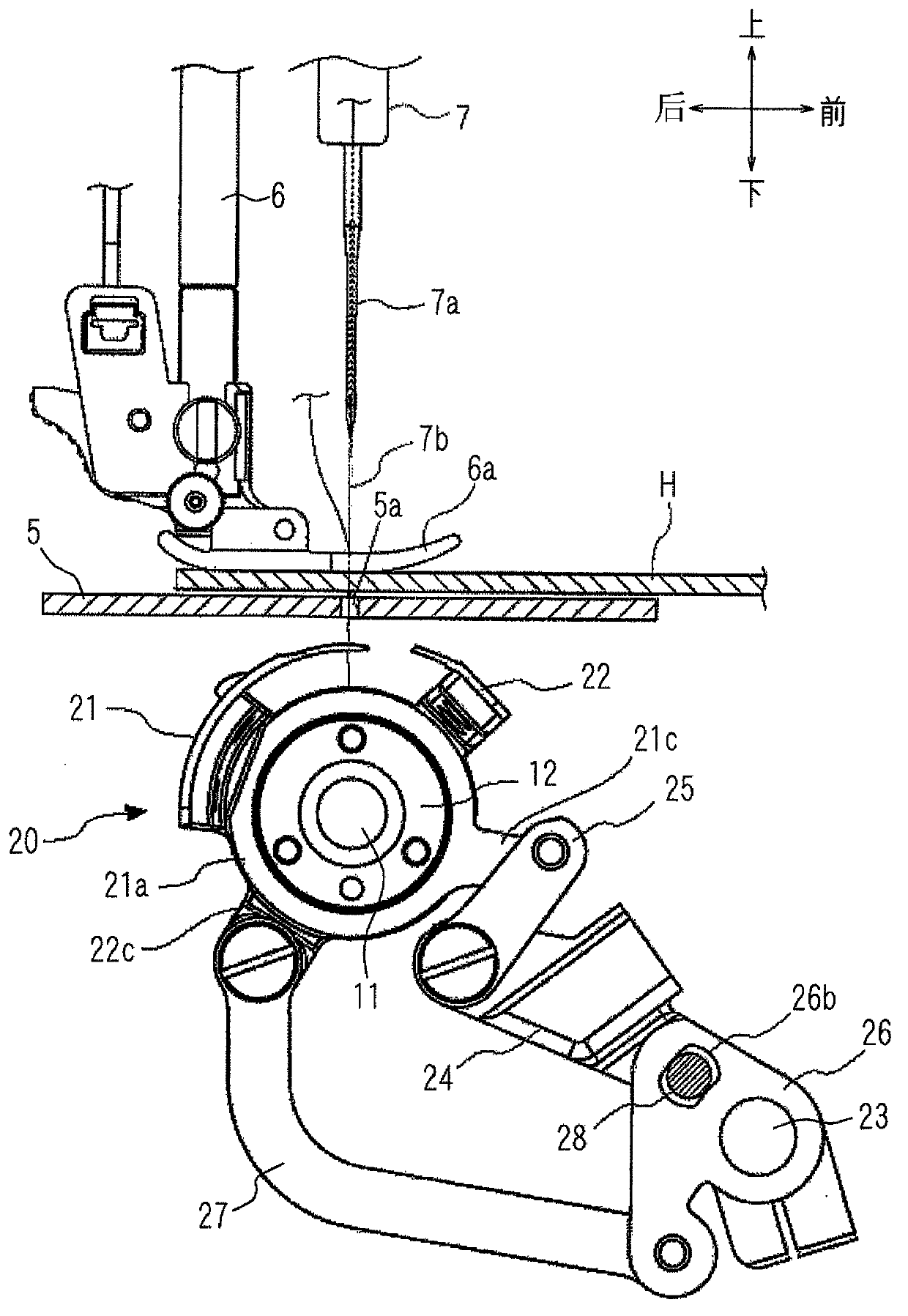

Buttonhole stitching machine

InactiveCN1424451APrevent movementReliable cut offProgramme-controlled sewing machinesWorkpiece carriersEngineeringBobbin

An eyelet buttonholing machine 1 is provided with freely vertically movable cloth pressers 55 and 56, a knife receiver 9 freely movable between an elevated position and a cutting position, a cloth cutting knife 11, an upper knife 61 and a lower knife 62 provided on a feed plate 58, an air cylinder 65 driving the upper knife 61 and the lower knife 62 from an opening position to a closing position, a presser driving cylinder 59 vertically driving the cloth pressers 55 and 56, a cloth cutting motor 8 vertically driving the knife receiver 9, and a controller 100 controlling the cloth cutting motor 8, the air cylinder 65 and the presser driving cylinder 59. After the cloth pressers 55 and 56 are elevated after sewing and eyelet hole formation, when the knife receiver 9 is positioned at a prescribed height between the elevated position and the cutting position, the controller 100 operates the air cylinder 65 and the upper knife 61 and the lower knife 62 are moved to the closing position. The invention is to shorten the remaining lengths of a bobbin thread and a core thread and to surely cut the bobbin thread and the core thread.

Owner:JUKI CORP

Heat-fixing unit and imaging apparatus

ActiveCN1521578AReliable cut offOhmic-resistance heatingElectrographic process apparatusThermal deformationThermostat

A heat roller with which a pressure roller is brought into press contact is rotatably supported by a bearing member made of a material which is softened when heated above a thermal fixation temperature, a thermostat in which a bimetal is exposed toward the heat roller is disposed at the opposite side of the heat roller with respect to the pressure roller, and a heat conduction member is made to intervene between the heat roller and the bimetal. According to the above configuration, the power supply to a fixation heater can be cut off by the thermal deformation of the bimetal. The heat roller is moved by softening of the bearing member, and the bimetal is mechanically deformed by pressing of the heat conduction member. Therefore, the power supply to the fixation heater can be cut off.

Owner:BROTHER KOGYO KK

Beveled bidirectional vertical pump device

ActiveCN103047185AGuaranteed uptimeEasy maintenancePump componentsPumpsImpellerHydraulic engineering

The invention belongs to the technical field of hydraulic engineering and discloses a beveled bidirectional vertical pump device which comprises a bidirectional rectangular water inlet runner, a rectangular water outlet runner, an eddy elimination and prevention cone, an inlet flared pipe, an impeller chamber, a guide vane part, a despinner, an annular siphonic water outlet structure, a rear water guide cone, an outlet flared pipe and a humped annular shell. The eddy elimination and prevention cone is arranged in the rectangular water inlet runner below the inlet flared pipe, an inlet of the impeller chamber is connected with the inlet flared pipe, and an outlet of the impeller chamber is connected with the guide vane part. The despinner, the rear water guide cone and the outlet flared pipe are sequentially arranged on the upper portion of the guide vane part, the upper annular side of the humped annular shell is smoothly connected with the upper edge of the rear water guide cone, the lower annular side of the humped annular shell is positioned in the rectangular water outlet runner to form the annular siphonic water outlet structure, and the humped tope of the annular siphonic water outlet structure is provided with a vent hole connector connected with a vacuum breaker valve. The beveled bidirectional vertical pump device is structurally reasonable and scientific, has four functions of self-discharging, self-sucking, pump-discharging and pump-sucking and is high in automation degree and convenient to operate and manage, efficiency of the pump device is improved, and investment is saved.

Owner:YANGZHOU UNIV

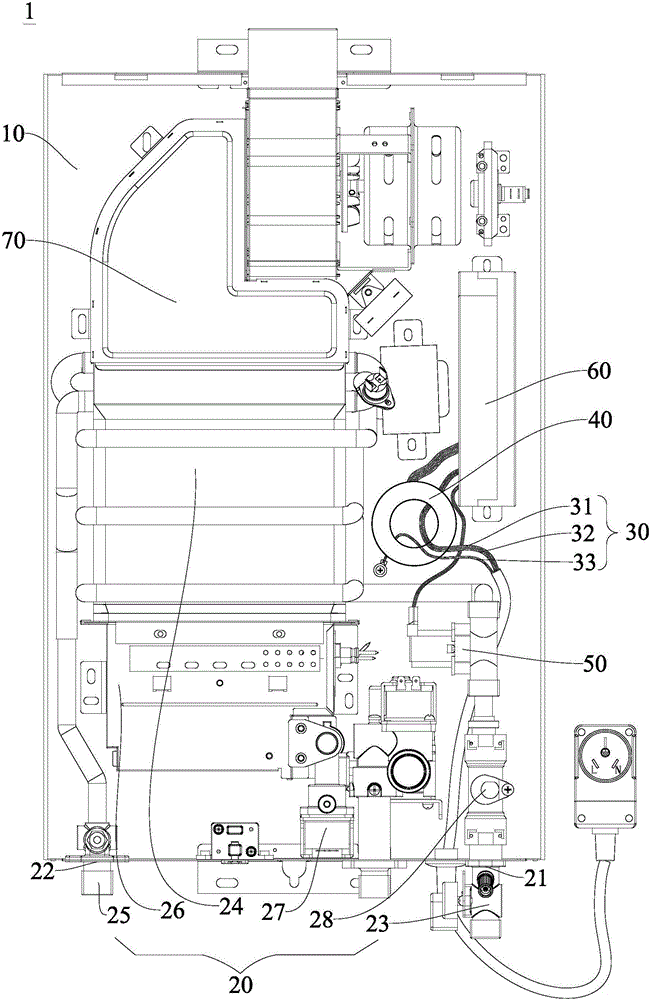

Water heater

InactiveCN105783273APrevent rustPrevent from being covered with limescaleWater heatersElectricityPower flow

The invention discloses a water heater. The water heater comprises a shell, a water path system arranged in the shell, a wire for supplying power to the water heater, a current transformer for detecting the current of the wire, a safety protection valve used for controlling a water flow in the water path system to be on and off, and a controller connected with the wire and communicated with the current transformer and the safety protection valve. When the current transformer detects that the current difference of a null line and a firing line of the wire or the current value of a ground wire of the wire is larger than or equal to a preset value I, the controller controls the safety protection valve to cut off the water flow of the water path system. According to the water heater, electricity leakage can be sensitively and accurately judged, and therefore during electricity leakage, the water flow in the water path system can be reliability cut off, and happening of electric shock casualty accidents is prevented; and the detection precision of the current transformer is high, and work is stable.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

Roller pressing device

InactiveCN101172412AQuality improvementConstant widthRotary lithographic machinesPrinting press partsEngineeringActuator

The invention relates to device for pressing the roller (1)to a paired roller(2,3), capable of implementing constant compression force in the whole operation process by the following method. An actuator (5)for supporting lateral ends of a roller (1) is provided which can generate compression force, and produce the pressing movement of the roller, which runs along the desired compression force. The compression force is kept to a constant value by using a control device (7).

Owner:M A N ROLAND DRUCKMASCHINEN AG

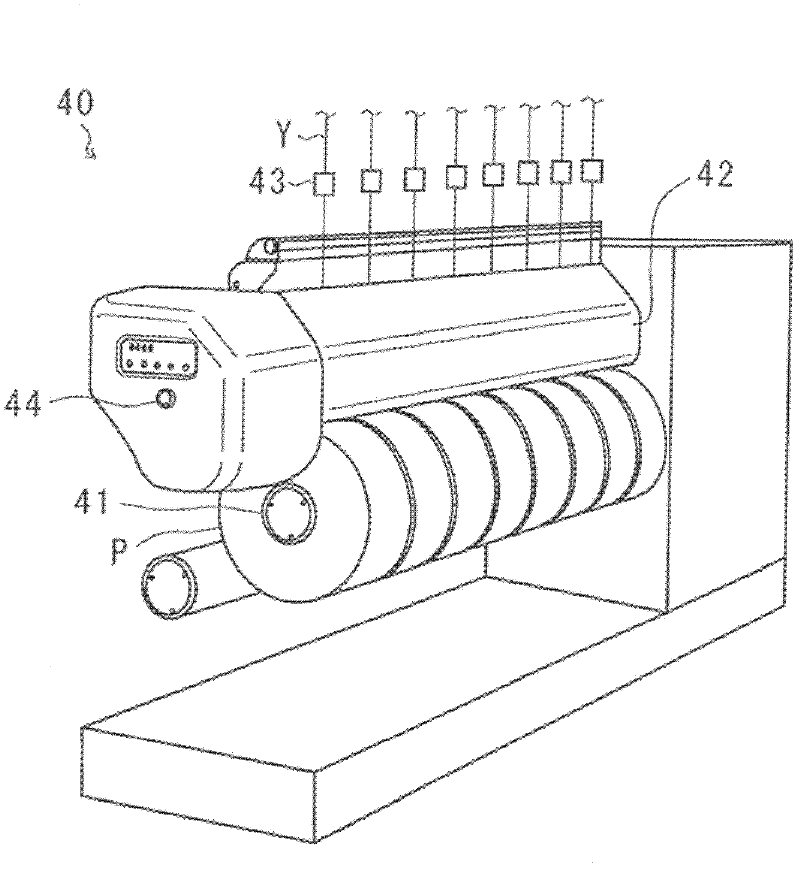

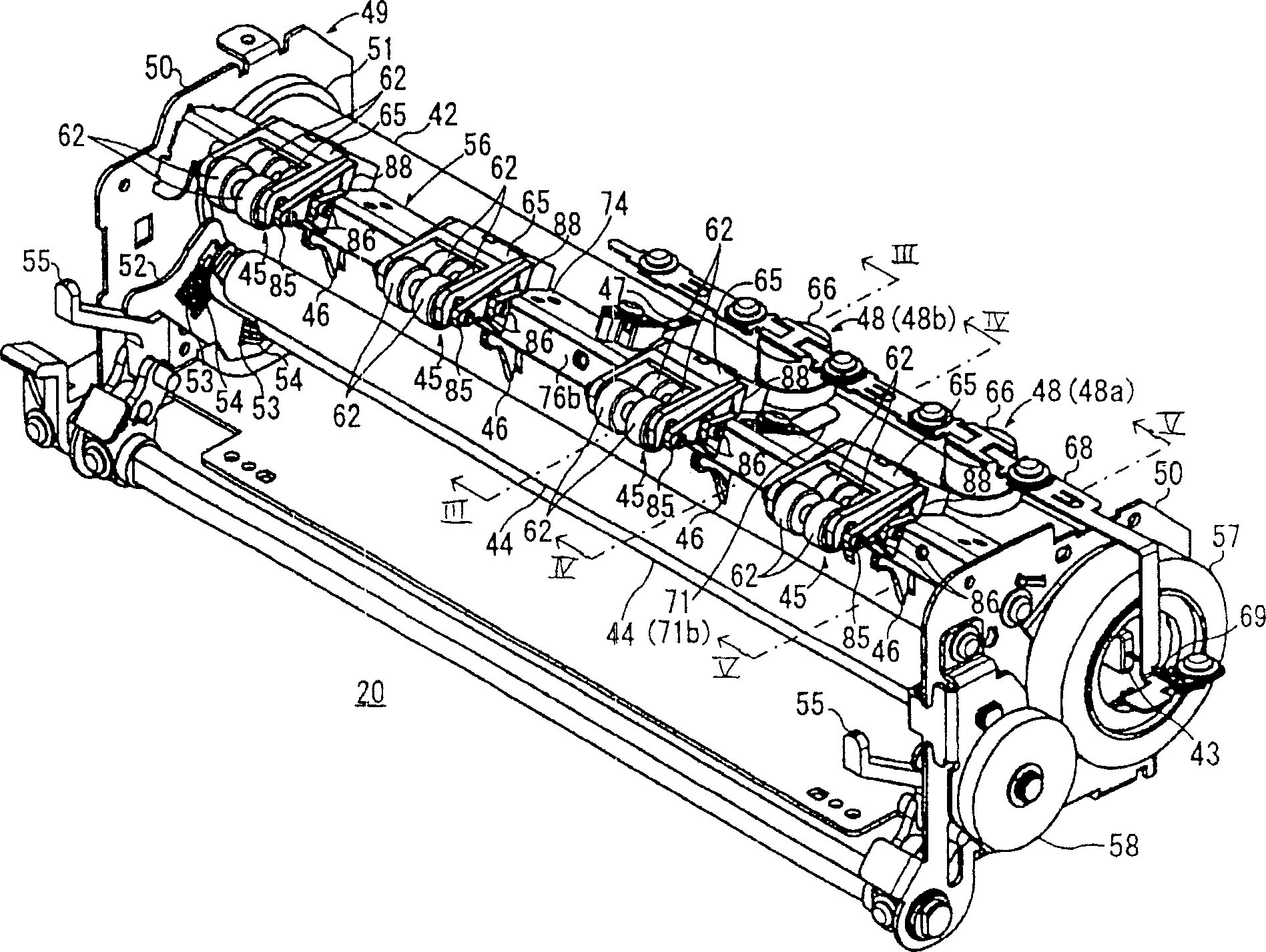

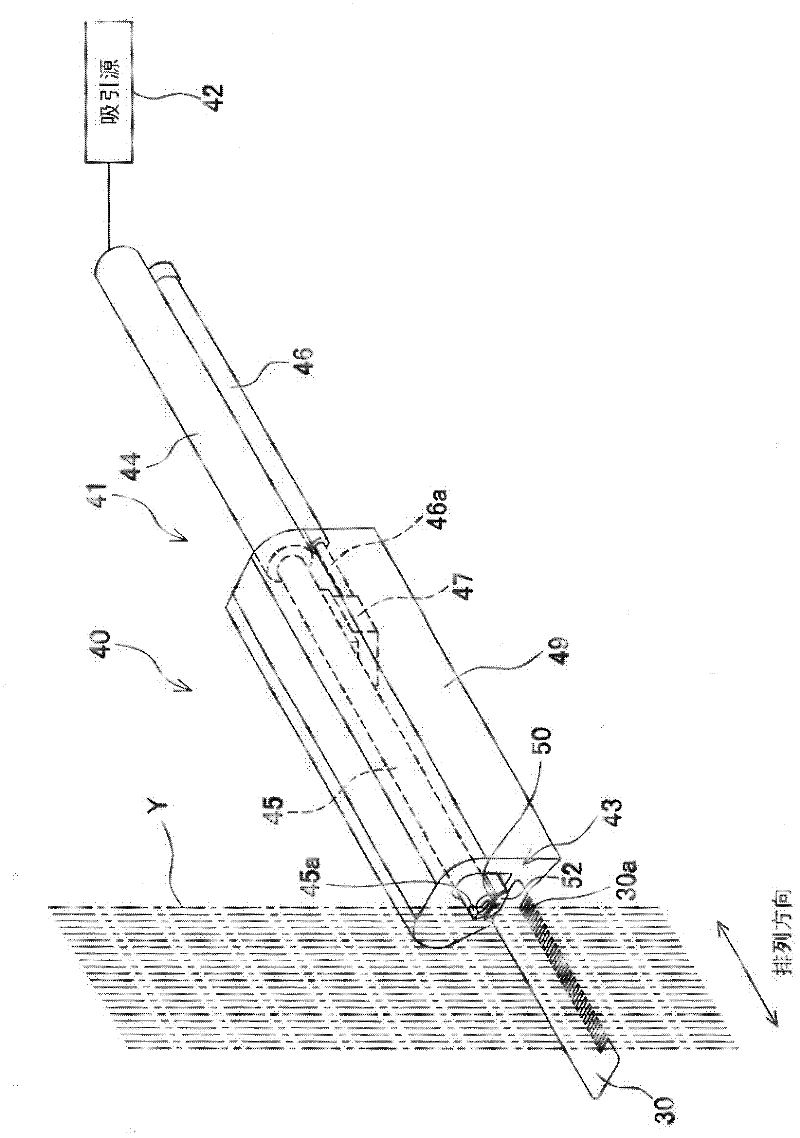

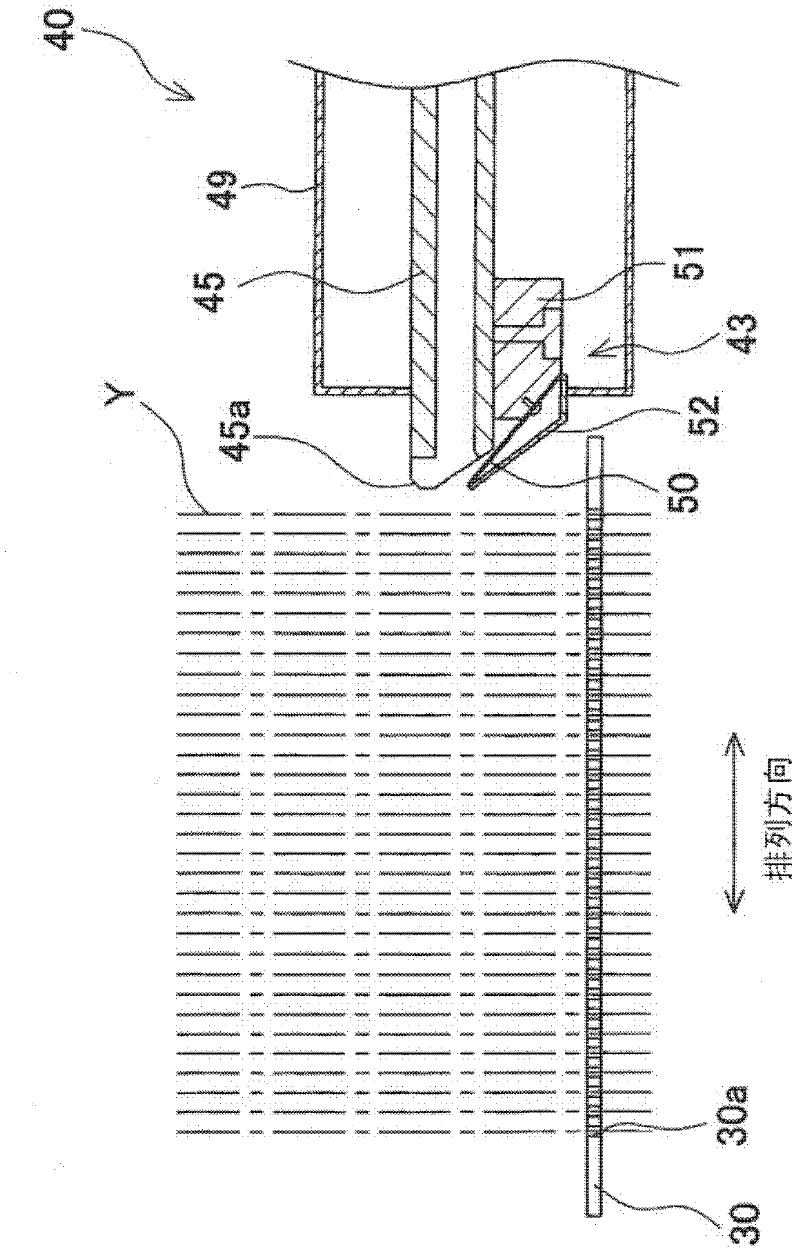

Yarn cutting-sucking device and spinning winder

All yarns are surely cut and sucked irrespective of the number of the yarns. A yarn cutting-sucking device 40 includes a cutter 43 arranged to be movable in the alignment directions of yarns Y, a sucking unit 41 which is provided in proximity to the cutter 43 and includes a sucking pipe 45 which is movable in the alignment directions in the same manner as the cutter 43, and a cylinder 46 which is arranged to move the sucking pipe 45 along the alignment directions. As the cylinder 46 is driven, the cutter 43 and the sucking pipe 45 move in an alignment direction in a synchronous manner.

Owner:TMT MACHINERY INC

Web cutting device

InactiveCN102555426AGuaranteed stabilityAvoid injuryRotary pressesMetal working apparatusEngineeringMechanical engineering

A web cutting device, which achieves cost reduction by a simplified structure, ensures operational stability, and enhances the reliability of the device, is provided. The web cutting device (10), is equipped with a cutting blade (16) for cutting a web (W), and comprises: a cutting blade support member (12) supporting the cutting blade and supported to be pivotable between a standby position and a cutting position; a return spring (23) for urging the cutting blade support member toward the standby position; a stopper pin (21) and an engaging groove (22) for stopping the cutting blade support member at least at the standby position; a cutting blade bearing member (13) provided with a slit (27) for receiving the cutting blade, and a knock bolt (28) for pivoting the cutting blade support member to the cutting position; and drive means (15), composed of an L-shaped lever (31) and an air cylinder (32), for moving the cutting blade bearing member toward and away from the cutting blade support member.

Owner:KOMORI CORP

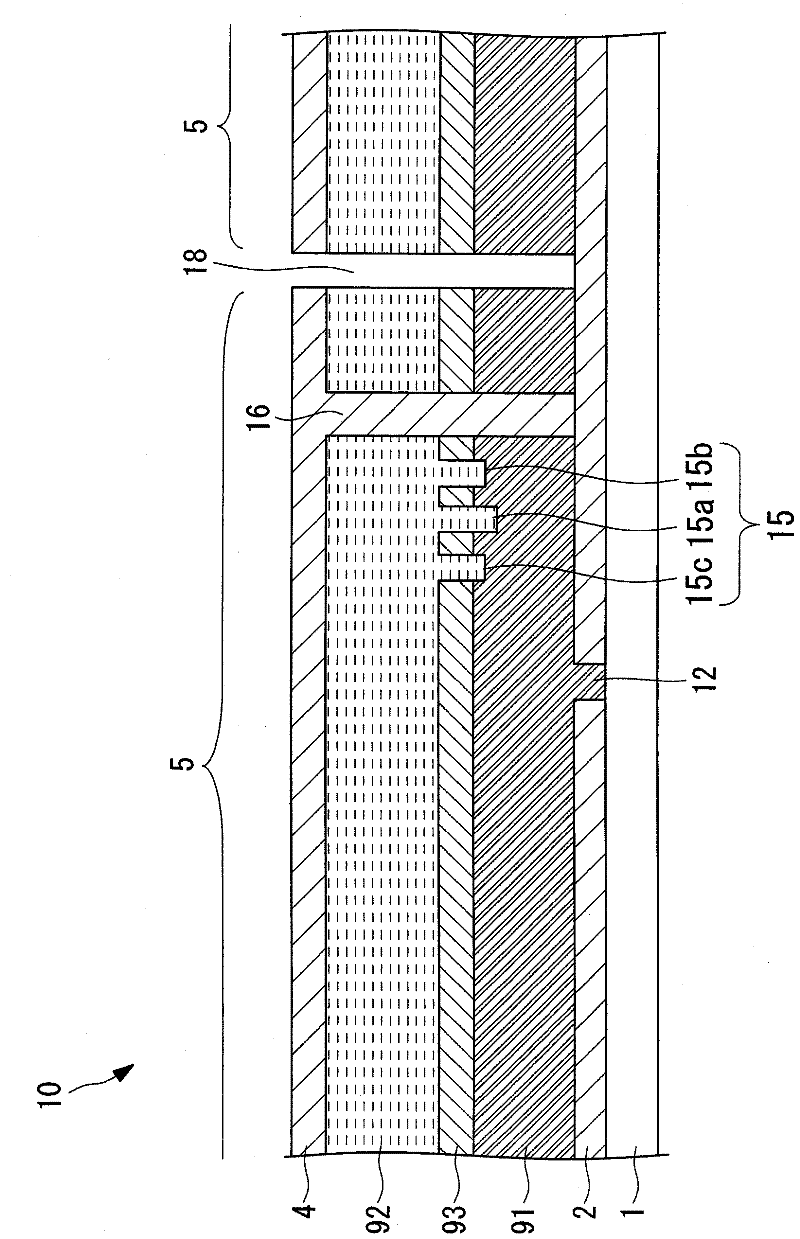

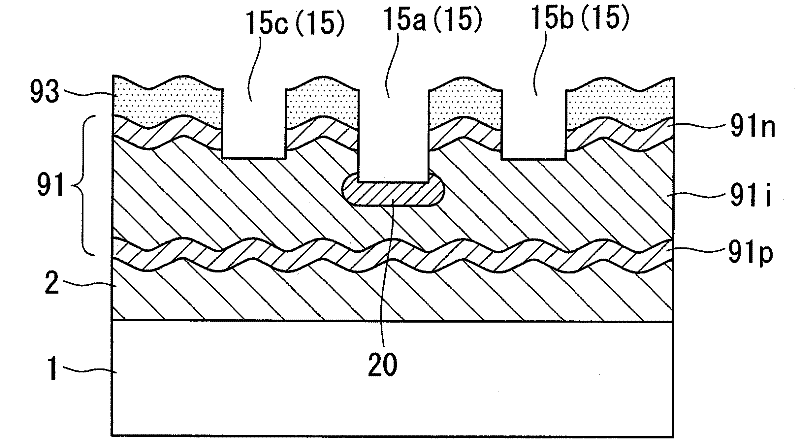

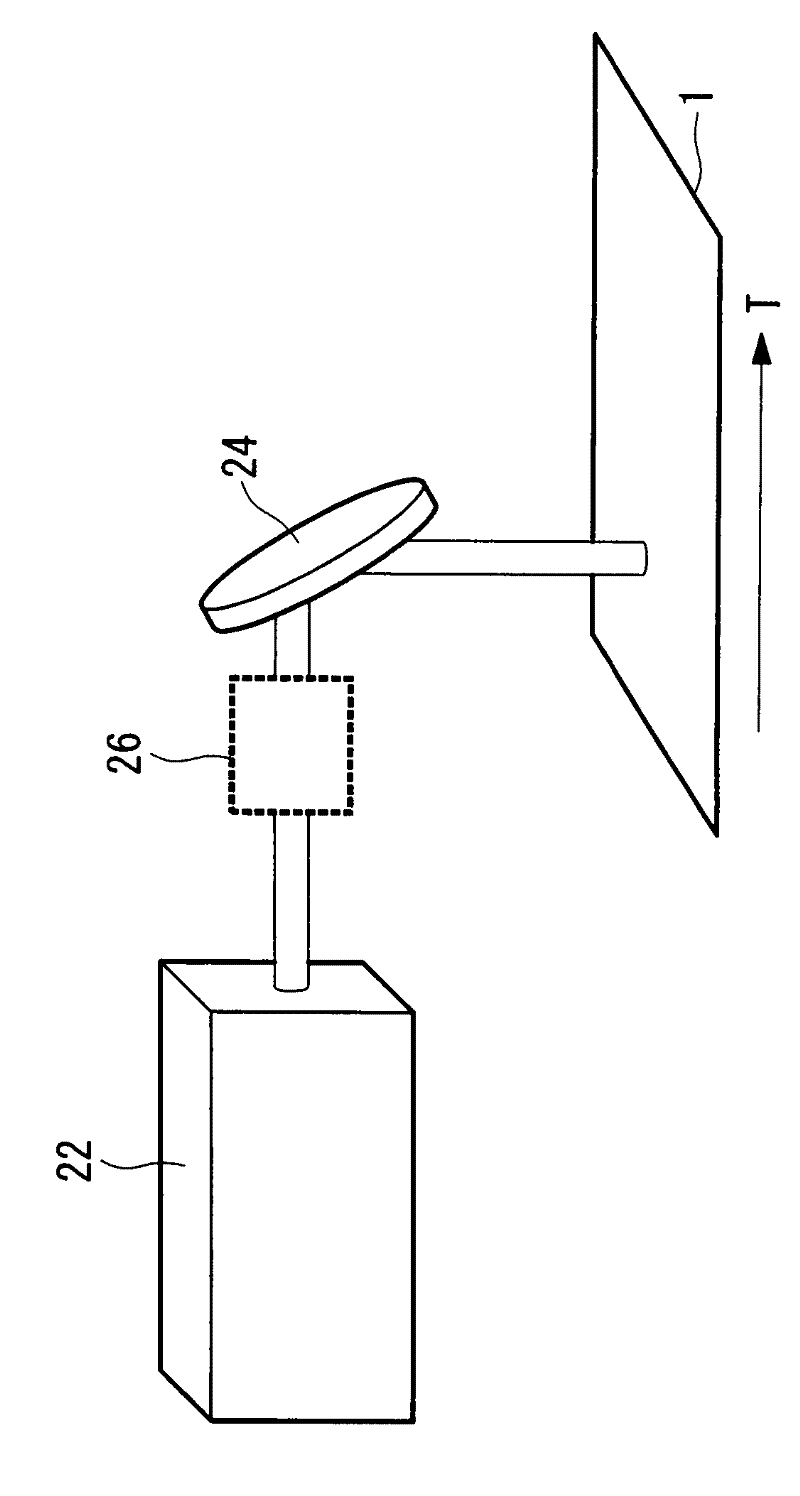

Photoelectric conversion device manufacturing method, photoelectric conversion device manufacturing device, and photoelectric conversion device

InactiveCN102227817AForming accuratelyReliable cut offWelding/soldering/cutting articlesPhotovoltaic energy generationBeam diameterManufactured apparatus

Provided are a photoelectric conversion device manufacturing method which can control the depth of a processing groove to a desired value, a photoelectric conversion device manufacturing apparatus and a photoelectric conversion device. The photoelectric conversion device (10) has a groove formation step which applies a pico-second laser to an intermediate contact layer separation groove (15) constituting a photoelectric conversion device (10) and forms a processing groove (15) in a predetermined scan direction by relatively moving the pico-second laser against the intermediate contact layer separation groove (15). In the groove formation step, the pico-second laser is relatively moved so that interference fringes are arranged in parallel in one direction within a radiation range corresponding to the beam diameter of the pico-second laser and the interference fringes are connected in the scan direction.

Owner:MITSUBISHI HEAVY IND LTD

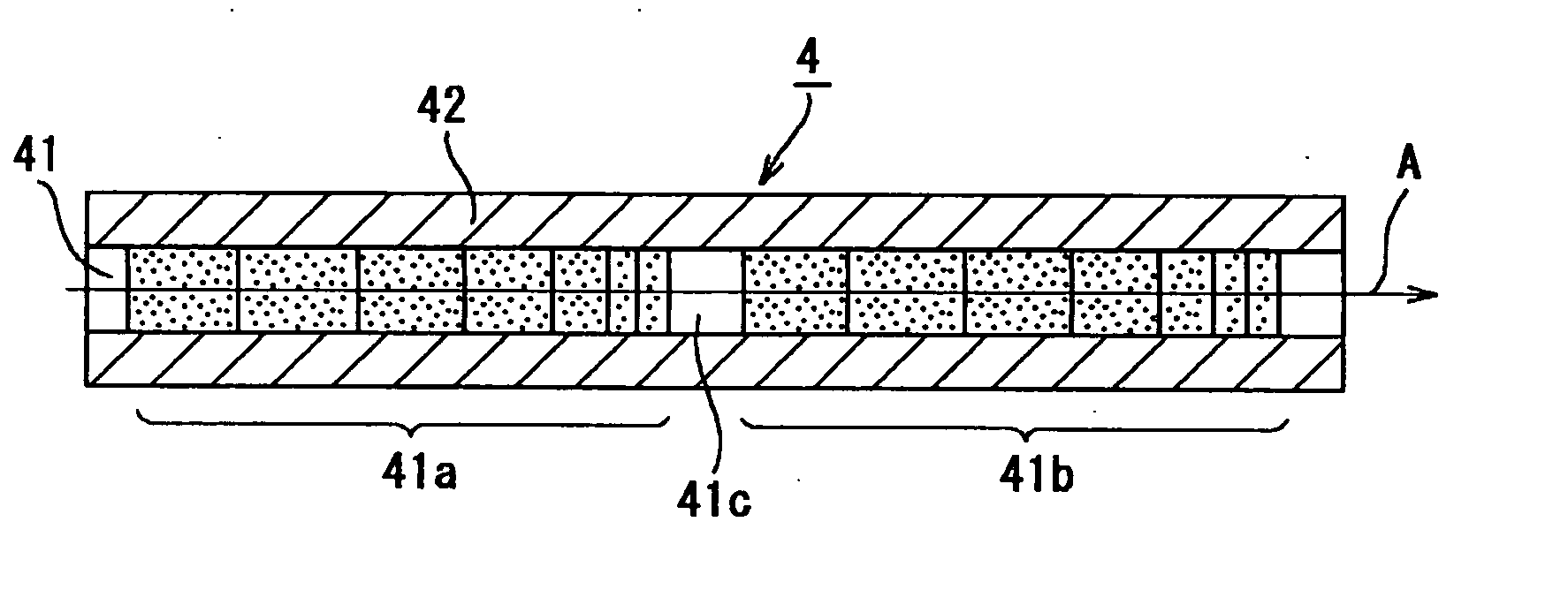

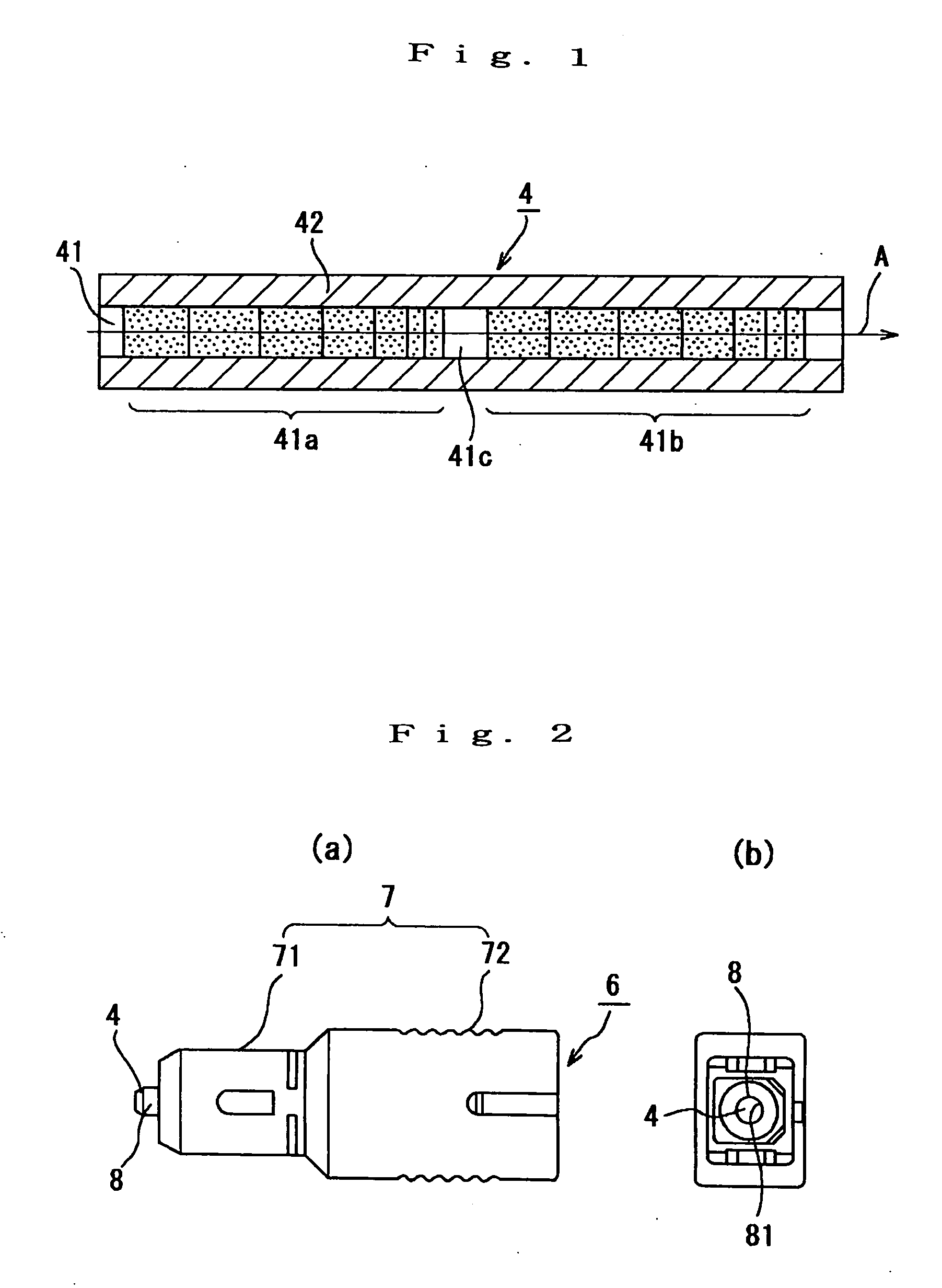

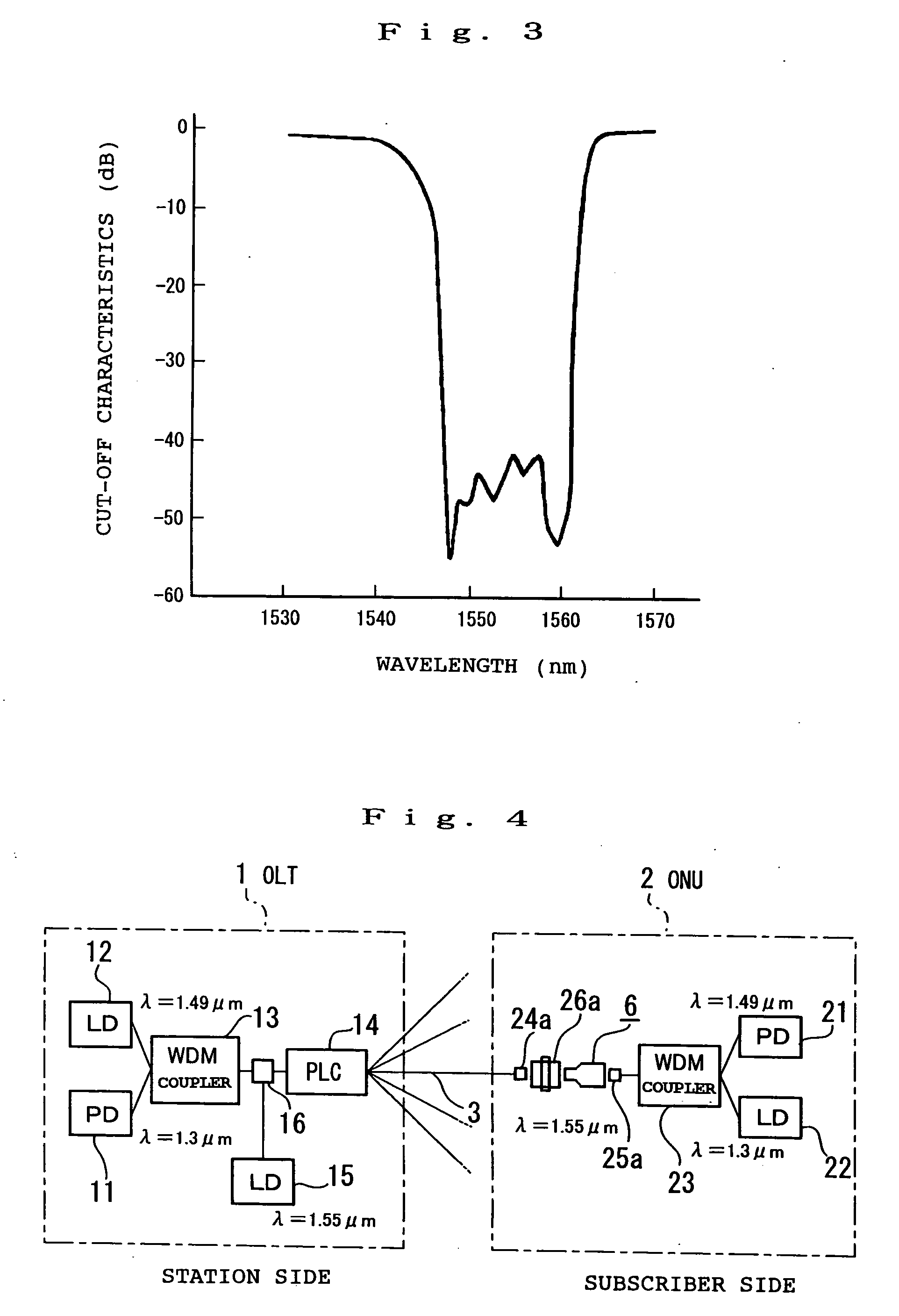

Signal cutout device, optical connector and optical fiber coupler

InactiveUS20050157982A1Reliable cut-offFirmly connectedCladded optical fibreCoupling light guidesGratingOptical axis

A signal cut-off device 4 includes an optical fiber which has a clad 42 on the outer periphery of a core 41, and first and second variation sections of a refractive index, 41a and 41b in which the period of a grating varies gradually along an optical axis are serially formed in the longitudinal direction of the core 41. An optical connector which is detachably connected to the predetermined place of an optical transmission line includes a housing which has a plug-styled portion at a front end part and a jack-styled portion at a rear end part, and a ferrule which is mounted in the plug-styled portion. The signal cut-off device 4 is installed in the hole of the ferrule. An optical fiber coupler includes a coupler body which multiplexes / demultiplexes an uplink signal (1260-1360 nm) and a downlink signal (1480-1580 nm), a COM port which is provided on the input side of the coupler body, and a 1.55 port and a 1.3 port which are provided on the output side of the coupler body. A second connector is mounted on the end part of an optical fiber constituting the COM port, a PD is mounted on the end part of an optical fiber constituting the 1.55 port, and an LD is mounted on the end part of an optical fiber constituting the 1.3 port.

Owner:SHOWA ELECTRIC WIRE & CABLE CO

Sewing machine

ActiveCN103374798ALimit riseLimit dropNeedle severing devicesTensioning devicesEngineeringSewing machine

The present invention provides a sewing machine. The sewing machine is provided with a thread cutting device which is used for cutting an upper thread and an under thread below a needle plate. The sewing machine of the invention is provided with a limiting component. When the thread cutting device operates, the limiting component limits rising and dropping of a thread hanging part. In the sewing process, the thread hanging part adjusts the leading-out length of the upper thread through dropping when a thread taking-up lever rises and rising when the thread taking-up lever drops. The thread taking-up lever rises and drops when the thread cutting device operates. The thread hanging part does not rise or drop under the function of the limiting component. Therefore, the thread cutting device cuts off the upper thread without effect by the position of the thread hanging part. The upper thread which is cut off can residue at the needle side with an approximately constant length. Therefore, the sewing machine can generate excellent stitch.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com