Non-initiating unlocking device and locking and unlocking method thereof

An unlocking device and non-pyrotechnic technology, which is applied in the docking device of aerospace vehicles, transportation and packaging, space navigation equipment, etc., can solve the problem of hot knife assembly volume and weight, the rope is easy to form carbon fragments, and the hot knife assembly is reliable. Low reliability and other problems, to achieve the effect of strong connection reliability, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

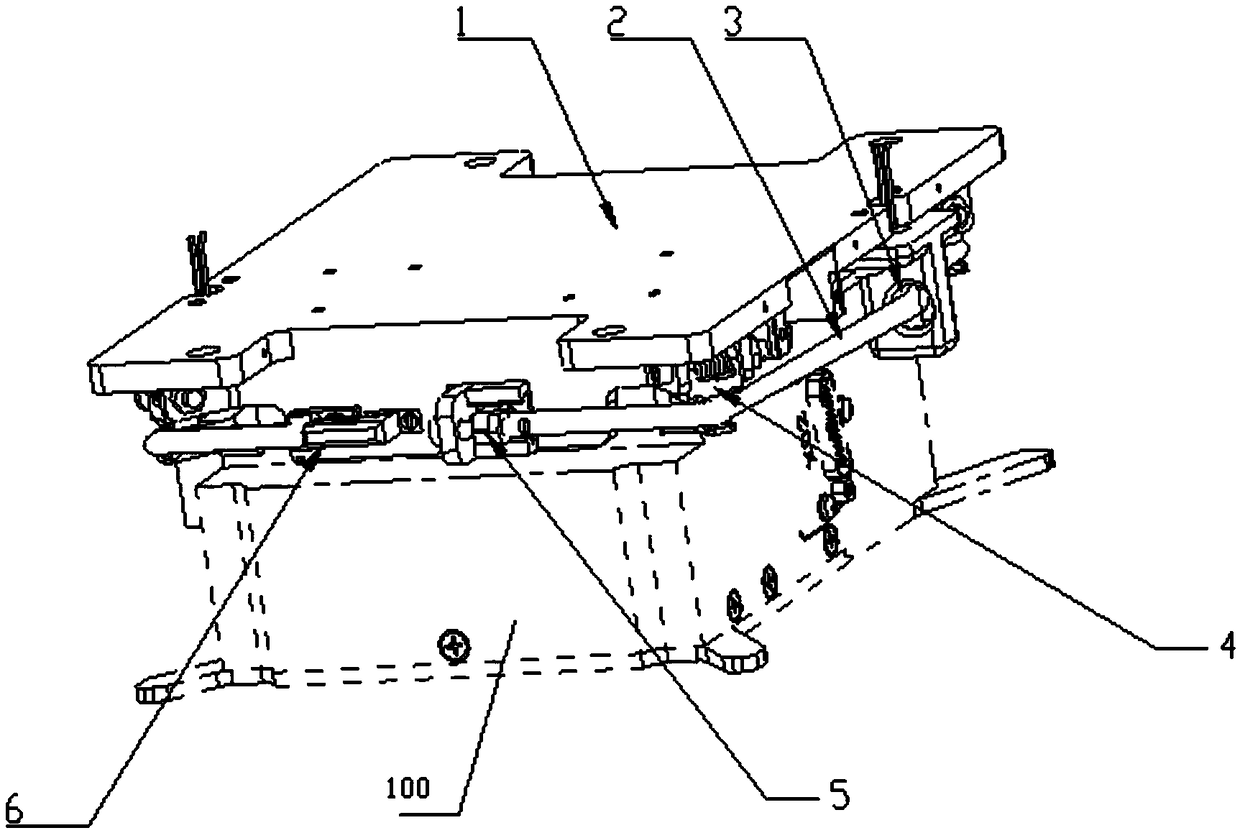

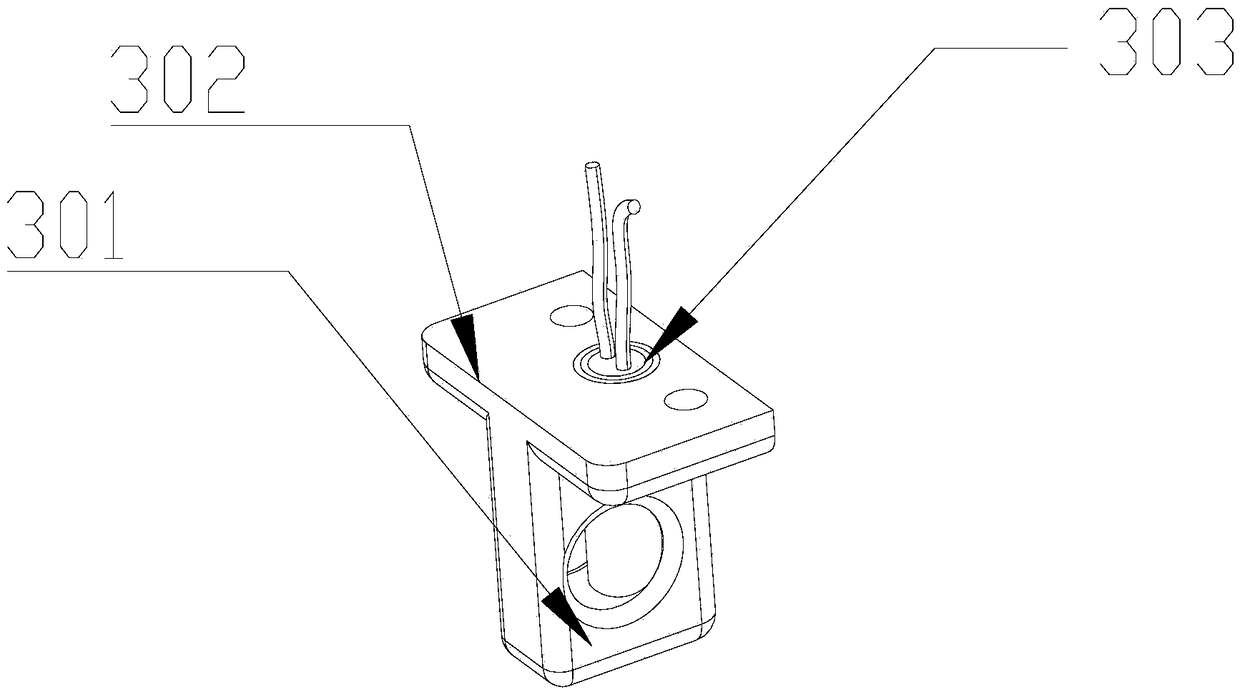

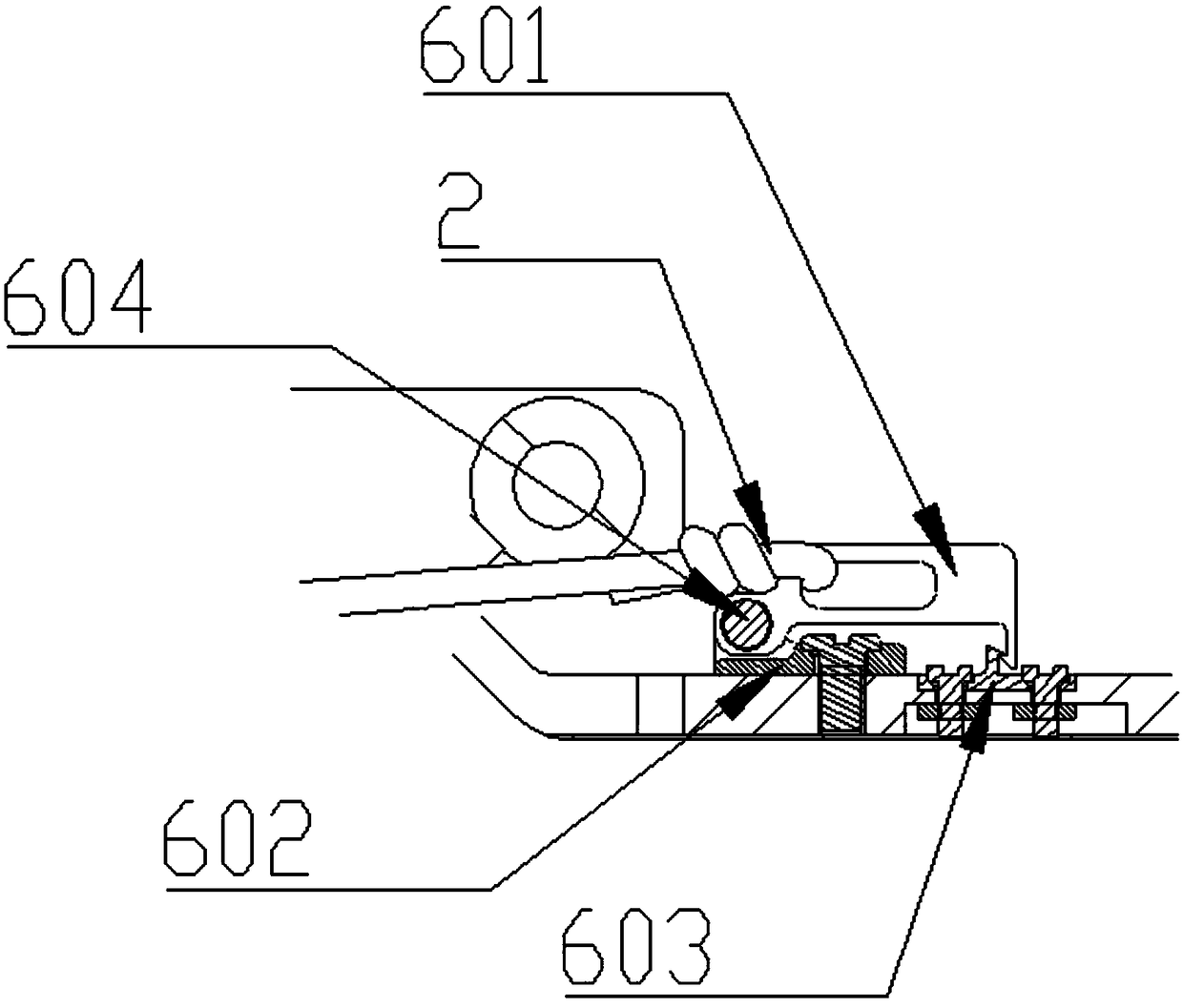

[0069] see figure 1 , the embodiment of the present invention provides a non-firework unlocking device for locking or unlocking the first part (not shown in the figure) and the second part 100, including a fastening rope 2, a hot knife assembly 3 and at least Two lock release parts 4, the lock release parts 4 are used to be fixed on the first part, the fastening rope 2 surrounds the second part 100, and provides tightening force to the lock release part 4 Make the lock release part 4 in the first state to lock the second part 100, the hot knife assembly 3 includes a hot knife 303 and a hot knife installation part 301, the hot knife installation part 301 is made of heat insulating material, The hot knife 303 is arranged in the hot knife installation part 301, the fastening rope 2 passes through the hot knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com