Three-position operating mechanism and transmission shaft thereof

An operating mechanism, three-station technology, applied in contact drive mechanism, air switch parts, electrical components, etc., can solve problems such as the consequences of ring network cabinets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

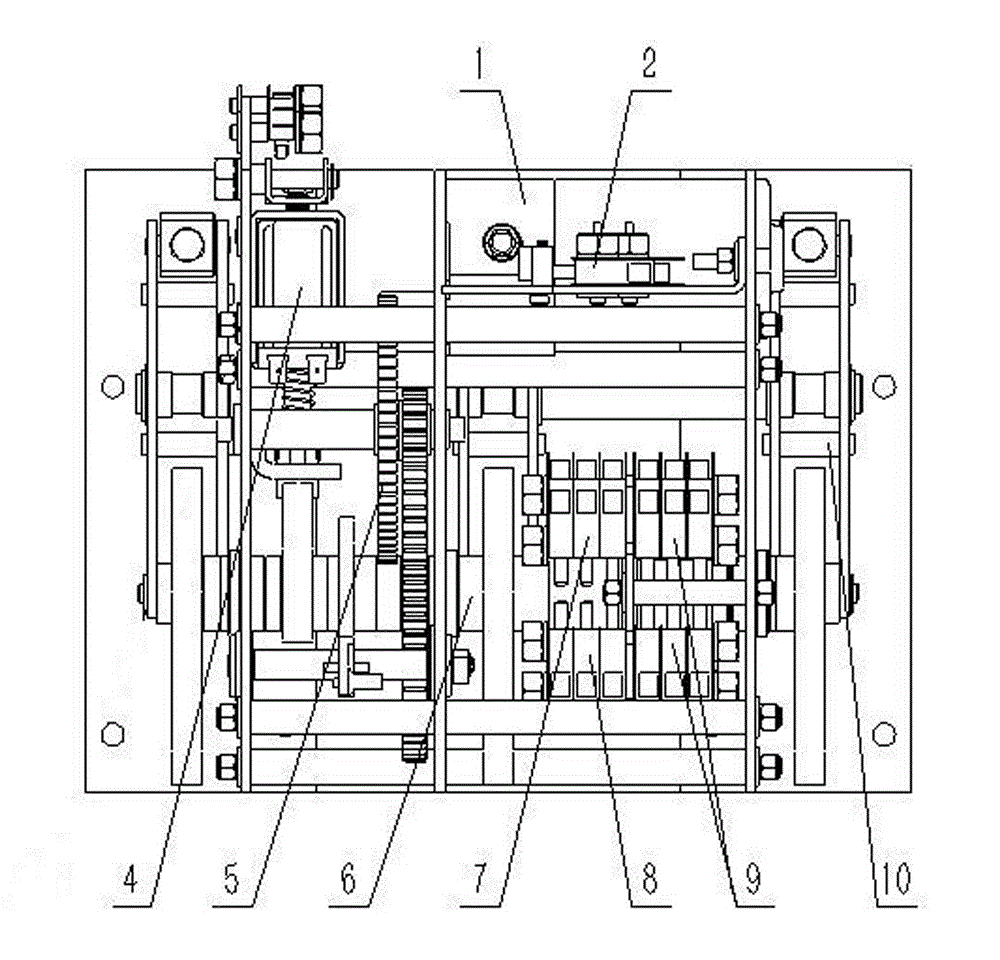

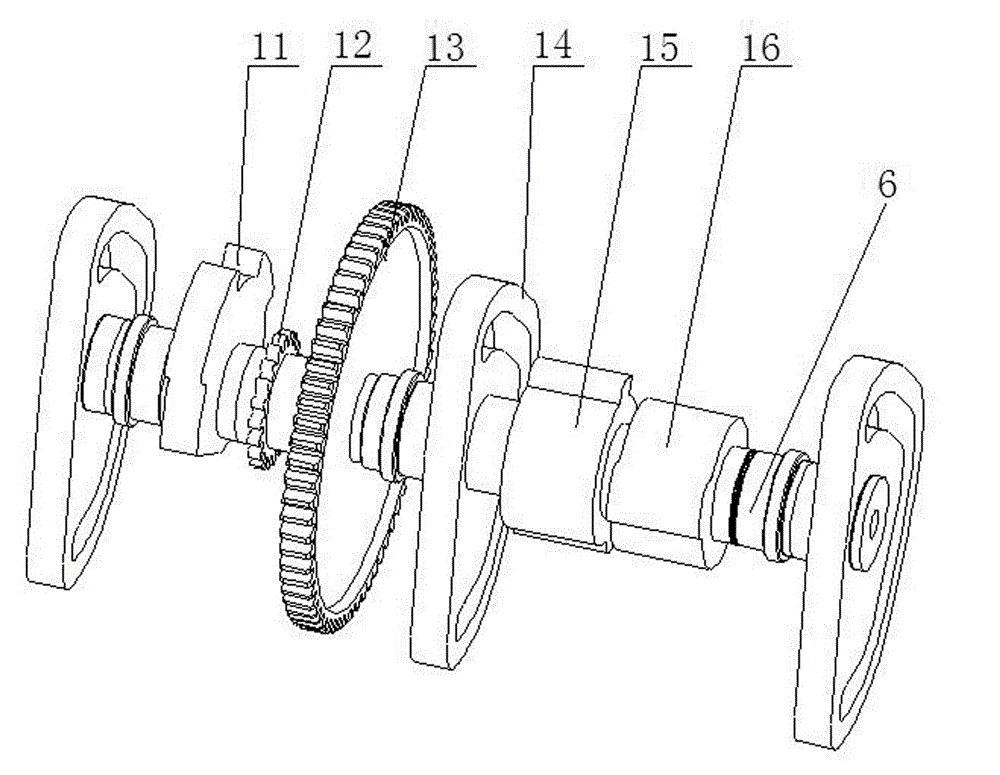

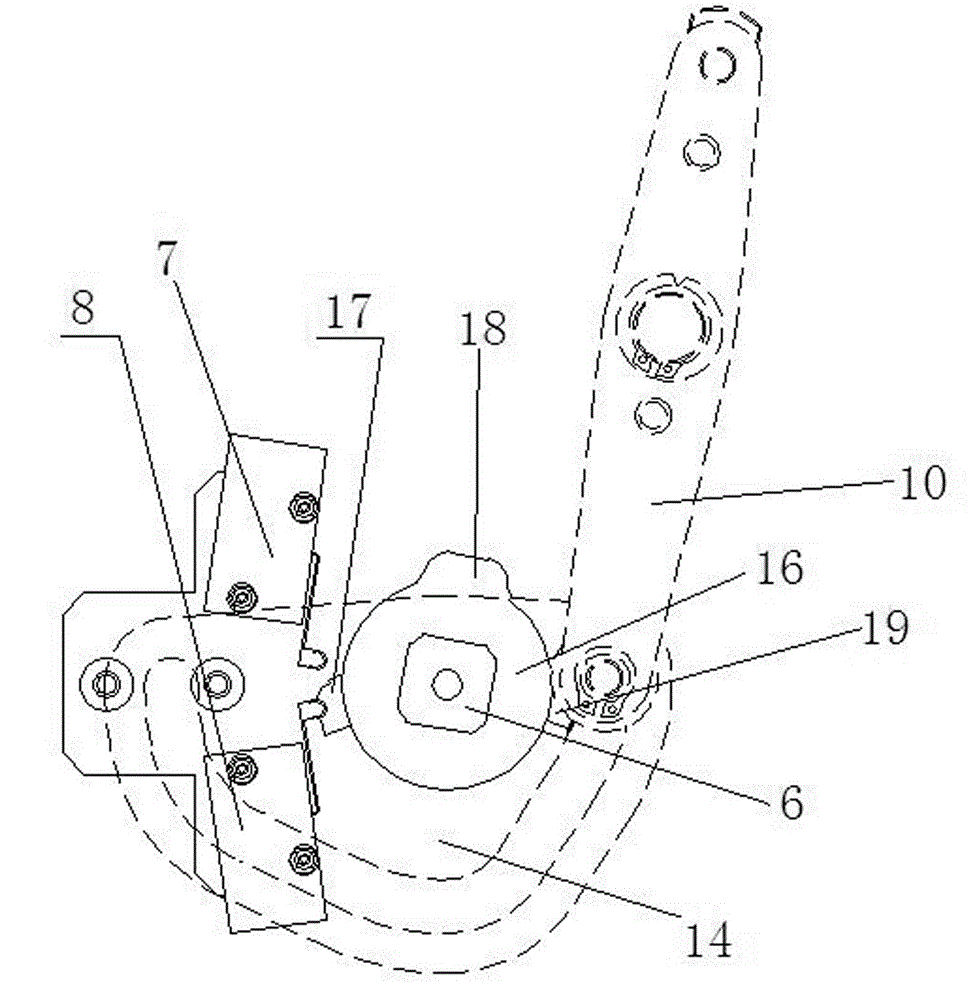

[0026] An example of a three-position operating mechanism Figure 1~10 Shown: including a frame, the frame is provided with a motor 1, a manual operating lever 23, a transmission shaft 6 and an output shaft parallel to the transmission shaft, and the motor shaft 25 of the motor is connected to the transmission shaft 6 through a gear transmission mechanism 5 , the output end of the manual operating lever 23 is provided with a transmission sleeve 24 which is used to prevent rotation and is set on the motor shaft, and an unlocking plate 26 and an unlocking travel switch 2 are arranged beside the manual operating lever, and the unlocking plate 26 is hinged on the frame. The hinge axis of the unlocking plate is perpendicular to the axial direction of the motor shaft. The outer peripheral surface of the drive sleeve has a conical thrust section. The inner plate surface of the travel switch 2 pushes and fits. When the motor is in the working mode, the transmission sleeve 24 on the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com