Buttonhole stitching machine

A sewing machine and buttonhole technology, which is applied to sewing machine components, sewing machine needle holders, and program-controlled sewing machines, etc., can solve the problems of fabric floating and fabric deviating from the original position, and achieve reliable cutting, preventing movement, and suppressing poor cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. However, the scope of the present invention is not limited to the examples shown in the drawings.

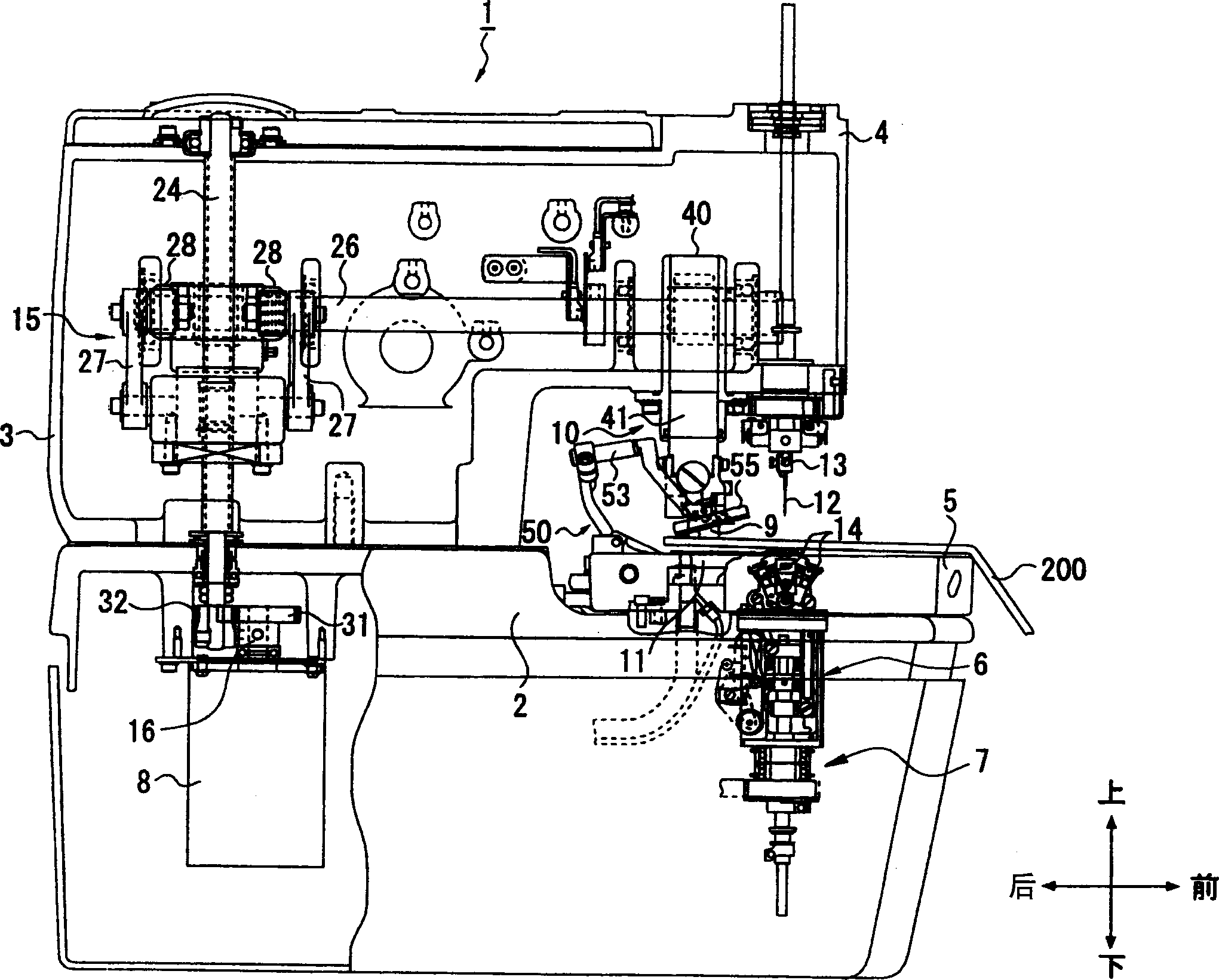

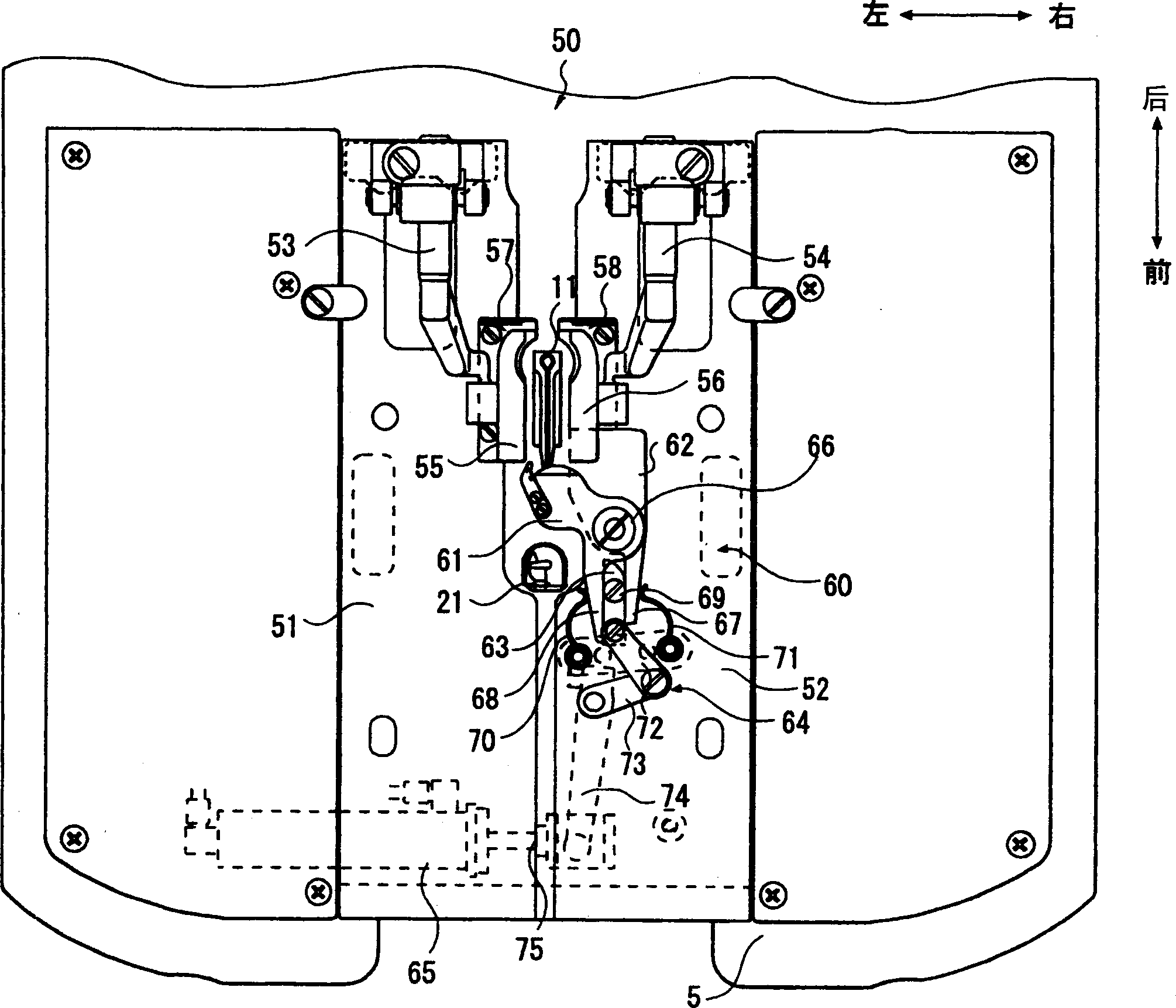

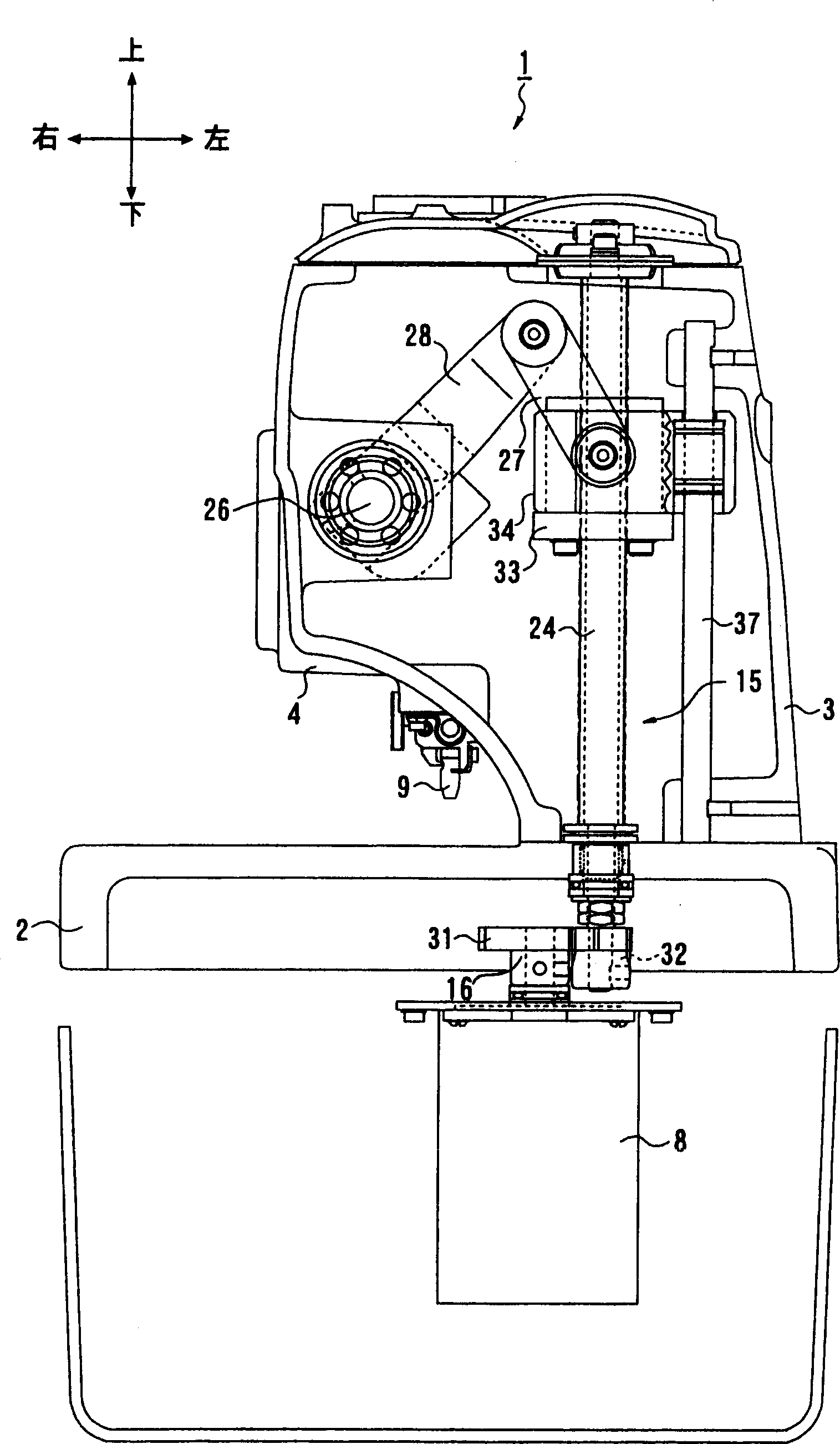

[0028] Such as figure 1 As shown, the buttonhole sewing machine 1 applying the present invention has: a machine base 2, a vertical body portion 3 arranged upright on the rear end portion of the machine base 2, and a vertical body portion 3 from the top of the vertical body portion 3 to the machine base portion 2. The machine head 4 that extends slightly in parallel, the needle bar 13 that extends downward from the front end of the machine head 4, the machine needle 12 that is installed on the lower end of the needle bar 13, and the machine needle 12 that is located in the machine table part 2. The rotary hook mechanism 6 below, the overall control device 100 for controlling the sewing machine 1 (such as Figure 4 shown), an operation panel 106 for inputting data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com