Novel cut pile jacquard machine

A jacquard machine, a new type of technology, which is applied to circular knitting machines for weft knitting with individual moving needles, textiles and papermaking, weft knitting, etc., and can solve the problem of irregular cuts and insufficient effect of loop-cut flannelette. , complex structure and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

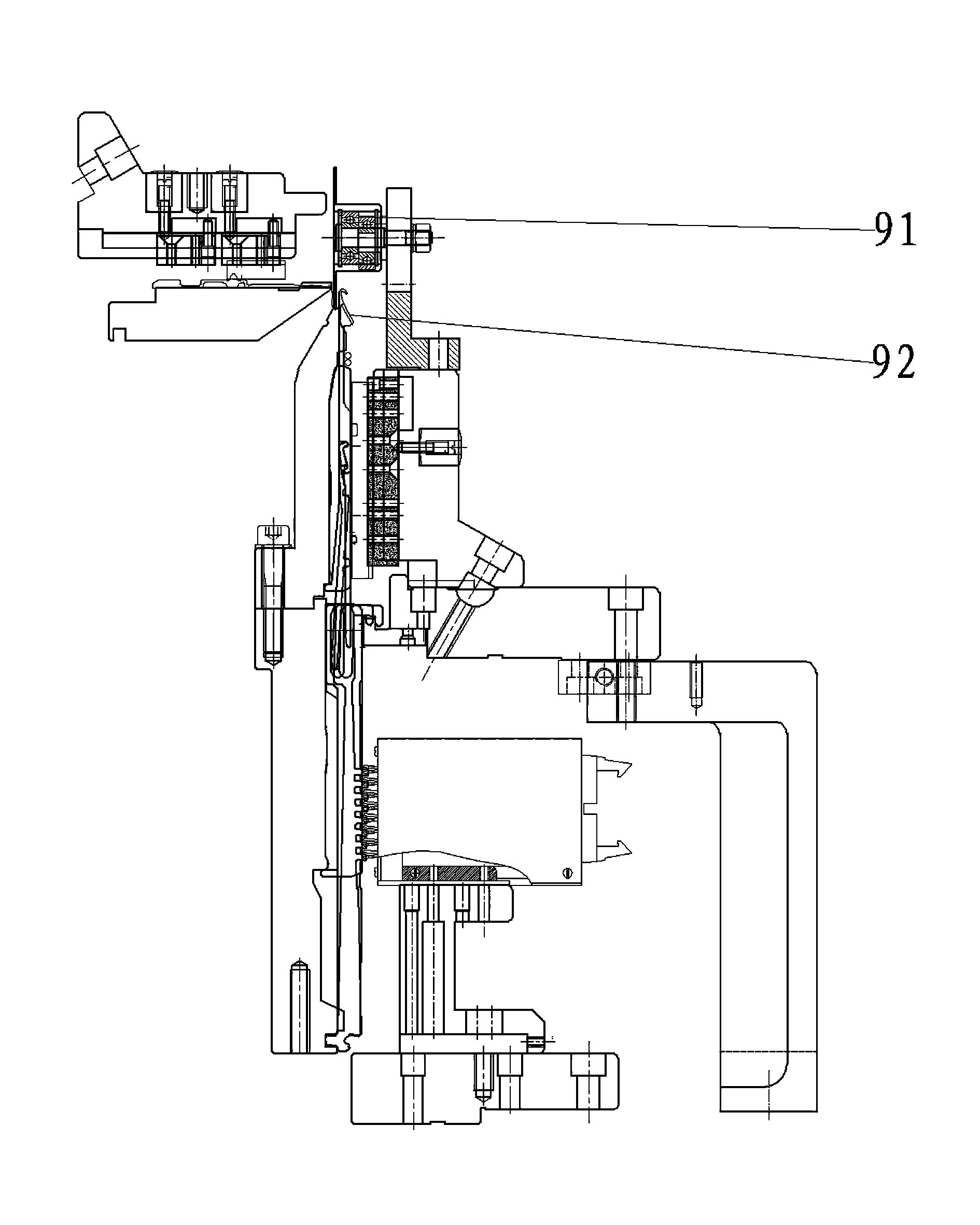

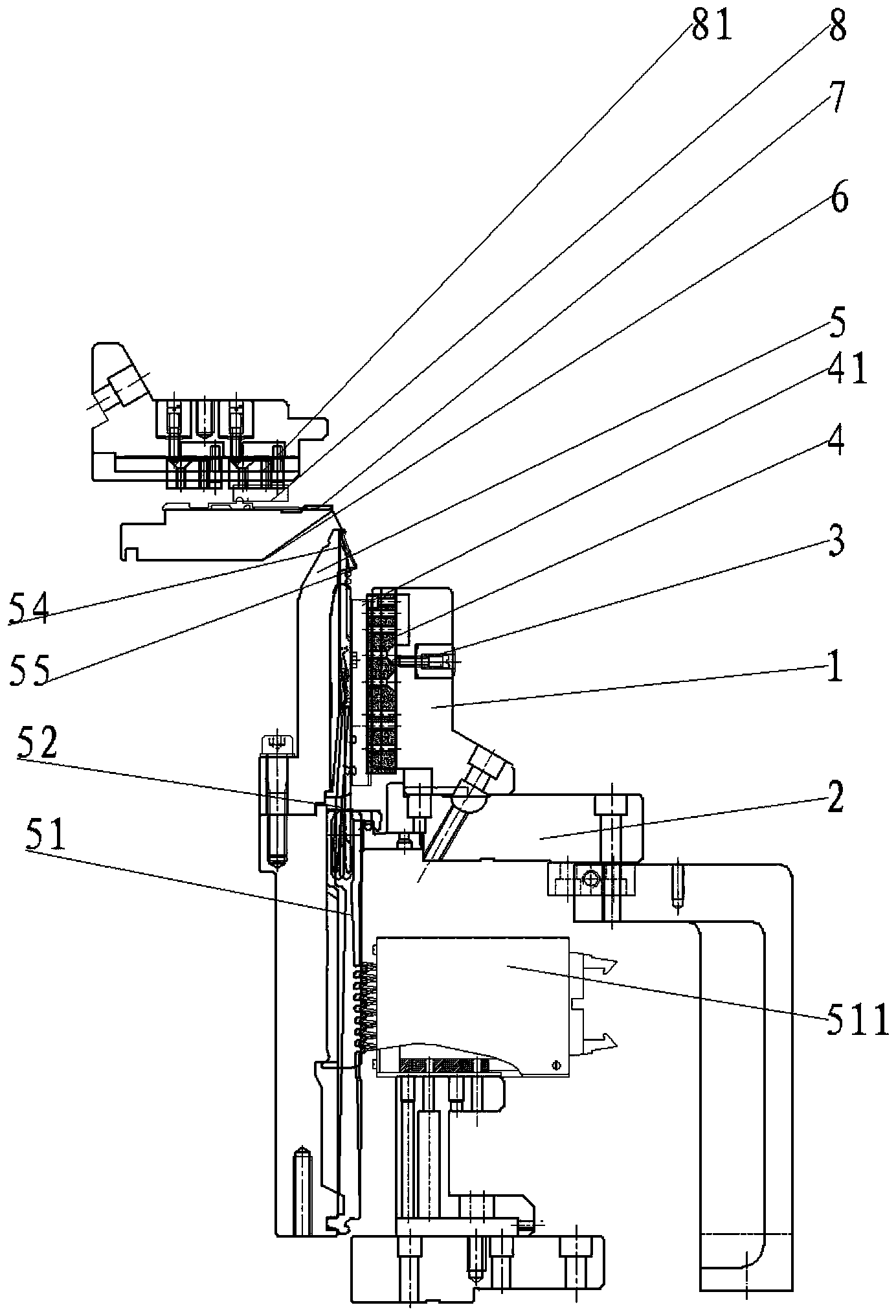

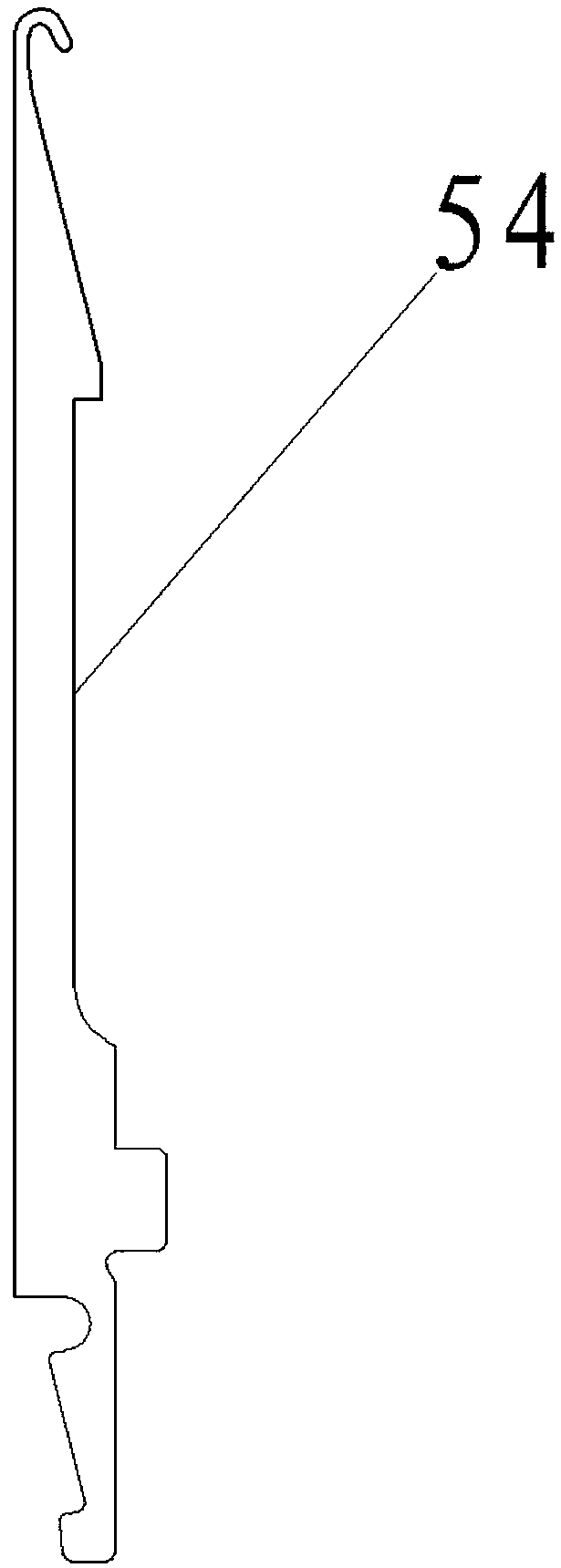

[0011] Such as figure 2 , image 3 , Figure 4 As shown, the new cut loop pile jacquard machine consists of a saddle 1, a saddle bottom ring 2 located at the bottom of the saddle 1, a scale device 3 installed on the saddle 1, and a slider 4 located at the outside of the saddle 1 , the lower triangle 41 located on the outside of the slider 4, the needle cylinder 5 located on the outside of the saddle bottom ring 2, the dial 6 located above the needle cylinder 5, the upper needle 7 installed on the dial 6, the upper needle 7 arranged on the upper The upper triangle 8 above the needle 7, the upper triangle seat 81 arranged on the upper triangle 8, the jacquard sheet 51 arranged inside the needle cylinder 5, the middle needle 52 arranged at the upper end of the jacquard sheet 51, the Electronic needle selector 511, characterized in that: the upper end of the middle needle 52 is provided with a crochet needle 54 and a knife needle 55 that cooperate with the lower triangle 41, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com