Sewing machine

A technology of sewing machine and machine needle, which is applied in the direction of sewing machine components, sewing equipment, mechanism of cutting thread in sewing machine, etc. It can solve the problem that the sewing machine cannot form stitches, etc., and achieve the effect of reliable limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

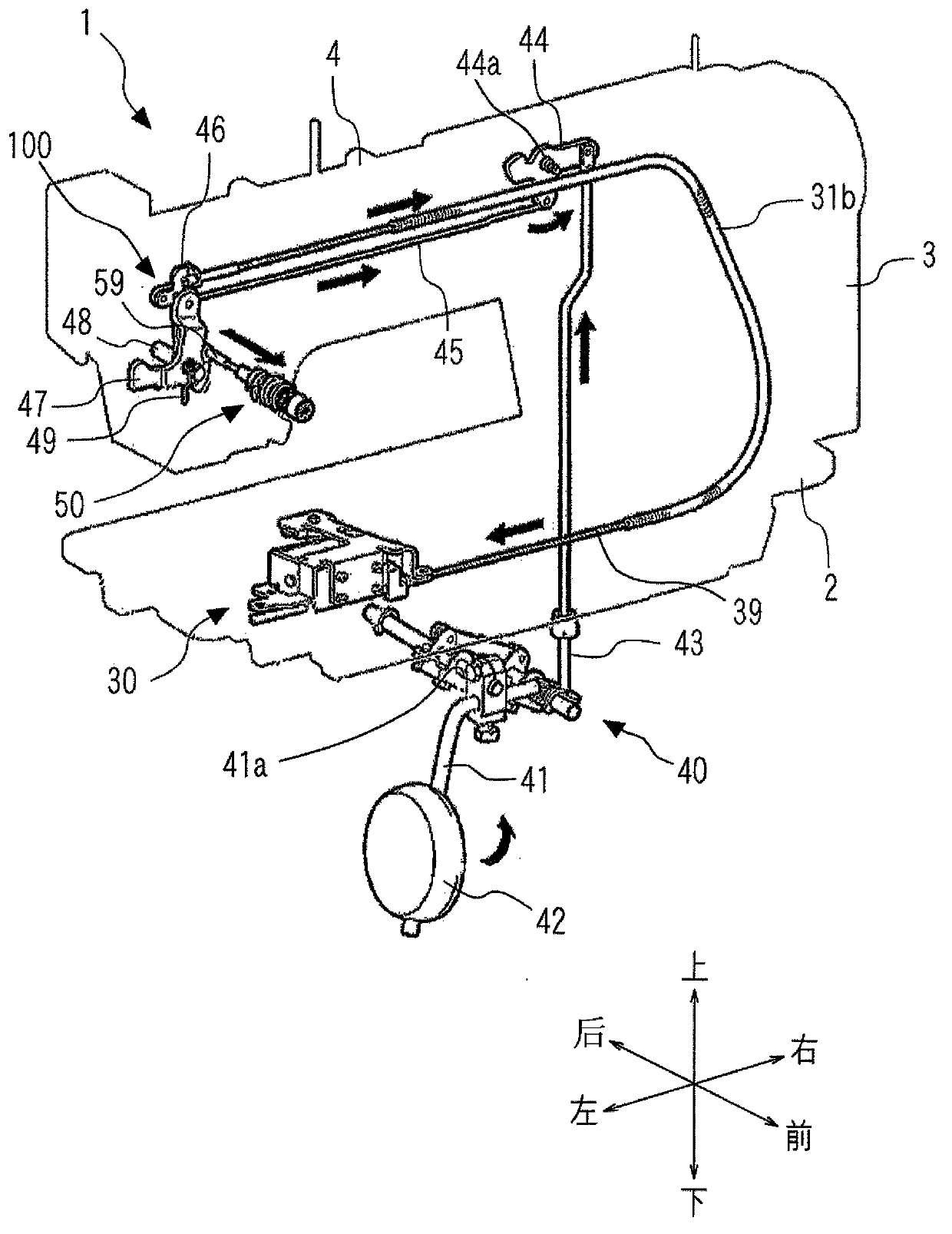

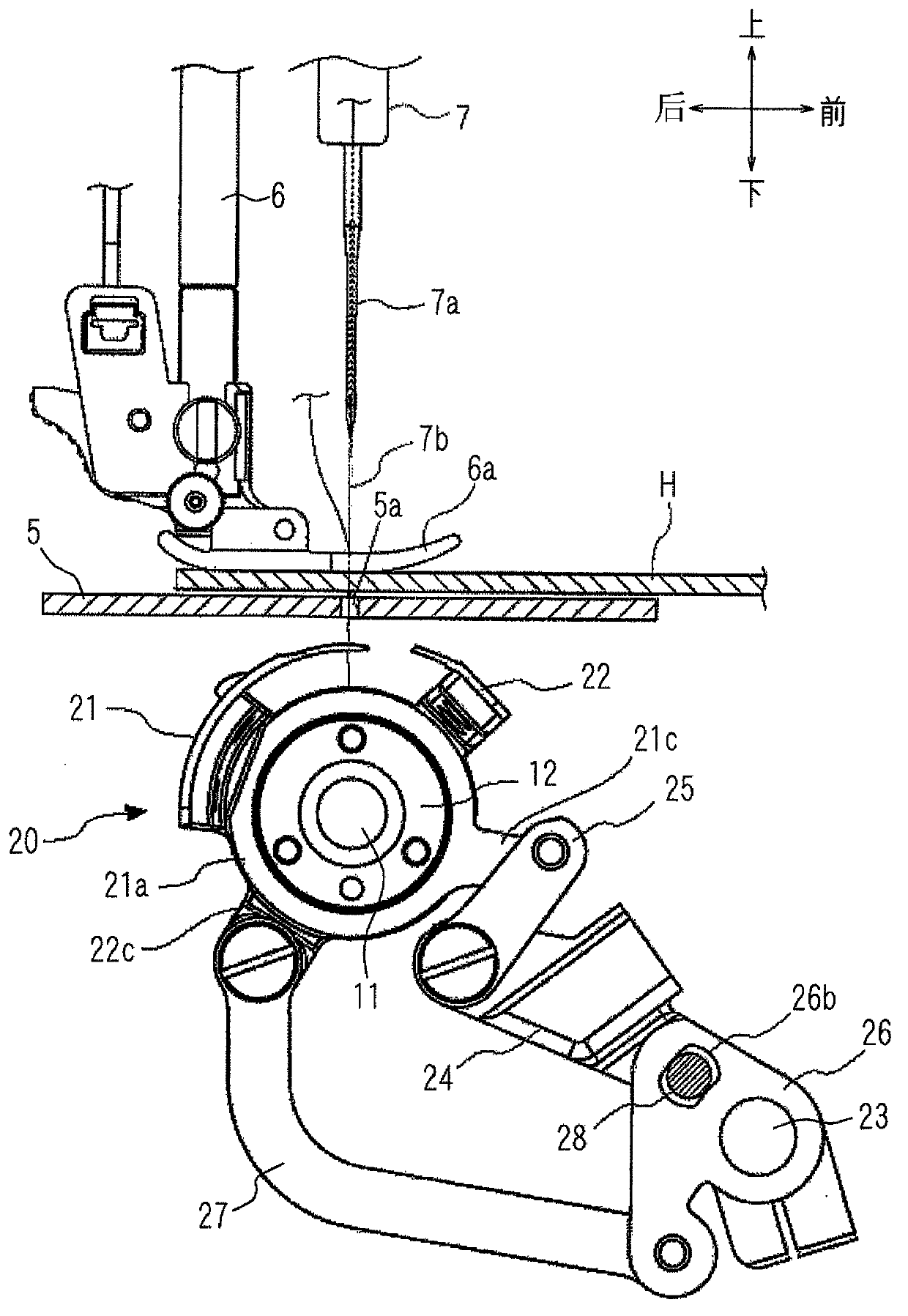

[0035] Embodiments of the present invention will be described. Directions (front and rear, left and right, and up and down) used in the following description are indicated by arrows in each figure.

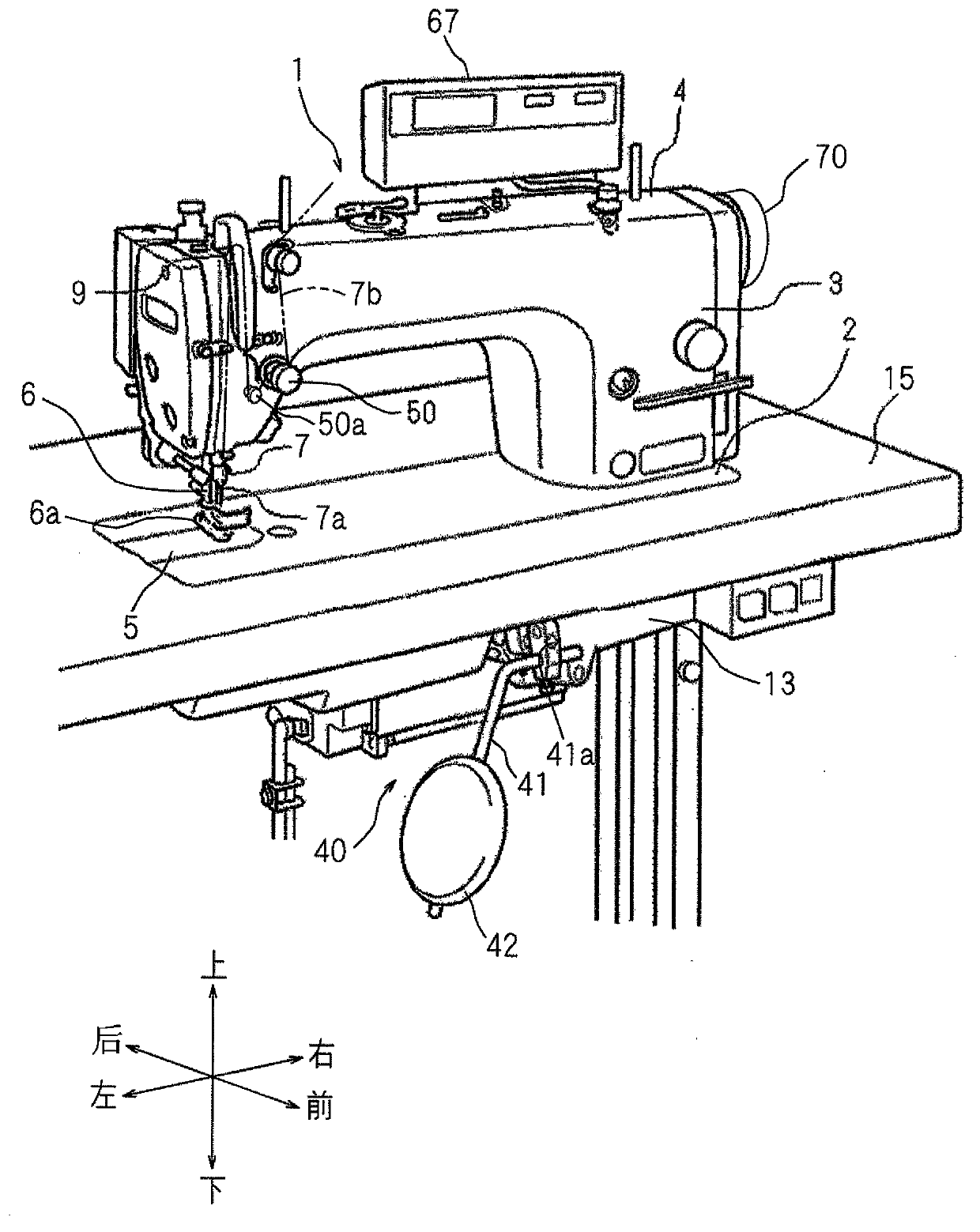

[0036] Such as figure 1 , figure 2 As shown, the sewing machine 1 has a machine base 2 , a column 3 and a machine arm 4 . The stand 2 is a long rectangular parallelepiped in the left-right direction, and is attached to the table 15 from above. The pillar 3 extends upward from the right end of the base 2 . The machine arm 4 extends leftward from the top of the pillar 3 . The sewing machine 1 has a needle plate 5 , a pressing bar 6 , a needle bar 7 and a thread take-up bar 9 . The needle plate 5 is installed on the upper surface of the left end portion of the frame 2 . The press bar 6 and the needle bar 7 are supported on the left end portion of the machine arm 4 so as to be able to ascend and descend. The lower ends of the pressing bar 6 and the needle bar 7 protrude below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com