Workover rig

A working machine and engine technology, which is applied to agricultural machinery and implements, agriculture, harvesters, etc., can solve the problems of longer and lower lengths of transmission devices, and achieve the effects of low cost, miniaturization, and compact assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

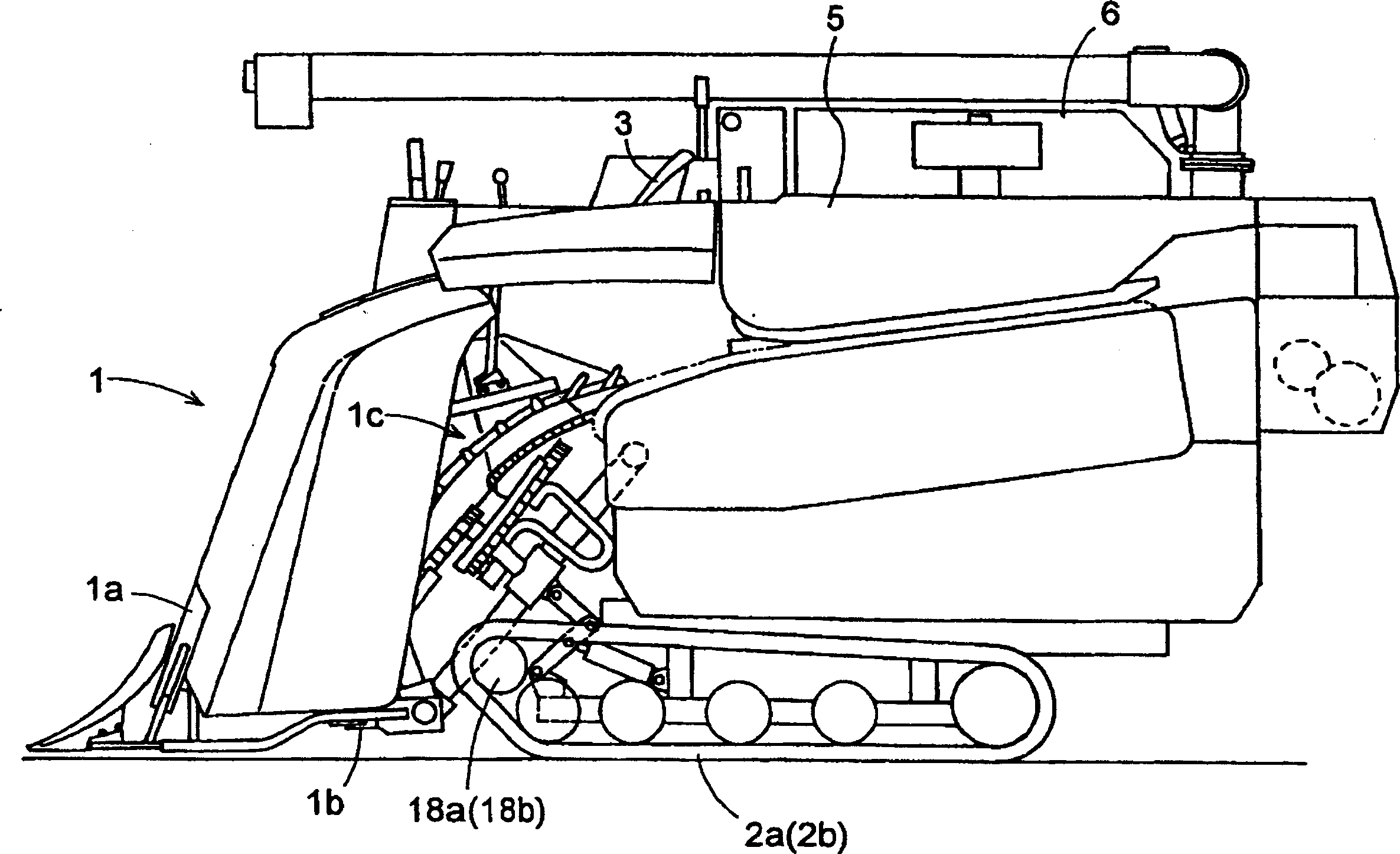

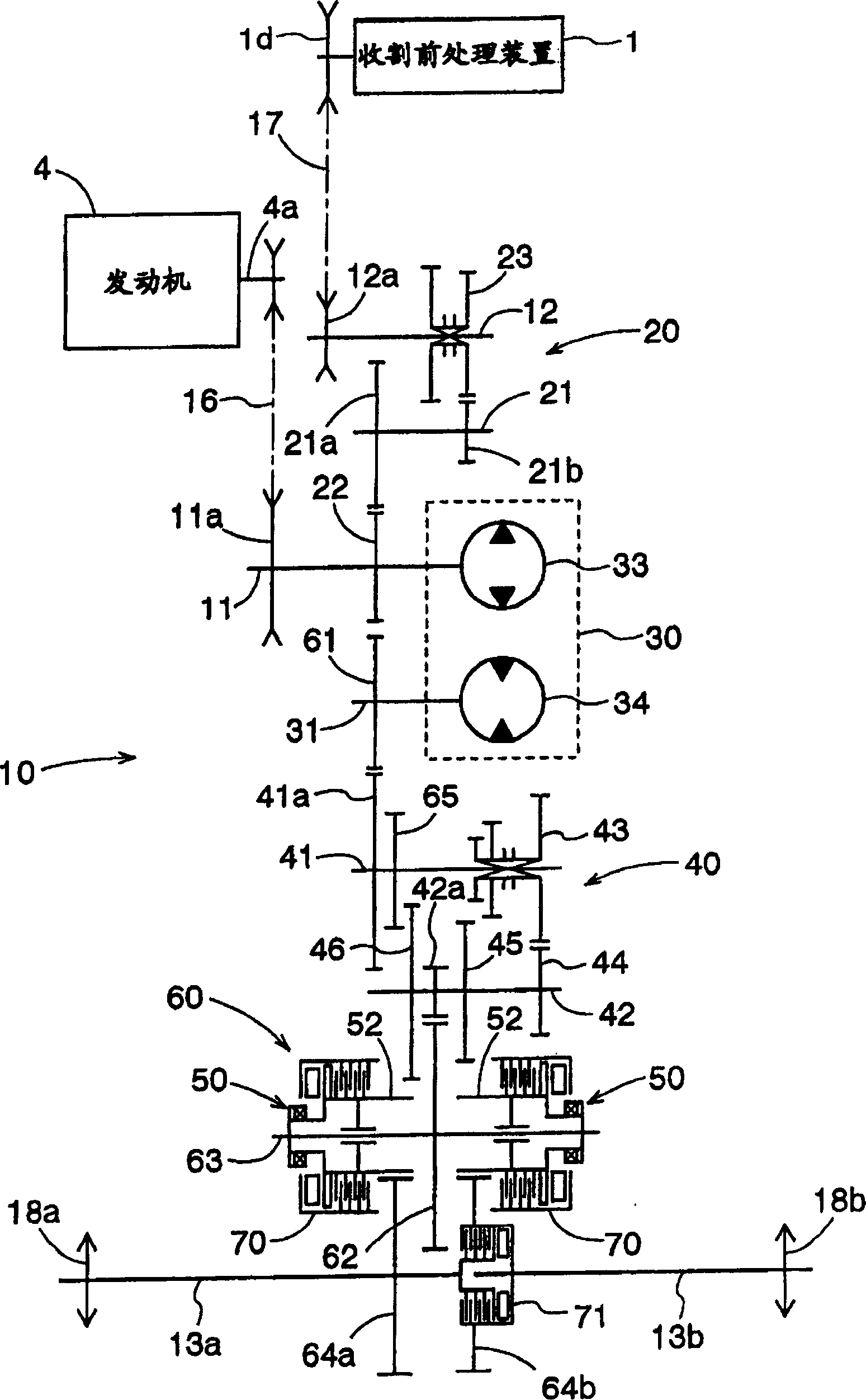

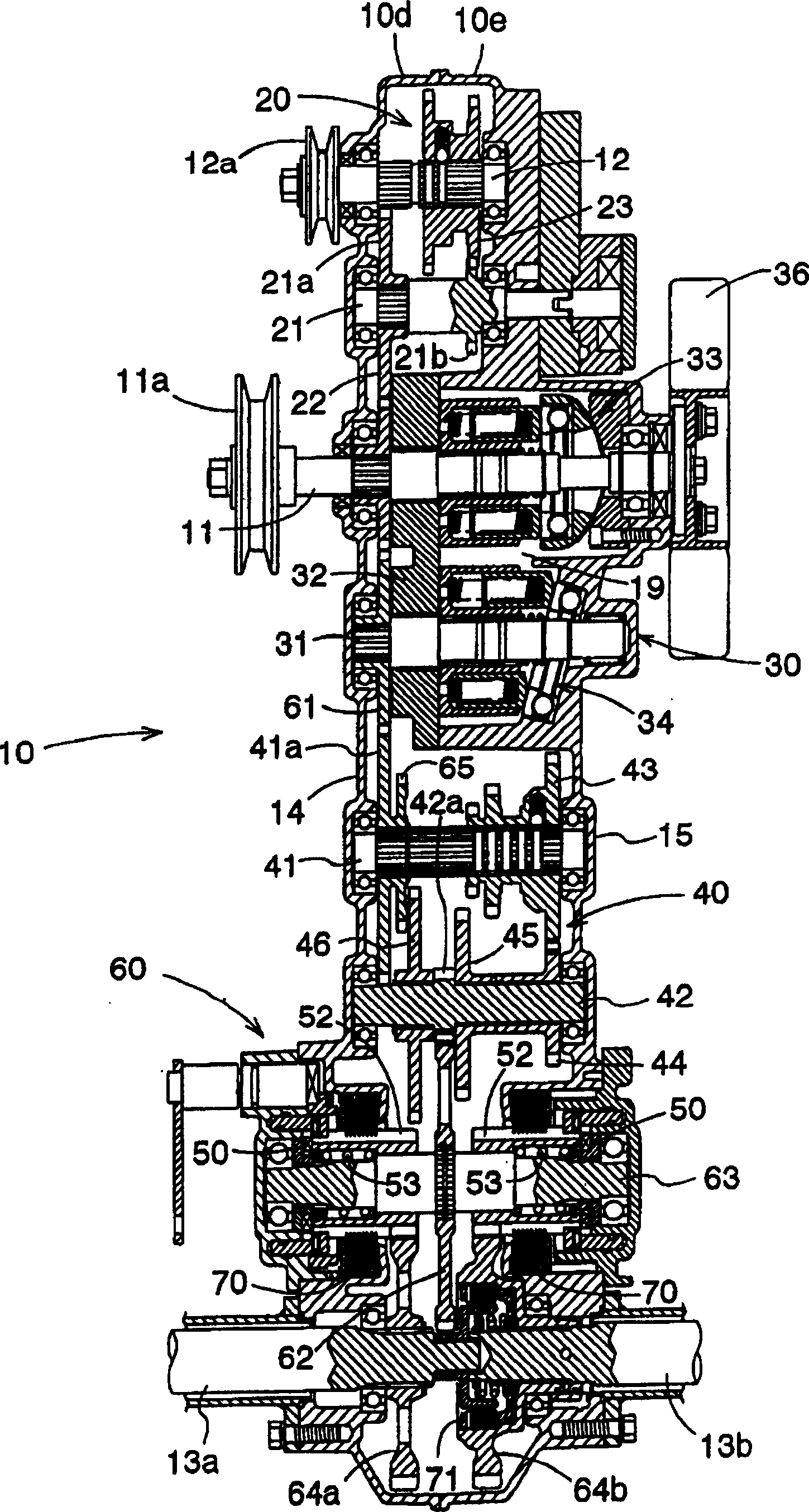

[0046] Below, combine Figure 1 to Figure 8 Embodiments of the work machine according to the present invention are described, and then, in conjunction with figure 1 with Figure 12 to Figure 20 The second embodiment will be described. In all the embodiments, a combine harvester is used as an example of a work machine, and its overall side view is shared. figure 1 . Therefore, for figure 1 It is only described in the first embodiment, and will not be repeated in the second embodiment.

[0047] 1st form of implementation

[0048] figure 1 In the combined harvester shown, No. 1 is a pre-harvest processing device. This pre-harvesting treatment device 1 is carried out by lifting up the ear stalk of erect growth such as rice and wheat, handles the lifting device 1a, the clipper type harvesting device 1b that the ear stalk that lifts up is carried out harvesting process, and the ear stalk that will harvest The conveying device 1c etc. which convey to the rear of the body are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com