Yarn cutting-sucking device and spinning winder

A technology of attracting device and thread, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of failure, cutting failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

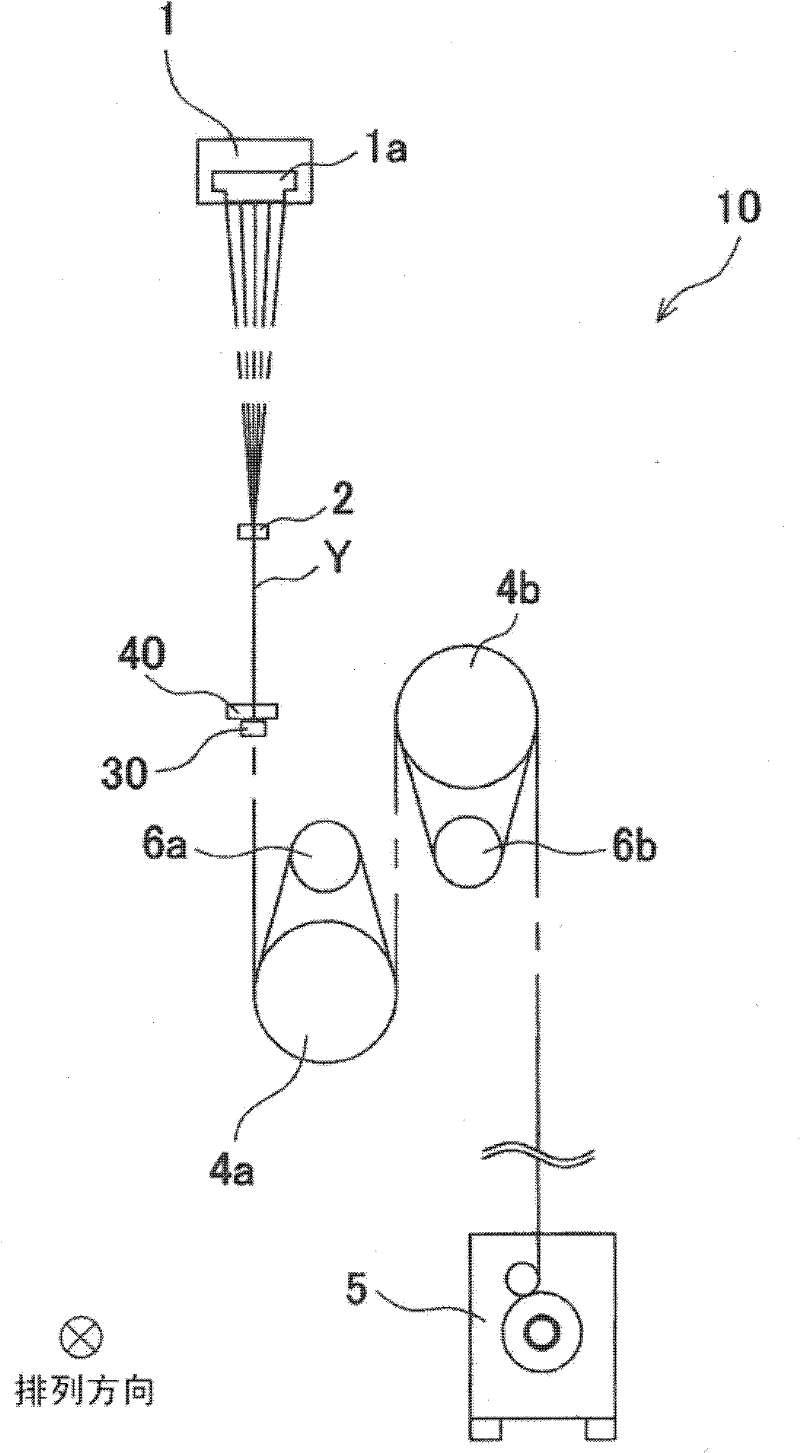

[0027] Next, embodiments of the present invention will be described. figure 1 It is a side view showing the general structure of the spinning coiler. Such as figure 1 As shown, the spinning coiler 10 attaches the oil agent through the oil supply nozzle 2 to the yarn Y having a plurality of filaments discharged from the spinning nozzle 1a of the spinning machine 1 above, and then uses two godet rollers to 4a and 4b stretch the yarn Y, and then transport it to the yarn winding device 5 located below and wind it up.

[0028] A plurality of filaments Y provided with a plurality of filaments are discharged from the spinneret 1a of the spinning machine 1, and these plurality of filaments Y are figure 1 A plurality of them are arranged in a direction (hereinafter referred to as an arrangement direction) perpendicular to the paper surface and run. The oil supply nozzle 2 sprays and deposits oil on the yarn Y having a plurality of filaments fed from the spinning machine 1 .

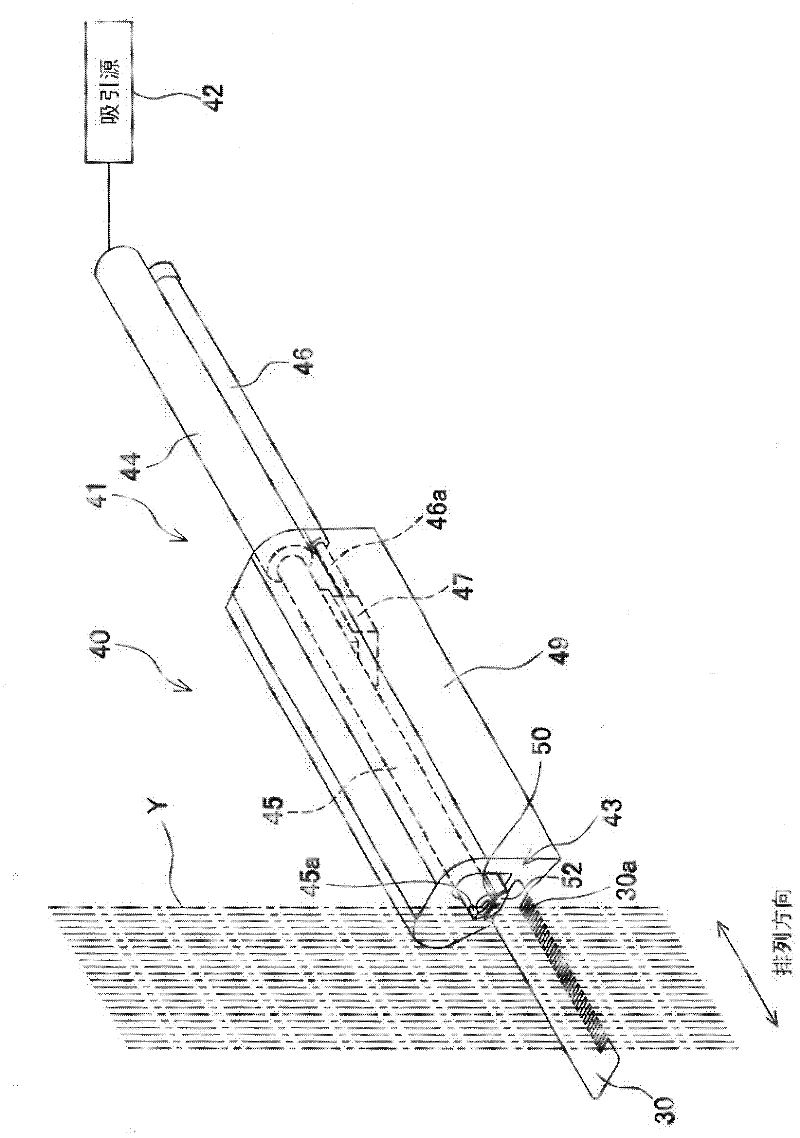

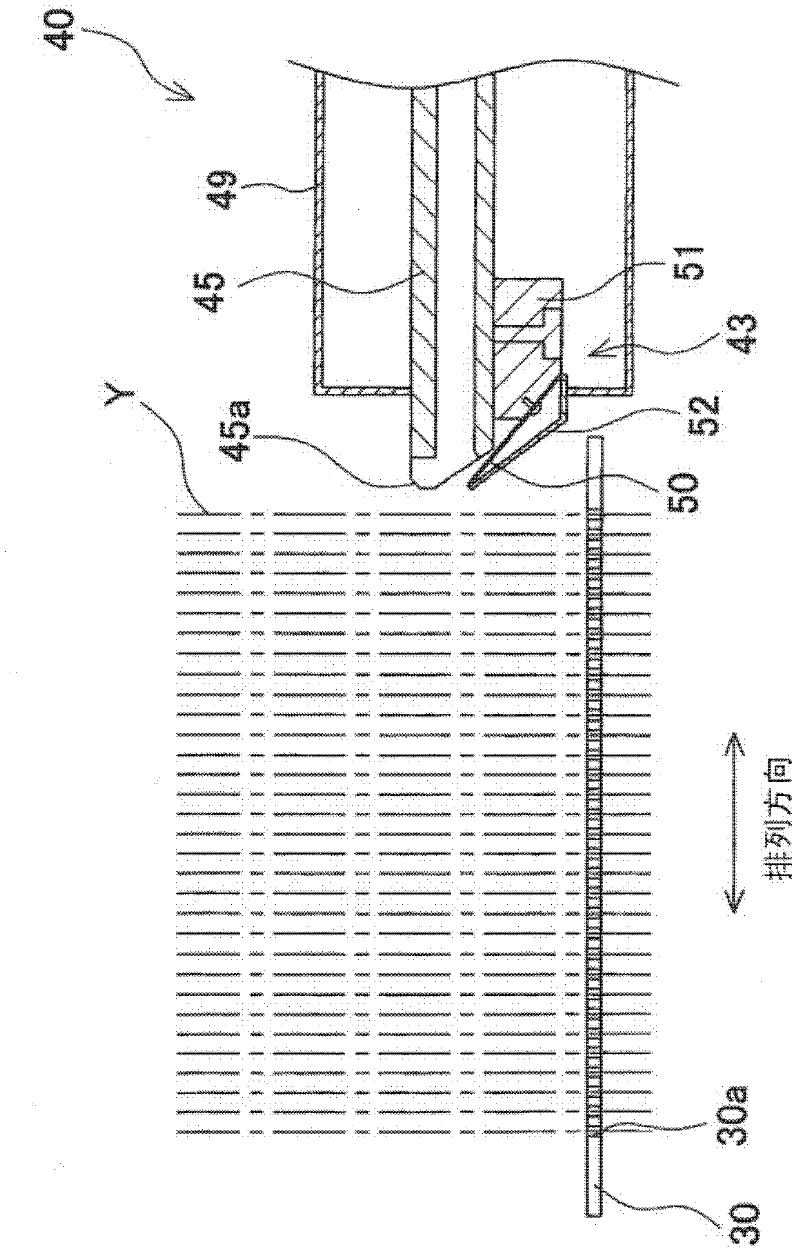

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com