Web cutting device

A technology of cutting device and web, which is applied in the direction of winding strips, transportation and packaging, printing, etc., can solve the problems of reduced reliability of the device, large number of parts, increased cost, etc., to ensure stability, simplify the structure, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

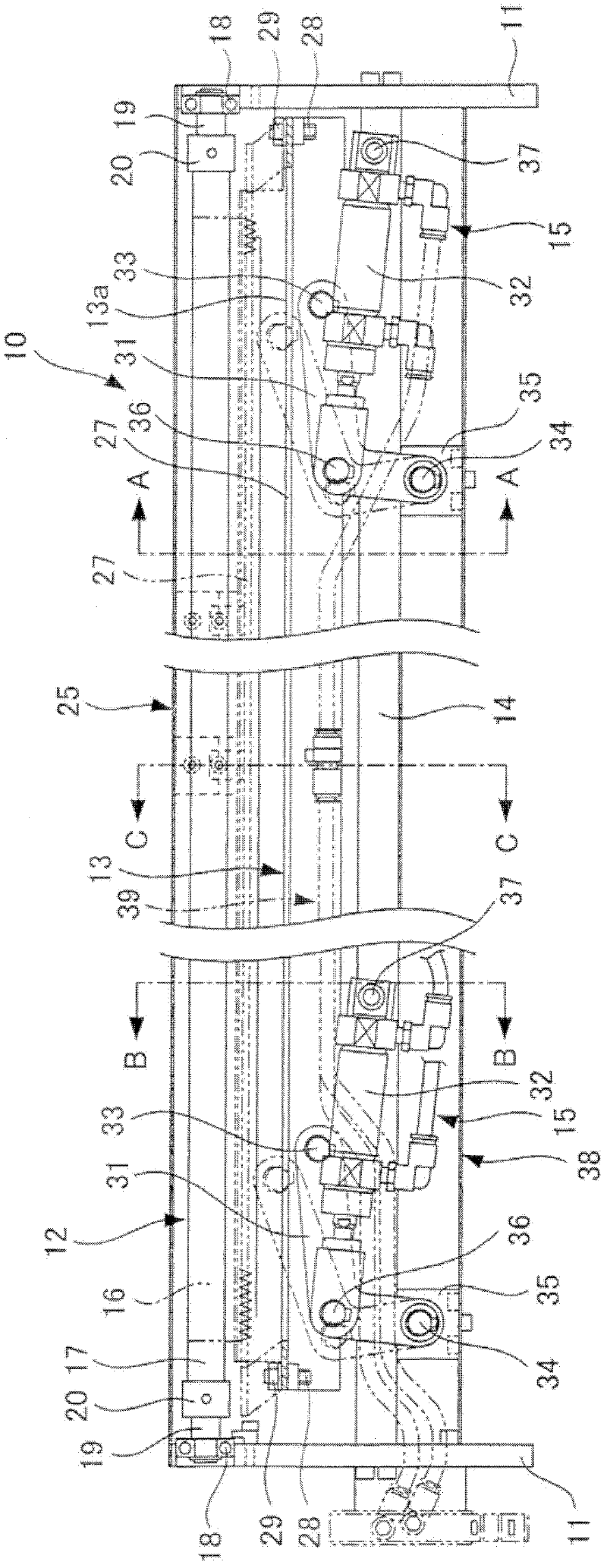

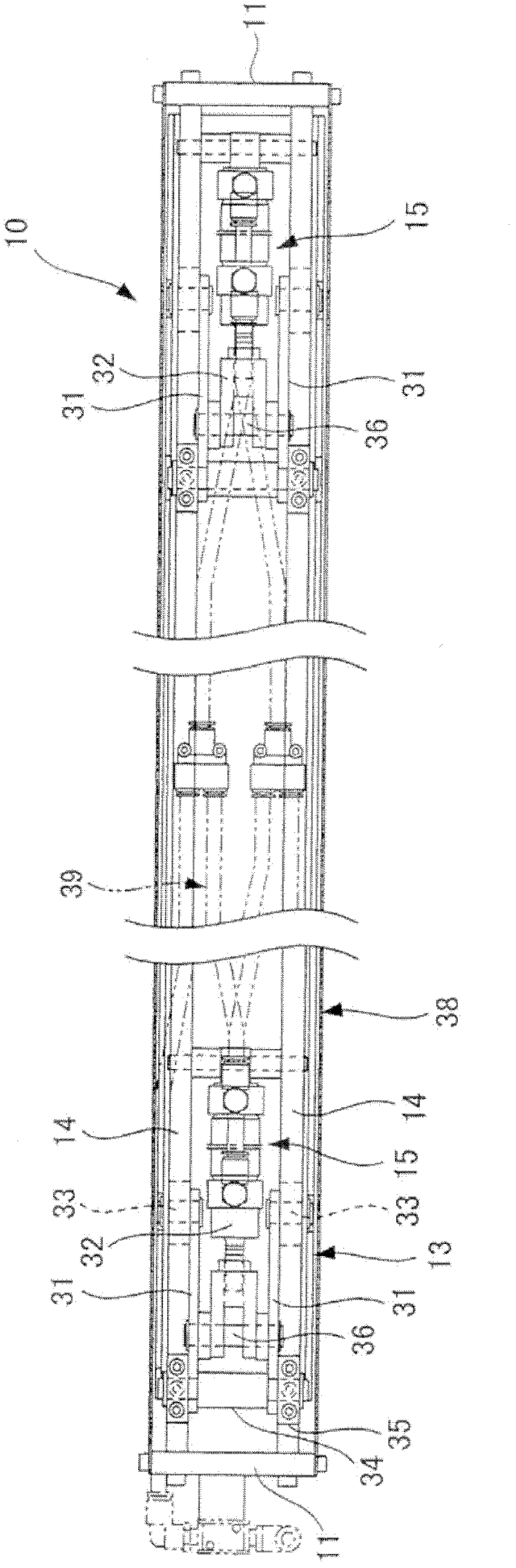

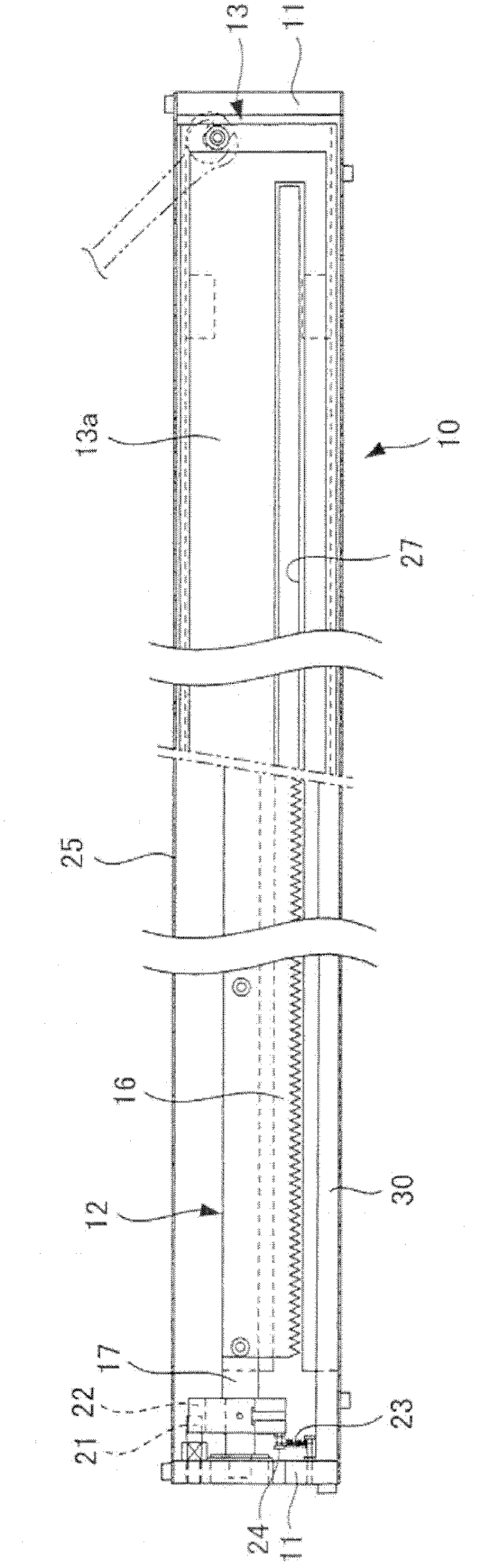

[0070] figure 1 is a front sectional view showing a roll paper cutting device according to Embodiment 1 of the present invention, figure 2 is a bottom sectional view of the web cutting device, image 3 is a top sectional view of the web cutting device, Figure 4A yes figure 1 A-A line sectional view of Figure 4B yes figure 1 B-B line sectional view, Figure 4C yes figure 1 The C-C line section diagram, Figure 5 It is the action state diagram of the web cutting device, Figure 5 (a) is the position of the knife when the positioning bolt touches the initial stage, Figure 5 (b) is the position of the knife when the positioning bolt abuts halfway, Figure 5 (c) is the position of the knife when the positioning bolt is pressed and cut.

[0071] As shown in the figure, the cutter support member 12 of the web cutting device 10 of the offset rotary printing machine is rotatably erected between the left and right side frames 11, and the cutter receiving member 13 is l...

Embodiment 2

[0089] Image 6 It is a top sectional view showing a roll paper cutting device according to Embodiment 2 of the present invention.

[0090] In this example, instead of the slit (blade receiving portion) 27 provided on the top surface portion 13a of the cutter receiving member 13 in Embodiment 1, a plurality of engaging knives are arranged in a row corresponding to each serration 16a of the serrated knife 16. Hole (blade receiving part) 40. Other structures are identical with embodiment 1, and image 3 The same components are given the same reference numerals, and repeated explanations are omitted.

[0091] According to this embodiment, in addition to having the same action and effect as Embodiment 1, it also has the following advantages: when cutting, the web W is pressed against the portion (top portion 13a) between the engaging knife holes 40, The roll paper W can be accurately scored without slack downward, and since the roll paper W is stretched by the front portion, cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com