Coil component

A coil component and coil technology, applied in the direction of transformer/inductor coil/winding/connection, inductor with magnetic core, etc., to achieve good wettability, eliminate height deviation, and improve flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

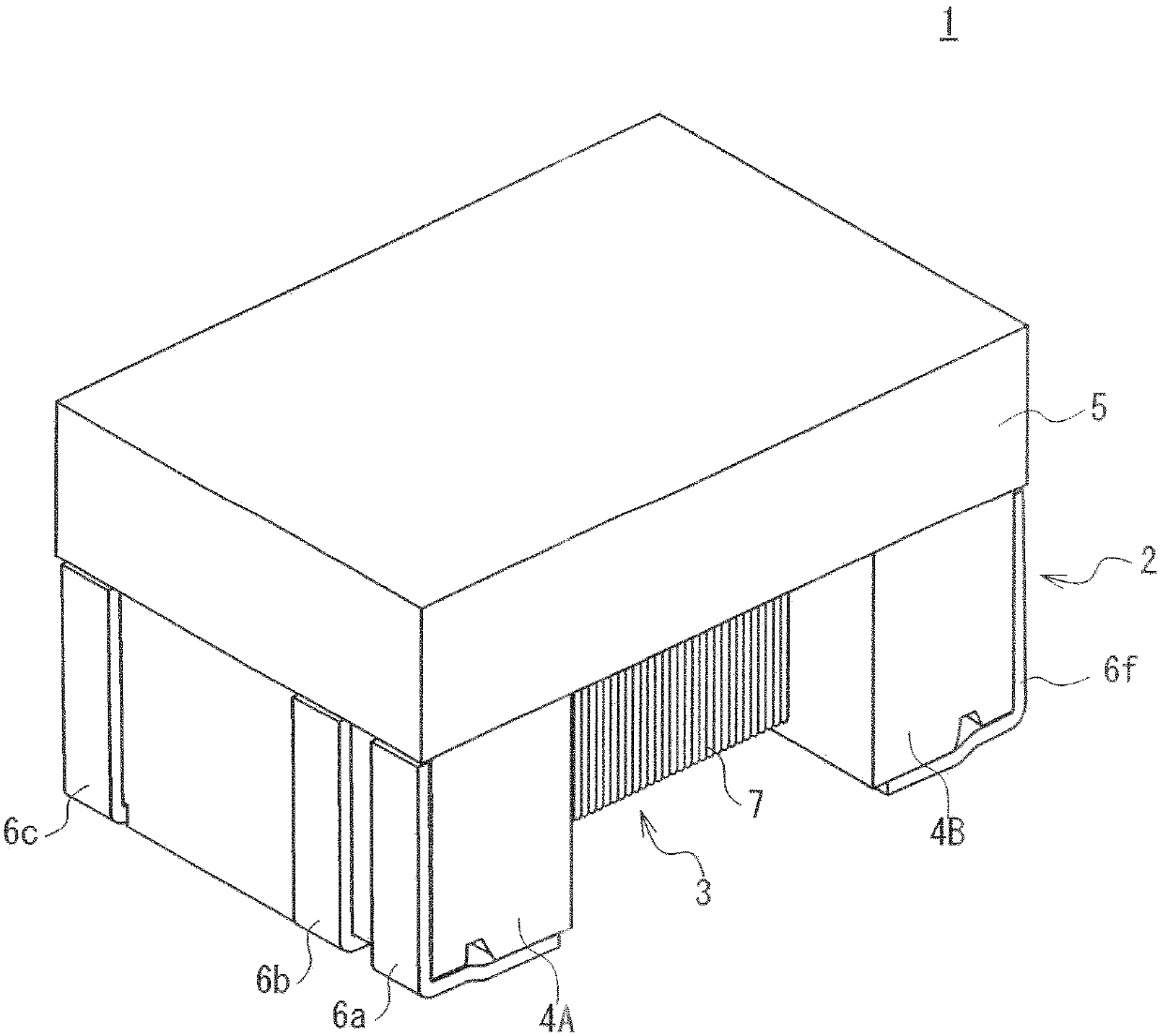

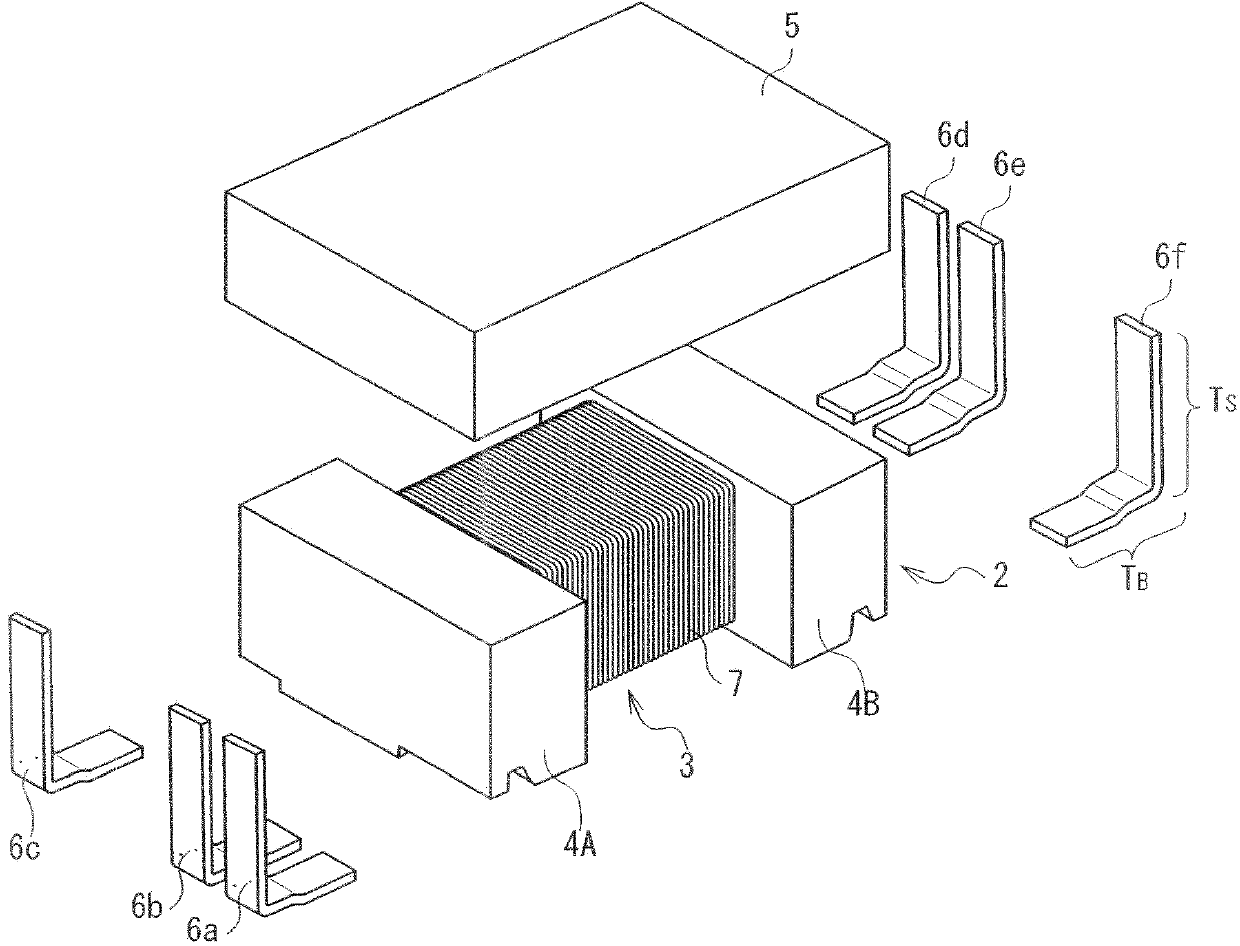

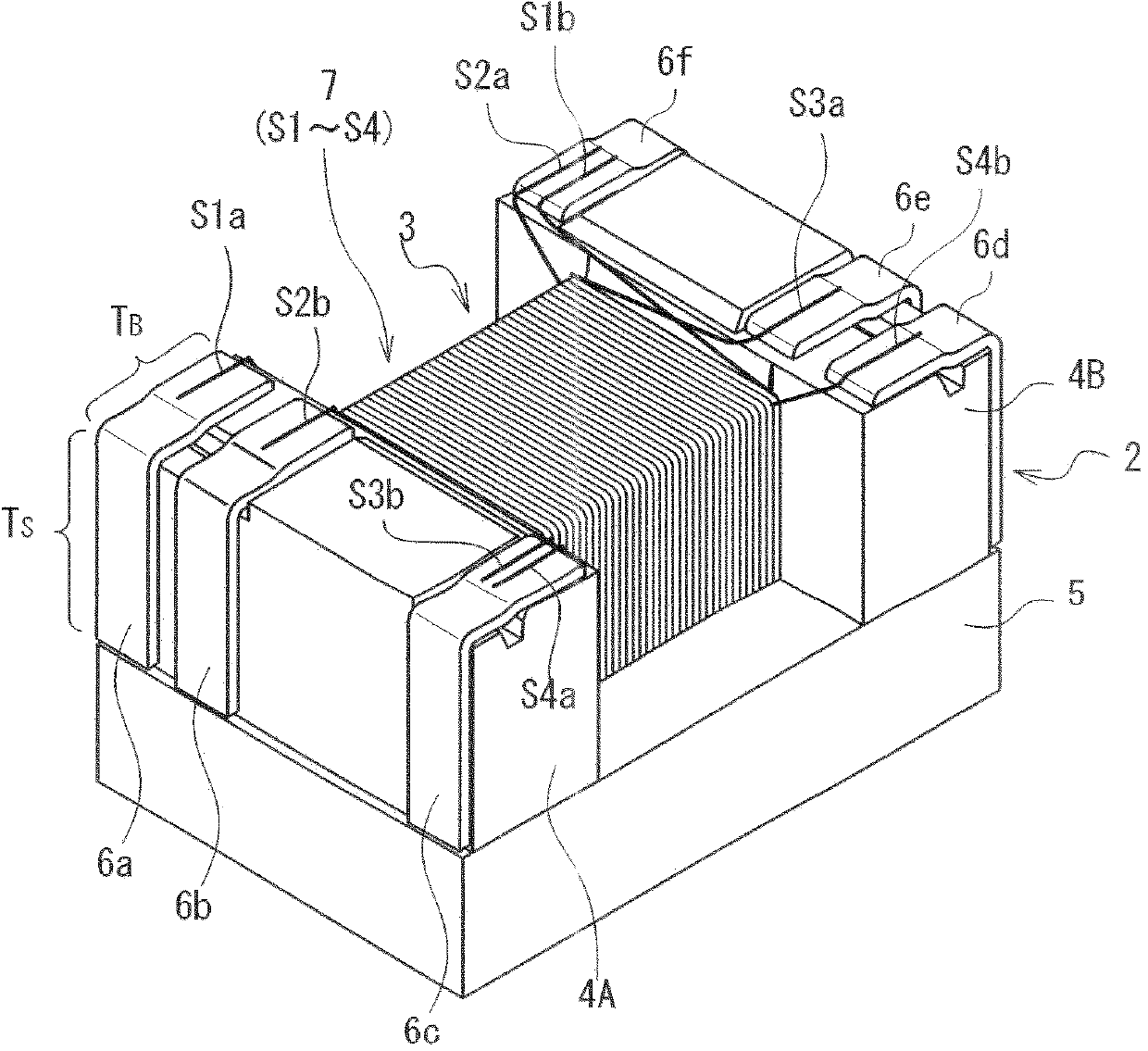

[0038] figure 1 It is a schematic perspective view showing the external configuration of the surface mount coil component according to the first embodiment of the present invention. in addition, figure 2 yes figure 1 An exploded perspective view of the coil assembly, image 3 means to make figure 1 A rough perspective view of the state where the coil part is turned upside down.

[0039] Such as Figure 1 ~ Figure 3 As shown, this coil component 1 includes a drum core 2 , a plate-shaped core 5 , six terminal metal fittings 6 a to 6 f , and a coil 7 made of a wire wound around the drum core 2 . Although not particularly limited, the coil component 1 is a surface mount type pulse transformer, and its size is about 4.5 mm×3.2 mm×2.6 to 2.8 mm, or about 3.2 mm×3.2 mm×2.8 to 2.9 mm.

[0040] Drum core 2 is made of, for example, a magnetic materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com